Automatic tooling replacement device

An automatic replacement and end picker technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of stamping lines, end picker fixing brackets that are not suitable for sound insulation protection of the whole line, large dimensions, and large space occupation. Achieve the effect of small footprint, easy maintenance and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

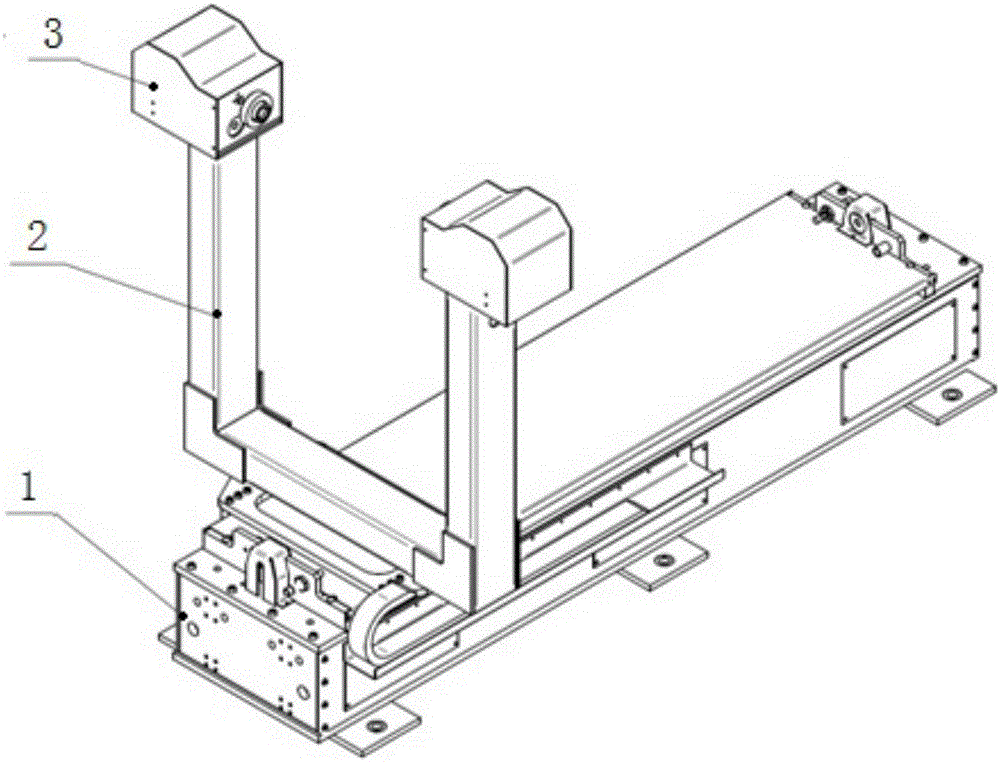

[0022] figure 1 Shown is the structural representation of the present invention.

[0023] The present invention includes three major parts: a fixed base 1 , an end picker bracket 2 and a quick change device 3 .

[0024] The fixed base 1 is used to drive the end effector support 2 to advance and retreat quickly.

[0025] The end effector support 2 has two stations, one is used to place the old end effector replaced from the robot, and the other is used to store the new end effector to be loaded on the robot.

[0026] The quick change device 3 is used for automatic locking and disengaging of the end effector.

[0027] The fixed base 1 is installed on the ground, the end picker support 2 is arranged on the fixed base 1, and the quick change device 3 is loaded on the top of the end picker support 2; the fixed base 1 is provided with a cylinder drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com