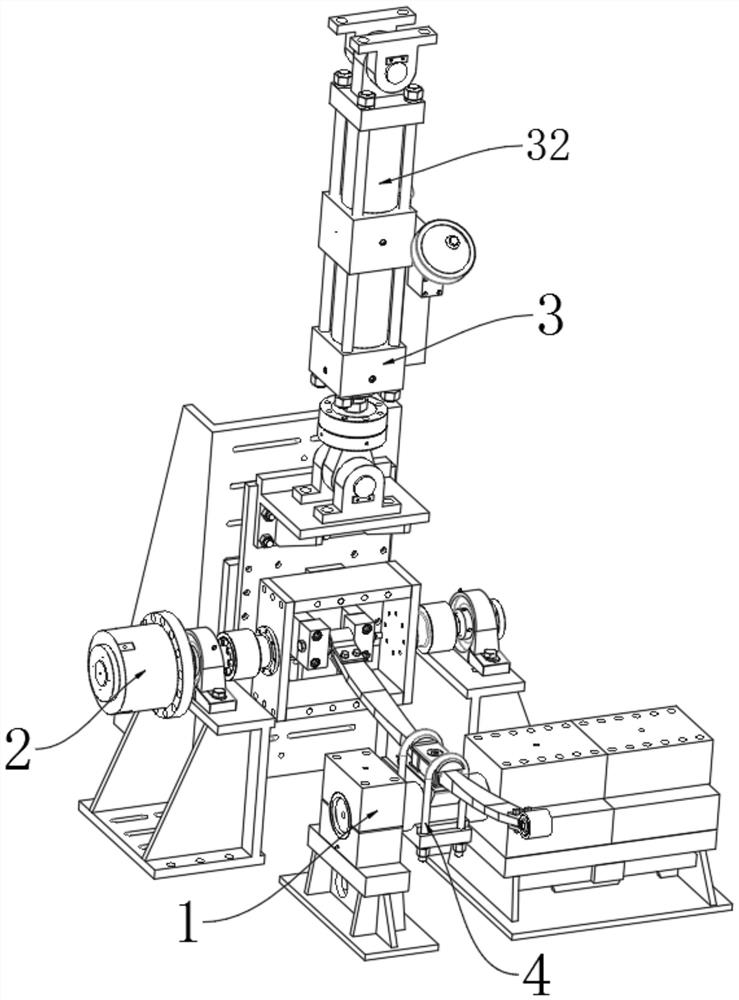

Composite material plate spring double-channel rack device and test method

A composite material plate and dual-channel technology, which is applied in the direction of measuring devices, elastic testing, mechanical parts testing, etc., can solve the problems of complex force of composite material leaf springs and inability to effectively simulate life, and achieve the effect of predicting fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

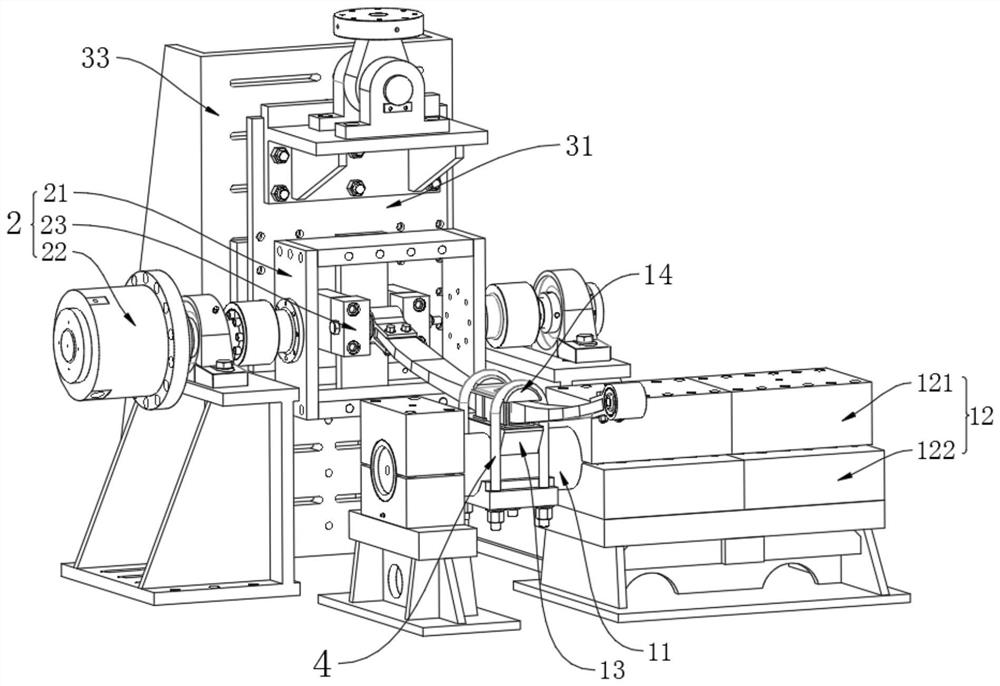

[0034] As an embodiment of the present invention, the torsion assembly 2 at least includes a torsion frame assembly 21 and a torsion power device 22, the metal ear at one end of the leaf spring is hingedly mounted on the torsion frame assembly 21, and the torsion power device 22 is used to Assembly 21 provides torsional force. The specific structure can be as follows: the torsional power device 22 can adopt a rotary actuator, the torsional frame assembly 21 is a frame structure and is fixedly connected with the rotary actuator, and a cushion block 23 can also be arranged in the torsional frame assembly 21, a double head The studs pass through the metal ears, and both ends are fixed on the symmetrically arranged spacers 23, so that the leaf spring is hingedly mounted on the torsion frame assembly 21 through the spacers 23 and the double-ended studs.

[0035] It can be understood that, in order to facilitate installation, the spacer 23 can include two bodies, and the two bodies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com