Judgment method and prediction method for creep failure life of polymer material

A polymer material and failure life technology, applied in the field of polymer materials, can solve the problems of inability to predict the creep failure life of materials and lack of failure criteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

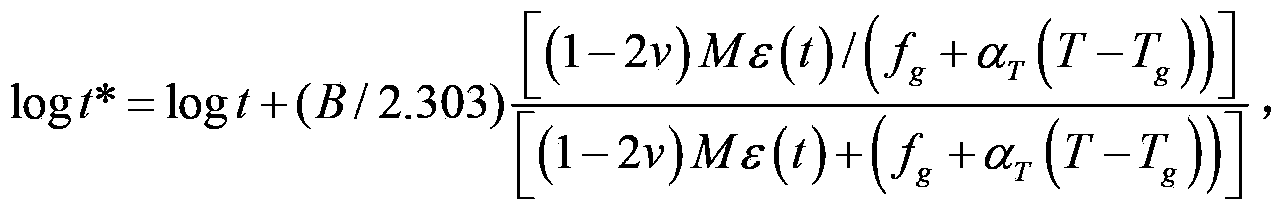

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1 Determination method and prediction method of creep failure life of polymer material

[0066] Polypropylene (T30s, Dushanzi Petrochemical) and polypropylene grafted maleic anhydride (grafting rate 1%, Pulaite Chemical Corp.) were used as the polymer material, and polypropylene / polypropylene was prepared by melt extrusion through a twin-screw extruder. Graft maleic anhydride blended materials, and then further prepare dumbbell-shaped specimens conforming to ASTM tensile test standards by compression molding or injection molding.

[0067] Judgment method of creep failure life:

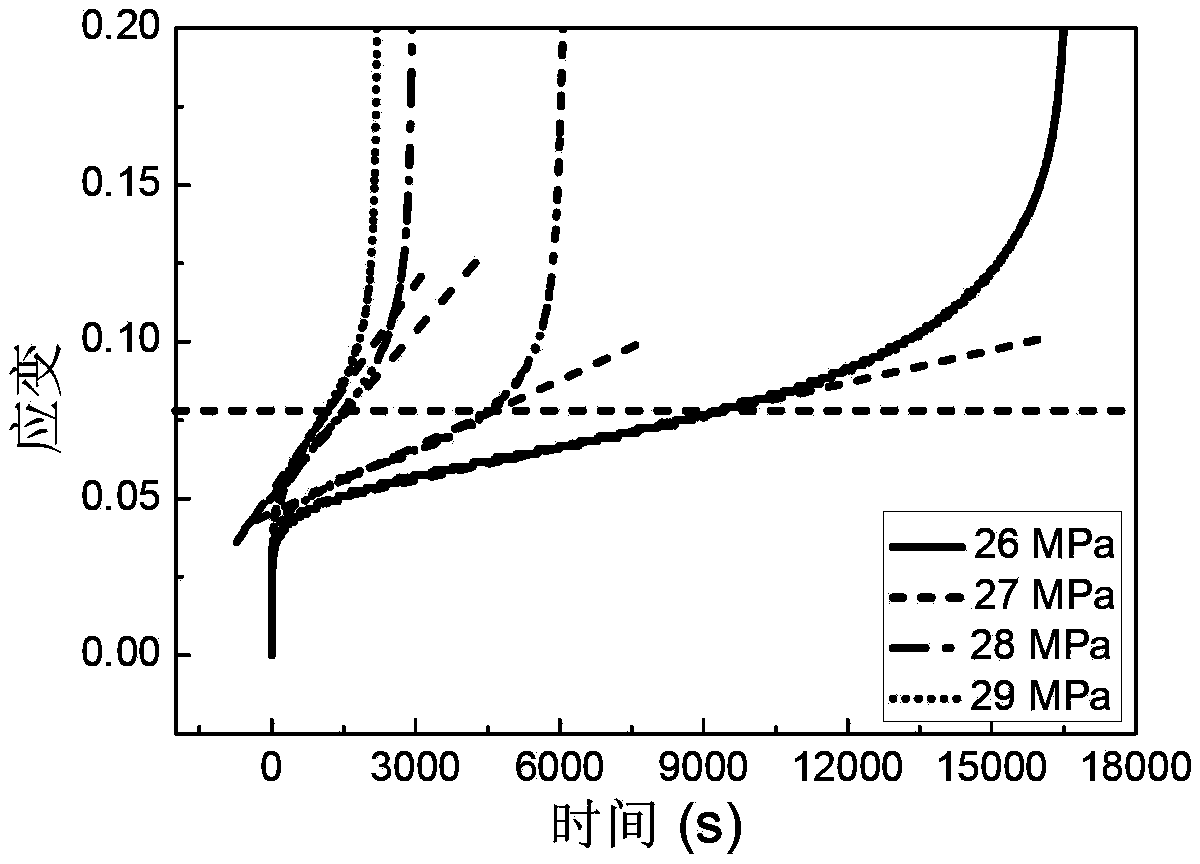

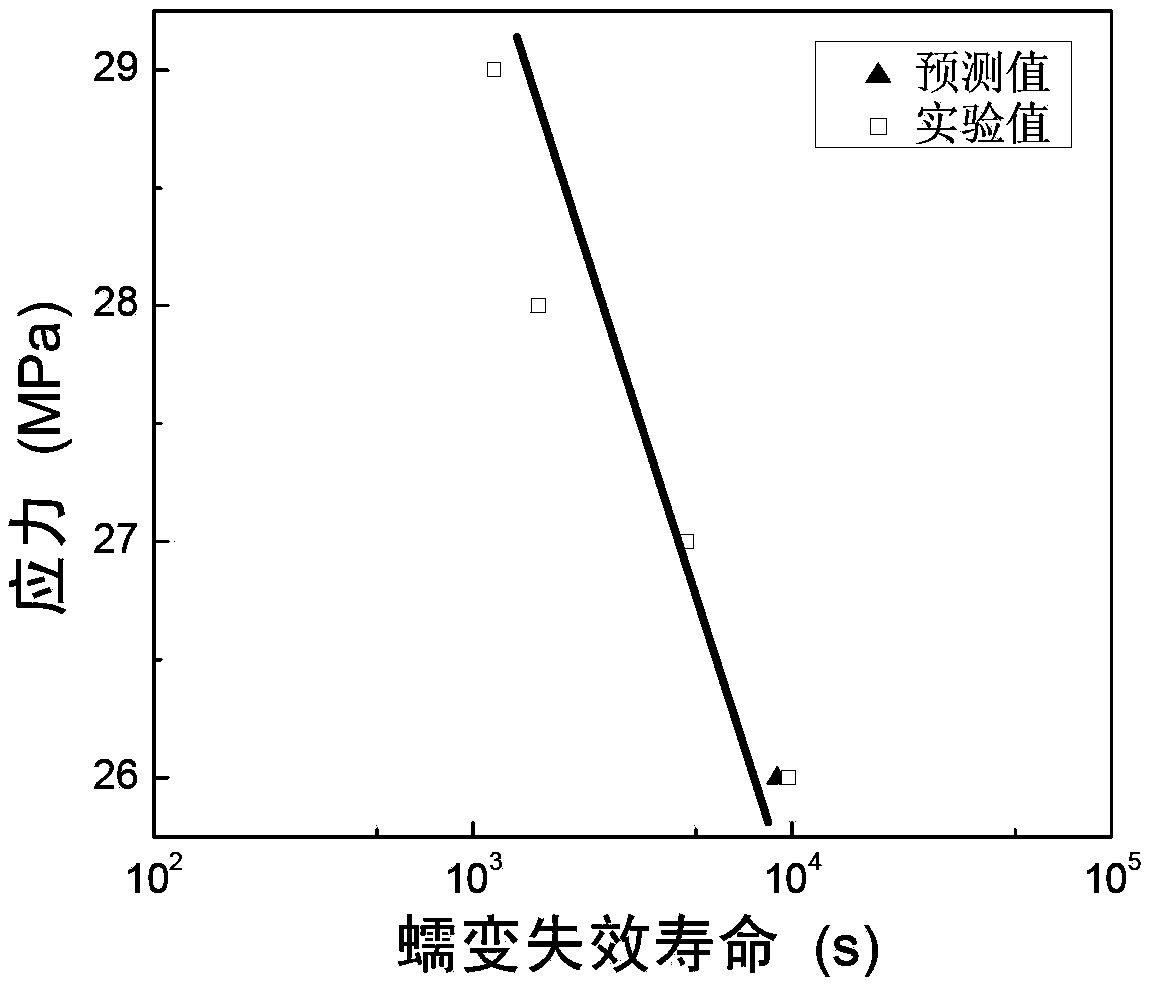

[0068] Creep experiments were carried out on the prepared tensile samples at 40°C (the yield stress of the material at this temperature was about 40MPa) and 26, 27, 28, and 29MPa using a tensile hot-table (TST350, Linkam Scientific Instruments) (GB / T11546.1--2008 / IS0899-1:2003), to obtain the creep failure curve of polypropylene / polypropylene grafted maleic anhydride blend material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com