Numerical simulation technology for hollow section porthole die extrusion welding process

A numerical simulation technology, technology of hollow profiles, applied in the direction of metal extrusion dies, electrical digital data processing, special data processing applications, etc., can solve problems such as termination of simulation calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

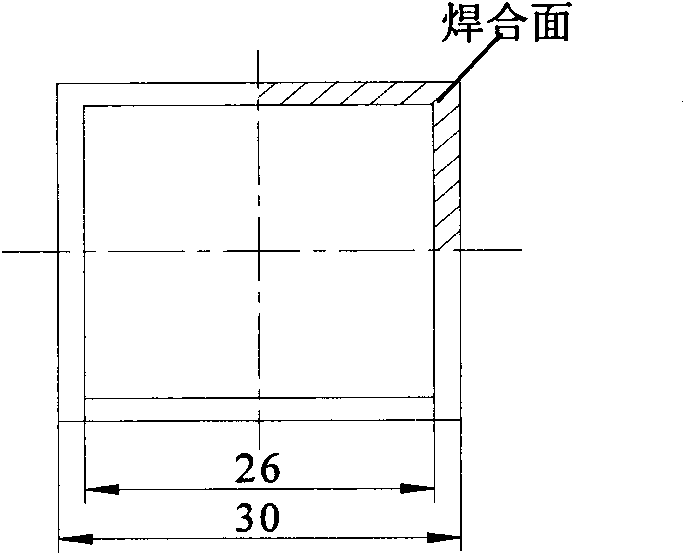

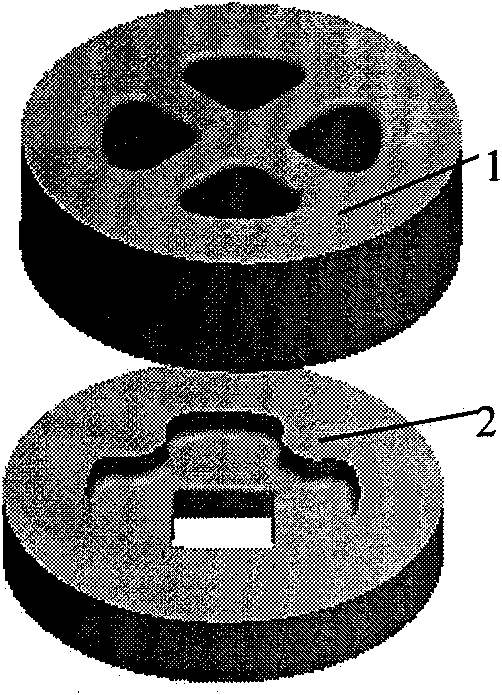

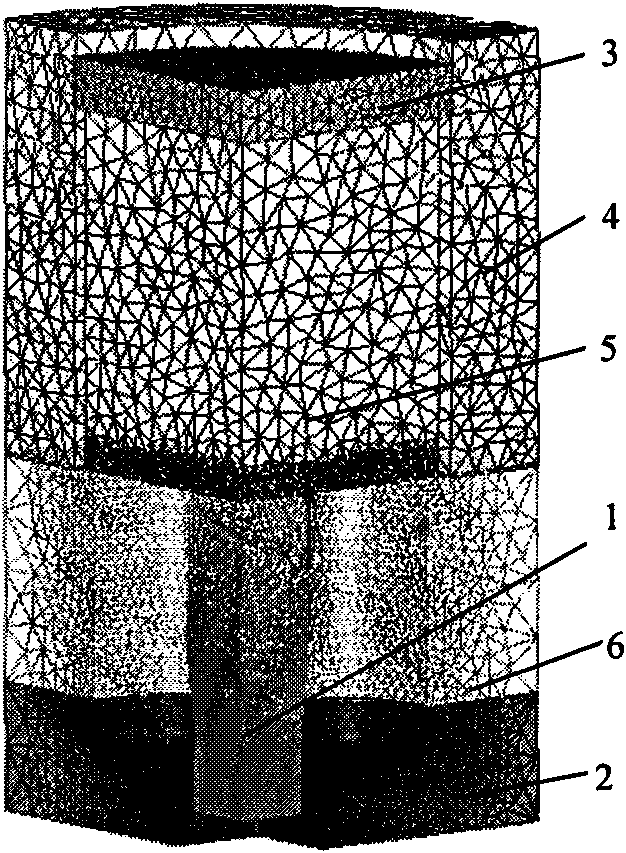

[0045] By adopting the finite element simulation technology of the extrusion welding process of the split mold of the present invention, the problem of the repairing of the interpenetrating unit grids of the welding surfaces is solved, and the realization of figure 1 The finite element simulation of the whole extrusion process of the square tube shown.

[0046] The size of the square tube is L30×t2mm, and the metal deformation body, that is, the billet diameter is Φ90mm, the diameter of the extrusion cylinder is Φ95mm, the extrusion ratio is 31.6, and the split ratio is 12.6. The shear friction model is selected between the blank and the mold, and according to the results of the ring compression experiment, the friction factor m=1 is taken.

[0047] The initial process conditions of extrusion are billet (A6005 aluminum alloy) temperature 480°C, extrusion cylinder temperature 400°C, mold (H13 hot work die steel) temperature 450°C, extrusion pad temperature 30°C, extrusion shaft...

Embodiment 2

[0064] The section and size of the asymmetric porous hollow profile are as follows: Figure 20 As shown, the solid mold structure is as Figure 21 shown. For such hollow sections with inconsistent welded surfaces and symmetrical surfaces, the numerical simulation analysis of the whole process of extrusion can only be completed by using the mesh repair technology of the welded surface of the present invention.

[0065] The finite element software Deform-3D is used for simulation. The absolute grid method is used for grid division. The calculation unit is a tetrahedral grid unit. Set the minimum size of the unit to be 1mm and the maximum to be 30mm during the simulation.

[0066] Assuming that the diameter of the billet and the extrusion cylinder is Φ238mm, and the extrusion ratio is 31, the shear friction model is selected between the billet and the die, and according to the ring compression test results of the billet and the die, the friction factor m=1 is taken.

[0067] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com