Apparatus and method for fatigue cracking test of steel bridge deck pavement

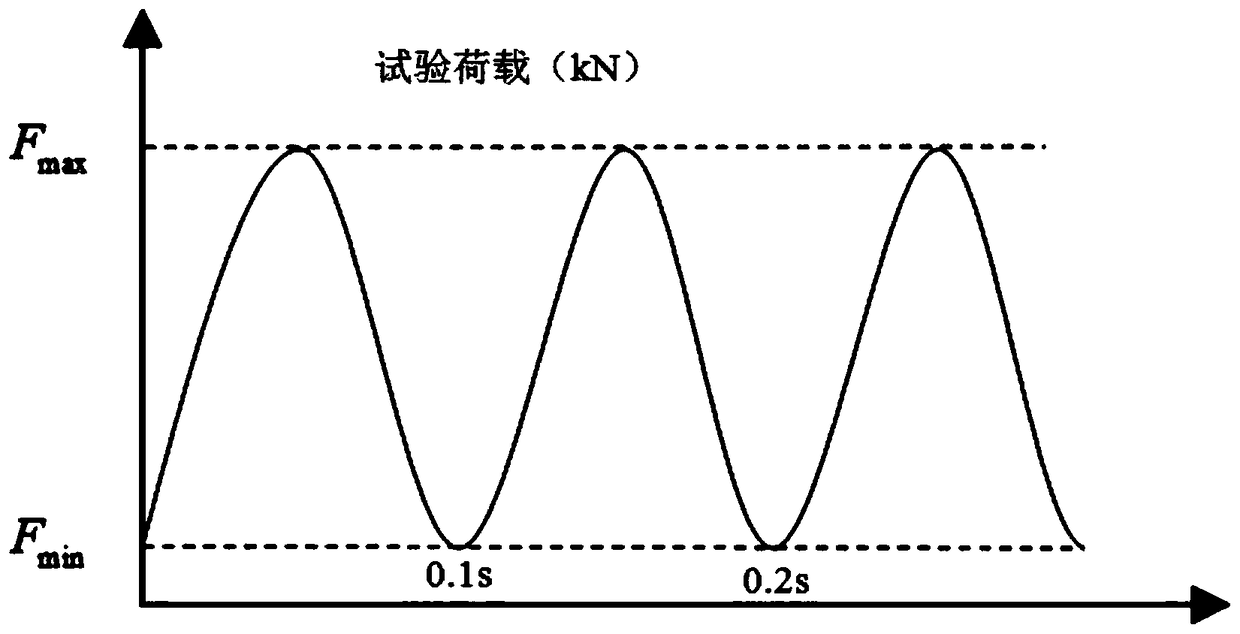

A technology of fatigue cracking and test device, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., to achieve the effects of careful logic, stable and reliable test results, and reasonable and feasible test methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

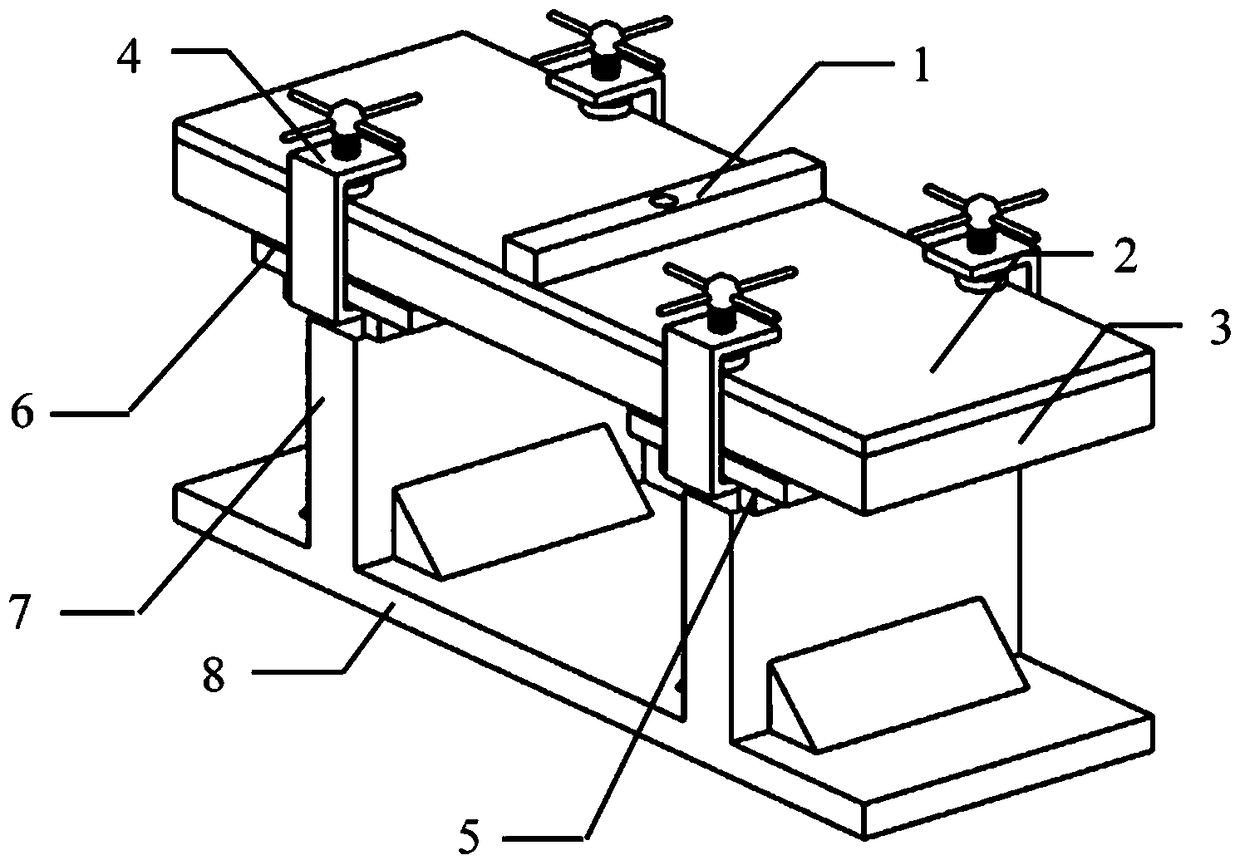

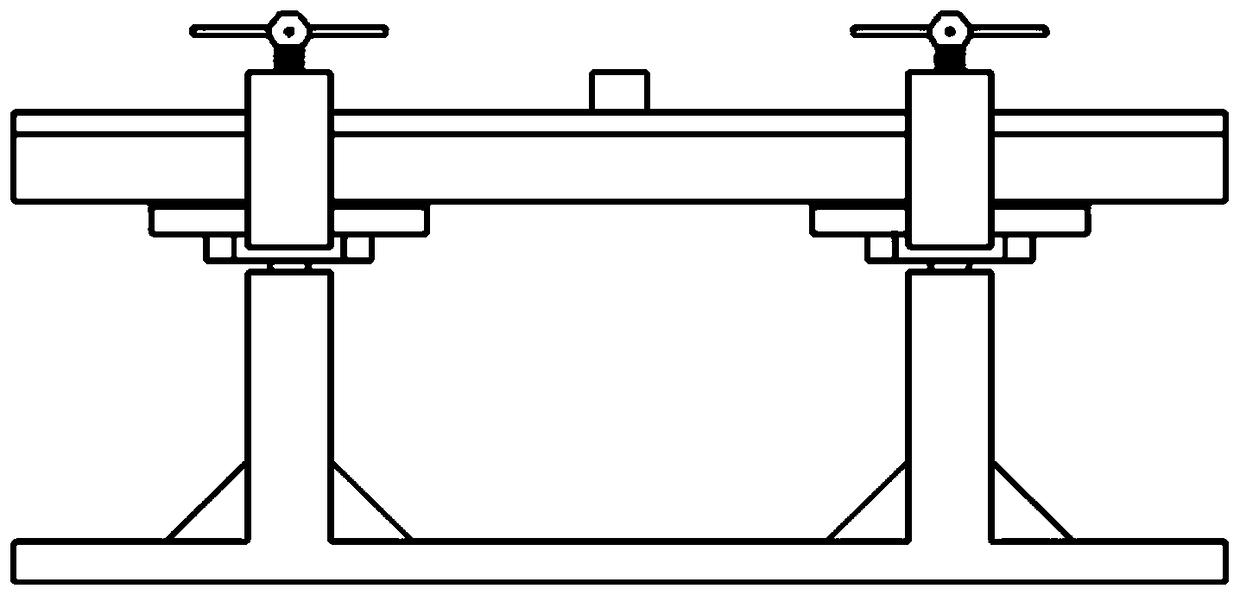

[0026] The design of the fatigue cracking test device for the steel bridge deck pavement will be further explained below in conjunction with the accompanying drawings.

[0027] Existing pavement material fatigue performance tests can be divided into two categories, one is to directly test the material, such as small beam bending fatigue test, split fatigue test, four-point bending fatigue test, etc.; the other is to test the composite beam of pavement The test is to apply load to the pavement layer and steel plate composite at the same time to simulate the stress condition of the pavement layer. In terms of the intuitiveness and rationality of the test, the composite beam test has obvious advantages. However, the existing composite beam tests have the disadvantages that the boundary conditions or loading state do not conform to the actual situation, and the demand for loading force and loading equipment is too high. Therefore, the design concept of the present invention is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com