Method and device for predicting fatigue life of bearing steel

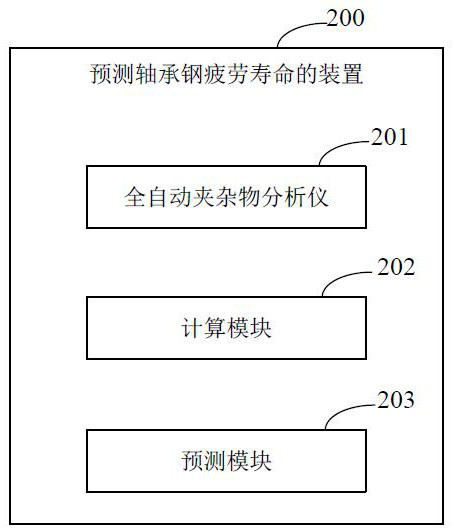

A fatigue life and bearing steel technology, applied in the field of steel materials, can solve the problems such as the inability to further predict the long fatigue life of bearing steel and the inability to predict the uniformity of inclusion distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

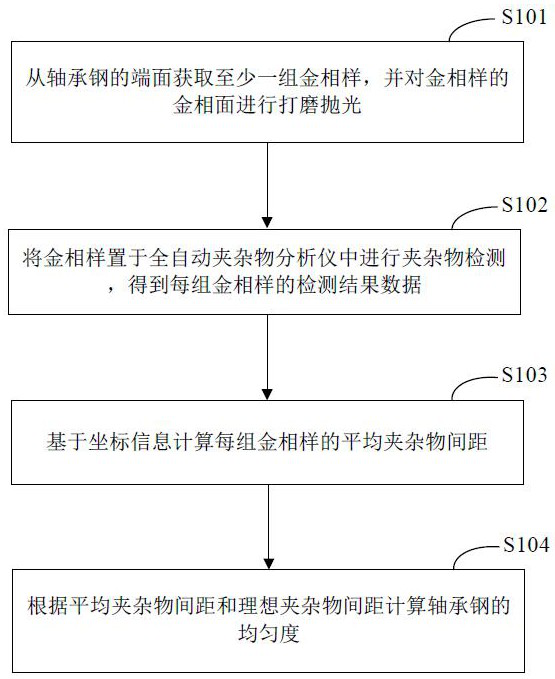

Method used

Image

Examples

Embodiment approach

[0069] As a preferred implementation, the code of the Python program includes:

[0070] # load library

[0071] import pandas as pd

[0072] import numpy as np

[0073] # read data

[0074] df = pd.read_excel(r'C:\Users\cff\Desktop\coordinates.xlsx')

[0075] X = df['x'].values

[0076] Y = df['y'].values

[0077] # Find the minimum value

[0078] MINDIS = []

[0079] for i in range(len(df)):

[0080] Dis = []

[0081] for j in range(len(df)):

[0082] if j != i:

[0083] dis = np. sqrt((X[i]-X[j])**2 + (Y[i]-Y[j])**2)

[0084] Dis.append(round(dis,5))

[0085] mindis = min(Dis)

[0086] MINDIS.append(mindis)

[0087] # tidy up, output

[0088] df['mindis'] = MINDIS

[0089] df.to_excel('export results.xlsx', index = None)

[0090] Step S104, calculating the uniformity of the bearing steel according to the average inclusion spacing and the ideal inclusion spacing.

[0091] Among them, the uniformity is related to the fatigue life, so the uniformity can be use...

Embodiment 1

[0112] 1. Sampling from the center of the end face of the bearing steel, assuming three metallographic samples of a cube of 10mm*10mm*10mm.

[0113] 2. Roughly grind the three metallographic surfaces with 180-mesh sandpaper to remove the skin to ensure the smoothness of the metallographic surface, and then use 300-mesh, 600-mesh, 1000-mesh, 1500-mesh and 2000-mesh sandpaper to finely grind in turn. The fine grinding process It is necessary to ensure that the last scratches are worn off.

[0114] 3. After finely grinding with the above-mentioned sandpaper, polish the metallographic surface. In order to prevent the polishing agent from affecting the test results, do not use the polishing agent, or first use the polishing agent for rough polishing, and finally need to change a polishing cloth. Thin face to face.

[0115] 4. Rinse the polished sample (i.e. metallographic sample) with deionized water, and quickly perform light polishing on a polishing machine with a clean polishin...

Embodiment 2

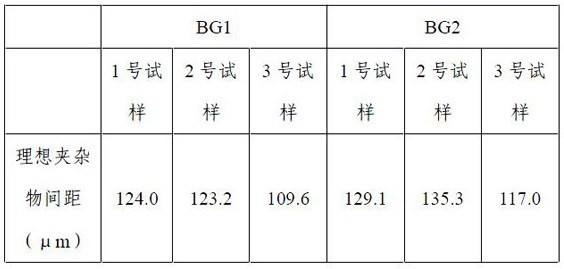

[0125] When implementing the present invention, the purpose of predicting the fatigue life of different heats of bearing steels can also be achieved by comparing the uniformity of inclusions in bearing steels of the same steel grade. For details, see the following examples. The second embodiment is basically the same as the first embodiment. The same, the similarities will not be repeated, the difference is:

[0126] 1. Take three metallographic samples of 10mm*10mm*10mm from the same part of the end of bearing steel BG1 and bearing steel BG2 of a certain brand, and select the surface where the end is located as the metallographic surface.

[0127] 2. After the metallographic surface of each metallographic sample undergoes steps such as rough grinding, fine grinding, rough polishing, and fine polishing, use Aspex to detect all samples (ie, metallographic samples), where the detection area is set to 32.363mm², the inclusion size range is set from 0.5μm to 12μm.

[0128] 3. Exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com