Distributed redundant constant-pressure water supply control system

A distributed control and control unit technology, applied in the field of online maintenance, energy-saving constant pressure water supply control system, and high reliability, which can solve the problems of inability to maintain normal pressure, frequent pressure maintenance, and incompetence for large-scale water supply systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] In order to illustrate the technical solution of the present invention more clearly, a typical embodiment in actual application is now selected and described in combination with the accompanying drawings. Apparently, the described embodiment is only one embodiment of the present invention, not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative efforts shall fall within the protection scope of the present invention.

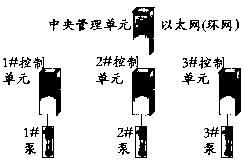

[0105] The pressurized pump group selected in the embodiment is a distributed redundant control system of 3 pumps, the appearance of which is as follows figure 1 shown.

[0106] 1. Hardware composition: The distributed redundant control system consists of 1 central management coordination unit, 3 independent distributed control units that can operate independently, 3 pumps, 6 digital sensors, and 6 analog sensors. One digital sensor and one analog sensor are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com