Patents

Literature

32results about How to "Predict fatigue life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prediction method for fatigue life of complex braided structure ceramic-based composite material

InactiveCN105760605APredict fatigue lifeDesign optimisation/simulationSpecial data processing applicationsFiberFailure strain

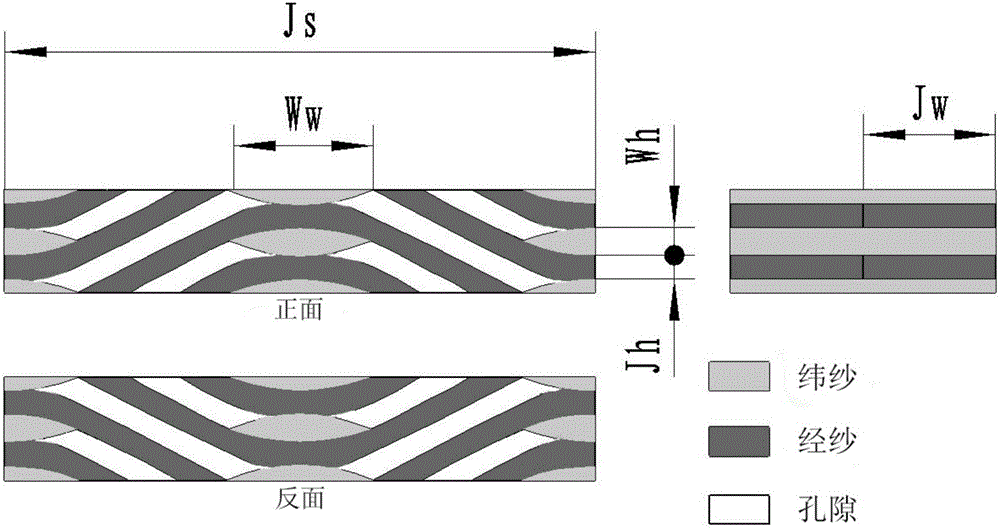

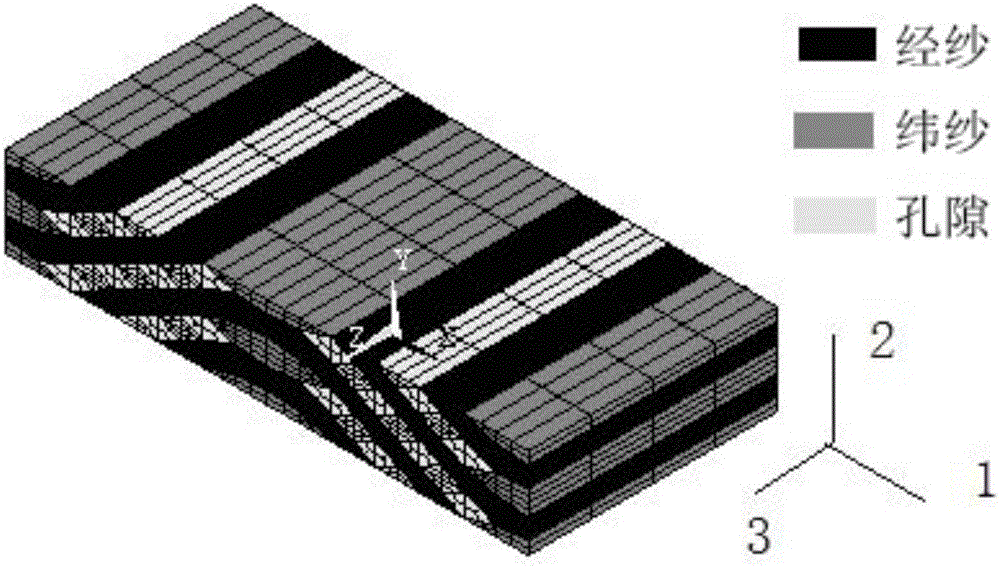

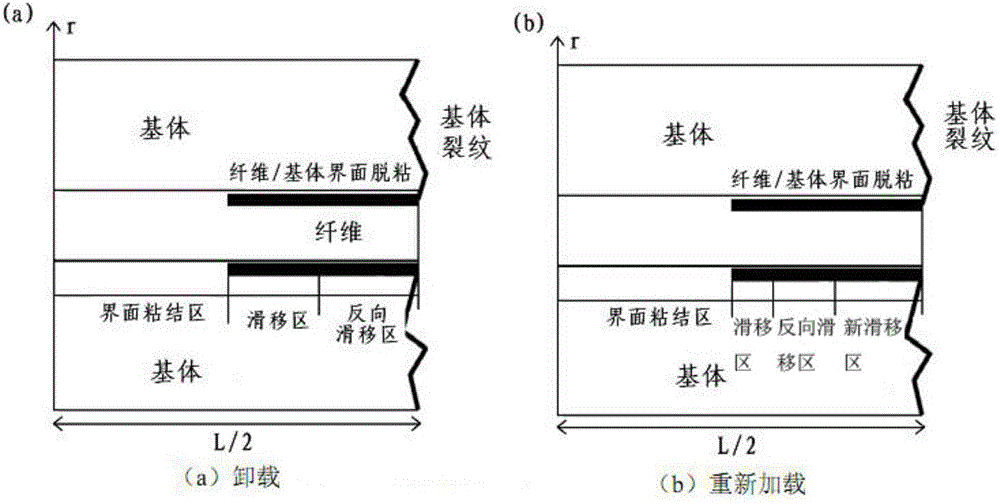

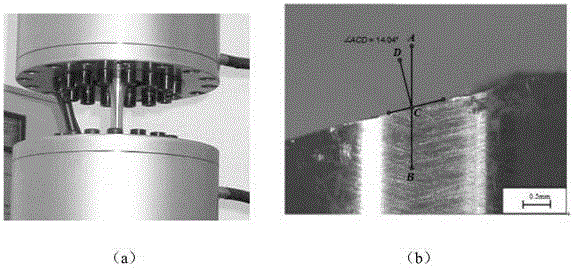

The invention discloses a prediction method for the fatigue life of a complex braided structure ceramic-based composite material.The prediction method comprises the steps that the fatigue performance under a cycle number and the fiber failure percentage under the cycle number are calculated; the relationship between the fiber failure percentage and a fiber failure critical value is determined; the unit-cell scale fatigue performance is calculated to obtain the maximum strain epsilon'max under the cycle; the relationship between the maximum strain epsilon'max and the maximum failure strain epsilonmax is determined; a fatigue life curve of the material is obtained.According to the prediction method, a microscale model taking account of fibers, a base body and pores and a unit-cell multi-scale prediction model taking account of warp yarn, weft yarn and holes are presented and overcome the defects that a micromechanical method cannot be directly applied to the braded material with the complex structure, and a macroscopic phenomenological method depends on a large quantity of tests and only can achieve prediction on the fatigue life of a special material, macromechanics and micromechanics are combined, a micromechanical stress strain field of a complex braided structure is supplied, and the application range of the material is widened while the fatigue life curve of the material is precisely predicted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

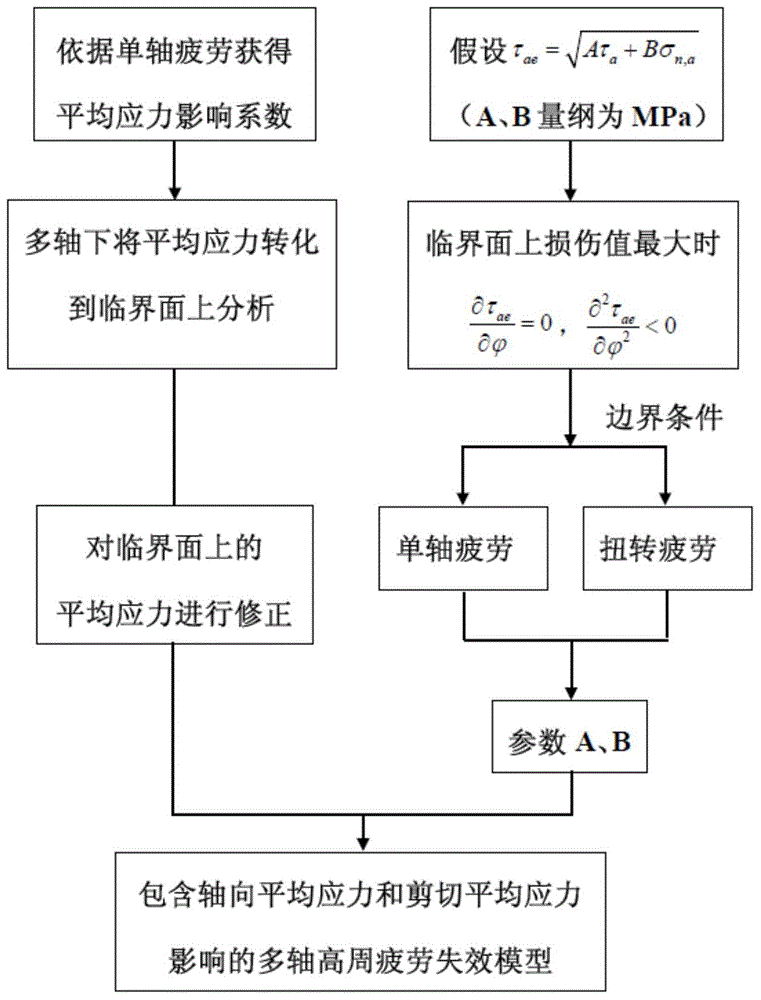

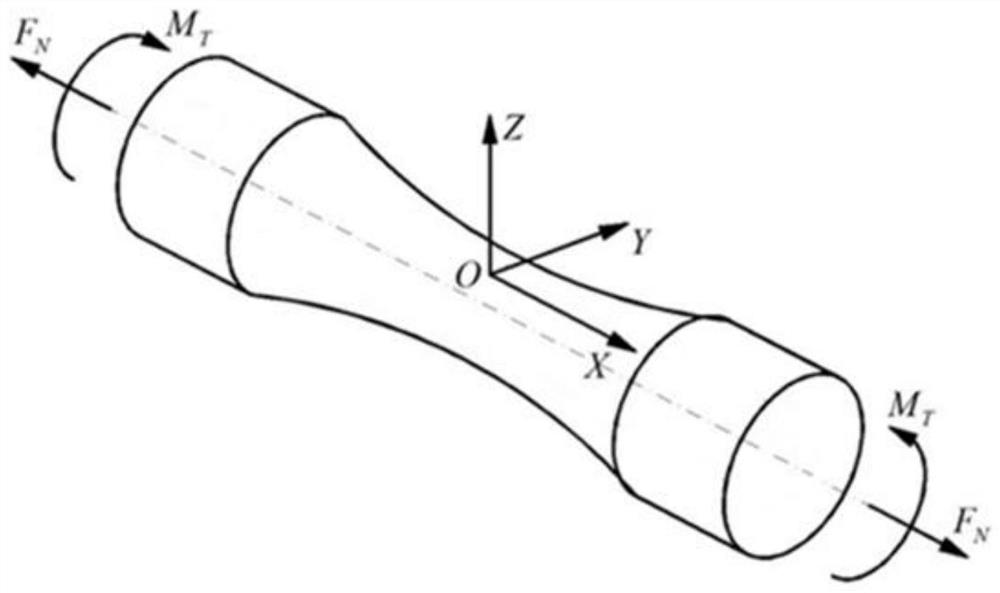

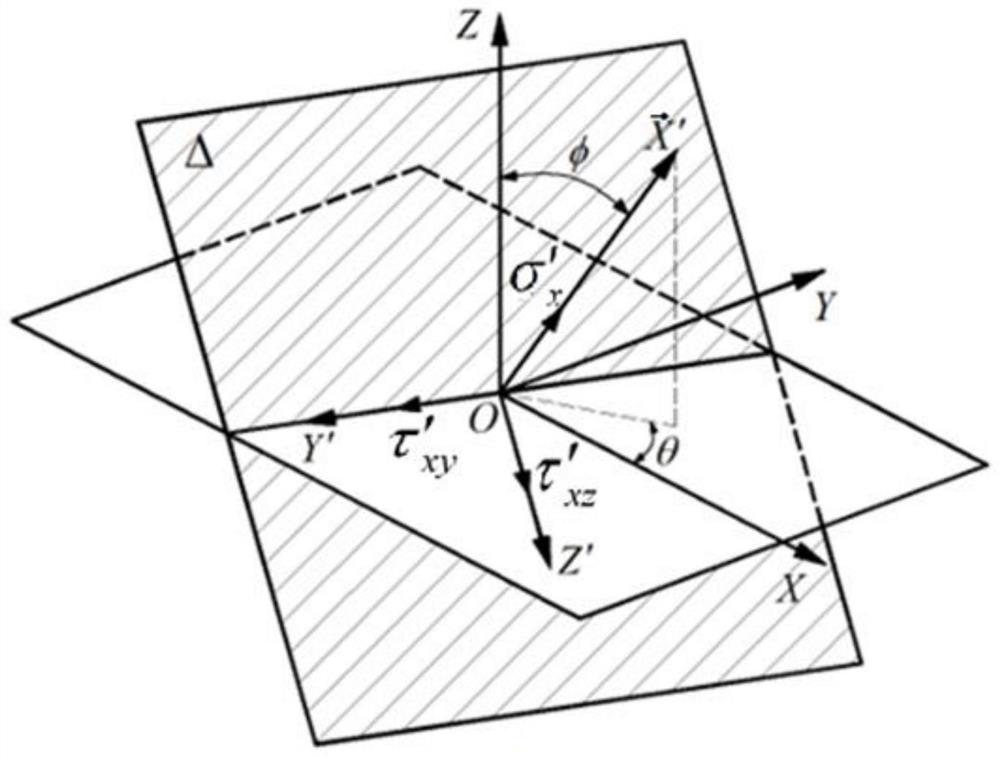

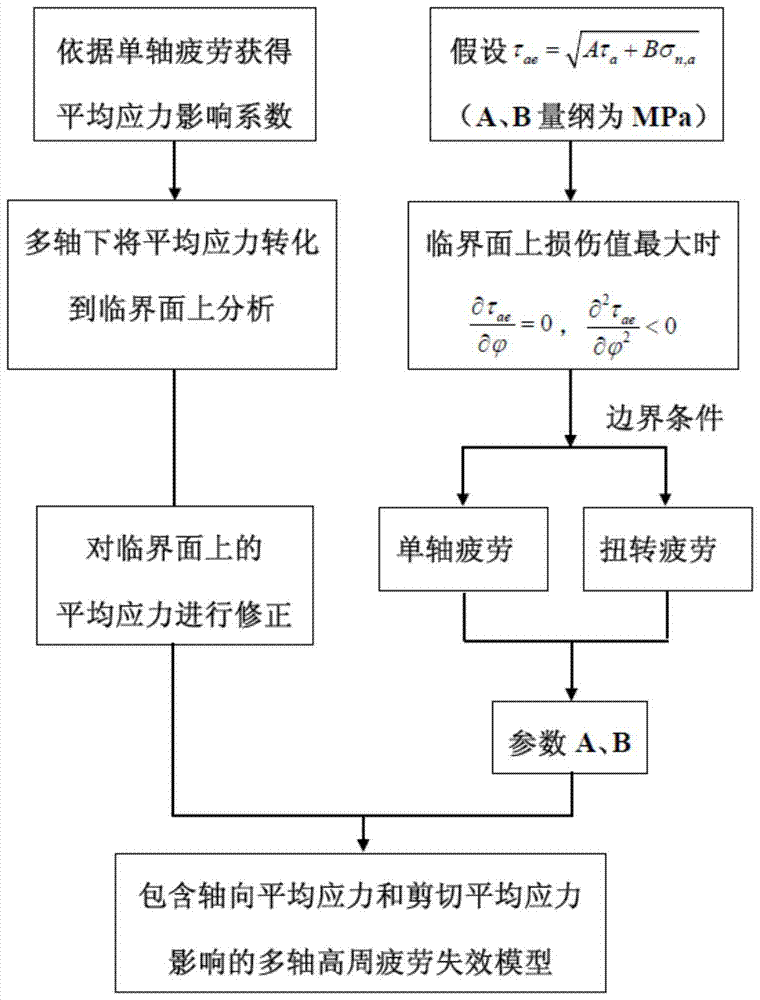

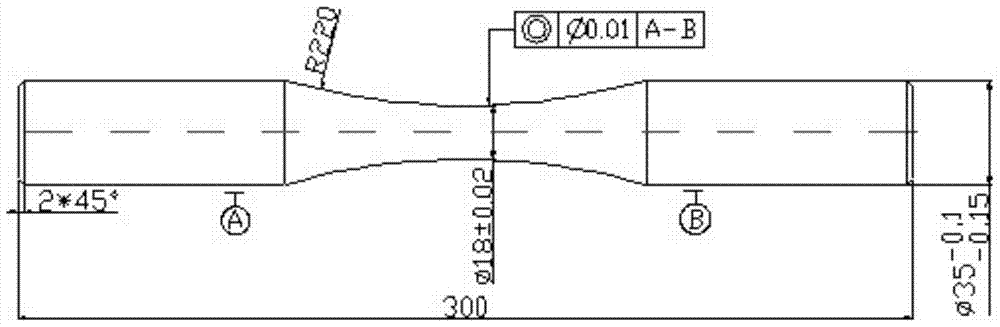

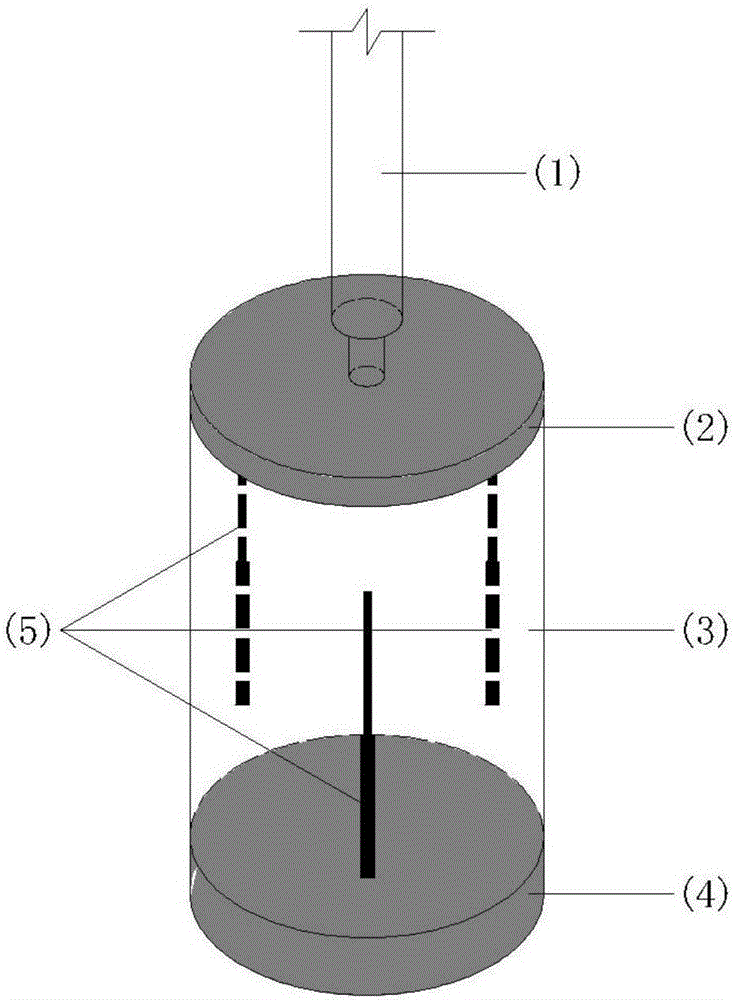

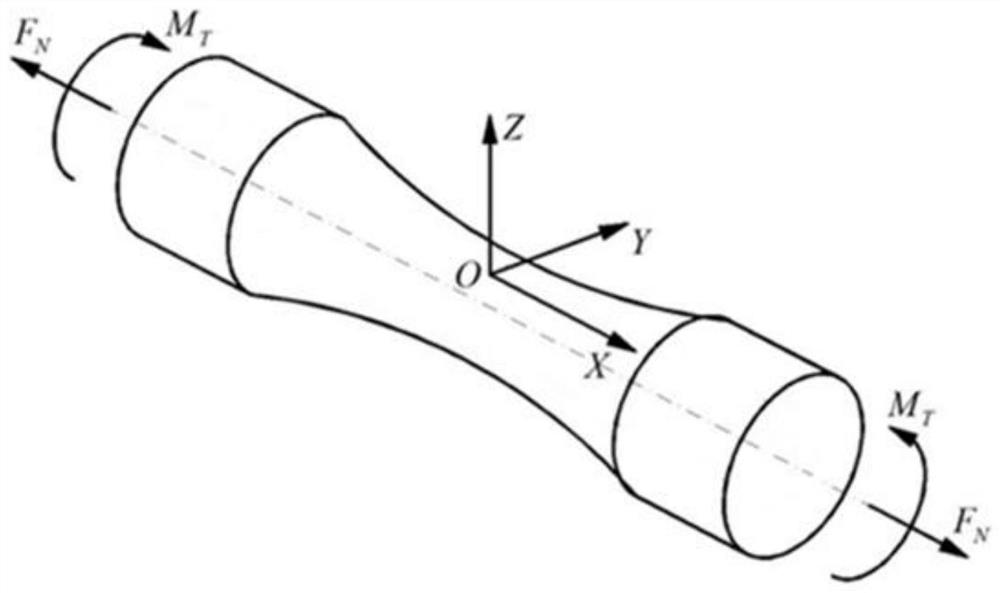

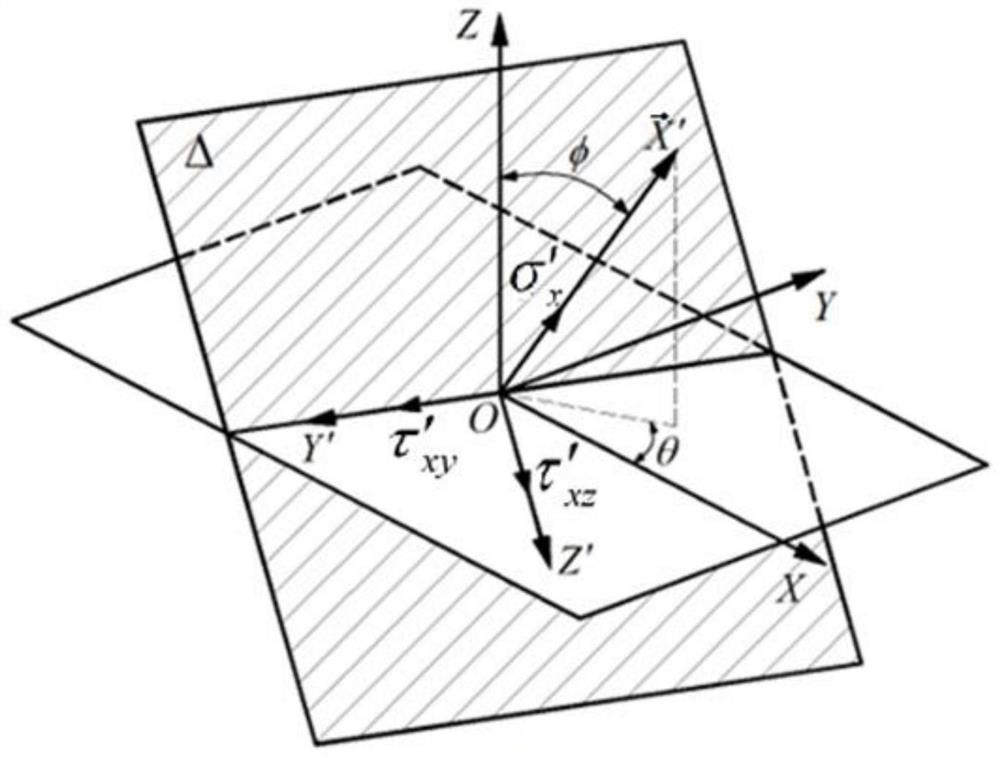

Prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect

ActiveCN104699976APredict fatigue lifeAccurate predictionSpecial data processing applicationsStrength propertiesFatigue loadingShear stress

The invention discloses a prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect; the prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect comprises the following steps: using the uniaxial fatigue and the pure torsional fatigue as the boundary conditions for calculating the biggest damage surface born by the material during the fatigue loading process and taking the biggest damage surface as the boundary surface, selecting the positive stress and the shearing stress on the boundary surface as the damage parameter, using the mean stress effect parameter obtained by the uniaxial fatigue for correnting the stress on the boundary surface, and establishing the metal material multiaxial high cycle fatigue failure prediction model including axial direction mean stress and shearing stress influence; the prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect is also applied to the situation without axial mean stress and shearing mean stress. The fatigue service life, the fatigue crack initiation and the initial extension direction of the material under multiaxial high cycle fatigue loading situation can be precisely forecasted while the axial mean stress and shearing mean stress are present.

Owner:XIANGSHAN WEIHUI MAGNET

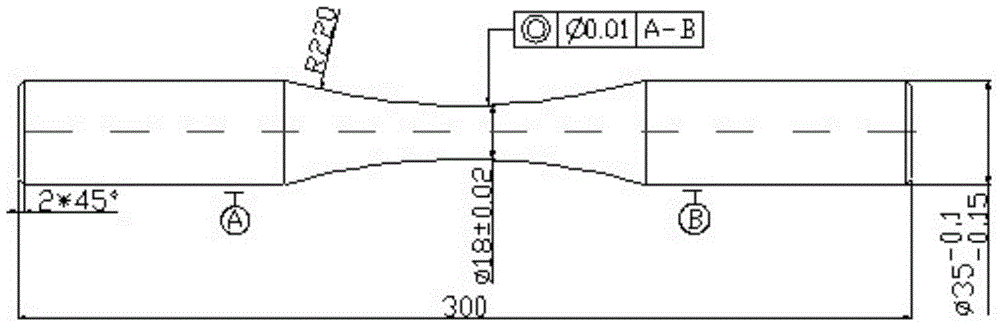

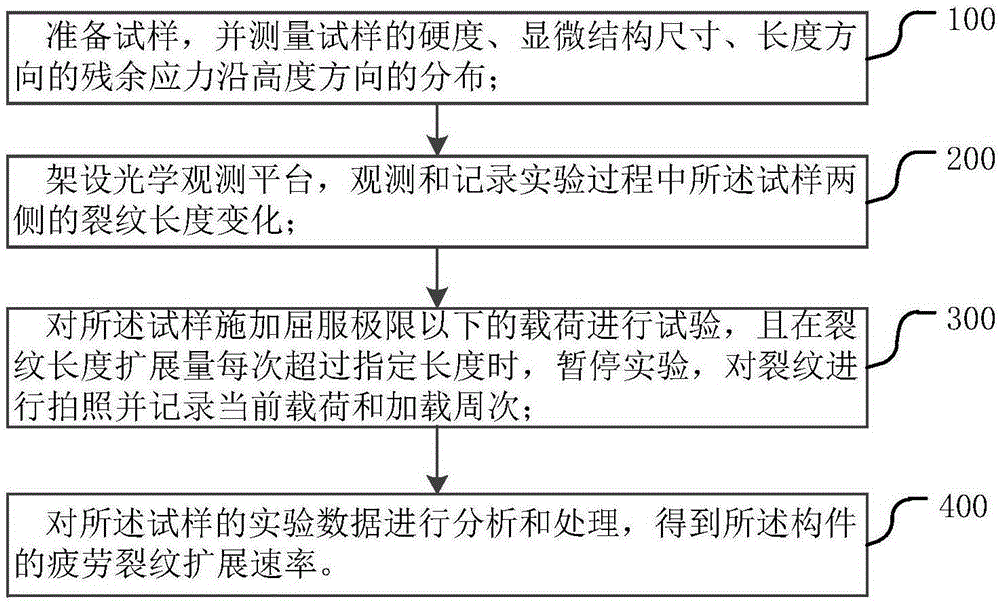

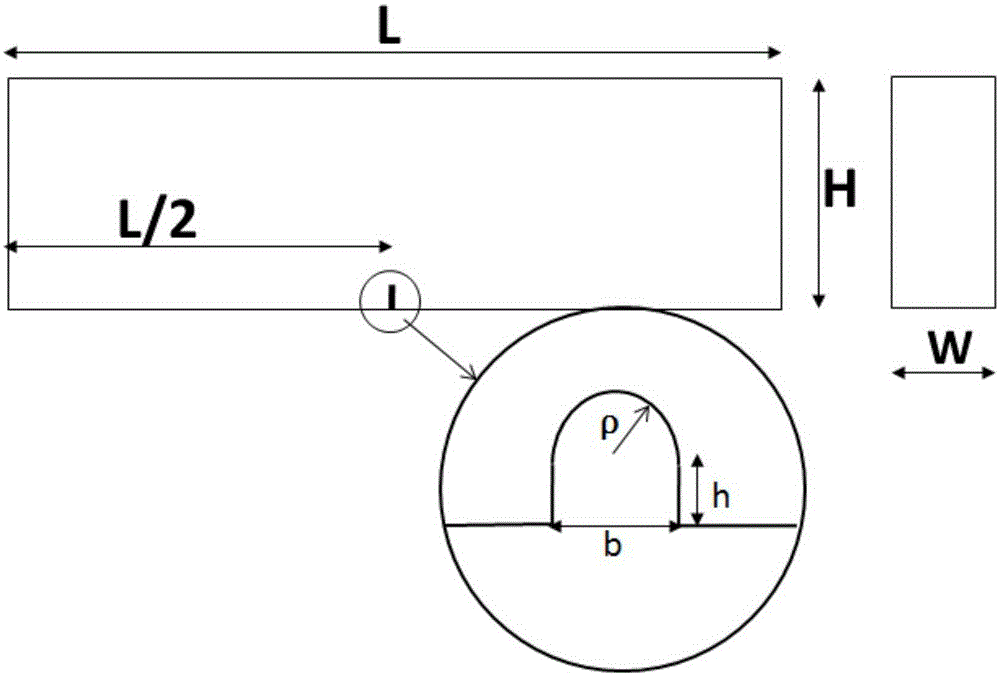

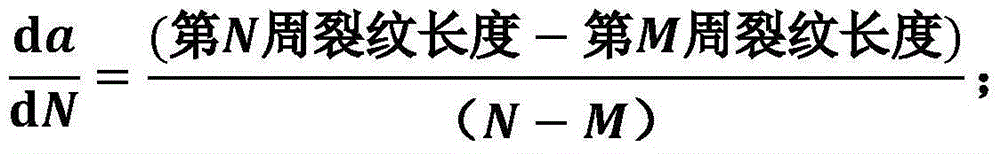

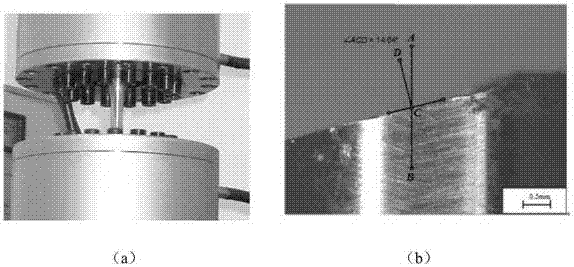

Measuring method for surface strengthening member fatigue crack expansion rate

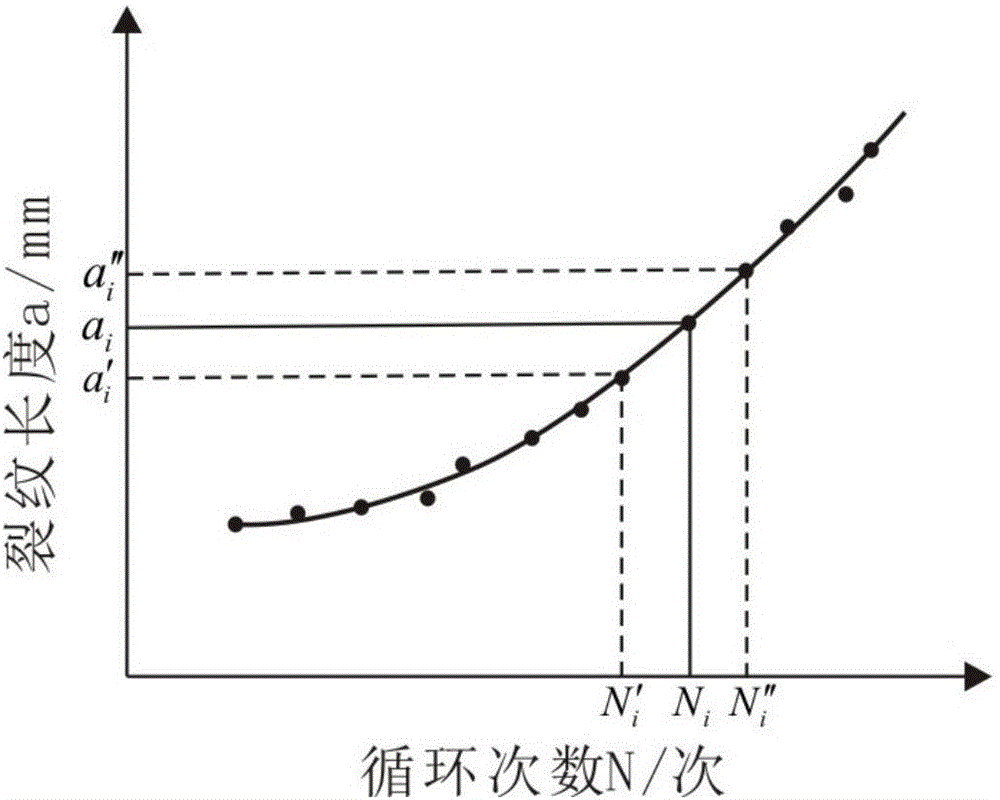

ActiveCN105181492AEnsure consistencyRealize determinationMaterial strength using repeated/pulsating forcesCurrent loadTested time

The invention provides a measuring method for a surface strengthening member fatigue crack expansion rate. The method comprises the following steps: sample preparation is carried out, and hardness, a microscopic structure size, distribution of a residual stress in the length direction along the height direction of a sample are measured; an optical observation platform is erected, crack length changes of two sides of the sample during the test process are observed and recorded; a load less than a yield limit is applied to the sample for test, when the crack length expansion amount exceeds an appointed length every time, the test is paused, the cracks are shot and the current load and loading cycles are recorded; the test data of the sample is subjected to analysis and processing, and the fatigue crack expansion rate of the member is obtained. In the measuring method, a sample is cut from a whole-size member directly, and the consistency of the sample and the member is kept. The problems are solved effectively that whole-size member test time is long, the material cost is high, a lot of test data is difficult to obtain, and measuring of the surface strengthening member fatigue crack expansion rate is achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

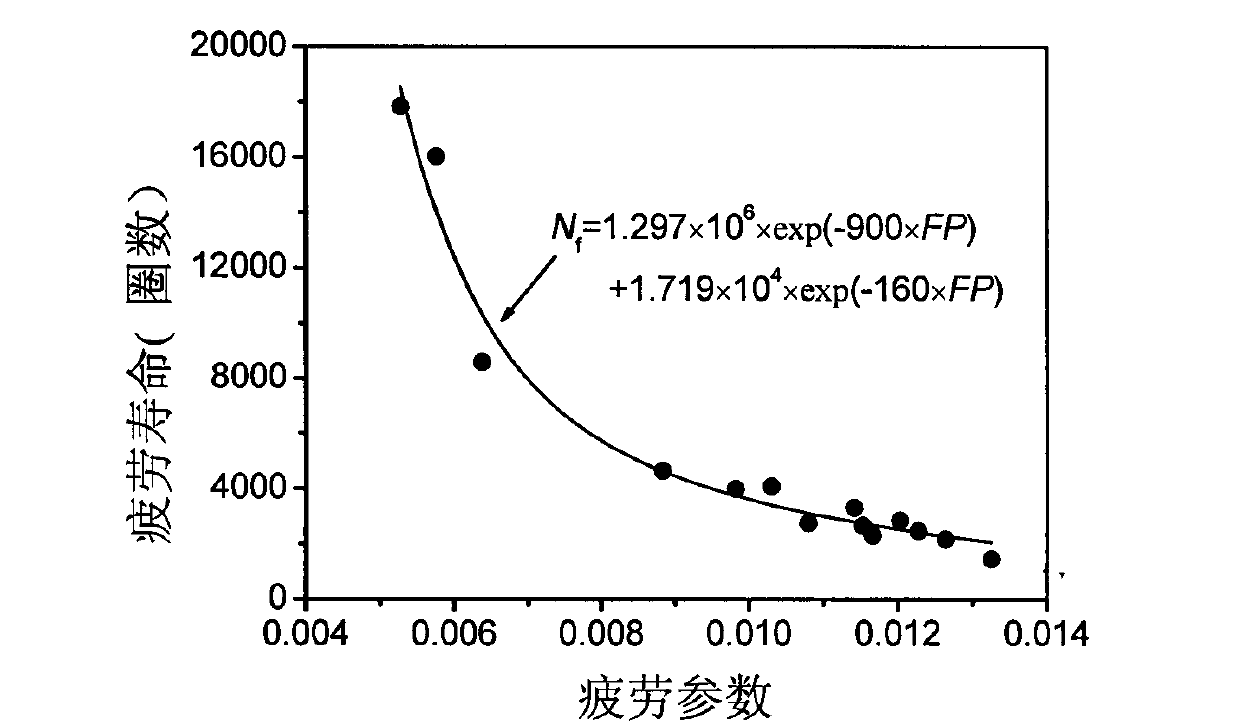

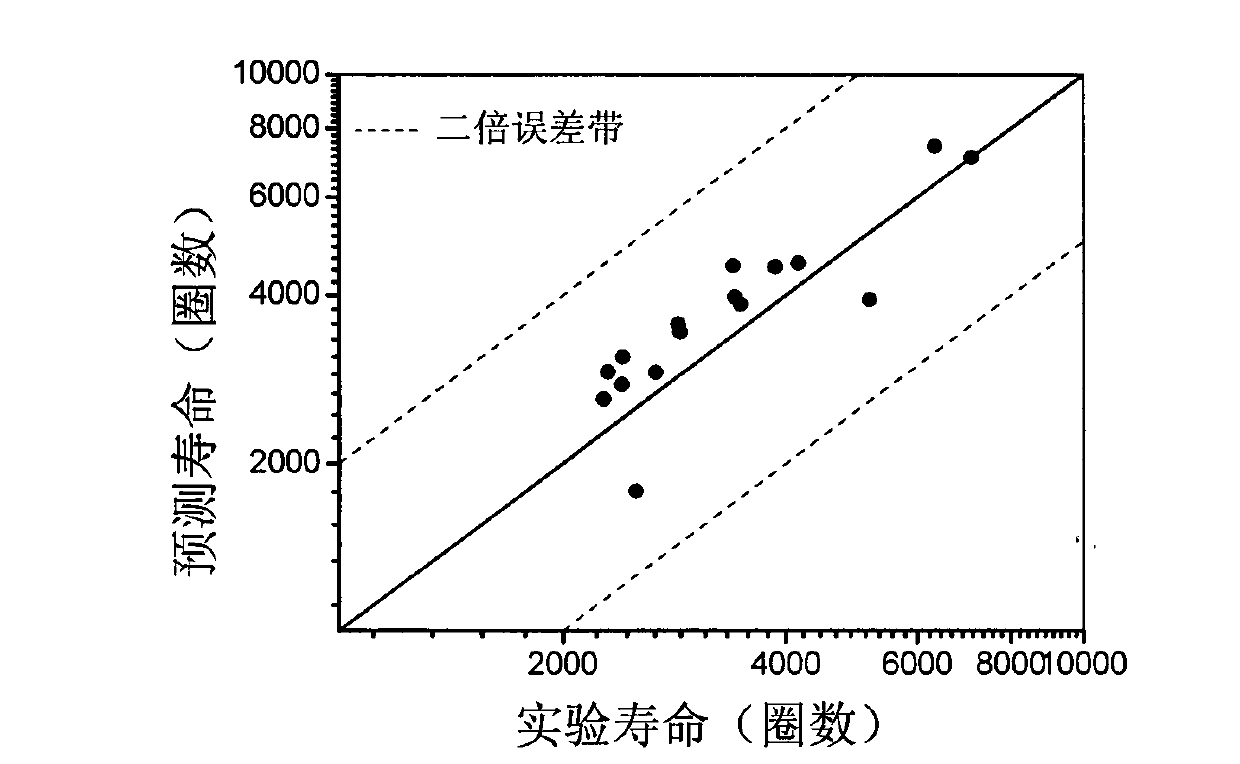

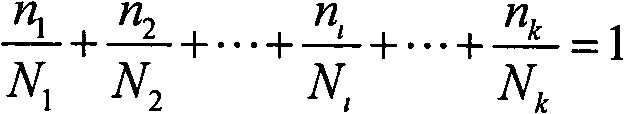

Method for predicting low-cycle fatigue life of metallic material under multi-step loading conditions

InactiveCN102980806APredict fatigue lifePromote engineering applicationMaterial strength using tensile/compressive forcesMetallic materialsReliability design

The invention discloses a method for predicting the low-cycle fatigue life of a metallic material under multi-step loading conditions. The method comprises the following steps of: (1) obtaining the low-cycle fatigue life of the metallic material through one-step and multi-step loaded asymmetric cyclic stress control fatigue experiments; (2) according to the working conditions of the fatigue experiments and the fatigue property of the material, determining a fatigue parameter (FP) calculation equation of the material during one-step loading, and establishing a fatigue life prediction model of the material under one-step loading conditions; (3) proposing a fatigue parameter (FP') calculation equation of the material during multi-step loading according to the nonlinear damage accumulation characteristics of the material in a multi-step loading process; and (4) establishing a low-cycle fatigue life prediction model of the metallic material under multi-step loaded asymmetric cyclic stress control conditions, and predicting the fatigue life of the metallic material. According to the method disclosed by the invention, the low-cycle fatigue life of the metallic material under the multi-step loaded asymmetric cyclic stress control conditions can be quickly predicted, thereby providing a theoretical reference for the reliable design and evaluation of parts.

Owner:CENT SOUTH UNIV

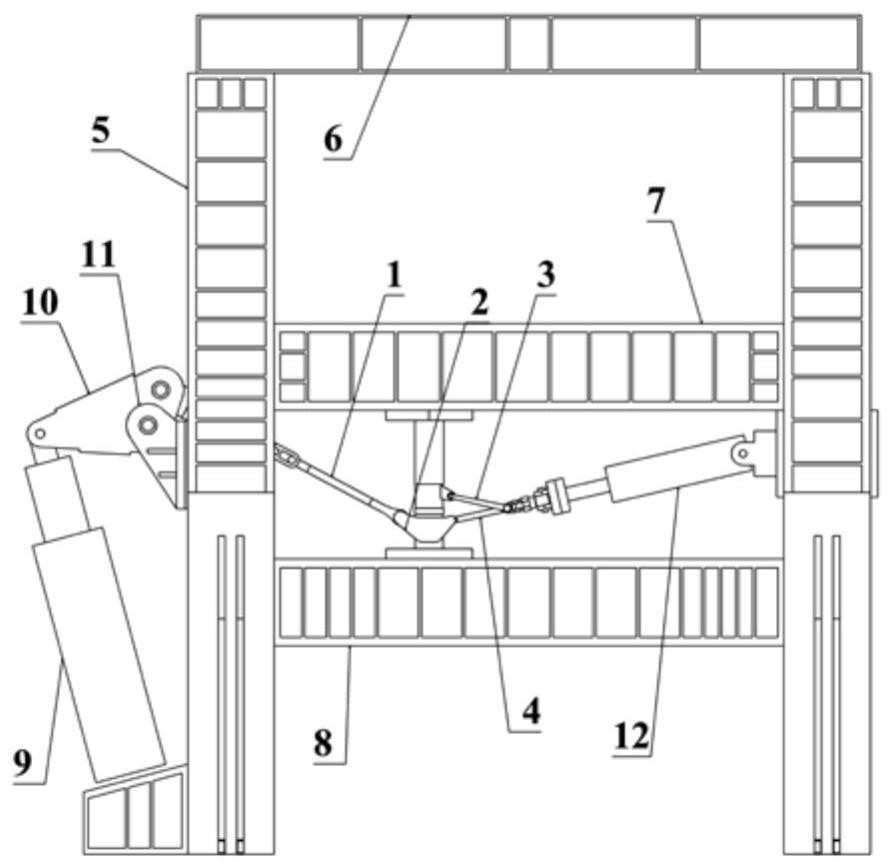

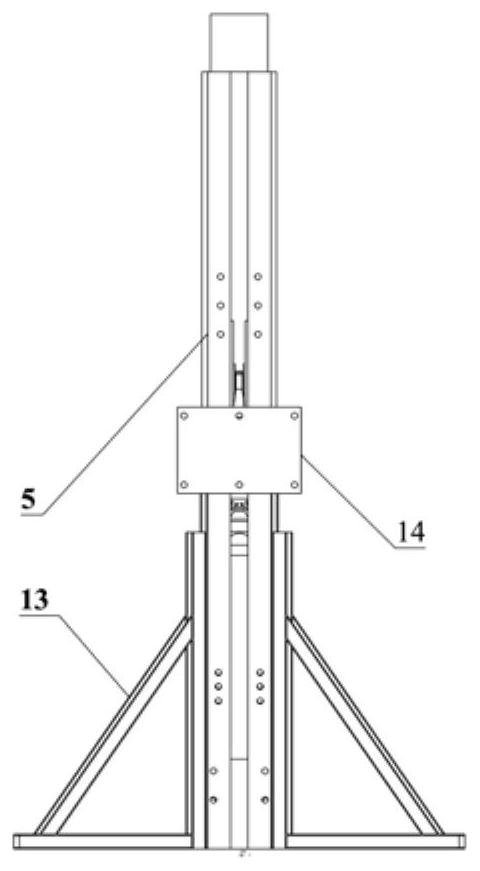

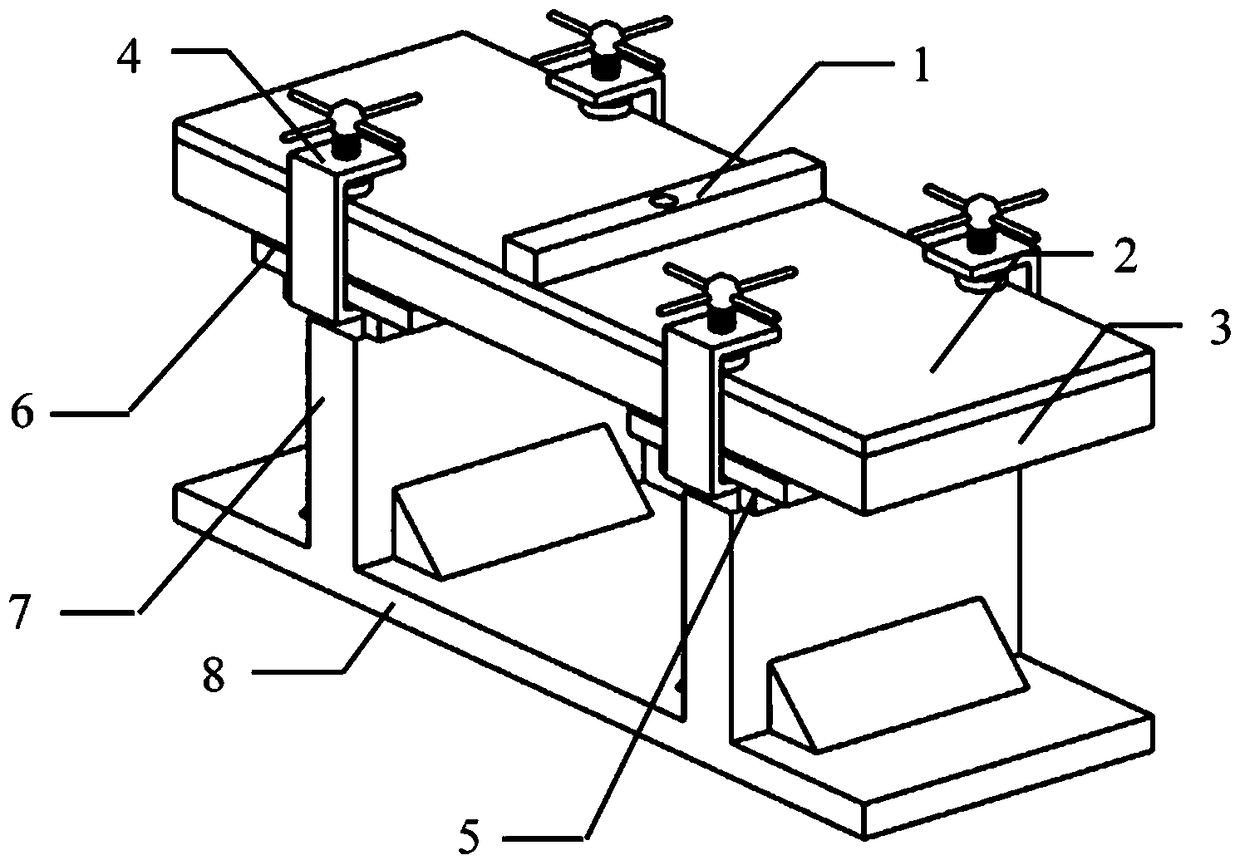

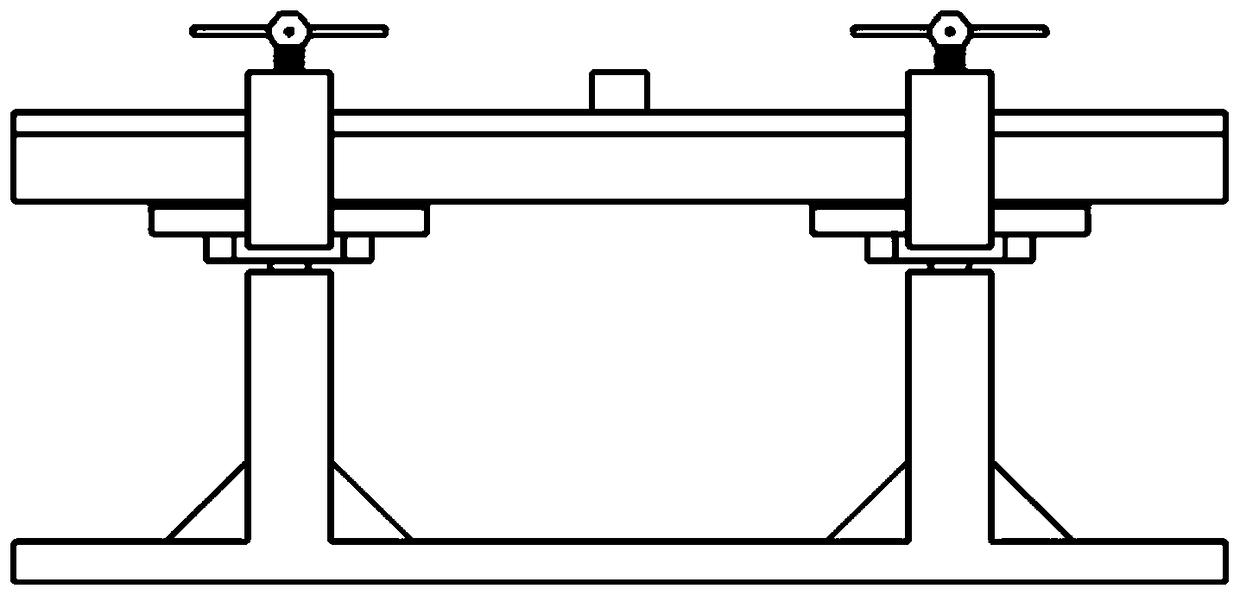

Testing apparatus and method for fatigue cracking of pavement on steel bridge

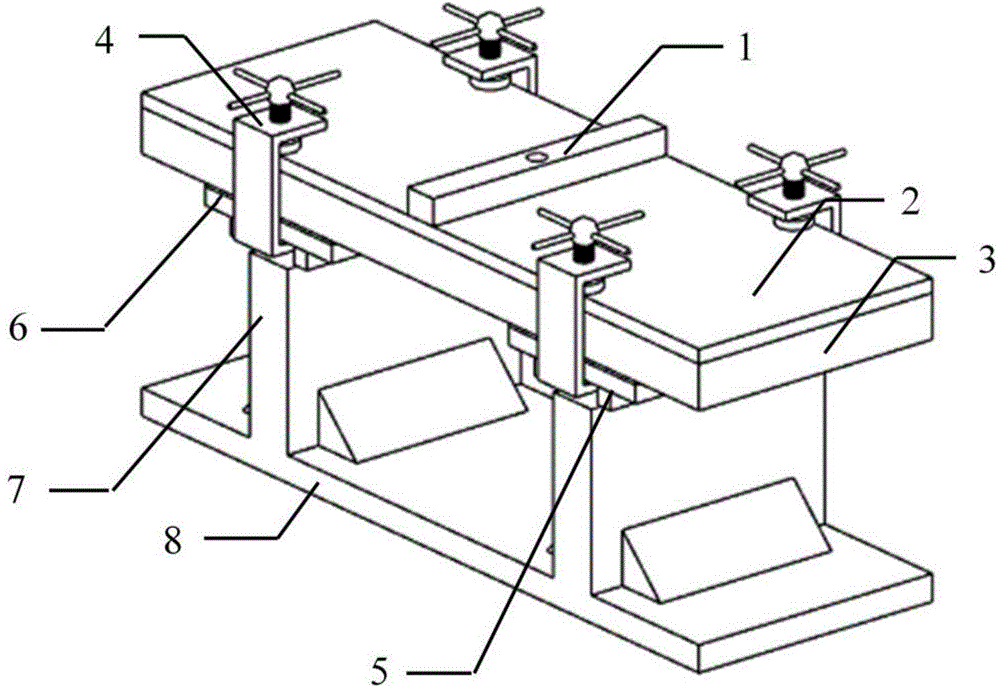

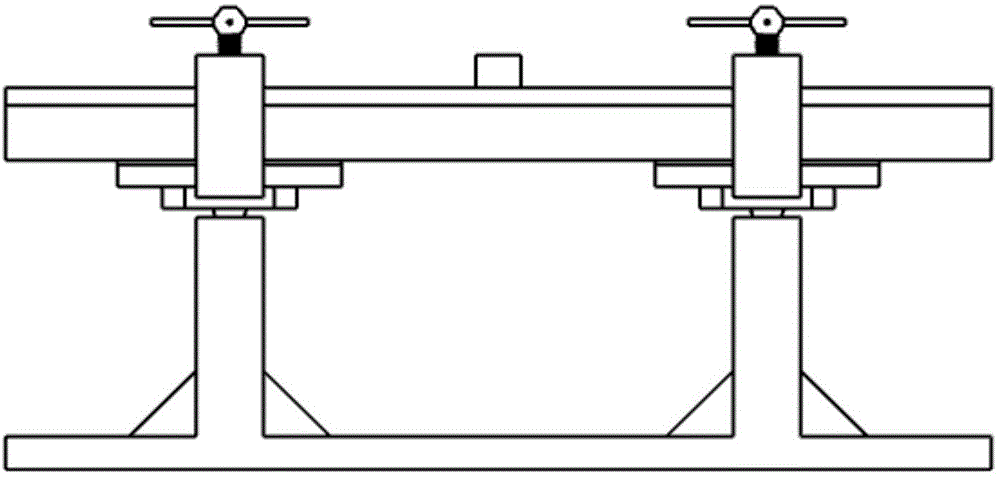

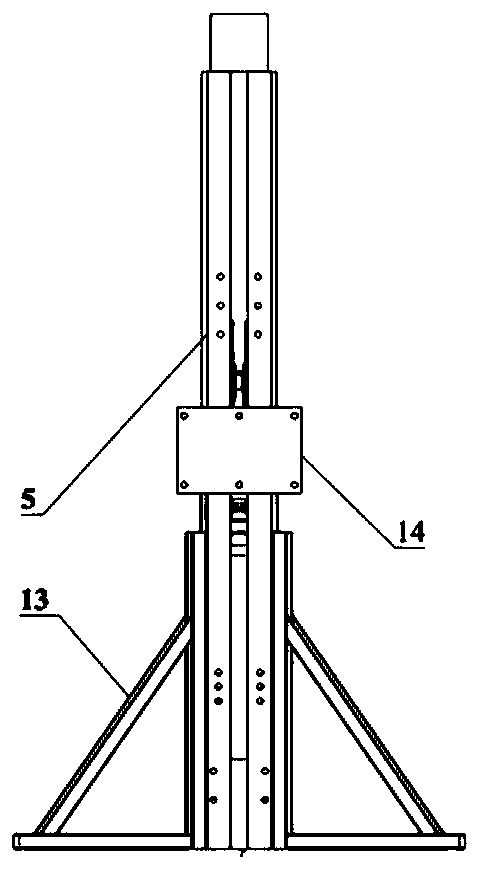

ActiveCN104897491AReliable test resultsReasonable and accurate simulationMaterial strength using repeated/pulsating forcesEngineeringStrain gauge

The invention provides a testing apparatus for fatigue cracking of a pavement on a steel bridge. A test piece is installed on the testing apparatus. The testing apparatus is characterized by comprising a testing platform used for applying load and a testing model used for simulating stress of the test piece, wherein the testing model comprises a support base which is equipped with at least two columns, loading plates are arranged on the columns, and the loading plates are fixed with the test piece through clamps. The invention further provides a testing method for fatigue cracking of the pavement on the steel bridge. The method comprises the following steps: determining the size of the test piece according to the size of the testing platform and load limit; fixing the fabricated test piece and the loading plates together through the clamps; applying load on the testing model by using the testing platform; and predicating the technical state of a pavement layer through displacement observation, foil gauge observation and DIC digital image processing of the state of the test piece in the process of testing, and evaluating the cracking fatigue life of the pavement layer.

Owner:NANJING COMM INST OF TECH

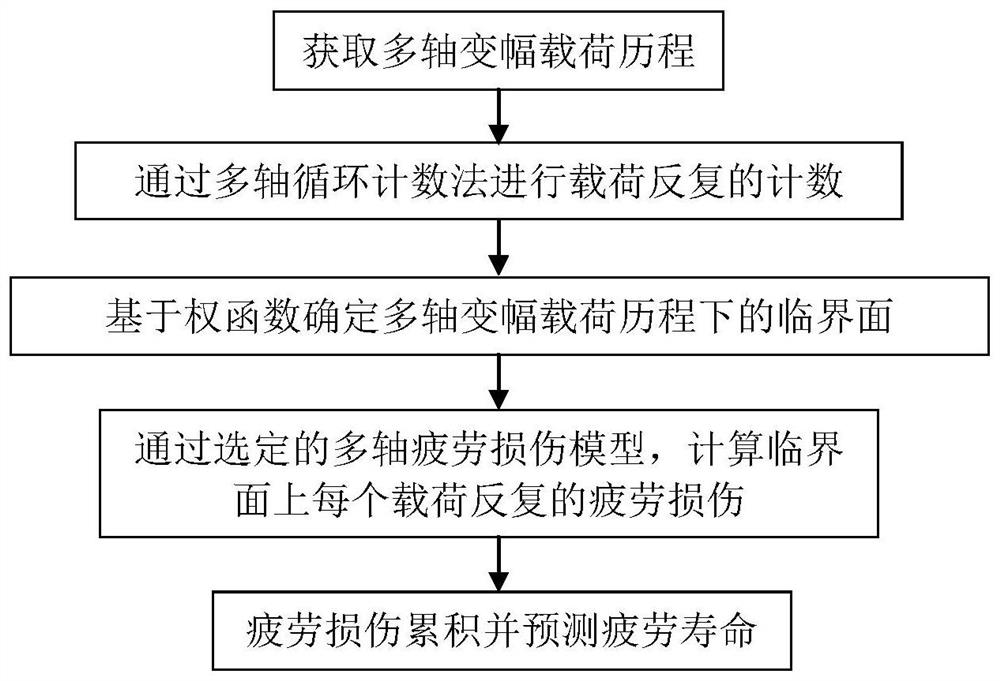

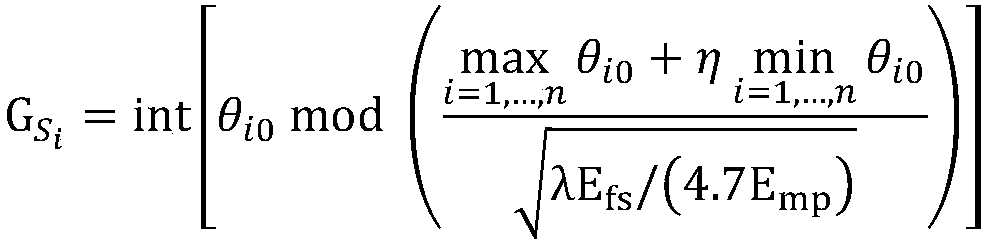

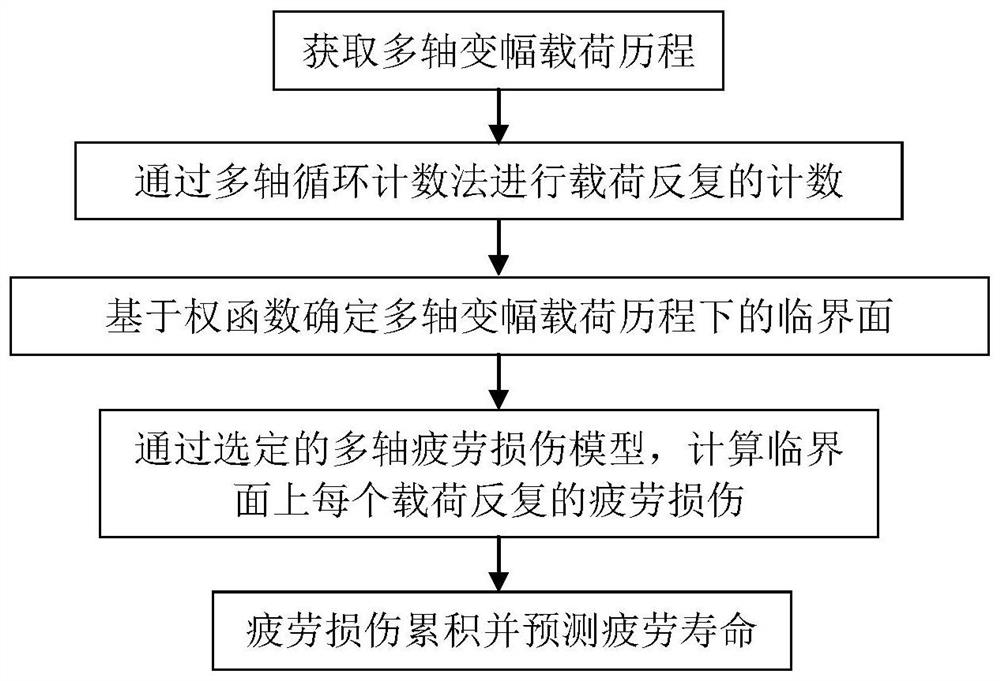

Fatigue life prediction method and device based on weighted average maximum shear stress plane

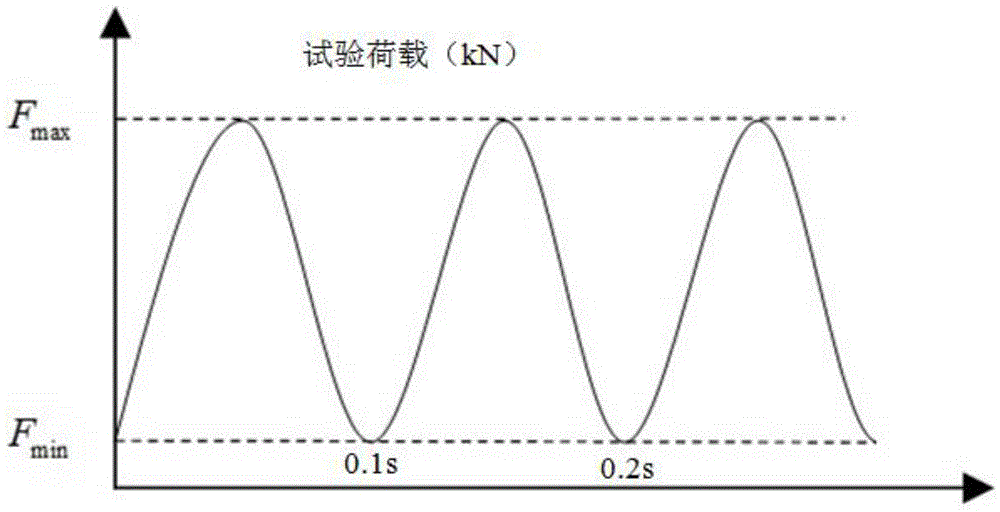

ActiveCN111624116APredict fatigue lifePromote engineering applicationMachine part testingMaterial strength using steady shearing forcesFatigue damageFatigue Intensity

The invention provides a fatigue life prediction method and device based on a weighted average maximum shear stress plane. The method relates to the field of multi-axis fatigue strength theories, andcomprises the following steps: (1) synthesizing multi-axis variable-amplitude load processes into an equivalent stress process through a von Mises equivalent stress formula, and performing cyclic counting on the von Mises equivalent stress process through a Wang-Brown multi-axis cyclic counting method; (2) taking the proposed weighted average maximum shear stress plane as a critical plane under ahigh-cycle multi-axis variable-amplitude load; (3) calculating a fatigue damage parameter on the critical surface in each repeating by counting; (4) carrying out fatigue damage calculation by adoptinga Zhang-Shang model; and (5) accumulating damage calculated in each repeating by adopting a Miner linear accumulation rule, and finally calculating the fatigue life. The weight function proposed in the method can consider the main fatigue damage mechanism under multi-axis loading. The life prediction result shows that the life prediction method can better predict the fatigue life under multi-axisconstant amplitude and variable amplitude loading.

Owner:TSINGHUA UNIV +1

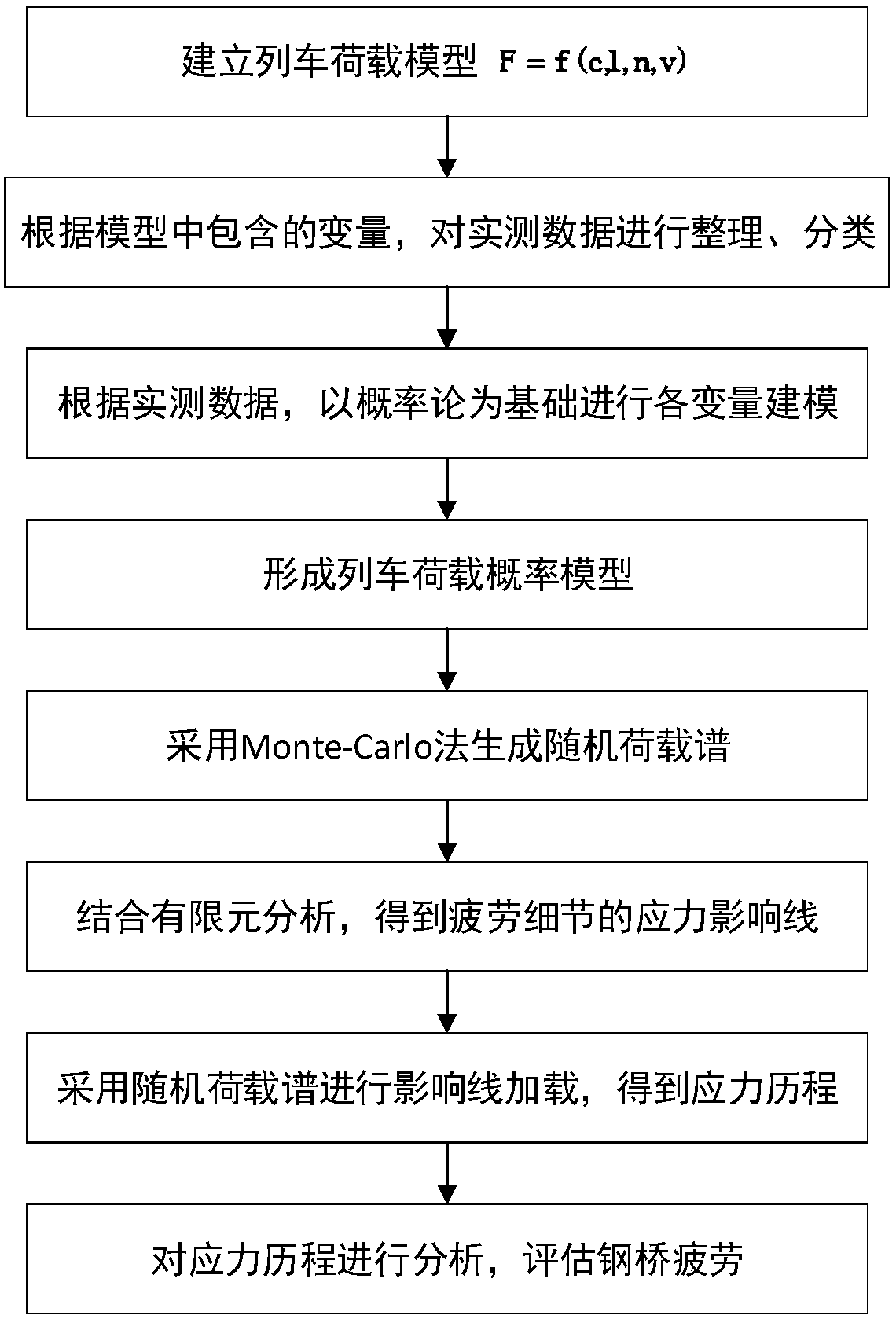

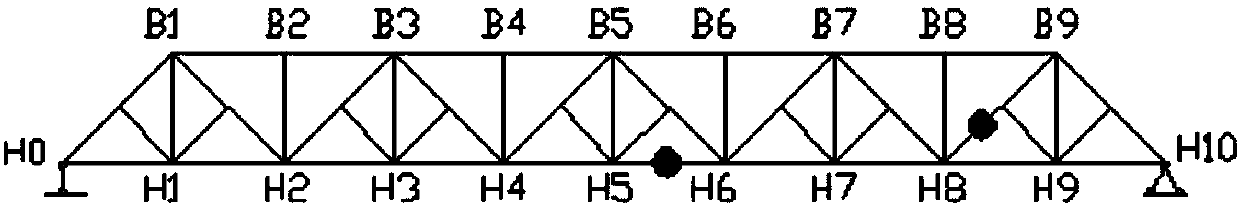

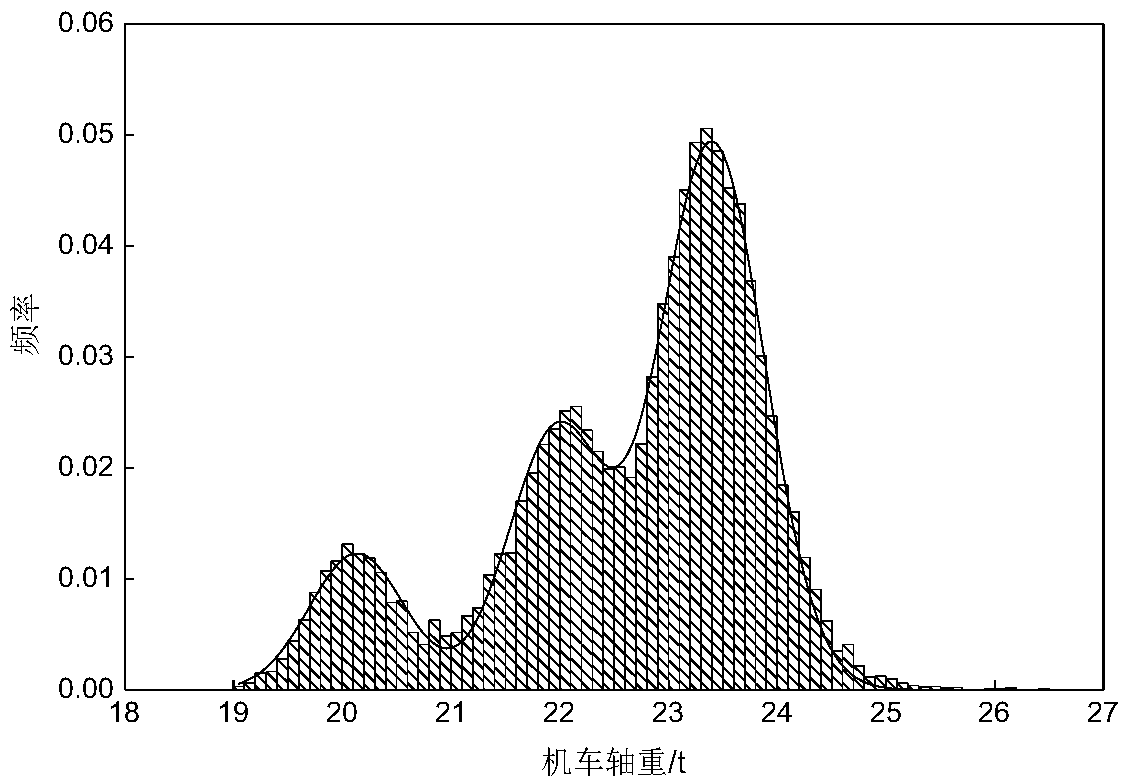

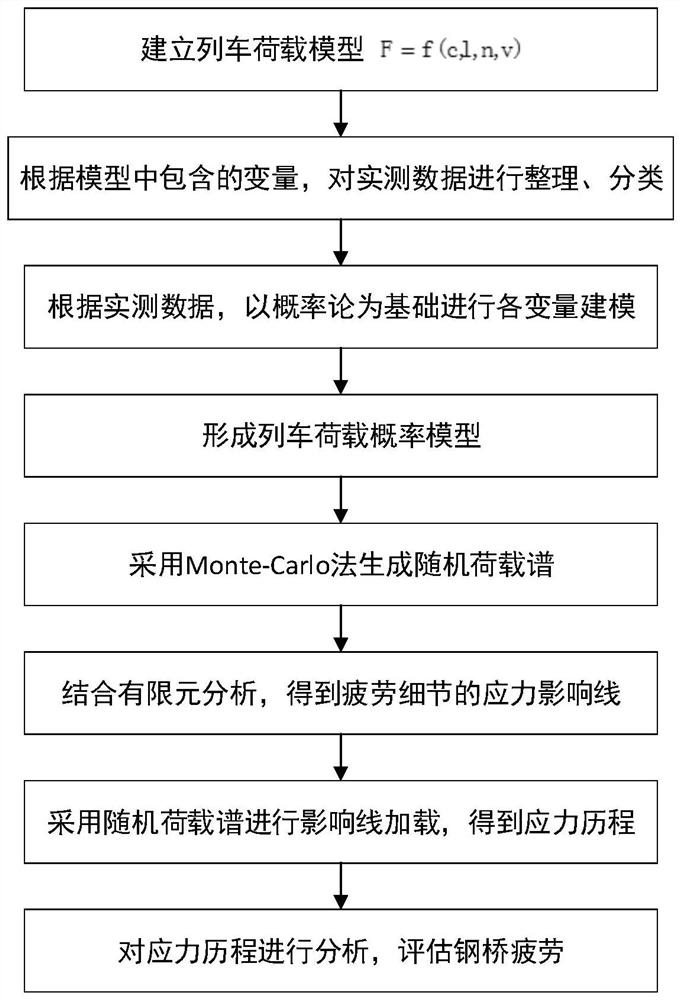

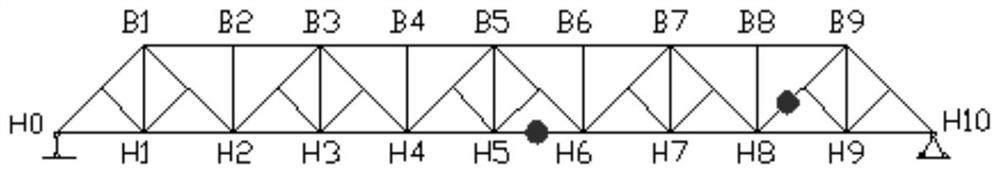

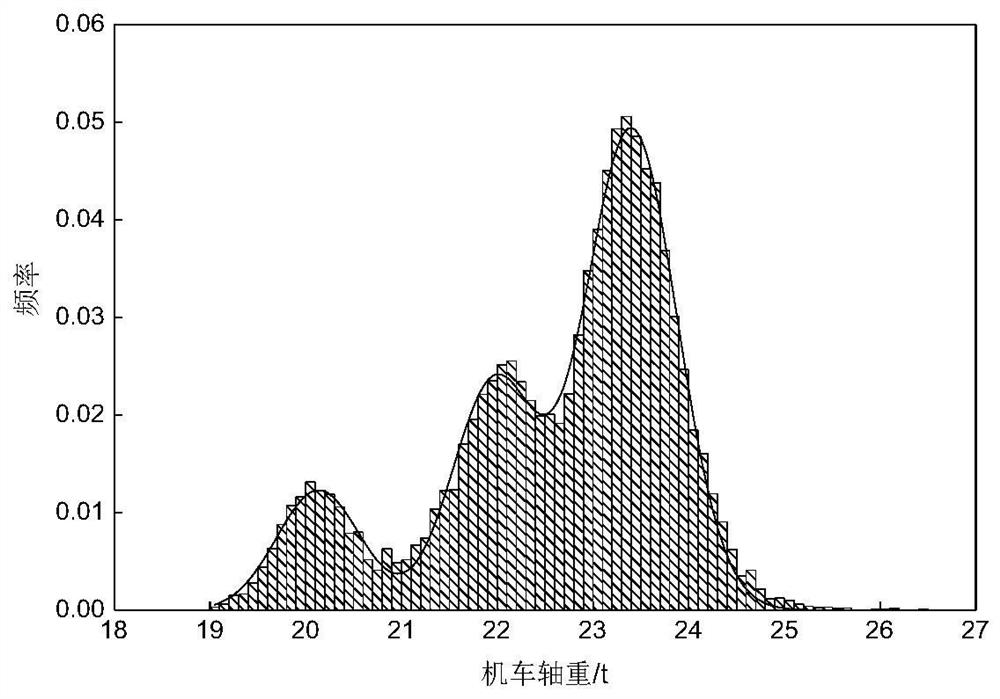

Steel bridge fatigue evaluation load modeling and fatigue evaluating method

ActiveCN107609317ASolve problems with fatigue assessment loadsGood fatigue assessmentSpecial data processing applicationsInfluence lineElement analysis

The invention discloses a steel bridge fatigue evaluation load modeling and fatigue evaluating method. The steel bridge fatigue evaluation load modeling and fatigue evaluating method comprises, step one, establishing a train load model; step two, processing and classifying measured data; step three, according to the measured data, establishing a probability model for parameters; step four, establishing a train load probability model; step five, generating a random load spectrum through a Monte-Carlo method; step six, through finite element analysis, acquiring stress influence lines of steel bridge fatigue details; step seven, performing influence line loading through the random load spectrum to obtain a stress history; step eight, analyzing the stress history to evaluate steel bridge fatigue. The steel bridge fatigue evaluation load modeling and fatigue evaluating method has the advantages of, through the fatigue evaluation load model which is established on the basis of the measured data for describing the load status of currently-running trains, achieving fatigue evaluation of any component of a steel bridge, establishing a complete train load modeling method, improving the utilization value of the measured data and ensuring more accurate and more practical steel bridge fatigue evaluation.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

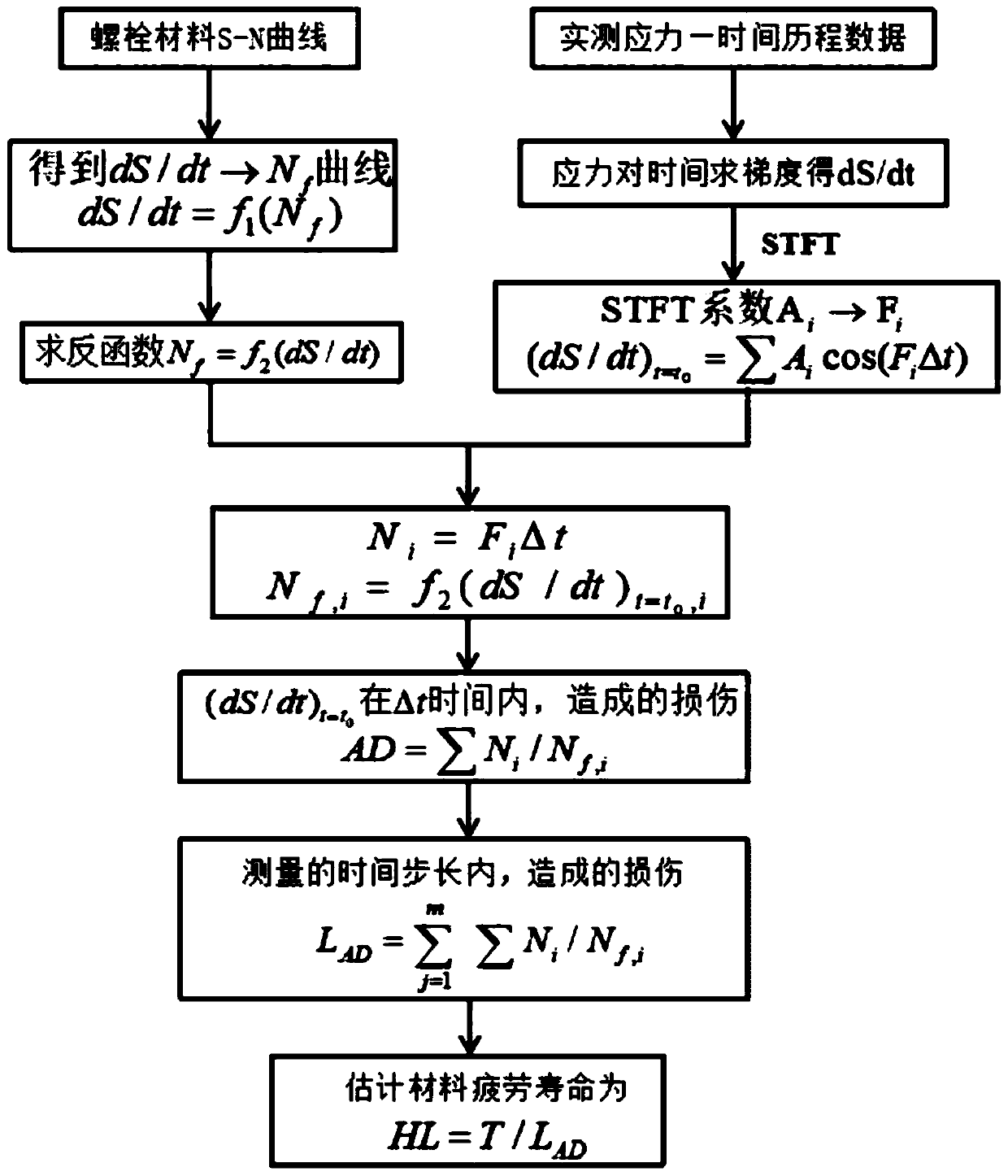

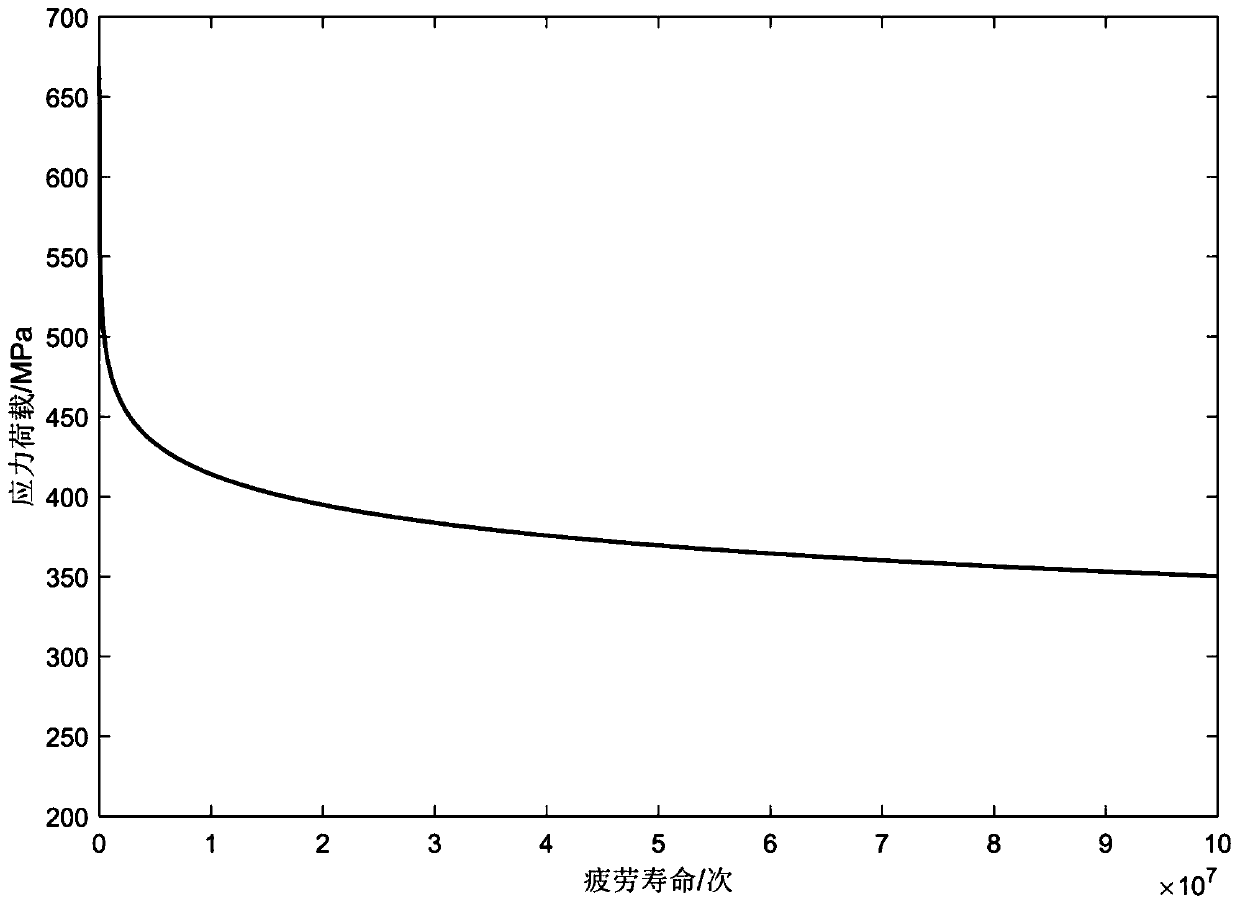

Water turbine top cover bolt fatigue prediction method

PendingCN110569614AHigh limitPredict fatigue lifeSpecial data processing applicationsTime domainDensity curve

The invention discloses a water turbine top cover bolt fatigue prediction method, which comprises the following steps: in a time domain range, solving the gradient of a stress load to a time history for acquired stress load-time history data to obtain the power density of a stress amplitude; performing power density conversion on the S-N curve of the top cover bolt material to obtain an S-N powerdensity curve of the bolt material; in the frequency domain range, performing short-time Fourier transform on the power density of the stress amplitude of the acquired data to obtain a curve that thestress amplitude changes along with the frequency at a certain moment; in combination with a bolt material S-N power density curve, performing fatigue life prediction on the top cover bolt by applyinga linear fatigue accumulation method. According to the method, fatigue life methods of a time domain and a frequency domain are fused, the process that the loading frequency of the stress load generates tiny cracks on the bolt is accurately represented, and meanwhile, the magnitude of the loading frequency represents the limit degree of high-cycle circulation. According to the prediction method,the damage degree of the bolt can be accurately judged, and the fatigue life of the top cover bolt is predicted.

Owner:国能大渡河瀑布沟发电有限公司

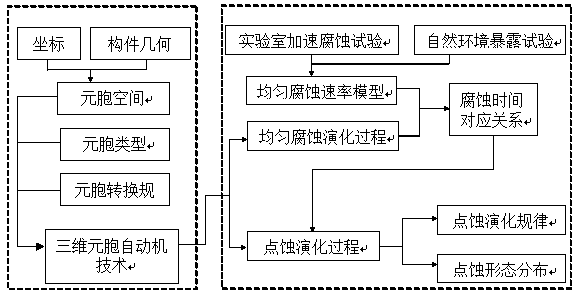

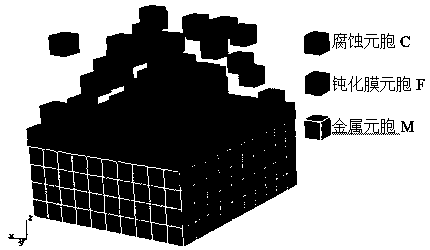

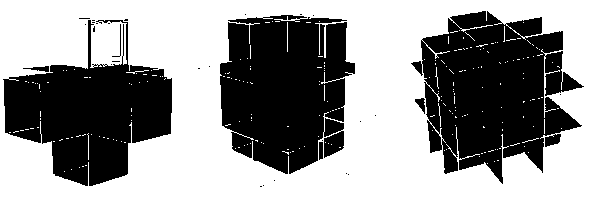

Metal corrosion form simulation method based on three-dimensional cellular automaton technology

PendingCN108959698APredicting Corrosion Fatigue LifePredict fatigue lifeWeather/light/corrosion resistanceDesign optimisation/simulationDiffusionCellular automation

The invention discloses a metal corrosion form simulation method based on a three-dimensional cellular automaton technology. The method comprises the following steps that: S1: establishing a three-dimensional cellular space, and determining a boundary condition; S2: determining a cellular type, and determining a cellular attribute on each case in the cellular space; S3: through a corrosion particle diffusion rule, a metal surface passivation film breakage rule and chemical reaction which happens in a corrosion process, determining a cellular conversion rule; S4: simulating the evolution process of even corrosion and corrosive pitting of the same construction member under the same environment; S5: comparing an even corrosion rate model obtained by an experiment with a simulated evolution process of even corrosion to obtain a corresponding relationship between corrosion duration and a step size; and S6: processing a cellular automaton simulation result of the corrosive pitting, and simulating the evolution rule and the form distribution of the corrosive pitting. The method can be used for simulating the real corrosion evolution process of a metal construction member under the specific external environment, and a foundation is provided for subsequent anti-corrosion researches.

Owner:SOUTHEAST UNIV

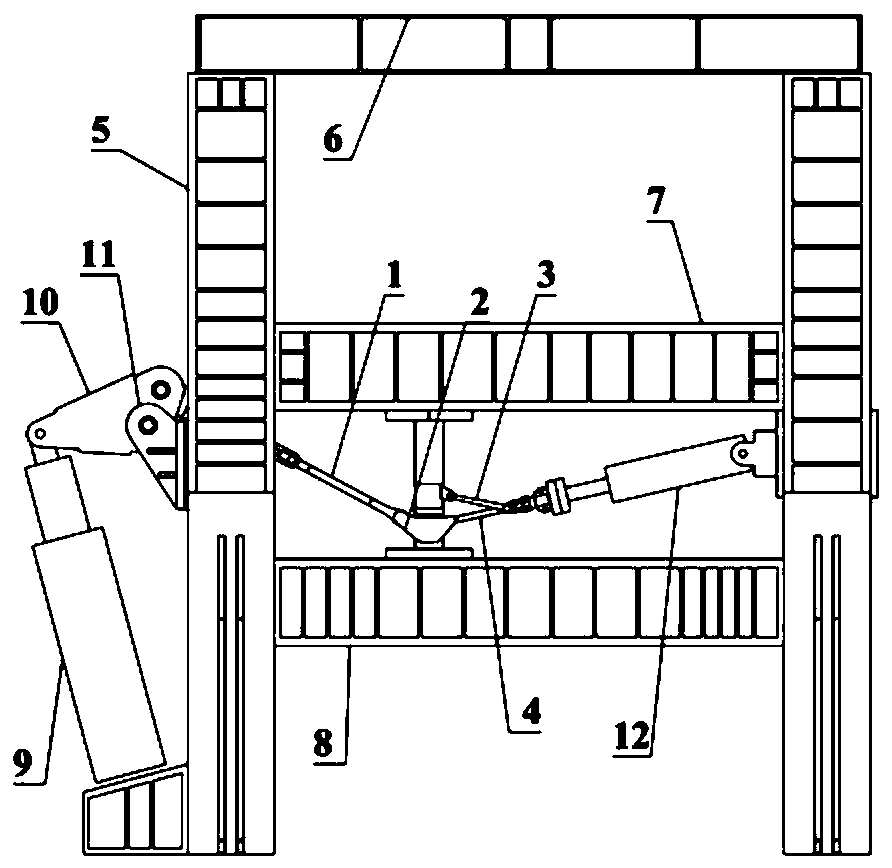

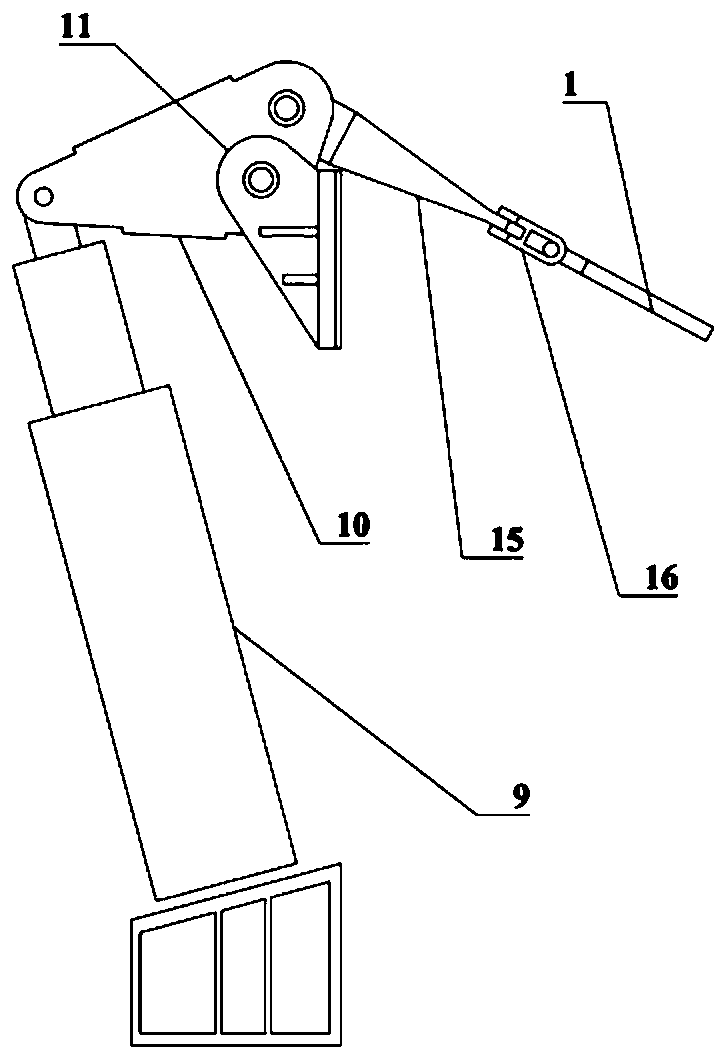

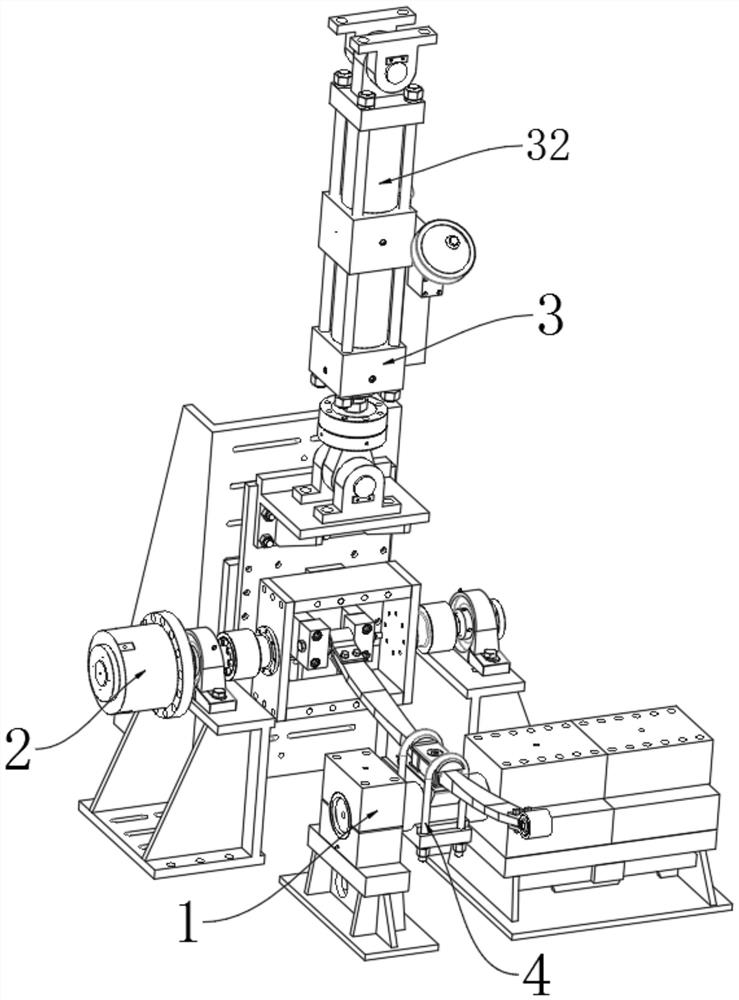

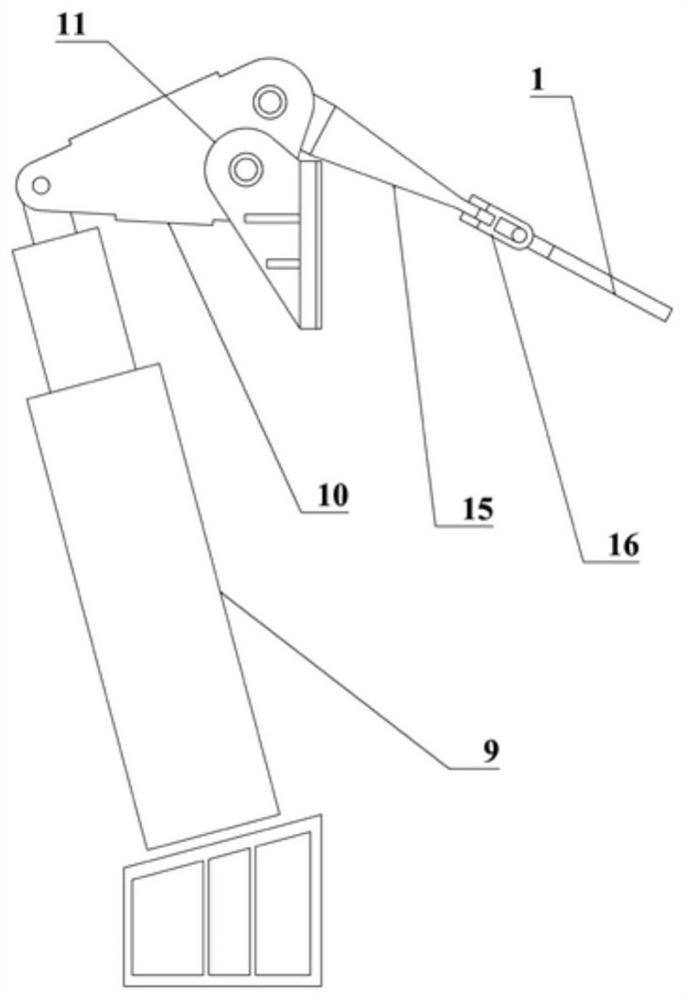

Undercarriage ejection main force transmission structure fatigue test device and test method thereof

ActiveCN111099036APredict fatigue lifeEvenly loadedMachine part testingAircraft components testingStructural fatigueClassical mechanics

The invention provides an undercarriage ejection process main force transmission structure fatigue test device and test method. The device comprises an ejection rod, a rotating sleeve, an upper torsion arm, a lower torsion arm, an ejection load loading mechanism, a traction load loading mechanism and a main force transmission device fixing mechanism. The test method mainly comprises steps of (1) mounting and fixing a test piece, (2) mounting and fixing an ejection loading device mechanism, (3) installing and fixing the traction loading device mechanism, (4) performing cyclic loading test, and(5) testing the residual strength under the working condition of the maximum catapulting force. The device is advantaged in that the fatigue life of a main force transmission structure is measured, ahydraulic actuating cylinder is adopted for loading, so the load is stable, and continuity is good; arrangement and installation of the test device can accurately simulate the real working condition of the main force transmission structure, construction and installation are simple, a test scale is reduced, and test cost is saved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

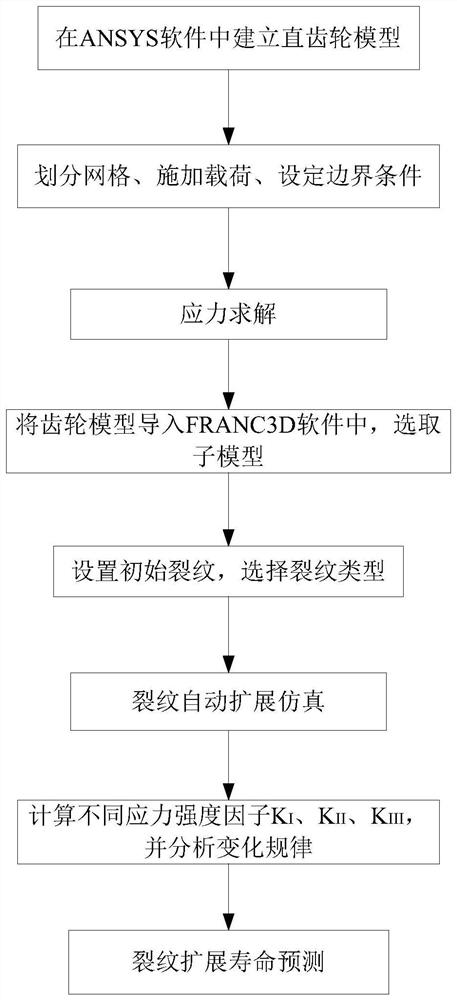

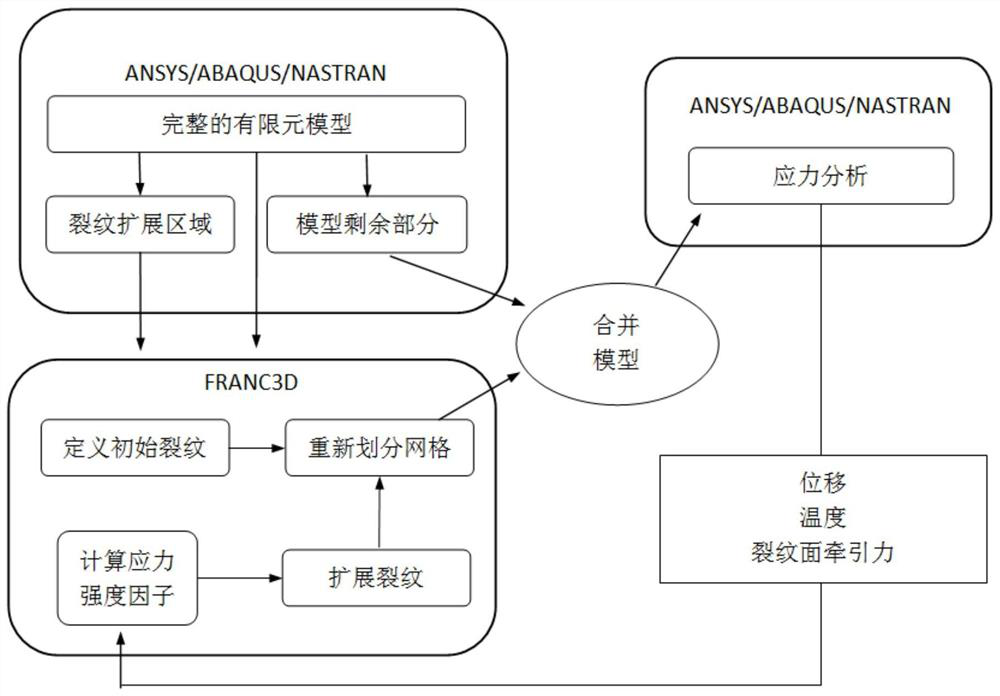

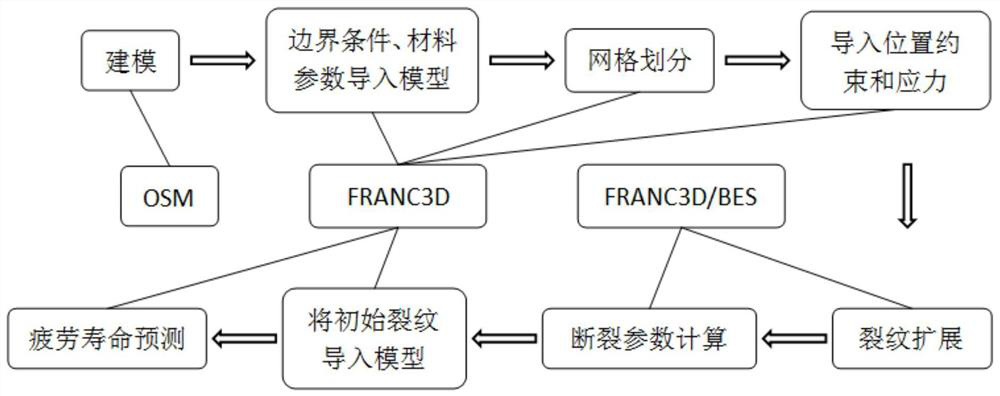

Spur gear tooth root crack propagation rule analysis method based on finite element simulation

PendingCN112182807APredict fatigue lifeAnalytical methods are accurate and reliableGeometric CADDesign optimisation/simulationAlgorithmStress intensity factor

The invention provides a spur gear tooth root crack propagation rule analysis method based on finite element simulation. The method comprises the following steps of firstly, establishing a gear simulation model by utilizing ANSYS, then completing load loading, mesh generation, boundary condition setting, stress solving and other work on the basis of the model, importing the model into FRANC3D to obtain data such as an expansion path and direction of a gear tooth root crack, stress intensity factor change in a crack expansion process, crack life prediction and the like, and finally, analyzing afinite element simulation result to obtain a spur gear tooth root crack propagation rule. According to the method, the propagation rule of the spur gear tooth root cracks is researched based on a numerical simulation method, the crack propagation situation is tracked, the distribution rule of crack tip stress intensity factors and a fatigue life prediction curve are obtained, the calculation precision is high, the experiment speed is higher, the efficiency is higher, and convenience is brought to the depth research of gear tooth root crack propagation.

Owner:NORTHEASTERN UNIV

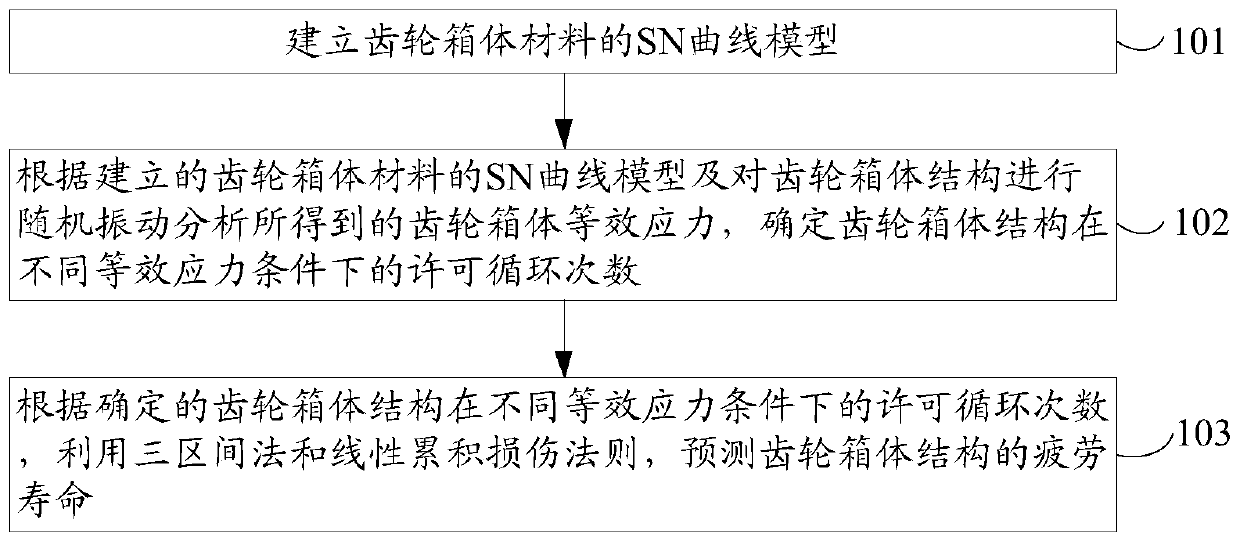

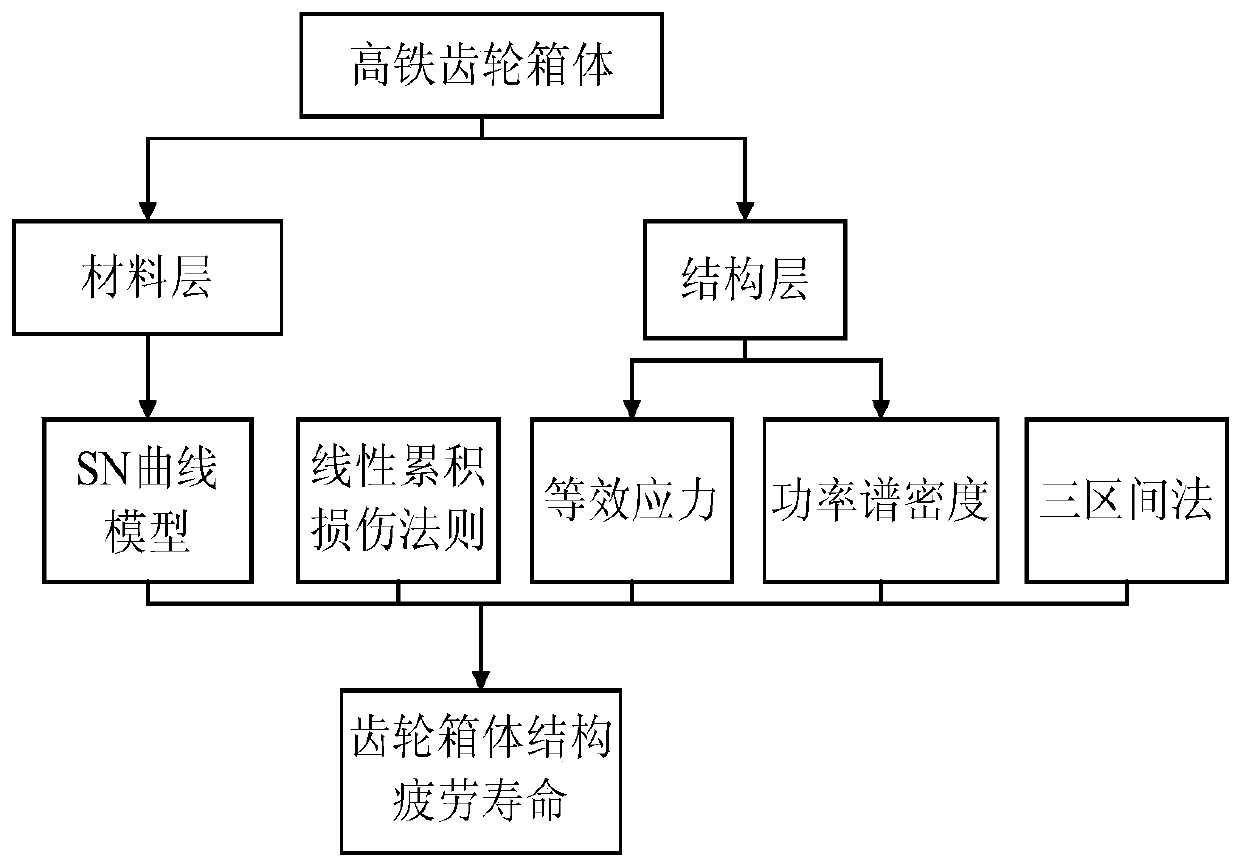

Prediction method and device for service life of high-speed railway gearbox casing structure

InactiveCN110243594APredict fatigue lifeAchieve Life PredictionMachine part testingEngineeringUltimate tensile strength

The invention provides a prediction method and device for service life of a high-speed railway gearbox casing structure, which can be used for predicting the service life of the high-speed railway gearbox casing structure. The method comprises the following steps of establishing an SN curve model of a gearbox casing material; determining the permission cycle times of the gearbox casing structure under different equivalent stress conditions according to the established SN curve model of the gearbox casing material and gearbox casing equivalent stress obtained by performing random vibration analysis on the gearbox casing structure; and predicting the fatigue life of the gearbox casing structure according to the determined permission cycle times of the gearbox casing structure under different equivalent stress conditions by using a three-section method and a linear accumulative damage rule. The prediction method and device in the invention relate to the field of fatigue strength.

Owner:UNIV OF SCI & TECH BEIJING

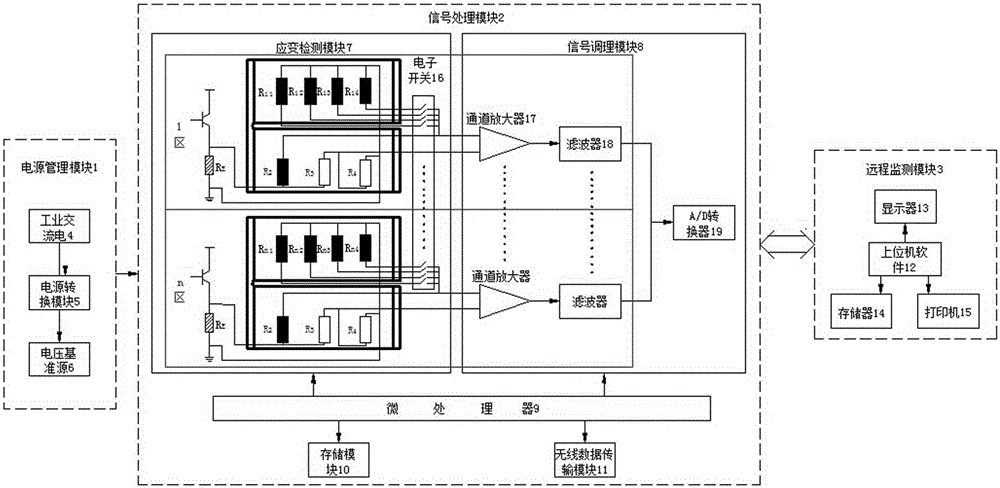

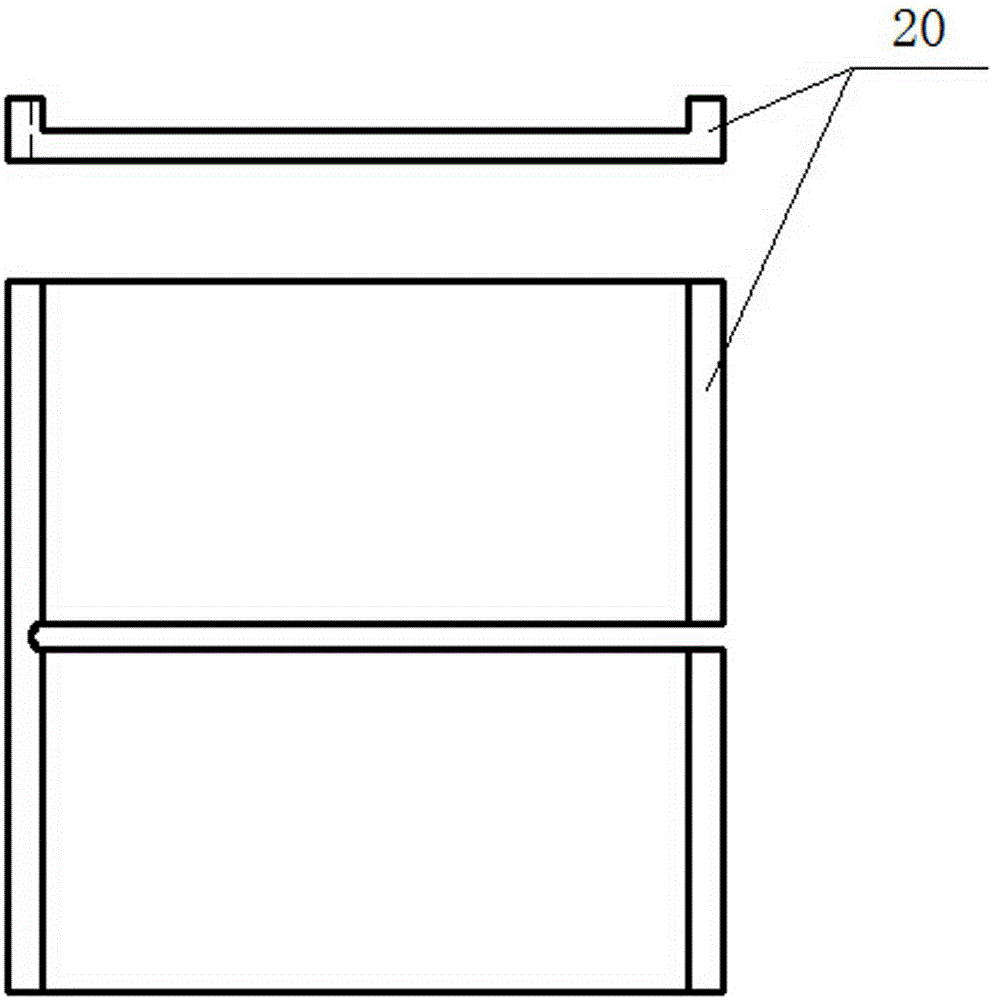

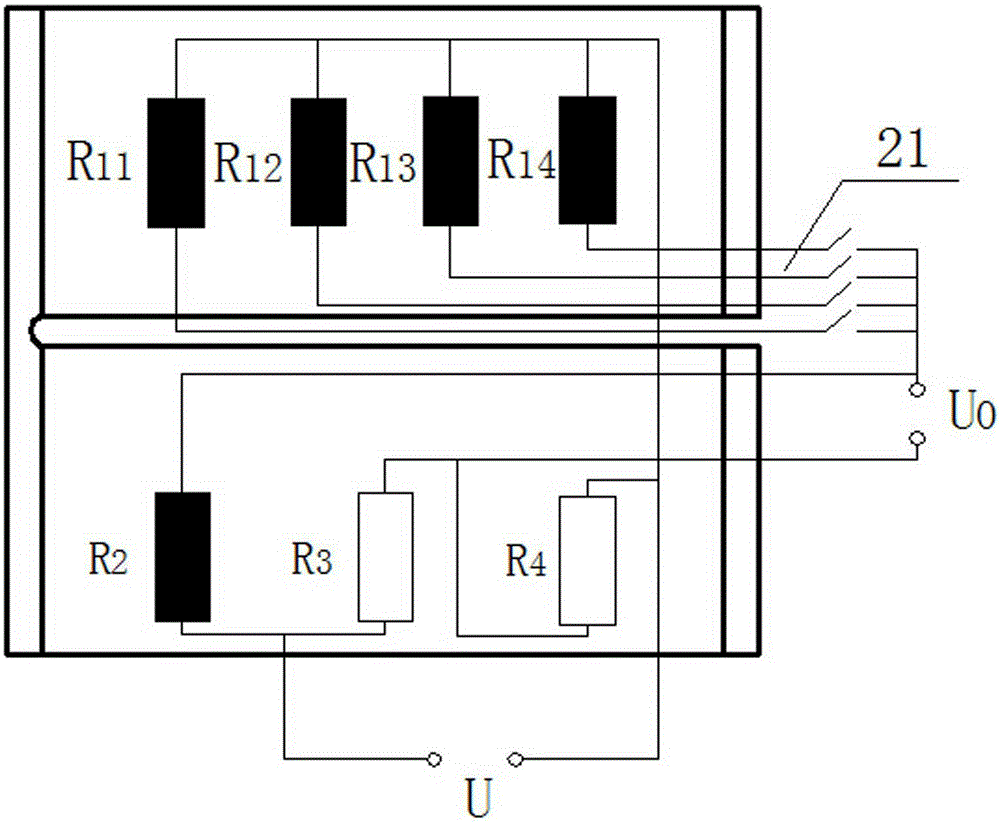

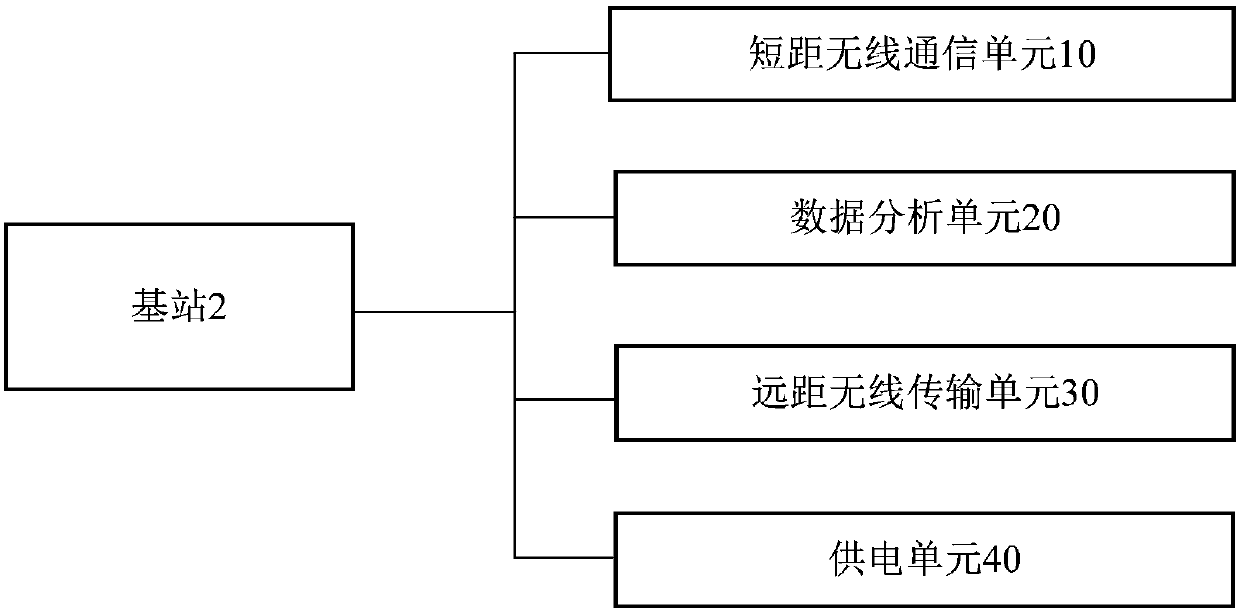

Cubic press health monitoring method and system

ActiveCN105241370AAccurate acquisitionEasy accessElectrical/magnetic solid deformation measurementElectronic switchWireless data transmission

The invention proposes a cubic press health monitoring method and system. The monitoring system comprises a power management module, a signal processing module and a remote control monitoring module which are serially connected. The signal processing module comprises a strain detection module, a signal conditioning module, a microprocessor, a storage module and a wireless data transmission module; the strain detection module comprises a strain collection sheet, a bridge-type compensation circuit, and an electronic switch; the signal conditioning module comprises a passage amplifier, a filter and an A / D converter; The remote control monitoring module is arranged in a remote monitoring room and acquires the test data through the wireless data transmission module. The aim of online health monitoring of cubic presses is achieved based on an electrical strain measuring method and modern wireless transmission technology. The cubic press health monitoring system can accurately acquire weak strain signal data, has the functions of online monitoring and real-time display and recording of equipment usage status, and can predicate the fatigue life of equipment in actual work conditions, thereby preventing great and malignant accidents and reducing losses.

Owner:GUILIN UNIV OF ELECTRONIC TECH

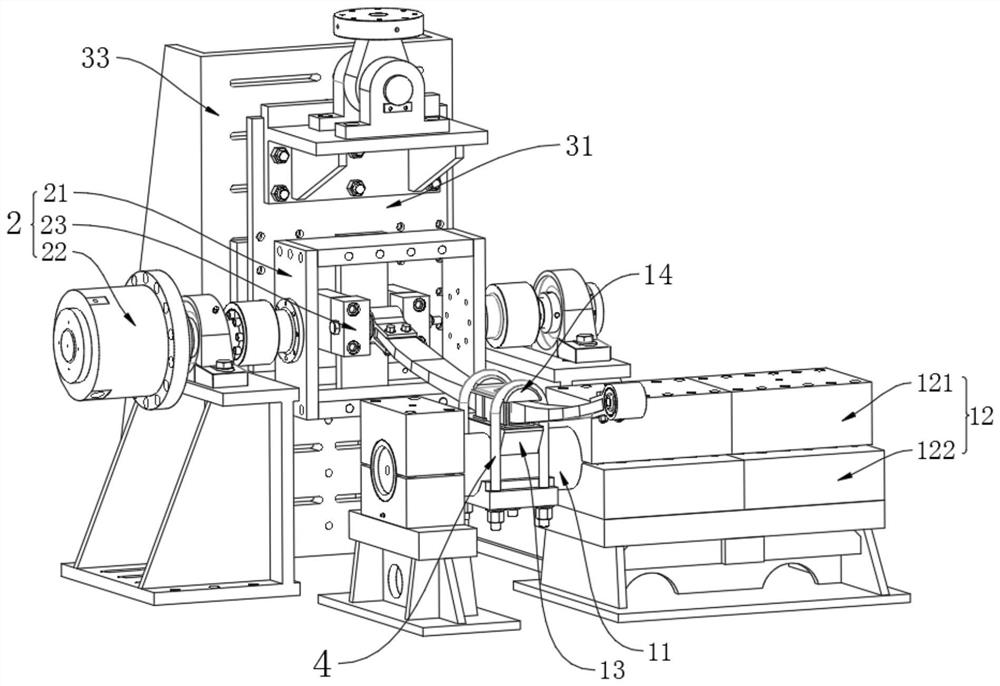

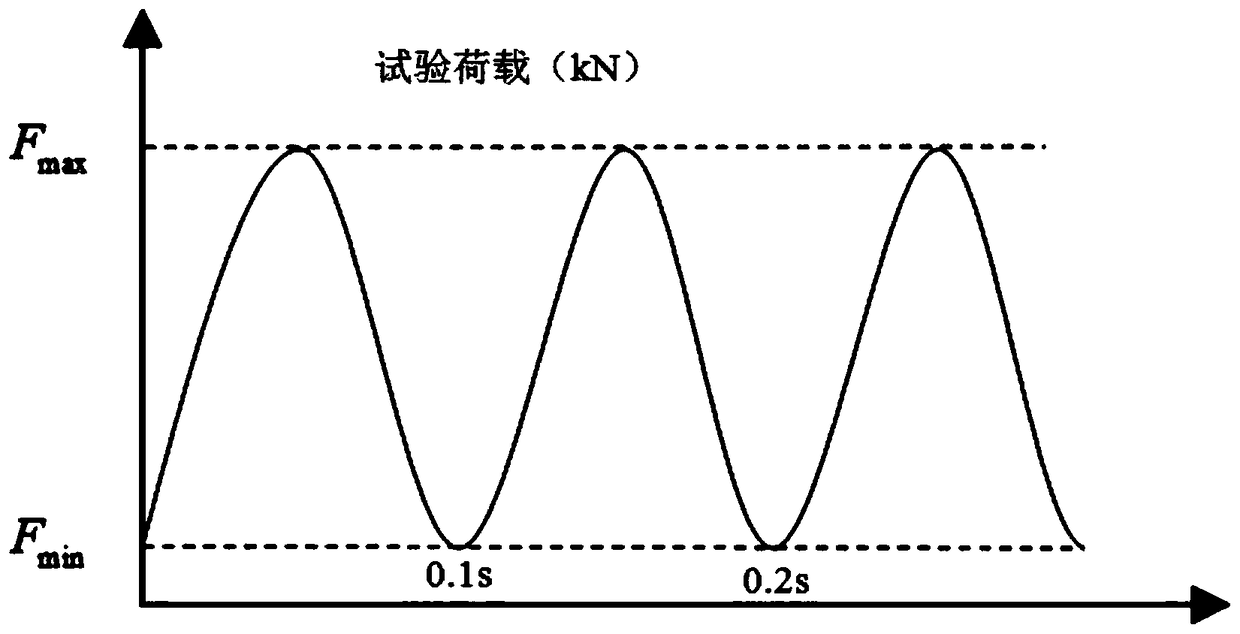

Composite material plate spring double-channel rack device and test method

PendingCN114046947ASimulate complex force situationsPredict fatigue lifeMachine part testingElasticity measurementEngineeringVertical force

The invention relates to a composite material plate spring double-channel rack device and a test method. The device at least comprises a plate spring fixing device, wherein the plate spring fixing device is used for fixing the middle part of a plate spring; a torsion assembly hinged to one end of the plate spring and used for applying torsion force to the plate spring; and a vertical loading assembly which is fixedly connected with the torsion assembly and is used for applying vertical force to the torsion assembly and transmitting the vertical force to the plate spring. During use, the vertical loading assembly and the torsion assembly apply acting force to the plate spring in a sine wave coordinated loading mode, the loading frequency of the vertical loading assembly and the torsion assembly is 2: 1, and the phase difference is 0. According to the rack device provided by the invention, the torsion assembly provides a torsion force for the plate spring, the vertical loading assembly provides a vertical force for the plate spring through the torsion assembly, and the torsion assembly and the vertical loading assembly form a composite force, so that the complex stress condition of the composite material plate spring in a road can be well simulated, and the fatigue life can be effectively predicted.

Owner:东风汽车底盘系统有限公司

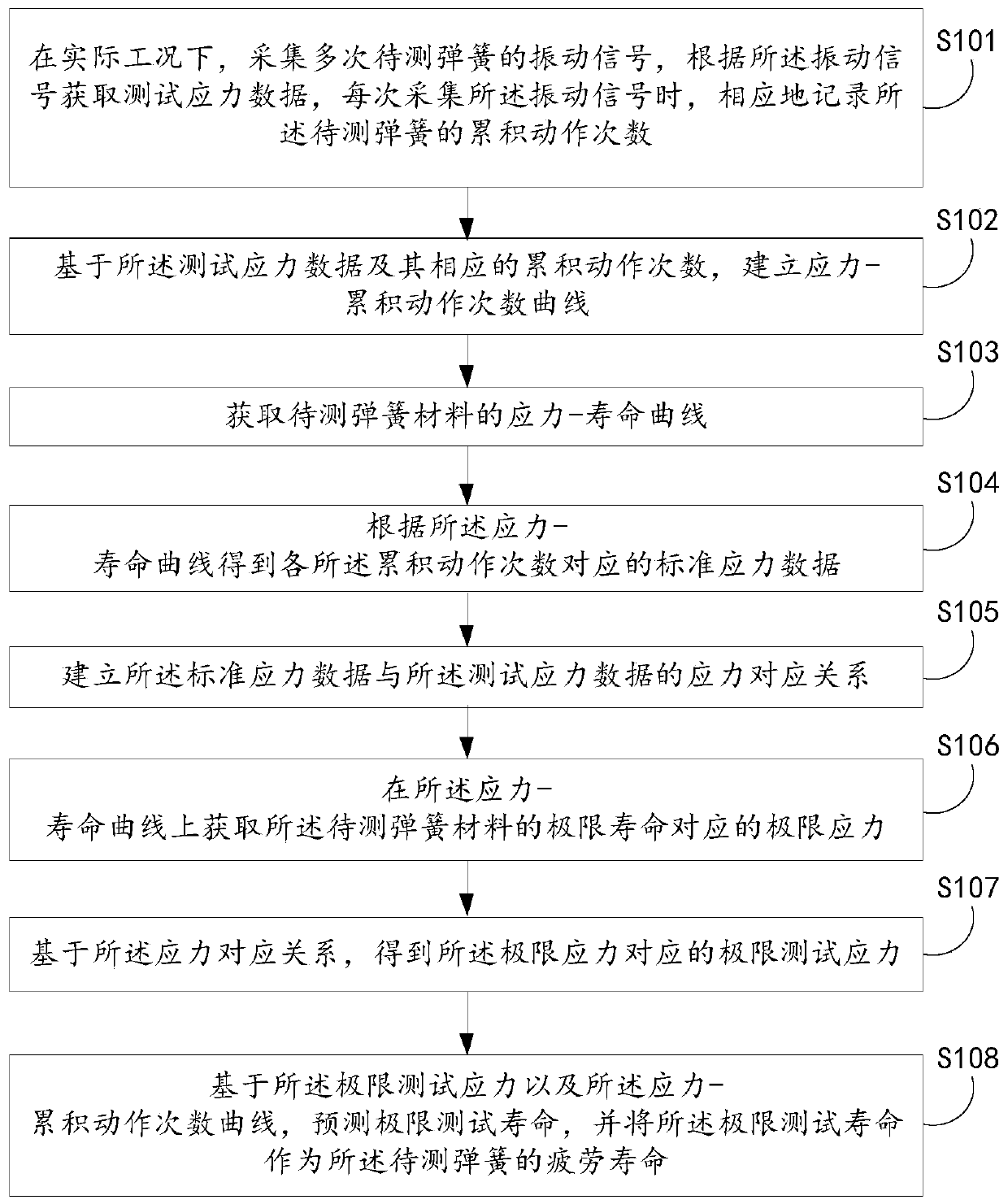

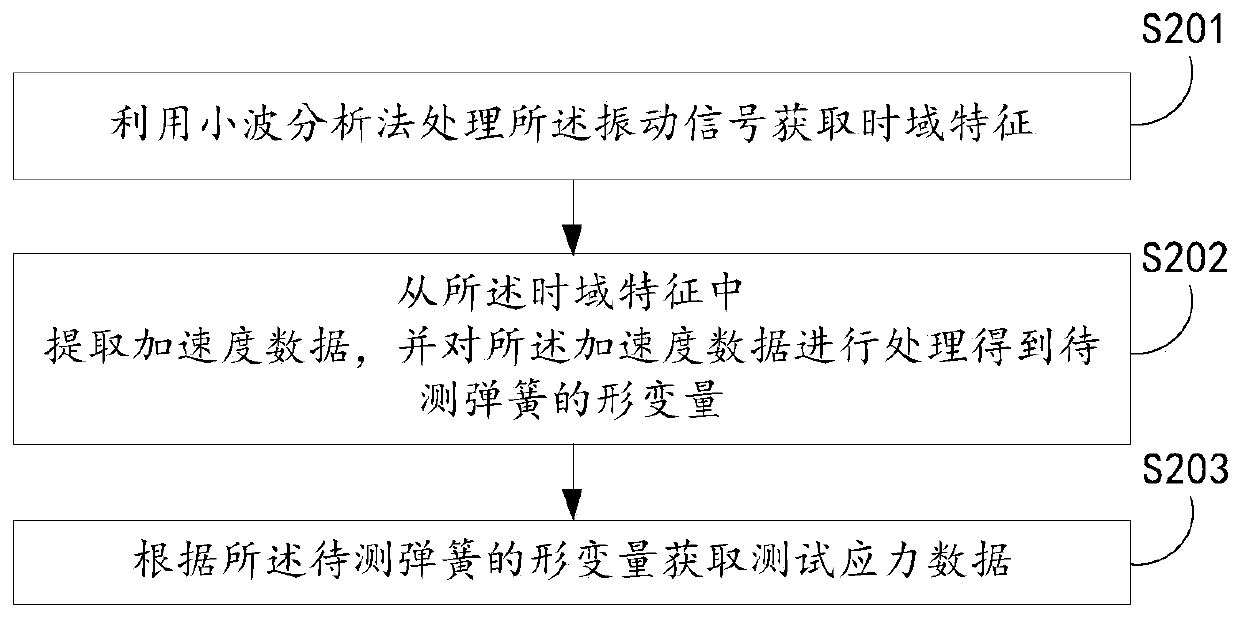

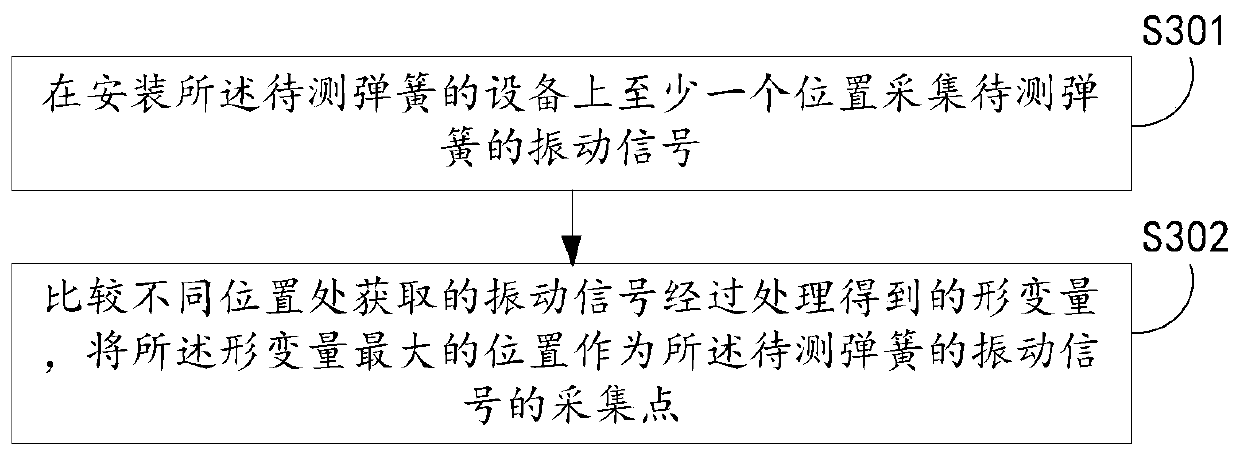

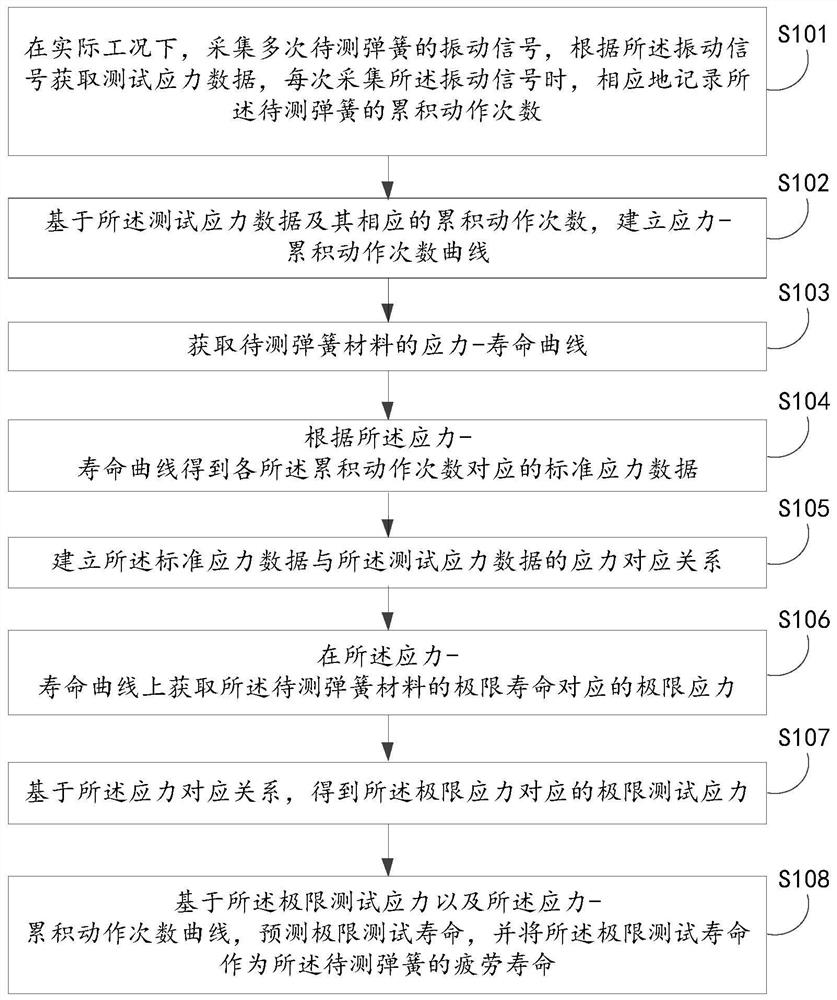

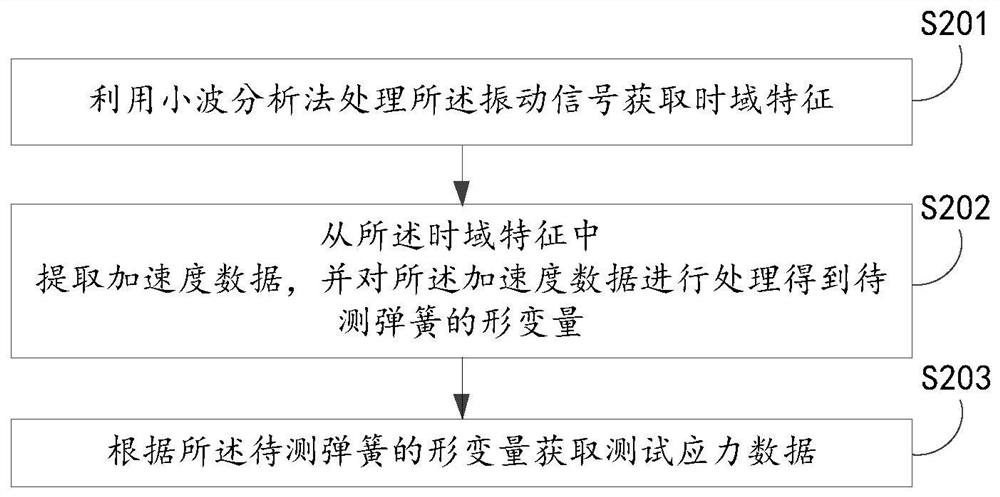

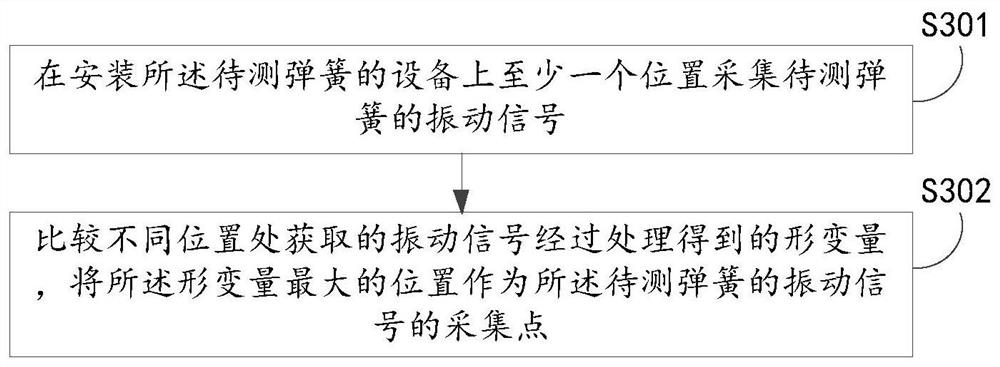

Analysis method of spring fatigue life

ActiveCN110726542APredict fatigue lifeGet informed of potential safety hazards in a timely mannerMachine part testingStructural engineeringAnalysis method

The embodiment of the invention discloses an analysis method of a spring fatigue life. The analysis method comprises the steps that a stress-cumulative action number curve is established; a stress-life curve of a to-be-tested spring material is obtained; stand stress data corresponding to all cumulative action numbers are obtained according to the stress-life curve; the stress corresponding relationship between standard stress data and tested stress data is established; limit stress corresponding to the limit life of the to-be-tested spring material is obtained on the stress-life curve; basedon the stress corresponding relationship, limit testing stress corresponding to the limit stress is obtained; and based on the limit testing stress and the stress-cumulative action number curve, the limit testing life is predicted and serves as the fatigue life of a to-be-tested spring. According to the technical scheme, the fatigue life of a spring piece in the actual using environment can be truly reflected, thus engineering personnel can know potential safety hazards in time, and equipment damage is avoided.

Owner:SHANDONG TAIKAI HIGH VOLTAGE SWITCH

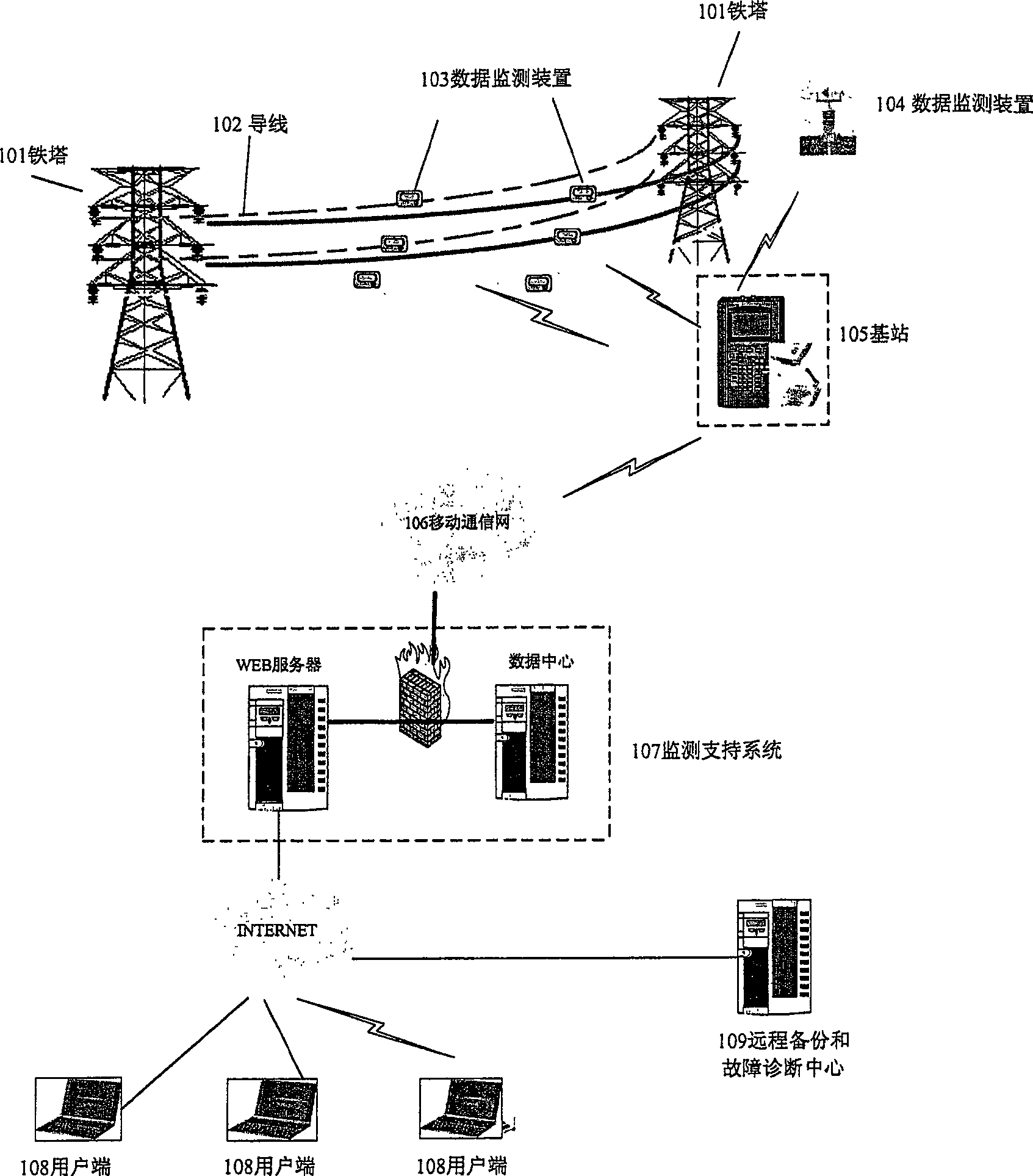

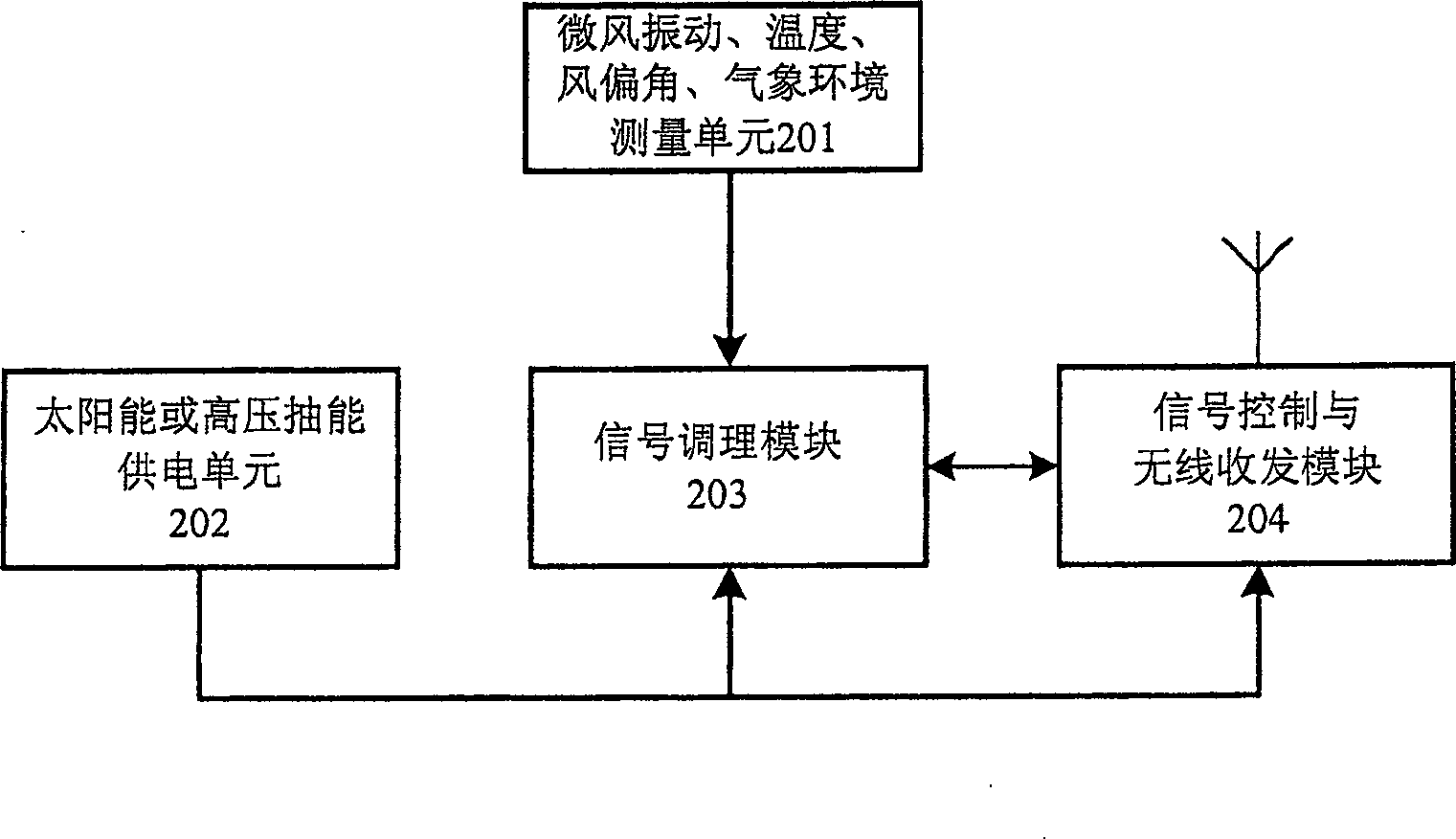

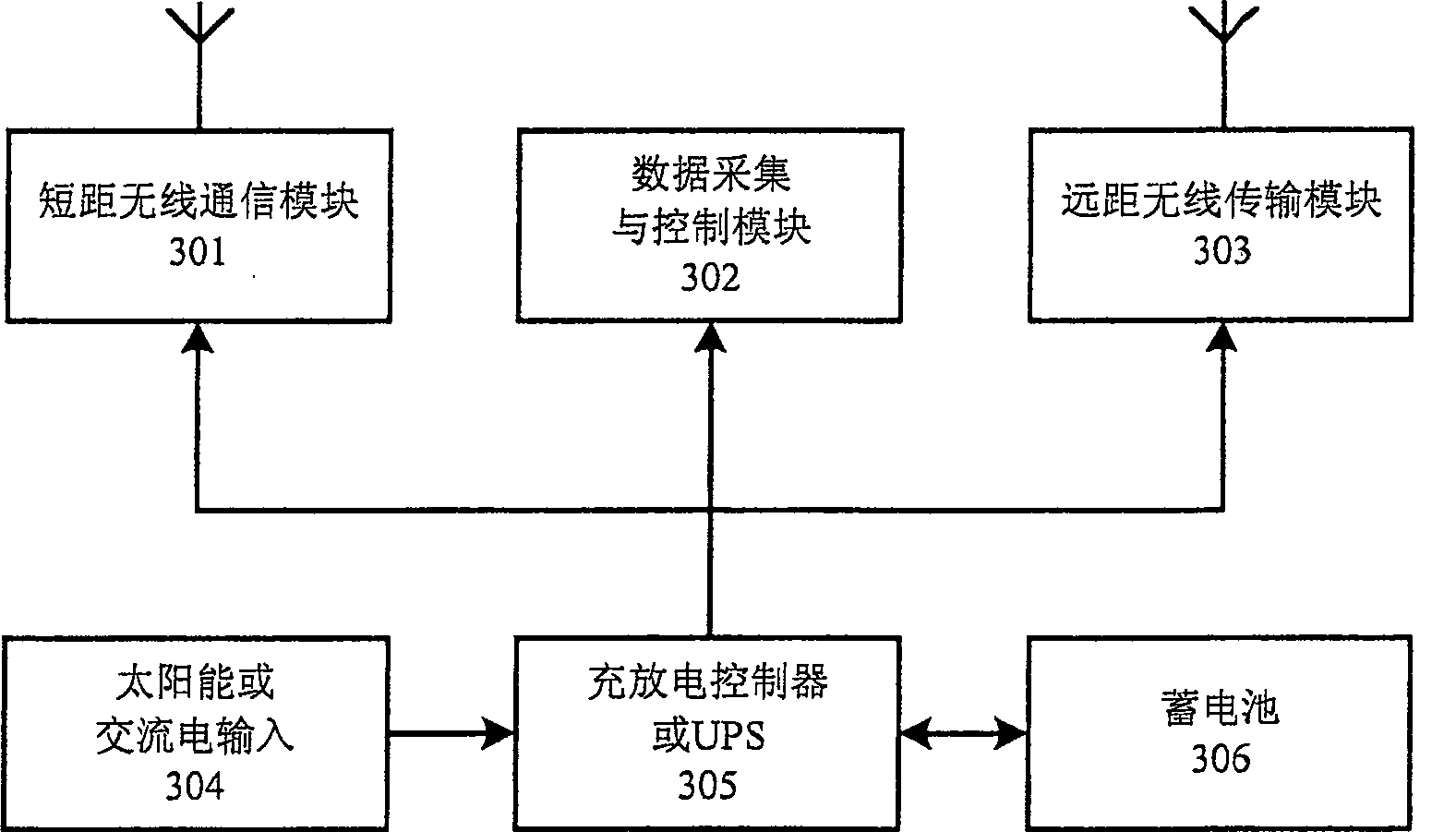

System and method for detecting online of built on stilts power transmission sequence

ActiveCN100538759CImprove securityImprove reliabilityTransmission systemsElectrical testingShortest distanceElectric power system

This invention relates to one rack electricity sending circuit online monitor system and method, which process online test on rack circuit micro wind vibration and wire temperature and bias wind and comprises data monitor device, base station and monitor supportive system, wherein, the data monitor device is in rack send circuit sent to base station through short distance sensor network broadcasting; base station receives the data to send to monitor supportive system center station through mobile communication network; the center station receives the network sending information to fulfill tasks of circuit micro wind vibration and wire temperature testing.

Owner:CHINA ELECTRIC POWER RES INST

A Multiaxial High Cycle Fatigue Failure Prediction Method for Metallic Materials Including the Effect of Mean Stress

ActiveCN104699976BPredict fatigue lifeAccurate predictionSpecial data processing applicationsStrength propertiesFatigue loadingShear stress

The invention discloses a prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect; the prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect comprises the following steps: using the uniaxial fatigue and the pure torsional fatigue as the boundary conditions for calculating the biggest damage surface born by the material during the fatigue loading process and taking the biggest damage surface as the boundary surface, selecting the positive stress and the shearing stress on the boundary surface as the damage parameter, using the mean stress effect parameter obtained by the uniaxial fatigue for correnting the stress on the boundary surface, and establishing the metal material multiaxial high cycle fatigue failure prediction model including axial direction mean stress and shearing stress influence; the prediction method of metal material multiaxial high cycle fatigue failure including mean stress effect is also applied to the situation without axial mean stress and shearing mean stress. The fatigue service life, the fatigue crack initiation and the initial extension direction of the material under multiaxial high cycle fatigue loading situation can be precisely forecasted while the axial mean stress and shearing mean stress are present.

Owner:XIANGSHAN WEIHUI MAGNET

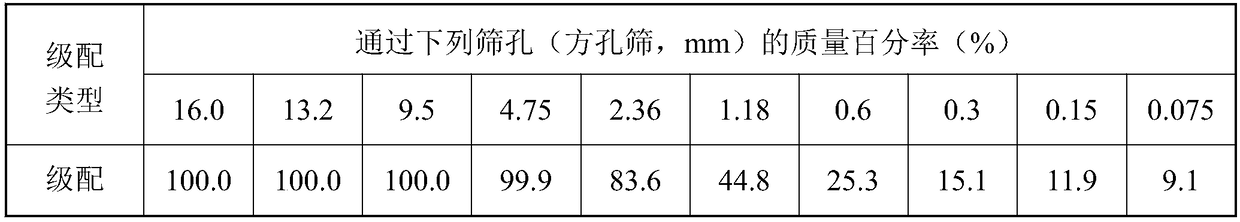

Dynamic modulus test method for asphalt mixture under bell wave loading mode

InactiveCN106706429APredict fatigue lifeDynamic modulus real testMaterial strength using tensile/compressive forcesWave loadingEngineering

The invention discloses a dynamic modulus test method for an asphalt mixture under a bell wave loading mode. The dynamic modulus test method comprises the following steps: applying a bell wave load to a cylindrical asphalt mixture test piece with the diameter of 10 cm and the height of 150 cm, applying a load sensor and a displacement sensor to respectively obtain time-varying data of a force value applied to the test piece and time-varying data of axial deformation of the test piece, and obtaining dynamic modulus values of the asphalt mixture under the bell wave loading mode under conditions of sample frequencies of 25 Hz, 10 Hz, 5 Hz, 1 Hz, 0.5 Hz and 0.1 Hz at each of temperatures of -10 DEG C, 4 DEG C, 21 DEG C, 37 DEG C and 54 DEG C through a data treatment mode in AASHTOTP62-07. All results are from test results, and the dynamic modulus values, obtained by test, of the asphalt mixture are real and reliable.

Owner:WUHAN UNIV OF TECH

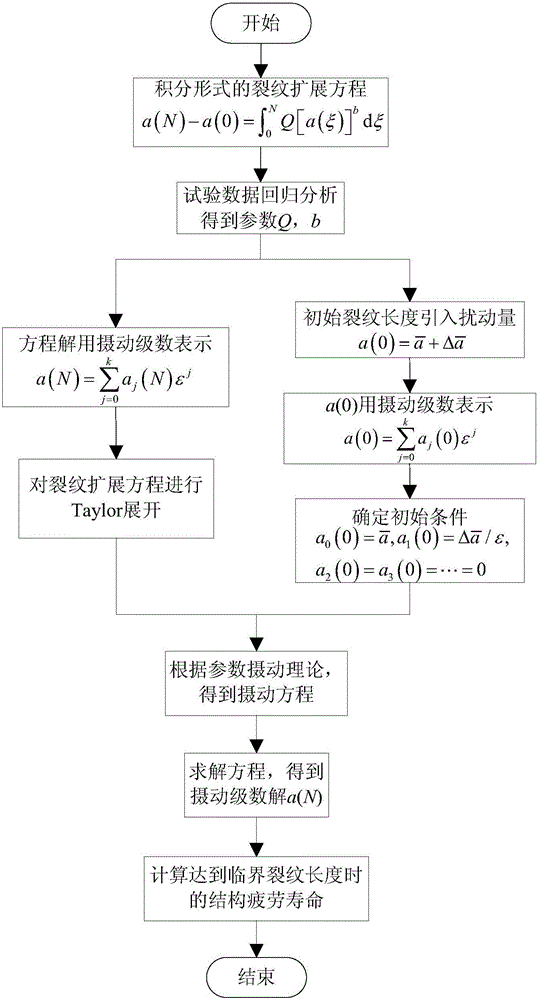

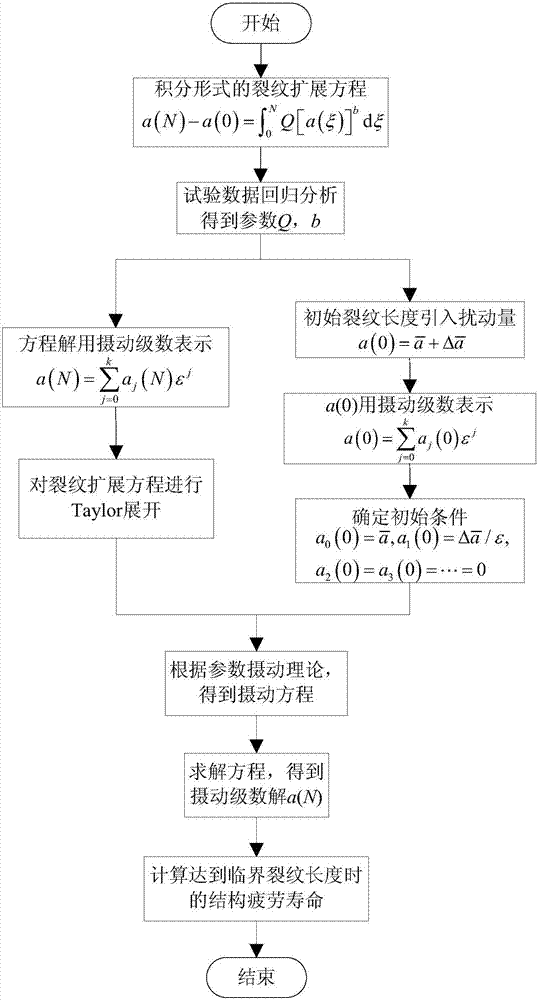

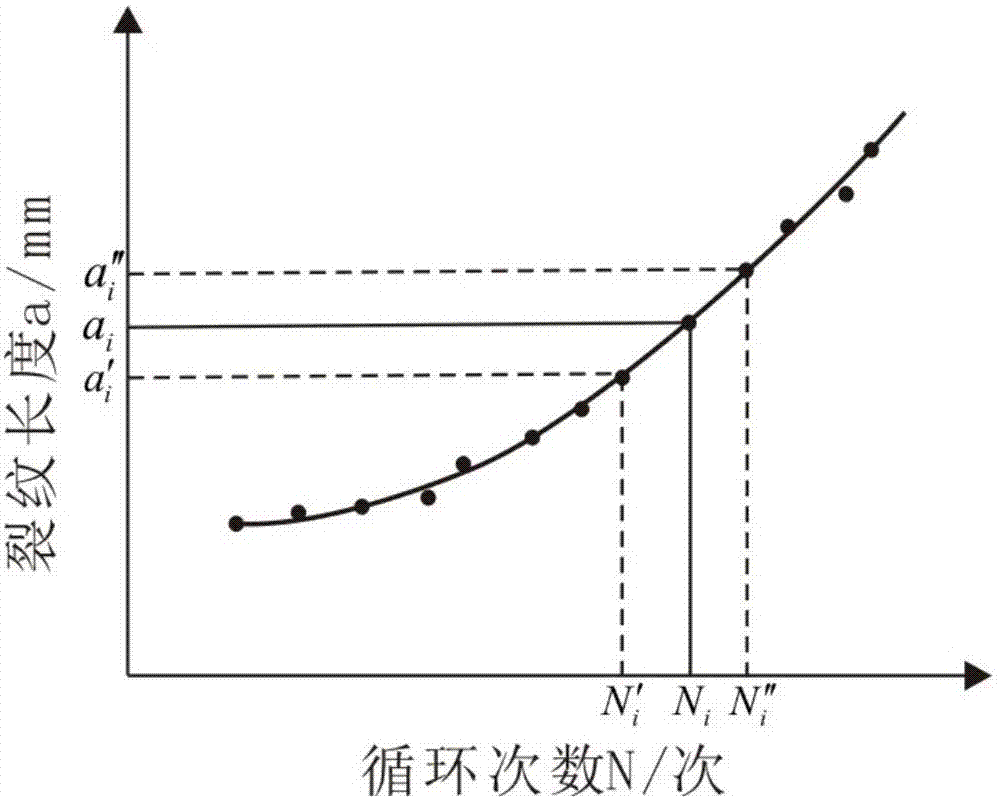

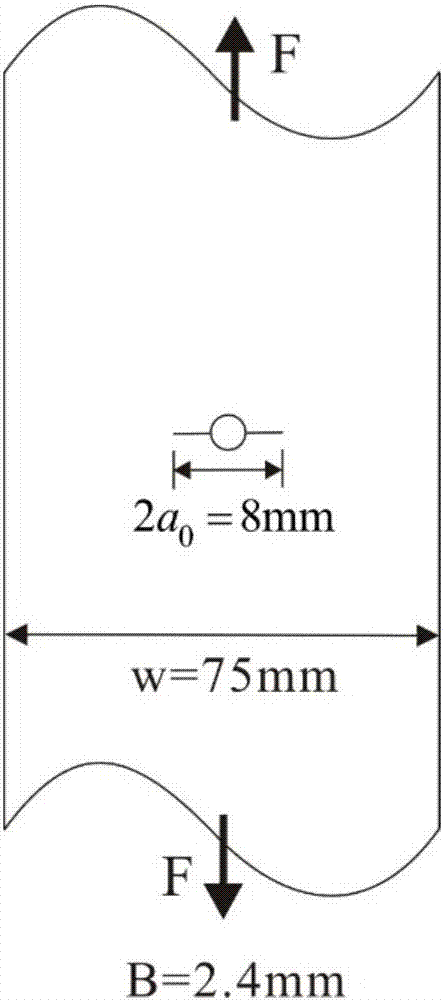

Metal structure fatigue crack expansion life prediction method based on Taylor perturbation series method

InactiveCN106055741APredict fatigue lifeRapid Analysis of Structural ResponseGeometric CADSpecial data processing applicationsObservational errorStructural fatigue

The invention discloses a metal structure fatigue crack expansion life prediction method based on Taylor perturbation series method, and the method comprises the steps of first describing fatigue crack expansion process of the metal structure by employing Paris formula; conducting integration to the Paris formula to obtain an integration-formed crack expansion equation; and conducting Taylor expansion to the crack expansion equation. Then considering apparatus measuring error and structure manufacturing error to make an initial crack length contain a small disturbance; expressing the solution of the crack expansion equation and the initial crack length in perturbation grades by introducing a small parameter Epsilon; determining the perturbation grades according to an nominal value of the initial crack length and the disturbance so as to get the value of each coefficient at an initial time; obtaining a crack expansion perturbation equation in combination with the Taylor expansion of the crack expansion equation based on parameter perturbation theory; then solving the perturbation equation to obtain a fatigue crack expansion length perturbation grades solution; calculating load cycle times when a critical crack length is reached; and taking the load cycle times as a predicted value of the metal structure fatigue crack expansion life.

Owner:BEIHANG UNIV

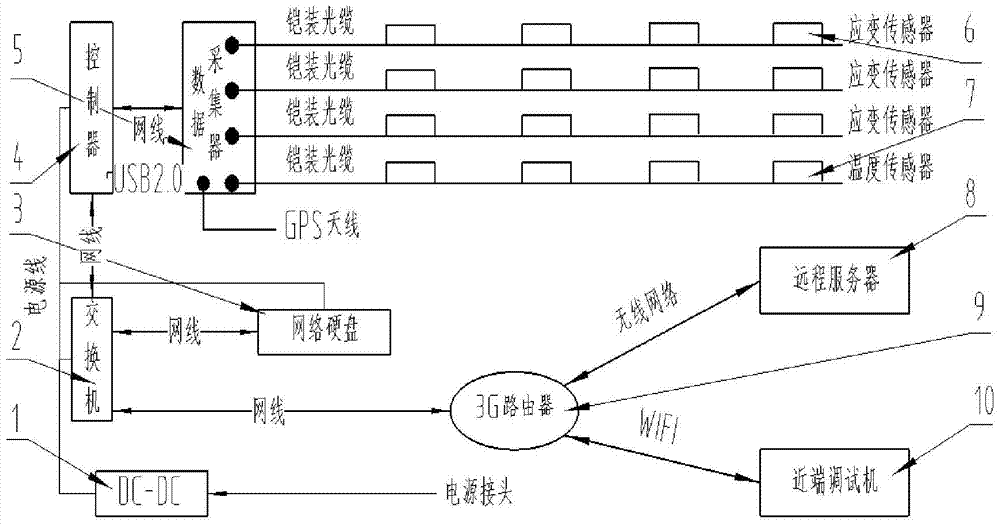

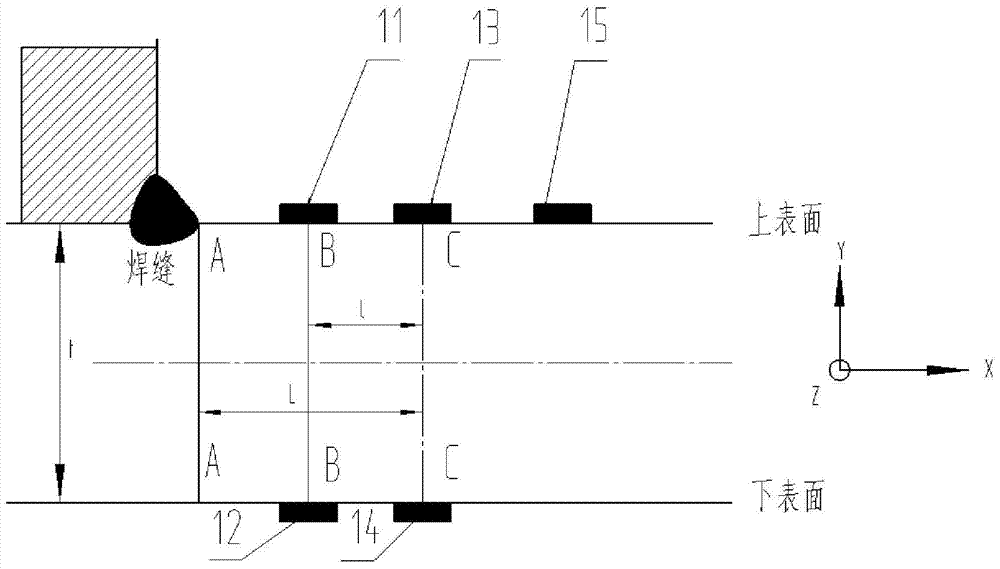

A high-speed train car body stress test device and its working method

ActiveCN105043443BAvoid the disadvantages of poor anti-electromagnetic interference abilityAccurately obtainedForce measurement by measuring optical property variationFiberGrating

The invention discloses a vehicle body stress testing device for a high speed train and a work method thereof. The test apparatus comprises a strain sensor, a temperature sensor, a controller, a data collector, a switch, a remote server and a near-end debugging machine, wherein the strain sensor and the temperature sensor are connected with the data collector through an armored optical cable, and the data collector and the controller are connected through a net cable for instruction and data transmission. A fiber grating sensor measures stress, and fiber can effectively overcomes the defects of poor anti-electromagnetic interference capability in a conventional electric test method. Accurate stress signal can be obtained under complex electromagnetic environment of a high-speed rail, and subsequent data processing s more convenient. For each channel of a data collector, a plurality of fiber grating sensors of a same type can be serially connected through one fiber wire, the wiring difficult is lowered, and the space of train equipment cabin can be saved. The vehicle body stress testing device and the working method thereof can be used for researching vehicle body stress gradually changing trend under different line conditions.

Owner:CHINA RAILWAYS CORPORATION

An Analysis Method of Spring Fatigue Life

ActiveCN110726542BPredict fatigue lifeGet informed of potential safety hazards in a timely mannerMachine part testingStructural engineeringReliability engineering

The embodiment of the present disclosure discloses a method for analyzing the fatigue life of a spring. The method includes: establishing a stress-cumulative action number curve; obtaining a stress-life curve of the spring material to be tested; and obtaining each of the cumulative actions according to the stress-life curve Standard stress data corresponding to the number of times; establish the stress correspondence relationship between the standard stress data and the test stress data; obtain the ultimate stress corresponding to the ultimate life of the spring material to be tested on the stress-life curve; based on the stress correspondence, obtain the limit The limit test stress corresponding to the stress; based on the limit test stress and the stress-cumulative action times curve, predict the limit test life, and use the limit test life as the fatigue life of the spring to be tested. The technical solution can truly reflect the fatigue life of the spring in the actual use environment, so that the engineering personnel can learn the potential safety hazards in time and avoid equipment damage.

Owner:SHANDONG TAIKAI HIGH VOLTAGE SWITCH

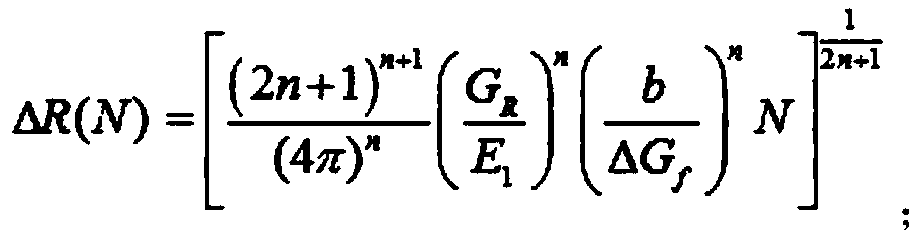

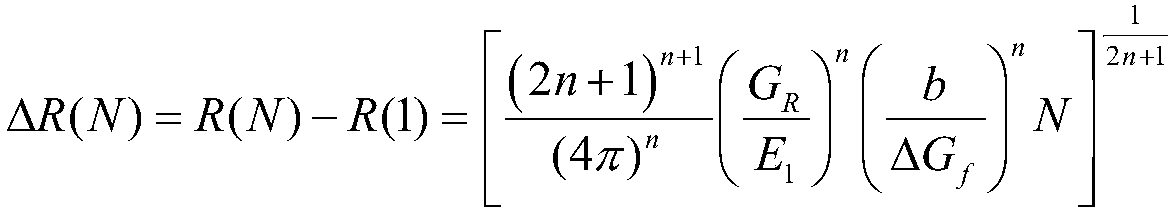

A Method for Evaluating the Fatigue Performance of Asphalt Mortar

ActiveCN106644786BPredict fatigue lifeEliminate time effectsMaterial strength using repeated/pulsating forcesFree energiesAsphalt mastic

The invention discloses a method for evaluating the asphalt mastic fatigue performance. The asphalt cement and aggregates are formed and are made into asphalt mastic test pieces; the asphalt mastic fatigue performance is evaluated through the crack expansion index delta R(N) in the given load circulation times N of the asphalt mastic test pieces. The method provided by the invention is combined with an asphalt and aggregate surface free energy test and dynamic mechanical analysis experiment method; the area defined by a stress-pseudo strain curve is used for expressing the energy dissipation after the damage of the fatigue test pieces; in addition, the time effect can be eliminated; the asphalt mastic fatigue performance is evaluated; the fatigue service life of the asphalt mastic and asphalt mixture is predicted. Compared with other fatigue tests, the test method provided by the invention has the advantages that the test investment is low; the test period is short; the practical stress state of the pavement can be represented under the dynamic load.

Owner:南京宁通智能交通技术研究院有限公司

Fatigue test device and test method for main force transmission structure of landing gear ejection

ActiveCN111099036BPredict fatigue lifeEvenly loadedMachine part testingAircraft components testingResidual strengthStructural fatigue

The invention provides a fatigue test device and test method for the main force transmission structure during the ejection process of the landing gear. The force device fixing mechanism; the test method mainly includes the following steps: (1) installation and fixing of the test piece; (2) installation and fixing of the ejection loading device mechanism; (3) installation and fixing of the restraining loading device mechanism; (4) cyclic loading test; (5) Residual strength test for the maximum ejection force condition. The invention measures the fatigue life of the main force transmission structure; adopts the hydraulic cylinder to load, the load is stable and the continuity is good; the layout and installation of the test device can accurately simulate the real working conditions of the main force transmission structure, and at the same time, the construction and installation are simple, reducing the The test scale saves test cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Apparatus and method for fatigue cracking test of steel bridge deck pavement

ActiveCN104897491BReliable test resultsReasonable and accurate simulationMaterial strength using repeated/pulsating forcesBridge deckSoftware engineering

The invention provides a testing apparatus for fatigue cracking of a pavement on a steel bridge. A test piece is installed on the testing apparatus. The testing apparatus is characterized by comprising a testing platform used for applying load and a testing model used for simulating stress of the test piece, wherein the testing model comprises a support base which is equipped with at least two columns, loading plates are arranged on the columns, and the loading plates are fixed with the test piece through clamps. The invention further provides a testing method for fatigue cracking of the pavement on the steel bridge. The method comprises the following steps: determining the size of the test piece according to the size of the testing platform and load limit; fixing the fabricated test piece and the loading plates together through the clamps; applying load on the testing model by using the testing platform; and predicating the technical state of a pavement layer through displacement observation, foil gauge observation and DIC digital image processing of the state of the test piece in the process of testing, and evaluating the cracking fatigue life of the pavement layer.

Owner:NANJING COMM INST OF TECH

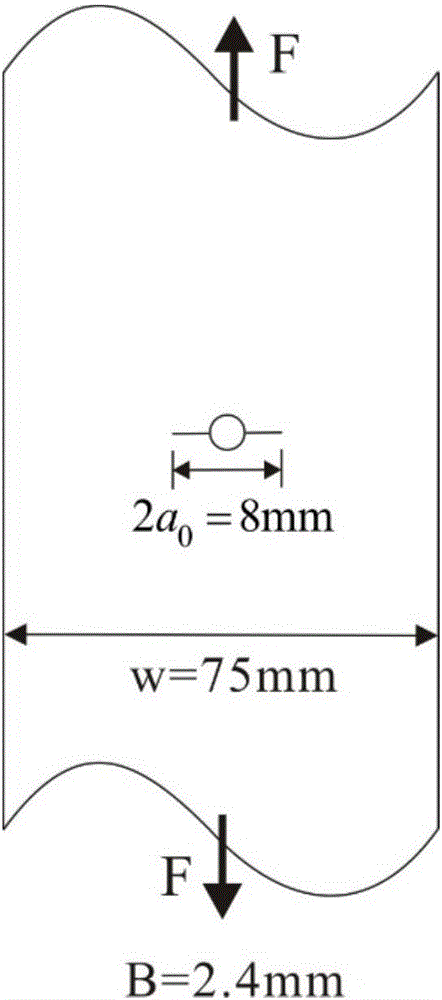

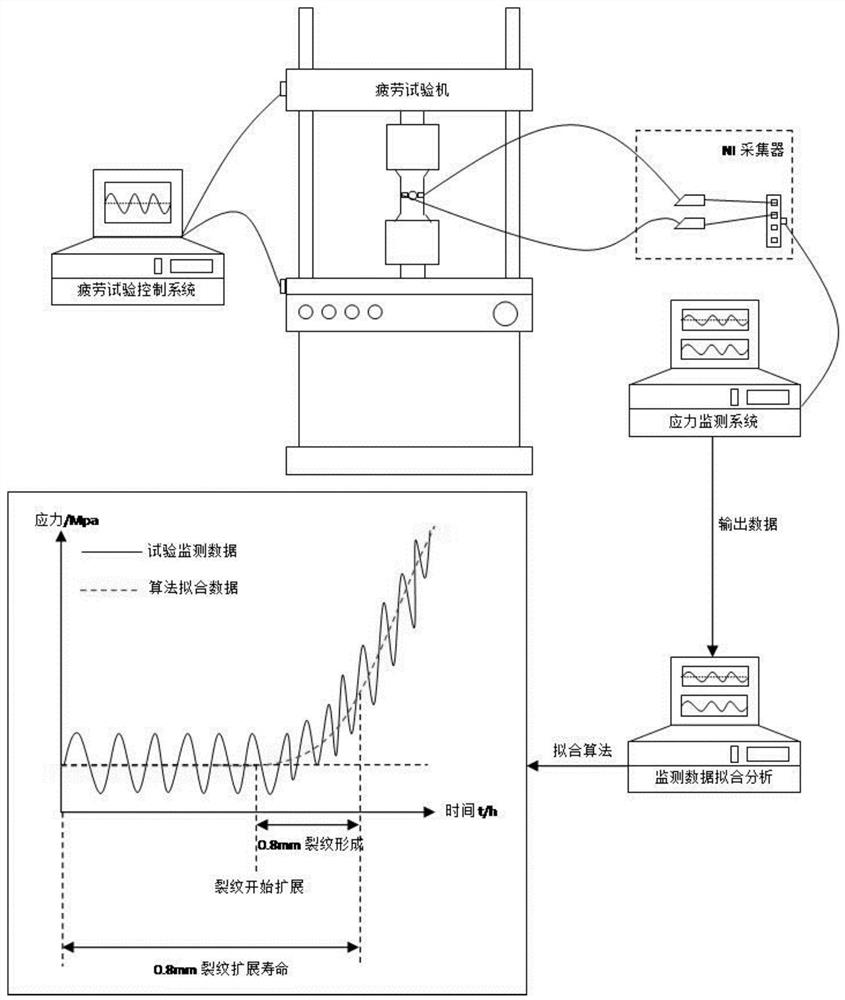

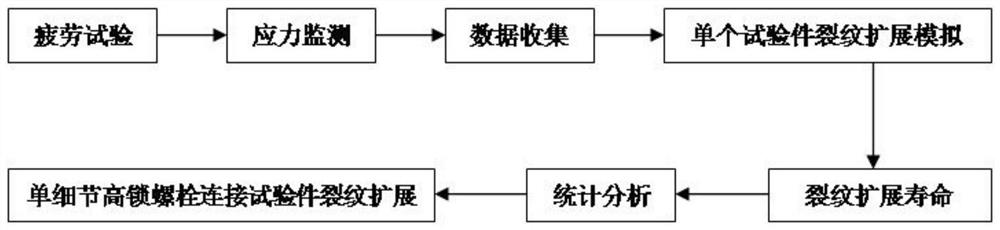

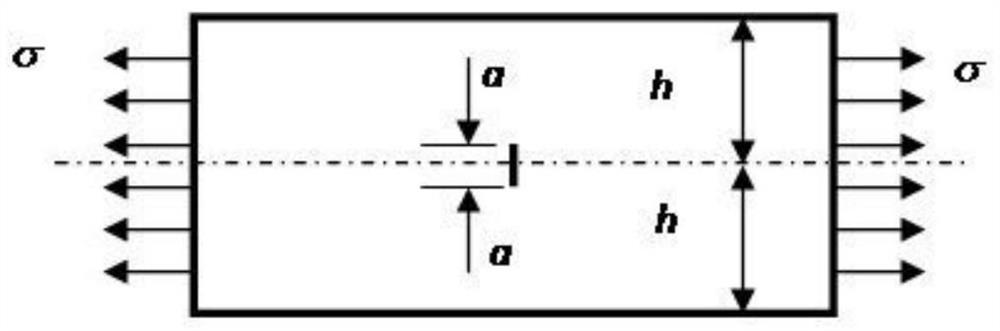

Life prediction method for fatigue crack growth of high-lock bolted joints based on stress monitoring

ActiveCN113340749BSimple structureEasy to operateDesign optimisation/simulationMaterial strength using repeated/pulsating forcesAcquisition apparatusControl system

This application belongs to the field of machinery, and in particular relates to a stress monitoring-based fatigue crack growth life prediction method for high-lock bolt connectors. The fatigue testing machine is set up through the fatigue test control system to apply a constant amplitude load to the standard test piece of high-lock bolts. Foil strain gauges are pasted on the edge of the hole of the standard test piece, and the stress change of the hole edge of the single-detail standard test piece is monitored in real time by the stress monitoring system. The test signal collected by the NI data collector is sent to the computer for real-time processing through the stress monitoring system, and the whole In the process of stress changing with time in the fatigue test, according to the law of stress changing with time at the hole edge of the single-detailed standard test piece, the crack growth life when the crack grows to 0.8mm is obtained by inferring the fitting curve. The application system has simple structure and convenient operation. Since it does not require a large amount of fracture analysis work, it does not have high requirements for sensors and acquisition equipment, thereby reducing labor costs and the cost of required test equipment.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

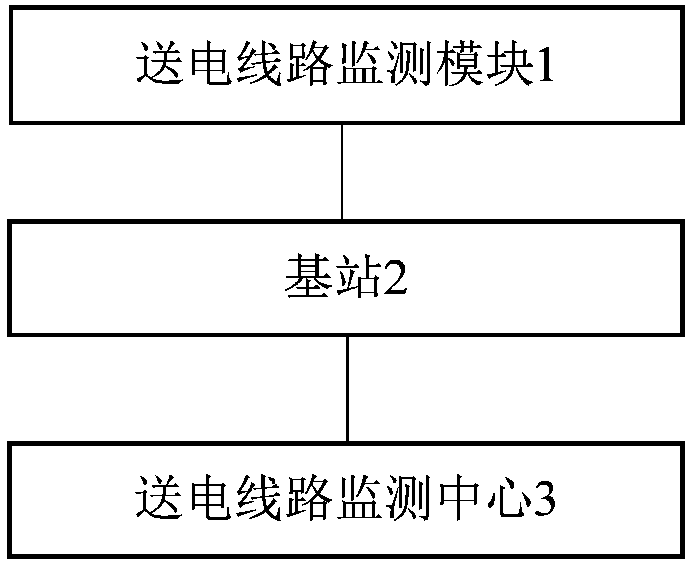

Overhead power transmission line on-line monitoring system

InactiveCN107612589AFacilitate condition maintenancePredict fatigue lifeTransmission systemsNetwork topologiesTransmission linePower transmission

The invention provides an overhead power transmission line on-line monitoring system, which comprises a power transmission line monitoring module, which is used for collecting overhead power transmission line indicator data from an overhead power transmission line and wirelessly outputting the collected overhead power transmission line indicator data, a base station, which is wirelessly connectedwith the power transmission line monitoring module and used for receiving and processing the overhead power transmission line indicator data output by the power transmission line monitoring module andwirelessly outputting the received and processed overhead power transmission line indicator data, and a power transmission line monitoring center, which is wirelessly connected with the base stationfor receiving and processing the overhead power transmission line indicator data output by the base station, and obtaining a monitoring result. The overhead power transmission line on-line monitoringsystem realizes intelligent monitoring of the overhead power transmission line by using the wireless sensor network technology.

Owner:韦彩霞

Fatigue life prediction method and device based on weighted average maximum shear stress plane

ActiveCN111624116BPredict fatigue lifePromote engineering applicationMachine part testingMaterial strength using steady shearing forcesFatigue damageFatigue Intensity

The invention provides a fatigue life prediction method and device based on the weighted average maximum shear stress plane, which relates to the field of multiaxial fatigue strength theory. The method includes: (1) passing the multiaxial variable amplitude load history through the von Mises equivalent stress formula The equivalent stress history is synthesized, and the von Mises equivalent stress history is counted by Wang‑Brown multiaxial cycle counting method; (2) The weighted average maximum shear stress plane is used as the high cycle multiaxial variable amplitude load. critical surface; (3) Calculate the fatigue damage parameters on the critical surface of each repetition obtained by counting; (4) use the Zhang-Shang model to calculate the fatigue damage; (5) use Miner’s linear accumulation rule to calculate the The damage is accumulated, and finally the fatigue life is calculated. The weighting function proposed in this method can take into account the main fatigue damage mechanisms under multiaxial loading. The life prediction results show that the life prediction method can better predict the fatigue life under multi-axis constant amplitude and variable amplitude loading.

Owner:TSINGHUA UNIV +1

A Load Modeling and Fatigue Evaluation Method for Steel Bridge Fatigue Evaluation

ActiveCN107609317BSolve problems with fatigue assessment loadsGood fatigue assessmentGeometric CADDesign optimisation/simulationInfluence lineElement analysis

The invention discloses a steel bridge fatigue evaluation load modeling and fatigue evaluating method. The steel bridge fatigue evaluation load modeling and fatigue evaluating method comprises, step one, establishing a train load model; step two, processing and classifying measured data; step three, according to the measured data, establishing a probability model for parameters; step four, establishing a train load probability model; step five, generating a random load spectrum through a Monte-Carlo method; step six, through finite element analysis, acquiring stress influence lines of steel bridge fatigue details; step seven, performing influence line loading through the random load spectrum to obtain a stress history; step eight, analyzing the stress history to evaluate steel bridge fatigue. The steel bridge fatigue evaluation load modeling and fatigue evaluating method has the advantages of, through the fatigue evaluation load model which is established on the basis of the measured data for describing the load status of currently-running trains, achieving fatigue evaluation of any component of a steel bridge, establishing a complete train load modeling method, improving the utilization value of the measured data and ensuring more accurate and more practical steel bridge fatigue evaluation.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

A Life Prediction Method for Fatigue Crack Growth of Metal Structures Based on Taylor's Perturbation Series Method

InactiveCN106055741BPredict fatigue lifeRapid Analysis of Structural ResponseGeometric CADSpecial data processing applicationsObservational errorStructural fatigue

The invention discloses a metal structure fatigue crack expansion life prediction method based on Taylor perturbation series method, and the method comprises the steps of first describing fatigue crack expansion process of the metal structure by employing Paris formula; conducting integration to the Paris formula to obtain an integration-formed crack expansion equation; and conducting Taylor expansion to the crack expansion equation. Then considering apparatus measuring error and structure manufacturing error to make an initial crack length contain a small disturbance; expressing the solution of the crack expansion equation and the initial crack length in perturbation grades by introducing a small parameter Epsilon; determining the perturbation grades according to an nominal value of the initial crack length and the disturbance so as to get the value of each coefficient at an initial time; obtaining a crack expansion perturbation equation in combination with the Taylor expansion of the crack expansion equation based on parameter perturbation theory; then solving the perturbation equation to obtain a fatigue crack expansion length perturbation grades solution; calculating load cycle times when a critical crack length is reached; and taking the load cycle times as a predicted value of the metal structure fatigue crack expansion life.

Owner:BEIHANG UNIV

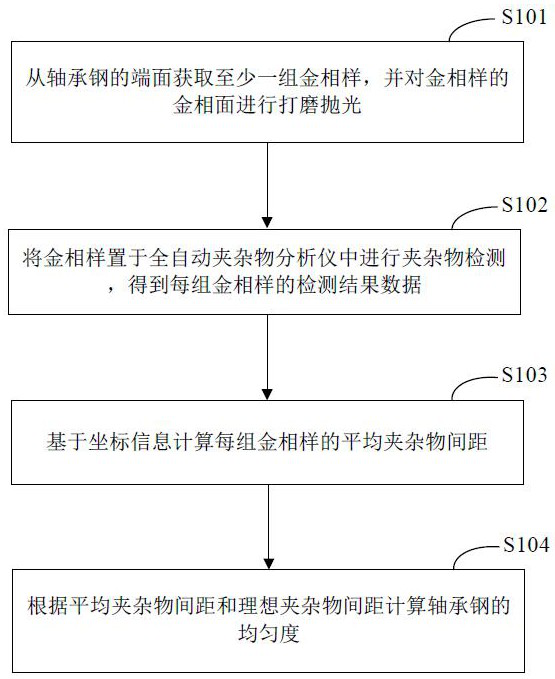

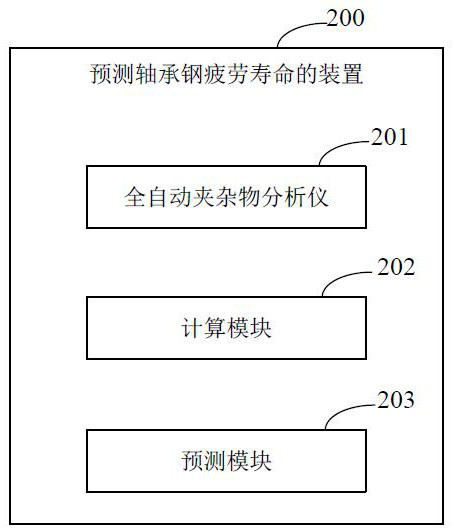

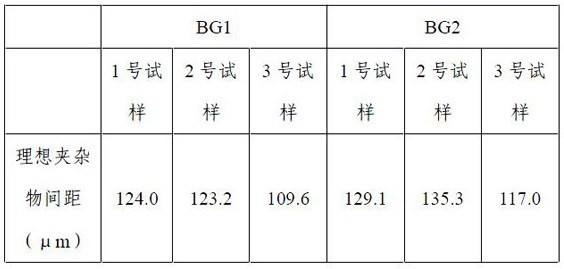

Method and device for predicting fatigue life of bearing steel

InactiveCN112666199APredict fatigue lifeMaterial analysis using wave/particle radiationFully automatedGrinding

The invention discloses a method and a device for predicting the fatigue life of bearing steel, and relates to the technical field of steel materials. One specific embodiment comprises the following steps: obtaining at least one group of metallographic samples from the end surface of bearing steel; grinding and polishing the metallographic surface of the metallographic samples; putting the metallographic samples into a full-automatic inclusion analyzer for inclusion detection to obtain detection result data of each group of metallographic samples; calculating the average inclusion distance of each group of metallographic samples based on the coordinate information; calculating the uniformity of the bearing steel according to the average inclusion distance and the ideal inclusion distance, wherein the uniformity is used for predicting the fatigue life of the bearing steel. According to the embodiment, the fatigue life of the bearing steel can be predicted by predicting the distribution uniformity of the inclusions.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com