Steel bridge fatigue evaluation load modeling and fatigue evaluating method

A fatigue and steel bridge technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult to reflect the actual situation, complex loads of bridges, complex applications, etc., to achieve improved use value, good fatigue assessment, Evaluate the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

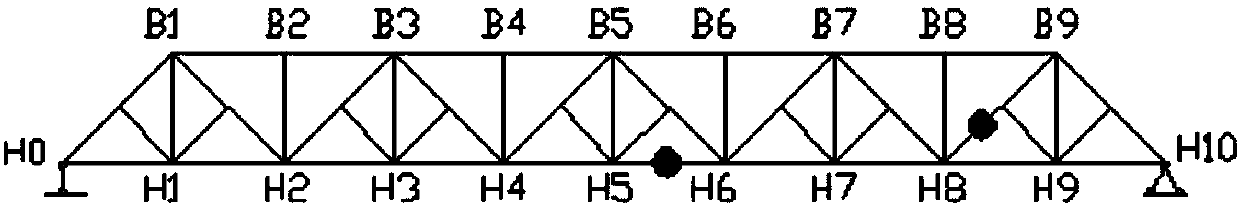

[0064] The fatigue assessment load modeling and fatigue assessment method of a steel bridge according to the embodiment of the present invention implements train load modeling based on actual measured data of passing vehicles. A certain through steel truss girder bridge with a bridge span of 75m is taken as an example to illustrate the fatigue evaluation load modeling and fatigue evaluation method of the steel bridge of the present invention.

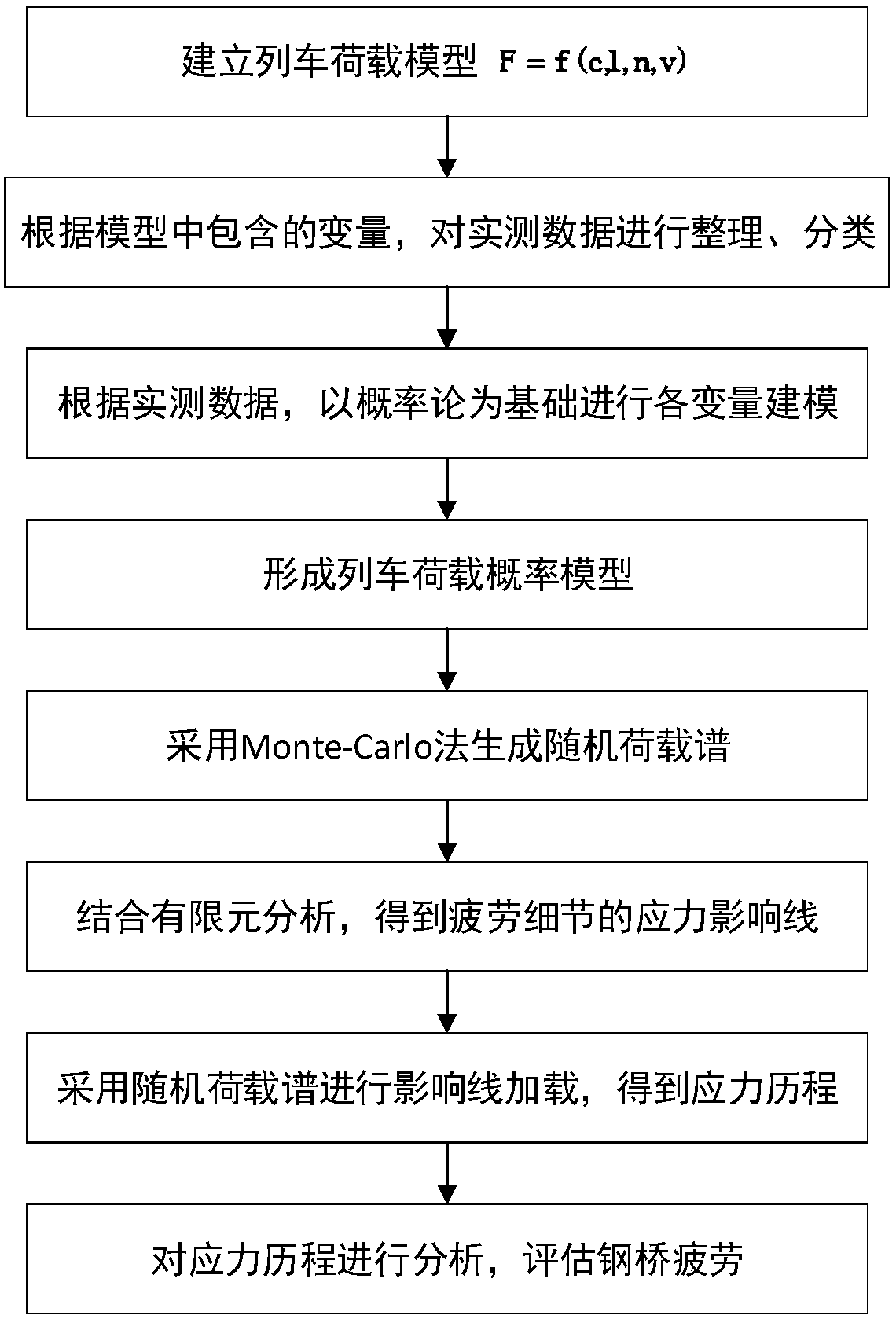

[0065] Such as figure 1 As shown, specifically including:

[0066] Step 1. Establish a train load model:

[0067] The load response and wheel-rail force of the train are monitored by sensors arranged on the steel bridge, and the load model of the train passing on the steel bridge is expressed as: F=f(c,l,n,v);

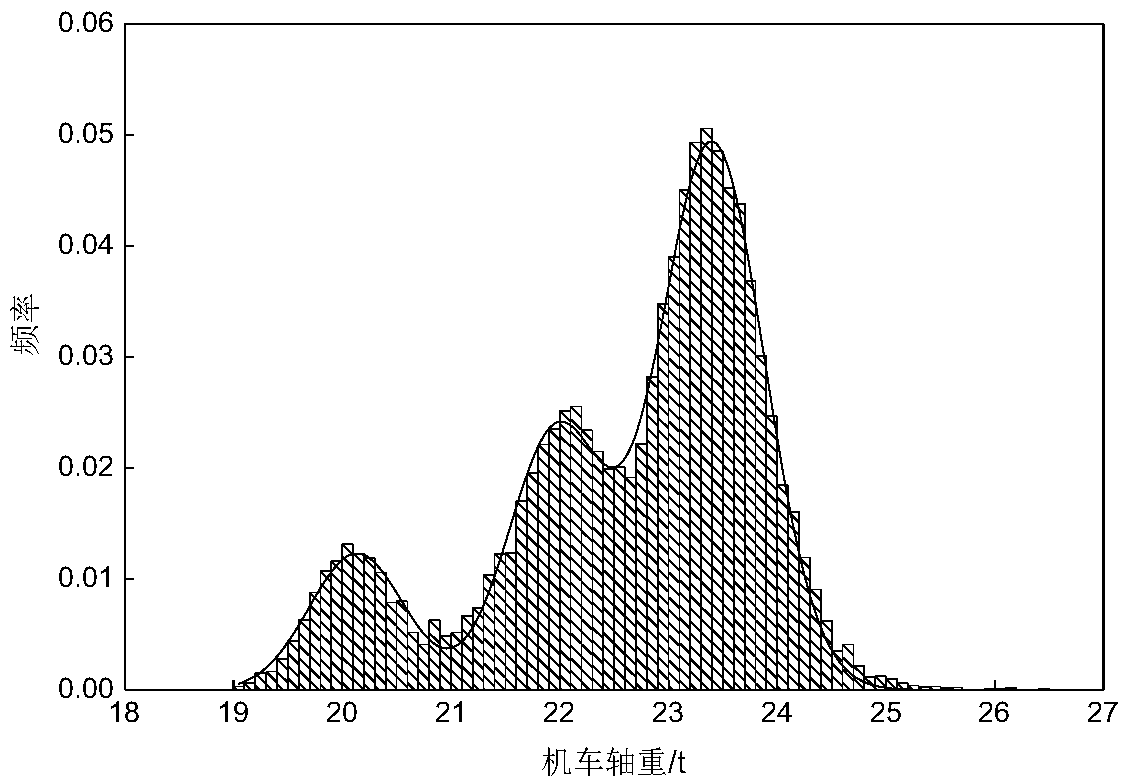

[0068] In the formula, the parameter c represents the train type, the parameter l repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com