Method for checking strength performances of variable-pitch bearing and hub connecting bolt and variable-pitch bearing and vane connecting bolt of fan

A pitch bearing and blade connection technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of incomplete load transmission paths between fan pitch bearings and hub and blade connection bolts, and inaccurate calculation strength performance. and other problems to achieve the effect of reducing workload, improving reliability, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] The method of checking the ultimate strength of the connecting bolts between the wind turbine pitch bearing and the hub and blades is as follows:

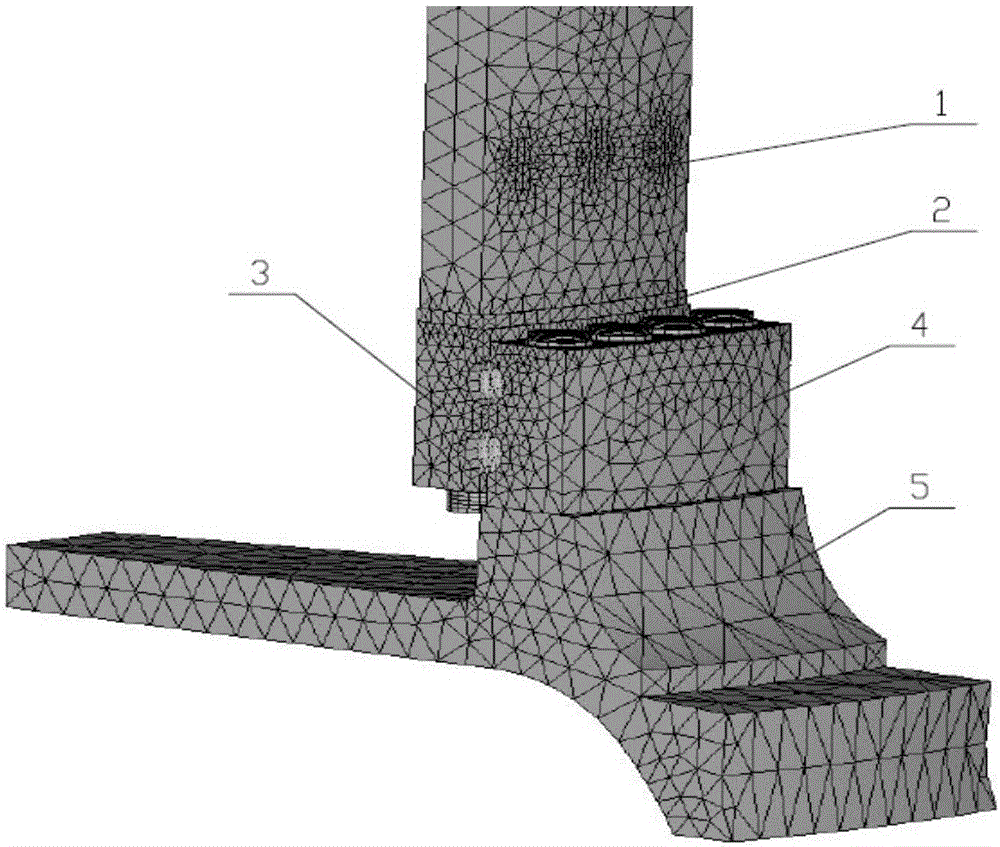

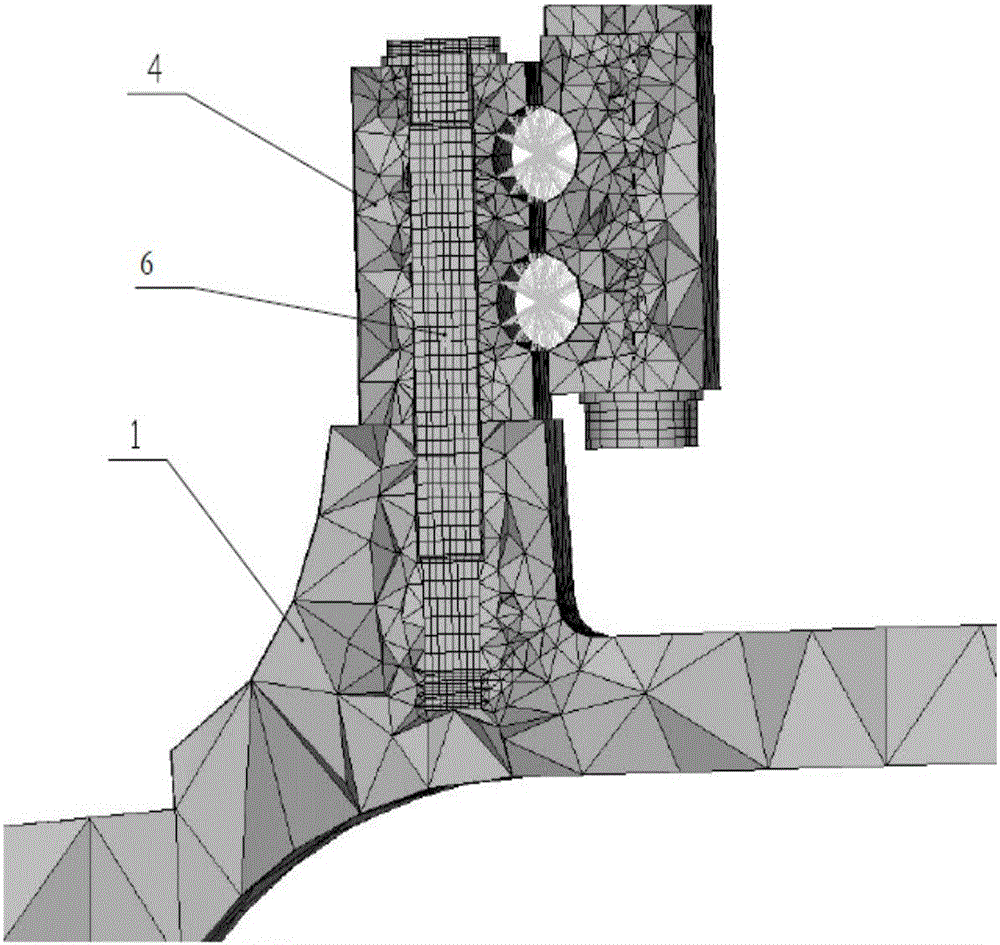

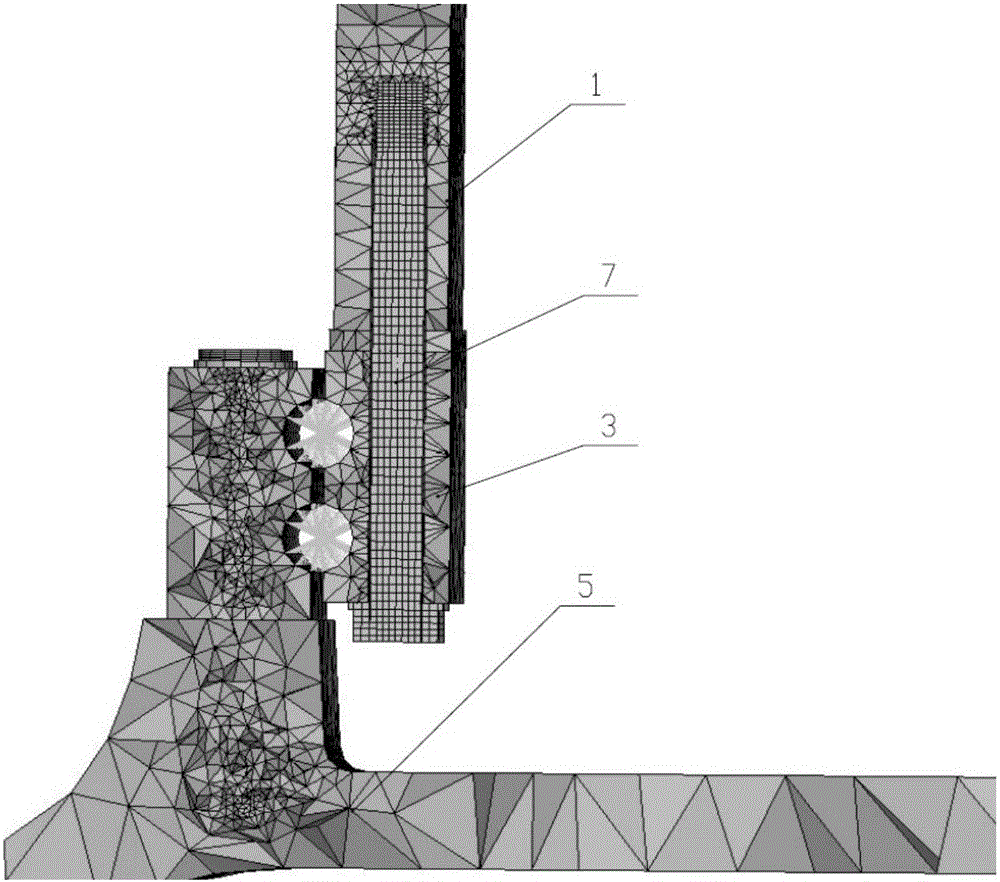

[0027] 1) if Figure 1-3 As shown, on the drawing software (such as CAD), the blade root part 1, the blade flange 2, the inner ring of the pitch bearing 3, the outer ring of the pitch bearing 4, the hub 5, the pitch bearing and the hub are connected on the drawing software (such as CAD) Bolt 6, pitch bearing and blade connection bolt 7 establish a periodic geometric model, and use finite element software to use solid element meshes for the above parts and assemble them to establish a finite element model. The load transfer path of this model is complete and consistent with the actual situation.

[0028] 2) Apply corresponding attributes to each part of the finite element model, where the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com