Prediction method for failure probability of fragile material under high-temperature creep state

A brittle material, failure probability technology, applied in the direction of probability network, probabilistic CAD, special data processing application, etc., can solve the problems that are not suitable for evaluating the reliability of brittle materials, and achieve the real effect of prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Predict the failure probability of glass-ceramic GC-9 material under creep of 50000h at 600℃.

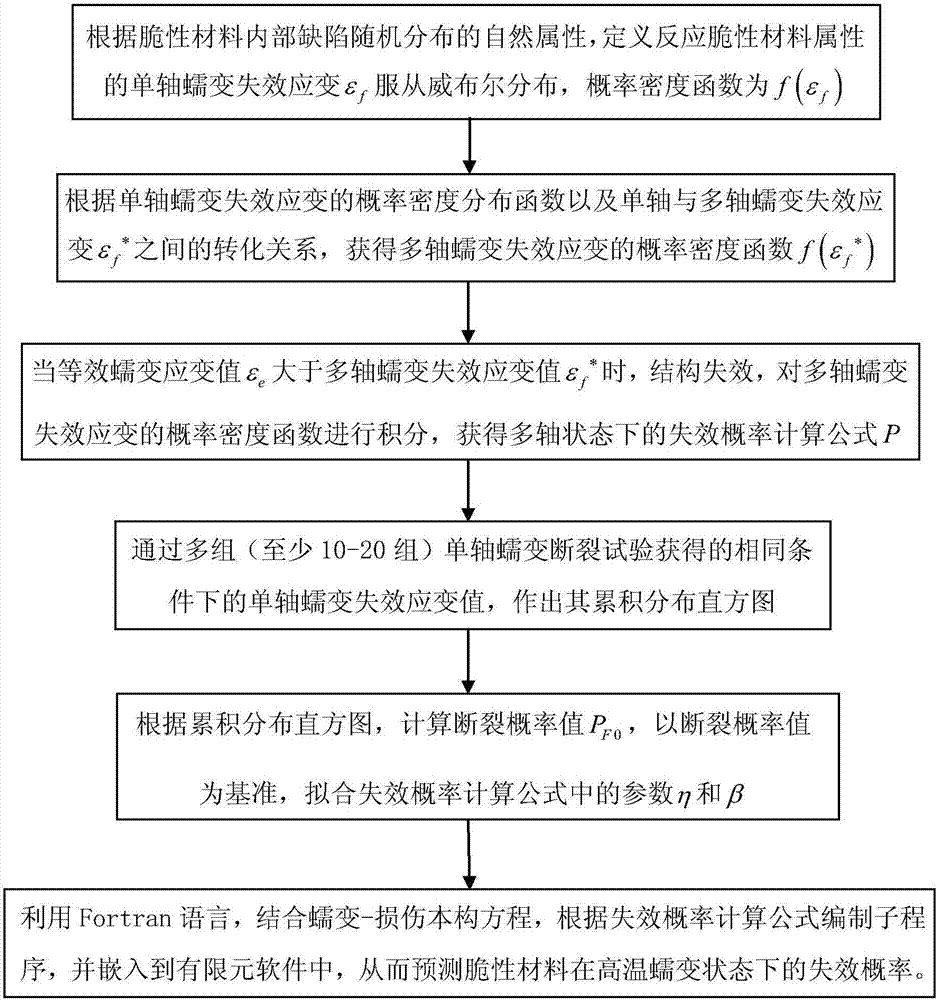

[0063] The failure probability prediction process of glass-ceramic GC-9 material creeping at 600°C for 50,000 hours is as follows: figure 1 The process shown is carried out.

Embodiment 2

[0065] Predict the failure probability of ceramic material YSZ under 650℃ creep for 50000h.

[0066] The failure probability prediction process of the ceramic material YSZ at 650°C for 50,000h creep is as follows: figure 1 The process shown is carried out.

[0067] Embodiment 1 and embodiment 2 are shown in table 1 in the parameter used in calculation process:

[0068] Table 1

[0069]

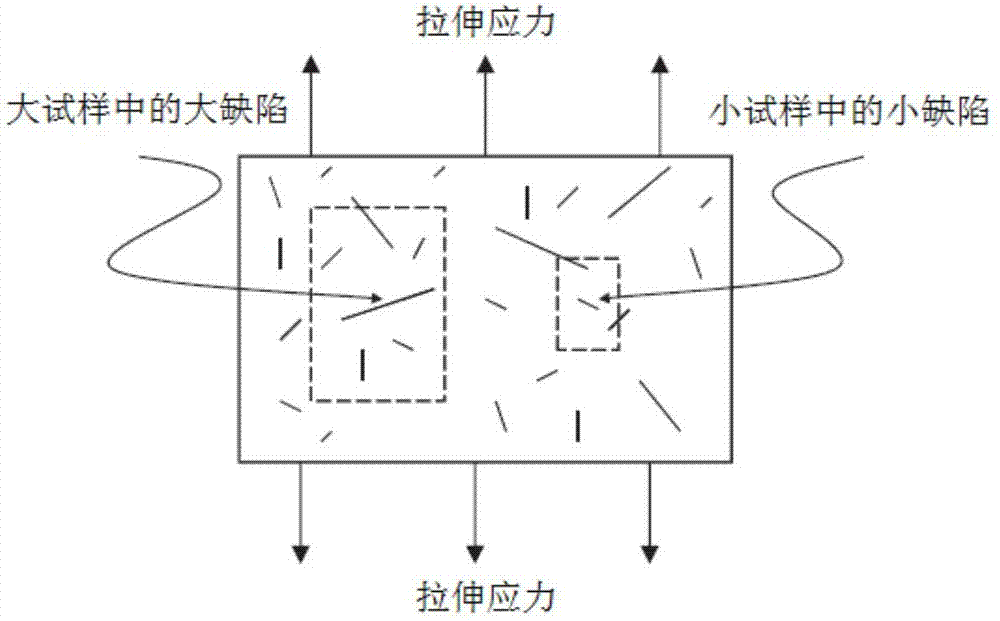

[0070] Weibull theory needs to consider the weakest chain assumption, that is, the structure is under constant uniaxial load, it is considered to be similar to a stretched N chain, each chain has a different failure strength, when the weakest chain fails, the entire structure fails . Therefore, the strength of a chain is relative to the weakest chain. The failure strength of each chain is different, depending on the internal defects of the sample, that is, "volume effect".

[0071] figure 2 It is a schematic diagram of the relationship between the sample volume size and the defect si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com