Prediction method for fatigue life of complex braided structure ceramic-based composite material

A fatigue life prediction, composite material technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of inability to accurately predict the fatigue life curve of complex braided structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Taking the 2.5D-C / SiC composite material as an example, the present invention predicts the S-N curve of the 2.5D-C / SiC composite material under the tension-tension fatigue load at room temperature. Table 1 shows the basic material properties of fiber bundles at room temperature.

[0102] Table 1 Basic properties of C / SiC fiber bundle materials at room temperature

[0103]

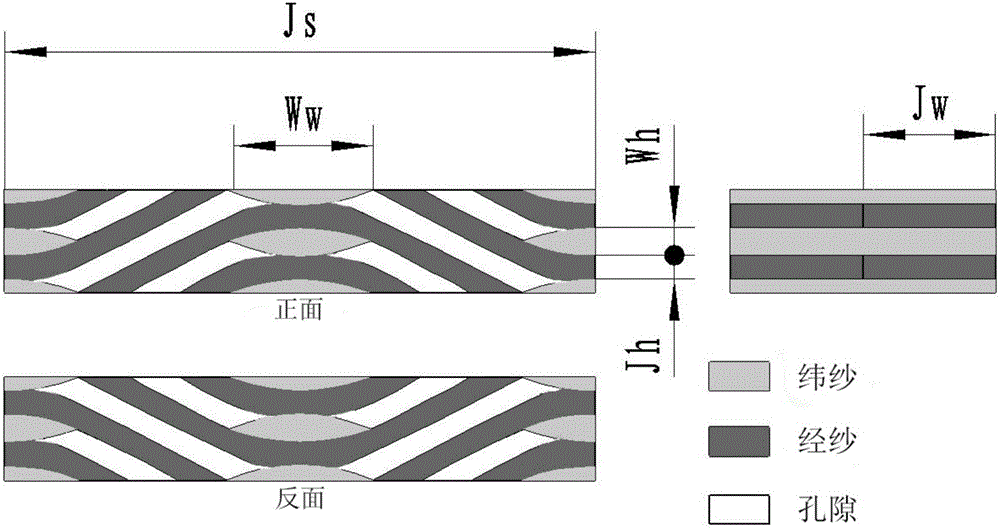

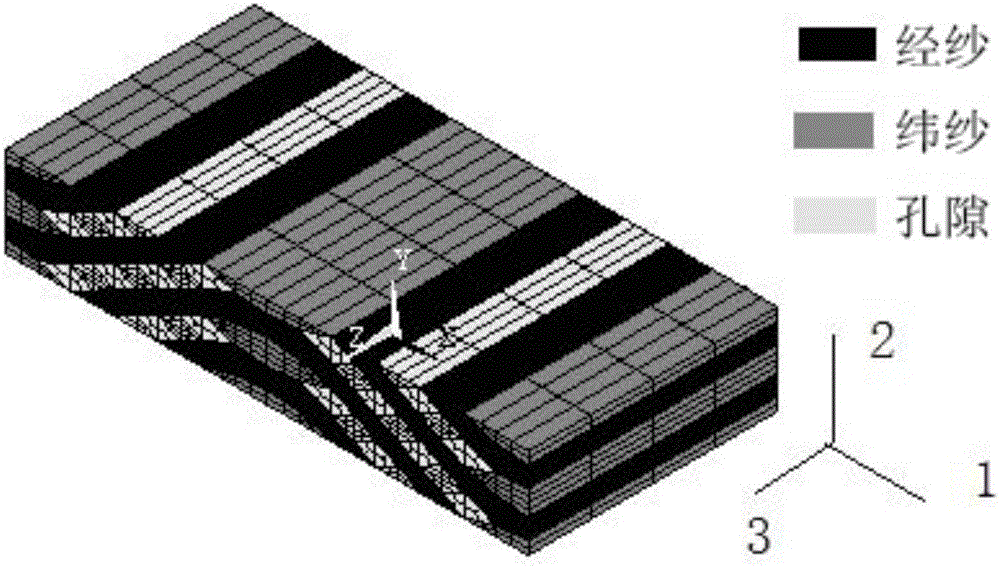

[0104] (1) Based on the finite element method, a 2.5-dimensional unit cell model is established. According to the periodic characteristics, the structural size of the selected unit cell model is as follows: figure 1 shown. The unit cell model has a total of 5 parameters. Js is the warp span; Jh is the warp height; Jw is the warp width; Ww is the weft width; Wh is the weft height, and the size parameters are measured by photomicrographs. Through ANSYS commercial software, a 2.5-dimensional braided C / SiC composite mesostructure model was obtained, and the geometric dimensions of the braided stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com