Water turbine top cover bolt fatigue prediction method

A prediction method and hydraulic turbine technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large amount of calculation, cannot be taken out by full cycle meter, and rain flow method cannot be fully cycled, etc., to achieve accurate damage degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

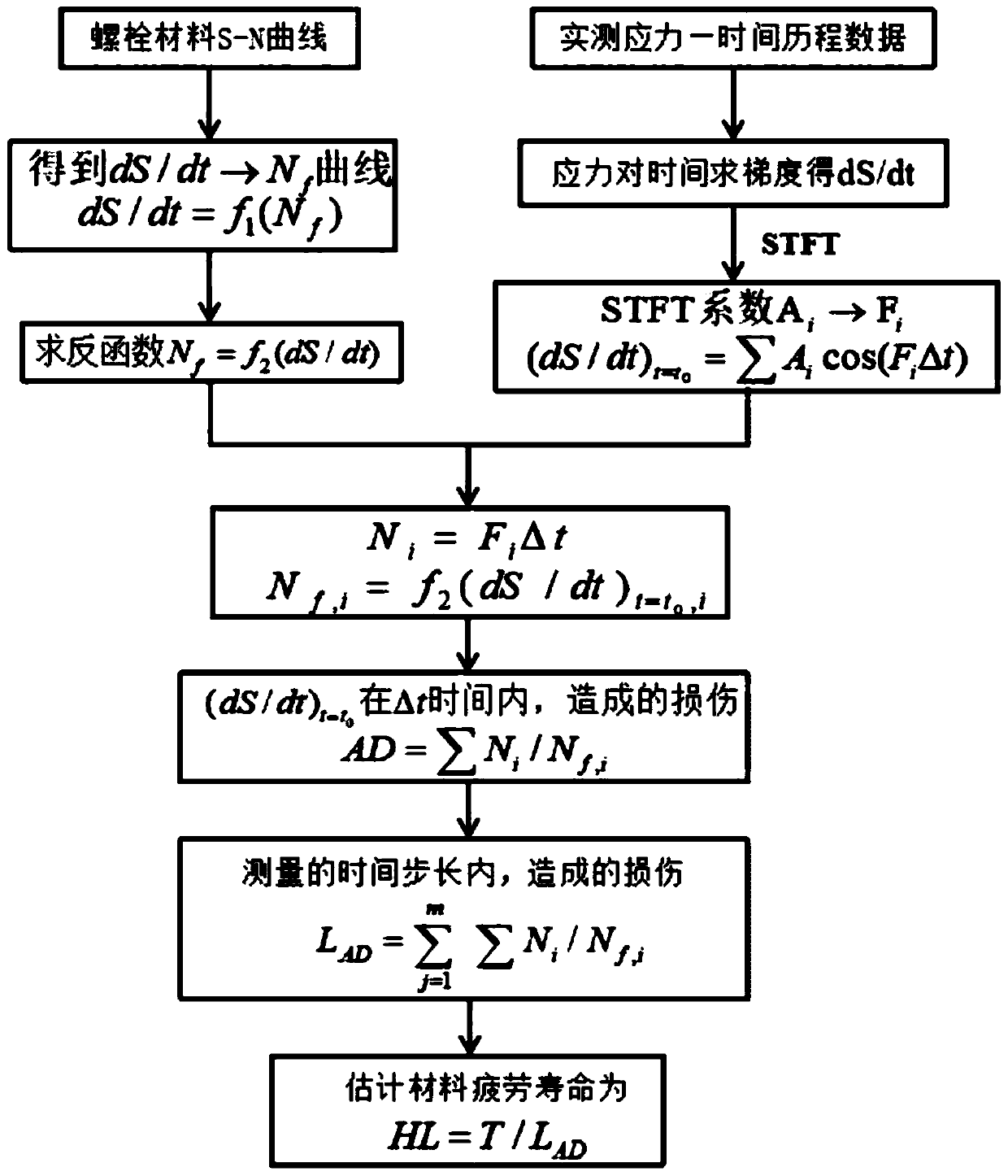

Method used

Image

Examples

Embodiment

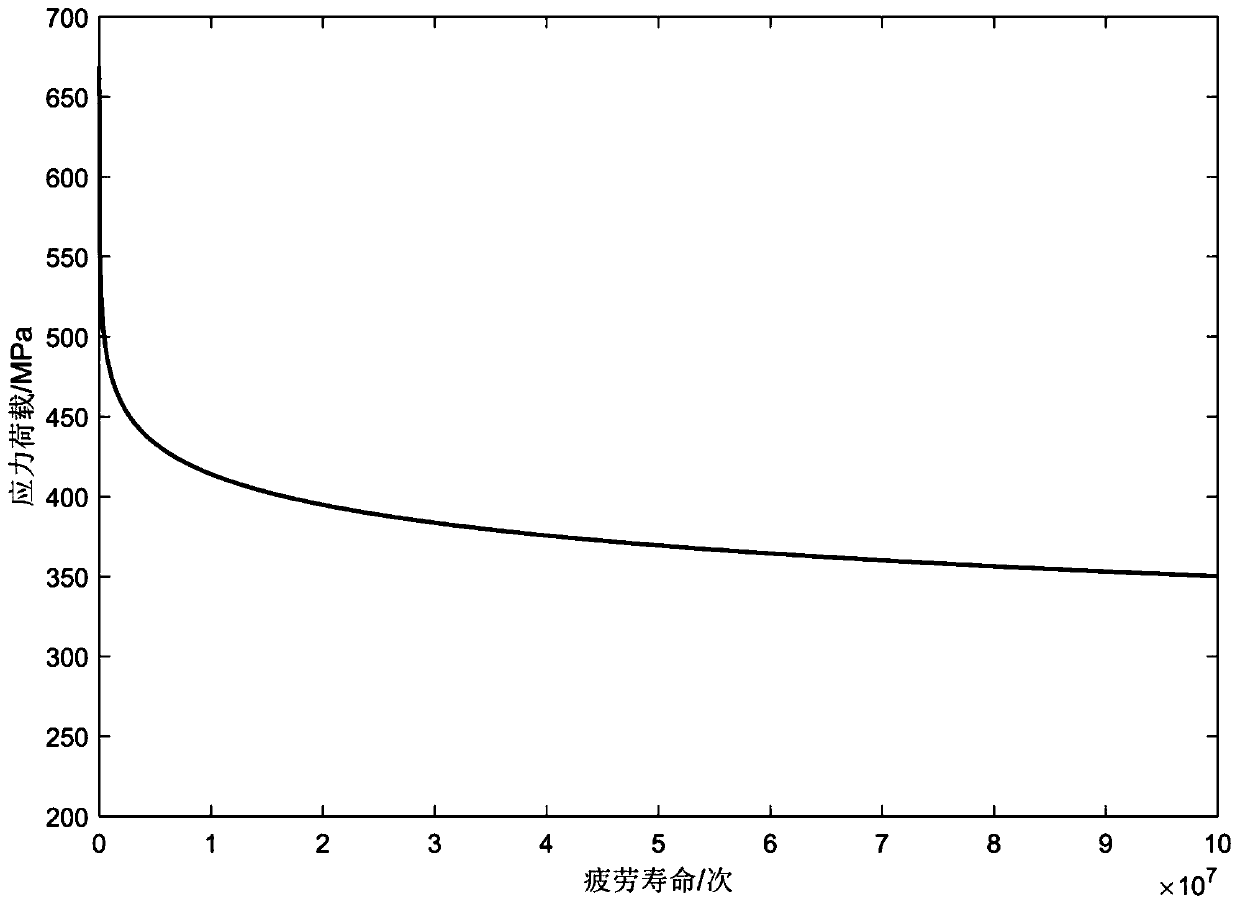

[0060] 1. The bolt material used in this application is 8.8-grade alloy steel. According to the "Mechanical Design Manual", the allowable stress [σ] of alloy steel is determined to be 640MPa, and the strength limit σ b =893MPa, the yield limit is 770MPa. Such as figure 1 As shown, the stress-fatigue life (S-N) curve of the determined material is

[0061] S=860.6764-63.8162 log N f

[0062] In this formula, S is the stress fatigue limit, MPa; N f is the fatigue life, times;

[0063] According to the above formula, the gradient of stress versus time, that is, the power density, is obtained as

[0064] r(dS / dt) i = Z i (860.6764-63.8162 log N f,i )×10 6

[0065] In this formula, Z i For the selected time t=t 0 Absolute value of power density to stress ratio, (dS / dt) i is the power density of stress versus time, N f,i is the limit cycle number when the material is fractured and damaged, and r is the reliability coefficient

[0066] 2. Perform an inverse function tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com