A high-speed train car body stress test device and its working method

A technology of stress testing and high-speed trains, applied in the direction of measuring devices, measurement of the change force of optical properties of materials when they are stressed, instruments, etc., can solve the problems of maintenance personnel, evaluation of difficult welding joints, wiring confusion, etc. Achieve the effects of avoiding poor anti-electromagnetic interference ability, improving wiring difficulty, and convenient data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

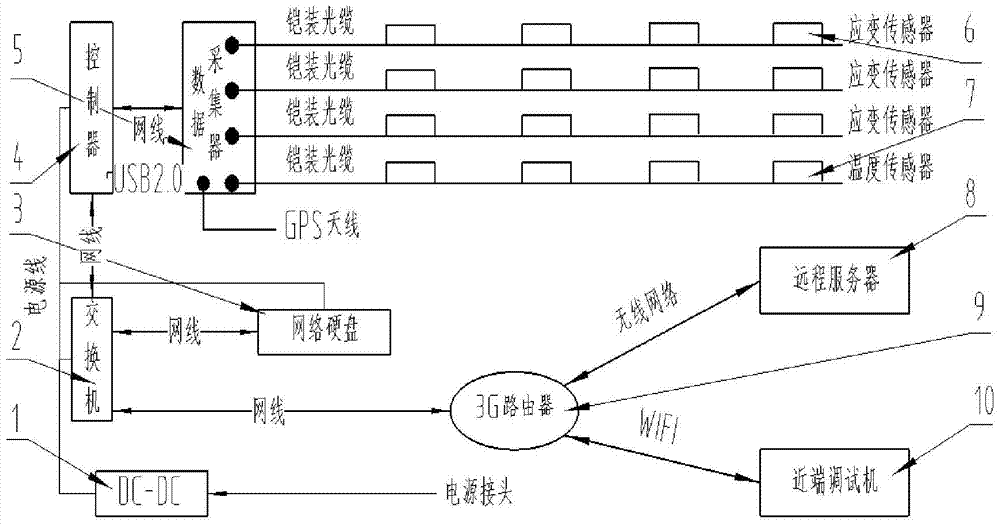

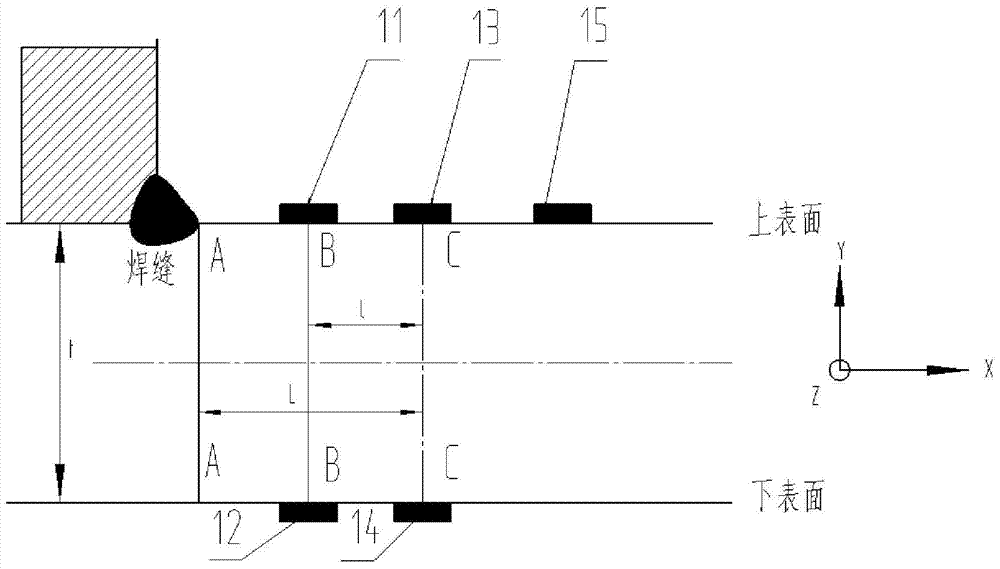

[0042] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, a high-speed train body stress test device includes a strain sensor 6, a temperature sensor 7, a controller 4, a data collector 5, a switch 2, a network hard disk 3, a remote server 8, a near-end debugging machine 10, and a 3G router 9 and the power converter 1, the strain sensor 6 and the temperature sensor 7 are connected to the data collector 5 through an armored optical cable, and the data collector 5 and the controller 4 are connected to transmit instructions and data through a network cable, so The controller 4, the network hard disk 3 and the 3G router 9 are all connected to the switch 2 through a network cable to realize data transfer and distribution, the controller 4 is provided with a USB interface, and the near-end debugging machine 10 is The USB interface on 4 or the WIFI function connection controller 4 of 3G router 9 carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com