Metal structure fatigue crack expansion life prediction method based on Taylor perturbation series method

A technology of fatigue crack growth and perturbation series, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of errors in initial crack measurement results, manufacturing errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

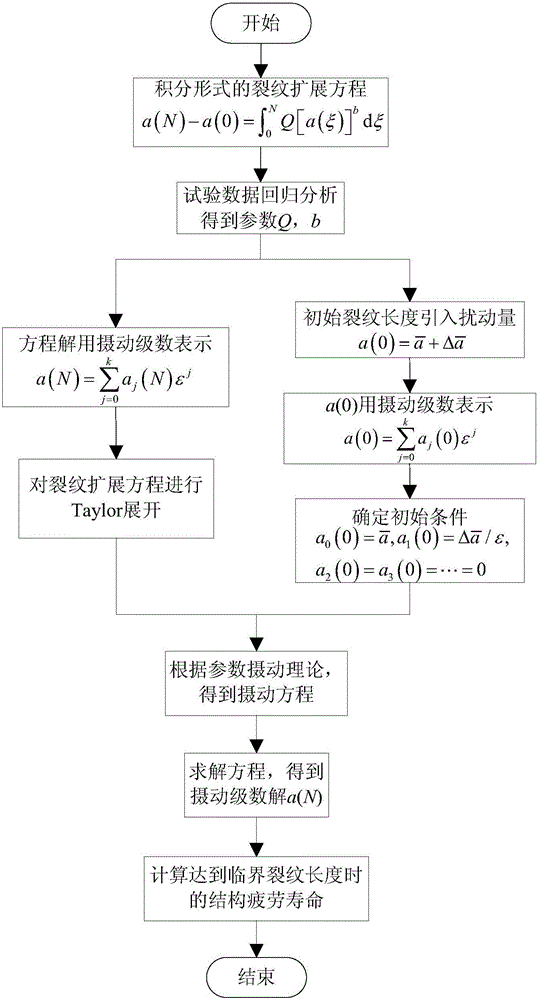

Method used

Image

Examples

Embodiment

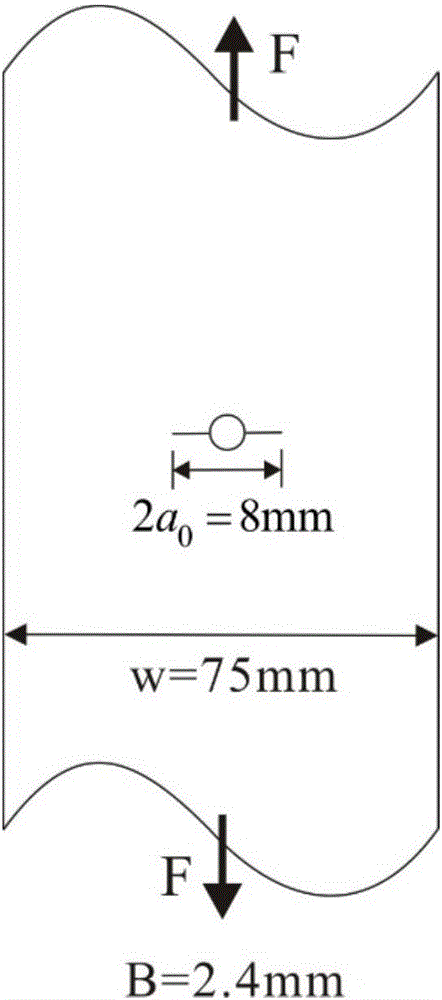

[0093] In order to understand more fully the characteristics of this invention and its applicability to engineering practice, the present invention uses image 3 The shown 475-T761 aerospace aluminum alloy center crack (MT) specimen was taken as an example to verify the crack growth fatigue life prediction. The MT sample is 75mm wide and 2.5mm thick, with a central crack, such as image 3 shown. The frequency of the applied load is 10Hz, and the length of the prefabricated half-crack is a 0 = 4mm, due to manufacturing errors, the actual initial half-crack length is a 0 =4.06mm, the half-crack length a and the corresponding number of load cycles N are shown in Table 1.

[0094] Table 1a-N test data points

[0095]

[0096] According to formula (5), calculate the tangent slope of each discrete point, and through regression analysis, the parameter value in the crack propagation equation (4) is obtained: Q=3.9547×10 -8 , b=3.3794. The initial half-crack length is a(0)=4.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical crack length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com