Metal corrosion form simulation method based on three-dimensional cellular automaton technology

A cellular automata, three-dimensional cell technology, applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

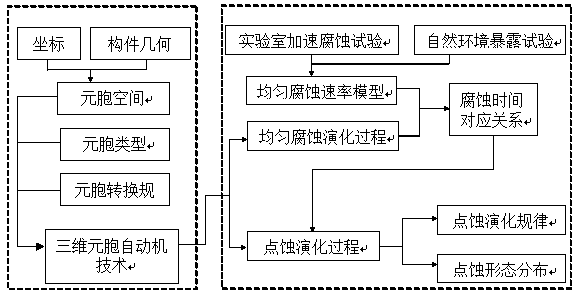

[0047] like figure 1 As shown, a kind of metal corrosion morphology simulation method based on three-dimensional cellular automata technology of the present invention mainly includes the following steps:

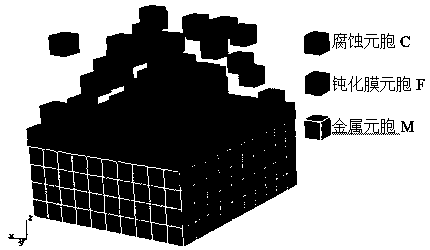

[0048] 1. Based on the geometric shape of the component, select the type of coordinate system, divide the metal component and the external corrosion environment into an array of cells according to the corrosion simulation accuracy requirements, establish a three-dimensional cell space, and determine the boundary conditions;

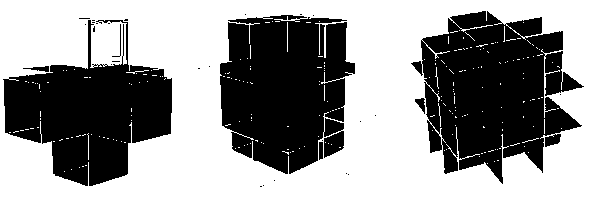

[0049] 2. Determine the various types of cells, and determine the properties of the cells on each grid position in the cell space according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com