Barrel Burr Cutting Machine

A cutting machine and burr technology, which is applied in the field of barrel burr processing equipment, can solve the problems of limited adsorption force, easy cutting, easy relative displacement between the barrel body and the leather cup, etc., so as to improve work efficiency, increase the limit degree, Relative Position Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

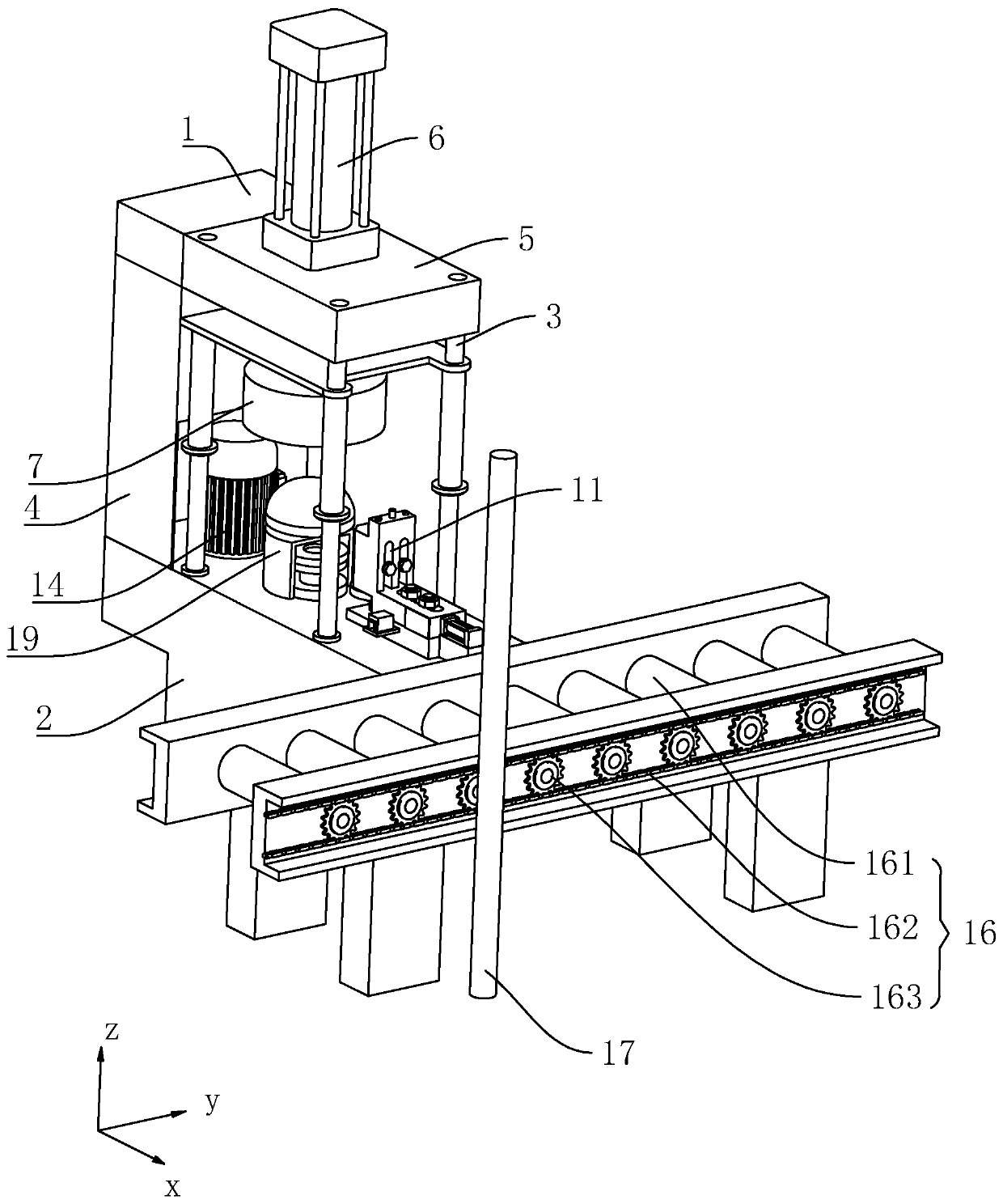

[0038] Embodiment 1: a kind of barrel body flash notch machine, such as figure 2 As shown, it includes a rack 1, and the rack 1 includes a base 2 of a cube, such as figure 2 As shown, a three-dimensional coordinate system is established with the center of the base 2 as the origin, the front of the base 2 is the x direction, the right side of the base 2 in the figure is the y direction, and the top of the base 2 in the figure is the z direction.

[0039] Such as figure 2 As shown, the frame 1 also includes a guide post 3 and a back plate 4, the guide post 3 is vertically arranged at the four corners of the base 2; The sides are drawn vertically upwards, and a top plate 5 is arranged on the top of the back plate 4 , and the projection of the top plate 5 on the z-axis just falls on the base 2 .

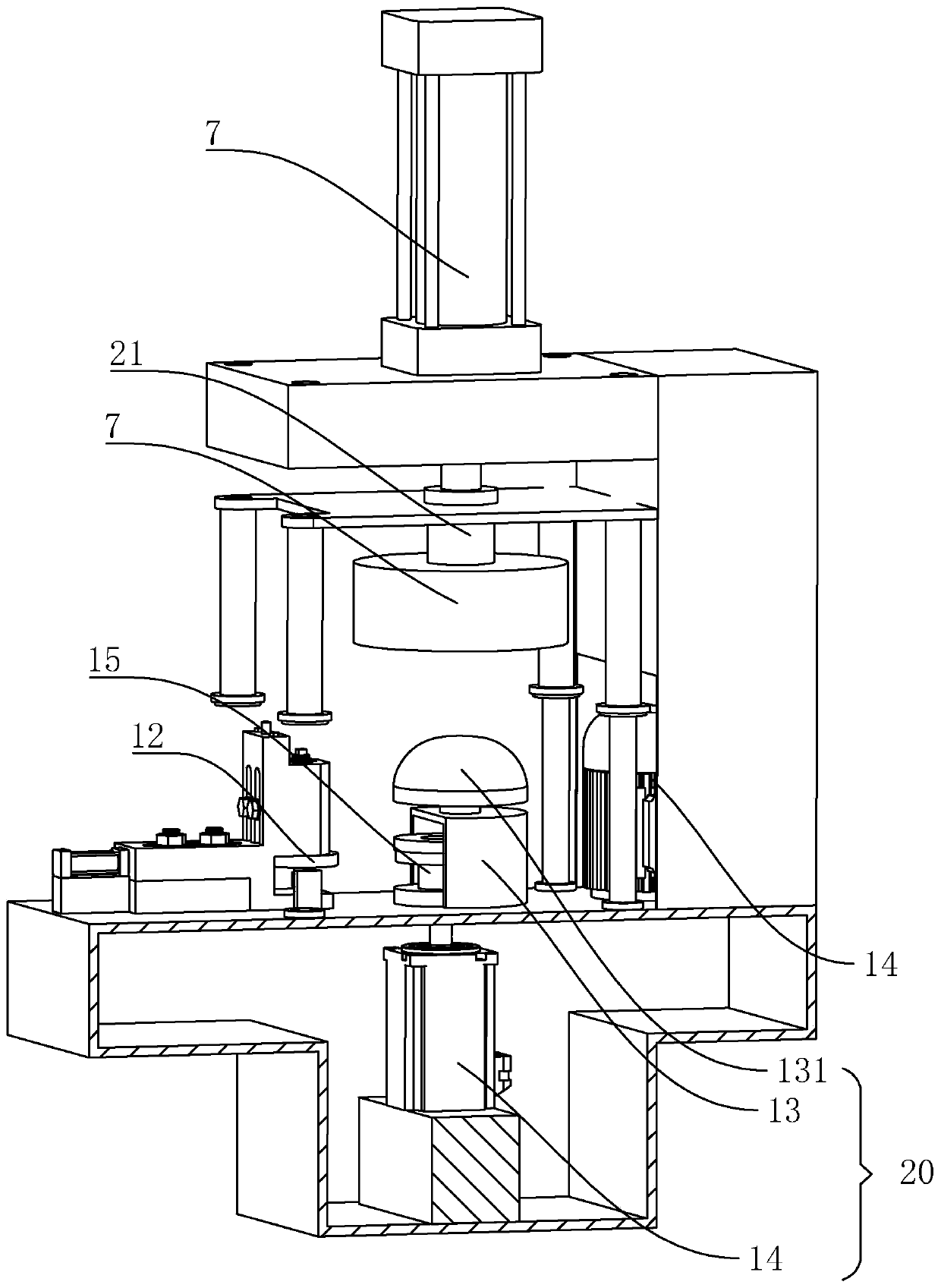

[0040] The frame 1 is provided with a part positioning mechanism 19 for limiting the parts to be cut. The part positioning mechanism 19 includes a driving rotating part 20 and a dri...

Embodiment 2

[0055] Embodiment 2: The difference with Embodiment 1 is that, as Figure 5 As shown, there is a transmission connection between the sipe 15 and the geared motor 14 in this embodiment, and a section of the first shaft 132 extends from the bottom of the I-shaped wheel of the sipe 15, and the first shaft 132 is sleeved and tensioned. Belt 18, tension belt 18 other ends are tightened on the output shaft of geared motor 14, and geared motor 14 rotates and drives knife groove 15 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com