ZrB2-SiC-Cf ultra-high temperature ceramic composite material and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of ZrB2-SiC-Cf ultra-high temperature ceramic composite materials and its preparation, can solve the problems of hindering low-temperature densification of powders, rapid grain growth, serious agglomeration, etc. The effect of suppressing structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: a kind of ZrB in this embodiment 2 -SiC-C f The preparation method of ultra-high temperature ceramic composite material is carried out according to the following steps:

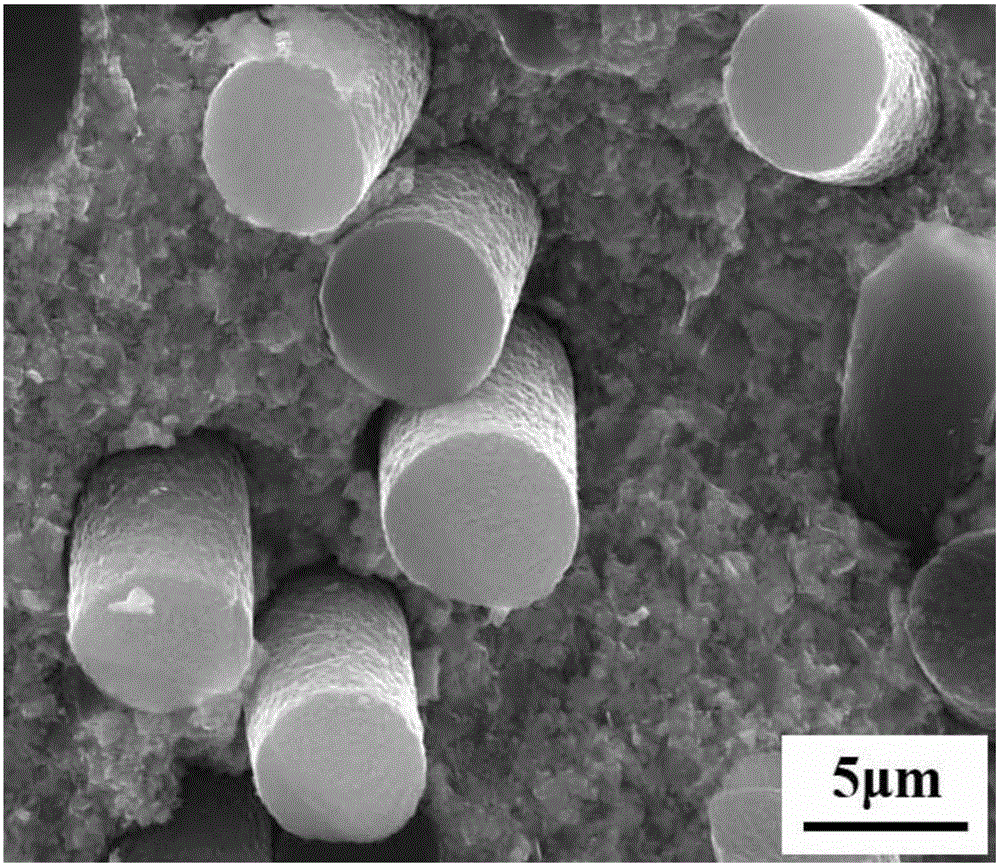

[0017] Step 1, ZrB with an average particle diameter of 150nm 2 Powder, SiC powder with an average particle size of 200nm and carbon fiber were added to absolute ethanol (the volume of absolute ethanol was about 30 times the total volume of powder and fiber), and ultrasonic cleaning was performed for about 30 minutes; where ZrB 2 The volume fraction of SiC is 60%, the volume fraction of SiC is 20%, and the volume fraction of carbon fiber is 20%;

[0018] Step 2, then pour it into a polytetrafluoroethylene ball mill jar for ball milling for 10 hours, and use WC balls as the milling balls. The ball milling speed is 220r / min, and then the rotary evaporator is used to rotate and dry in vacuum at a speed of 35r / min and a temperature of 80°C to obtain powder A;

[0019] Step 3. G...

specific Embodiment approach 2

[0021] Specific embodiment two: a kind of ZrB in this embodiment 2 -SiC-C f The preparation method of ultra-high temperature ceramic composite material is carried out according to the following steps:

[0022] Step 1, ZrB with an average particle diameter of 150nm 2 Powder, SiC powder and carbon fiber with an average particle size of 500nm were added to absolute ethanol (the volume of absolute ethanol was about 30 times the total volume of powder and fiber), and ultrasonic cleaning was performed for about 30 minutes; where ZrB 2 The volume fraction of SiC is 60%, the volume fraction of SiC is 20%, and the volume fraction of carbon fiber is 20%;

[0023] Step 2, then pour it into a polytetrafluoroethylene ball mill jar for ball milling for 10 hours, and use WC balls as the milling balls. The ball milling speed is 220r / min, and then the rotary evaporator is used to rotate and dry in vacuum at a speed of 35r / min and a temperature of 80°C to obtain powder A;

[0024] Step 3. G...

specific Embodiment approach 3

[0026] Specific embodiment three: a kind of ZrB in this embodiment 2 -SiC-C f The preparation method of ultra-high temperature ceramic composite material is carried out according to the following steps:

[0027] Step 1, ZrB with an average particle diameter of 150nm 2 Powder, SiC powder and carbon fiber with an average particle size of 500nm were added to absolute ethanol (the volume of absolute ethanol was about 30 times the total volume of powder and fiber), and ultrasonic cleaning was performed for about 30 minutes; where ZrB 2 The volume fraction of SiC is 50%, the volume fraction of SiC is 20%, and the volume fraction of carbon fiber is 30%;

[0028] Step 2, then pour it into a polytetrafluoroethylene ball mill jar for ball milling for 10 hours, and use WC balls as the milling balls. The ball milling speed is 220r / min, and then the rotary evaporator is used to rotate and dry in vacuum at a speed of 35r / min and a temperature of 80°C to obtain powder A;

[0029] Step 3. G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com