High-damage tolerance C/C-SiC composite material as well as preparation method and regulation and control method thereof

A composite material and damage tolerance technology, which is applied in the field of C/C-SiC composite materials with high fracture strain and its preparation and regulation, can solve the problems of poor toughness and low mechanical properties, and achieve improved density and improved mechanical properties , Reduce the effect of silicification damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

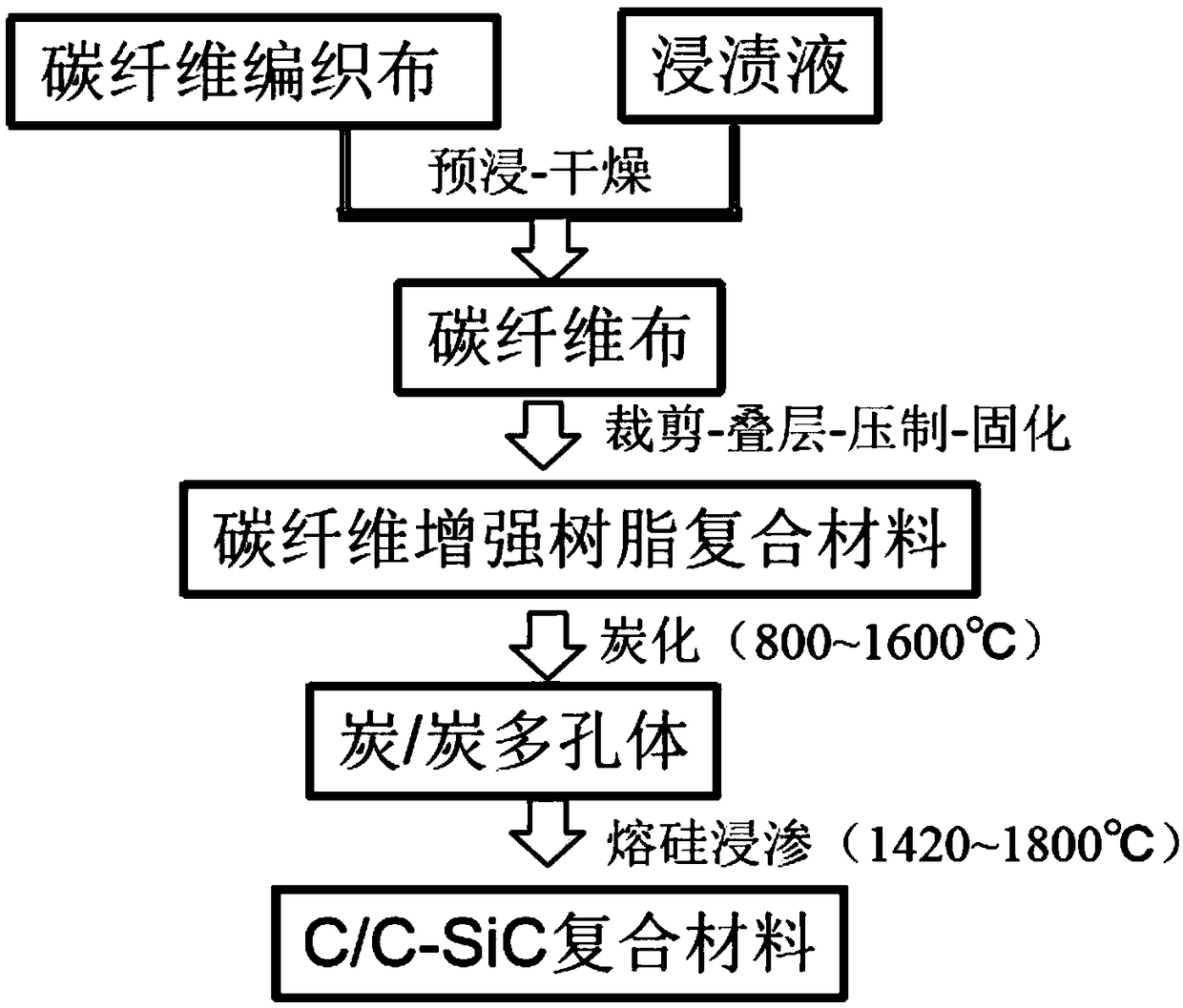

[0079] This embodiment provides a high damage tolerance C / C-SiC composite material and its preparation and regulation method. see figure 1 , is a schematic diagram of the process of the high damage tolerance C / C-SiC composite product of the present invention, and the specific preparation method is as follows:

[0080] Degumming treatment: put the above-mentioned carbon fiber cloth (plain cloth) in a vacuum sintering furnace, under the protection of nitrogen, rapidly heat up to 800 °C at a heating rate of 20 °C / min, and then cool the fiber to room temperature with the furnace to obtain Degummed carbon fiber woven cloth;

[0081] S1. Pre-impregnation-drying treatment: apply the impregnating solution on the degummed carbon fiber woven cloth to treat it. After the treatment is completed, arrange the obtained carbon fiber weaving in a constant temperature oven at 60°C for drying for 24 hours; the impregnating solution Contains A and B, the configuration process is as follows: Dis...

Embodiment 2

[0088] This embodiment provides a high damage tolerance C / C-SiC composite material and its preparation and regulation method. see figure 1 , is a schematic diagram of the process of the high damage tolerance C / C-SiC composite product of the present invention, and the specific preparation method is as follows:

[0089] Degumming treatment: put the above-mentioned carbon fiber cloth (plain cloth) in a vacuum sintering furnace, under the protection of nitrogen, rapidly heat up to 800 °C at a heating rate of 20 °C / min, and then cool the fiber to room temperature with the furnace to obtain Degummed carbon fiber woven cloth;

[0090] S1. Pre-impregnation-drying treatment: brush the impregnating liquid on the degummed carbon fiber woven cloth to process it. After the treatment is completed, arrange the obtained carbon fiber weaving in a constant temperature oven at 60°C for drying for 24 hours; the impregnating liquid Contains A and B, the configuration process is as follows: Disso...

Embodiment 3

[0097] This embodiment provides a high damage tolerance C / C-SiC composite material and its preparation and regulation method. see figure 1 , is a schematic diagram of the process of the high damage tolerance C / C-SiC composite product of the present invention, and the specific preparation method is as follows:

[0098] Degumming treatment: put the above-mentioned carbon fiber cloth (plain cloth) in a vacuum sintering furnace, under the protection of nitrogen, rapidly heat up to 800 °C at a heating rate of 20 °C / min, and then cool the fiber to room temperature with the furnace to obtain Degummed carbon fiber woven cloth;

[0099] S1. Pre-impregnation-drying treatment: brush the impregnating liquid on the degummed carbon fiber woven cloth to process it. After the treatment is completed, arrange the obtained carbon fiber weaving in a constant temperature oven at 60°C for drying for 24 hours; the impregnating liquid Contains A and B, the configuration process is as follows: Disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com