Patents

Literature

39 results about "Failure assessment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Failure assessment, as used in the context of software systems design, is the science of determining the circumstances under which a particular algorithm fails and then correcting the cause. It is directly related to the notion of algorithm accuracy, robustness, and reliability.

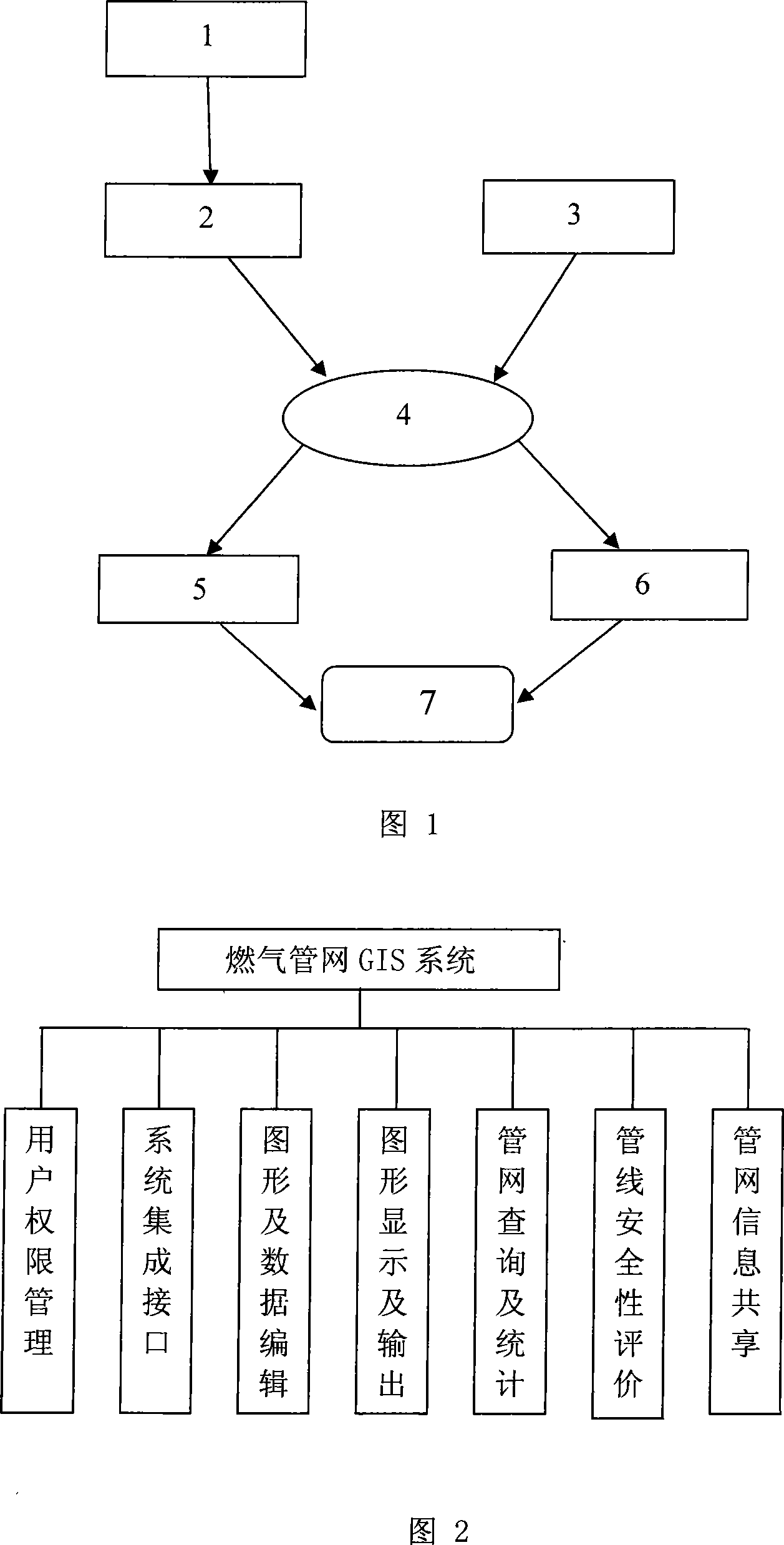

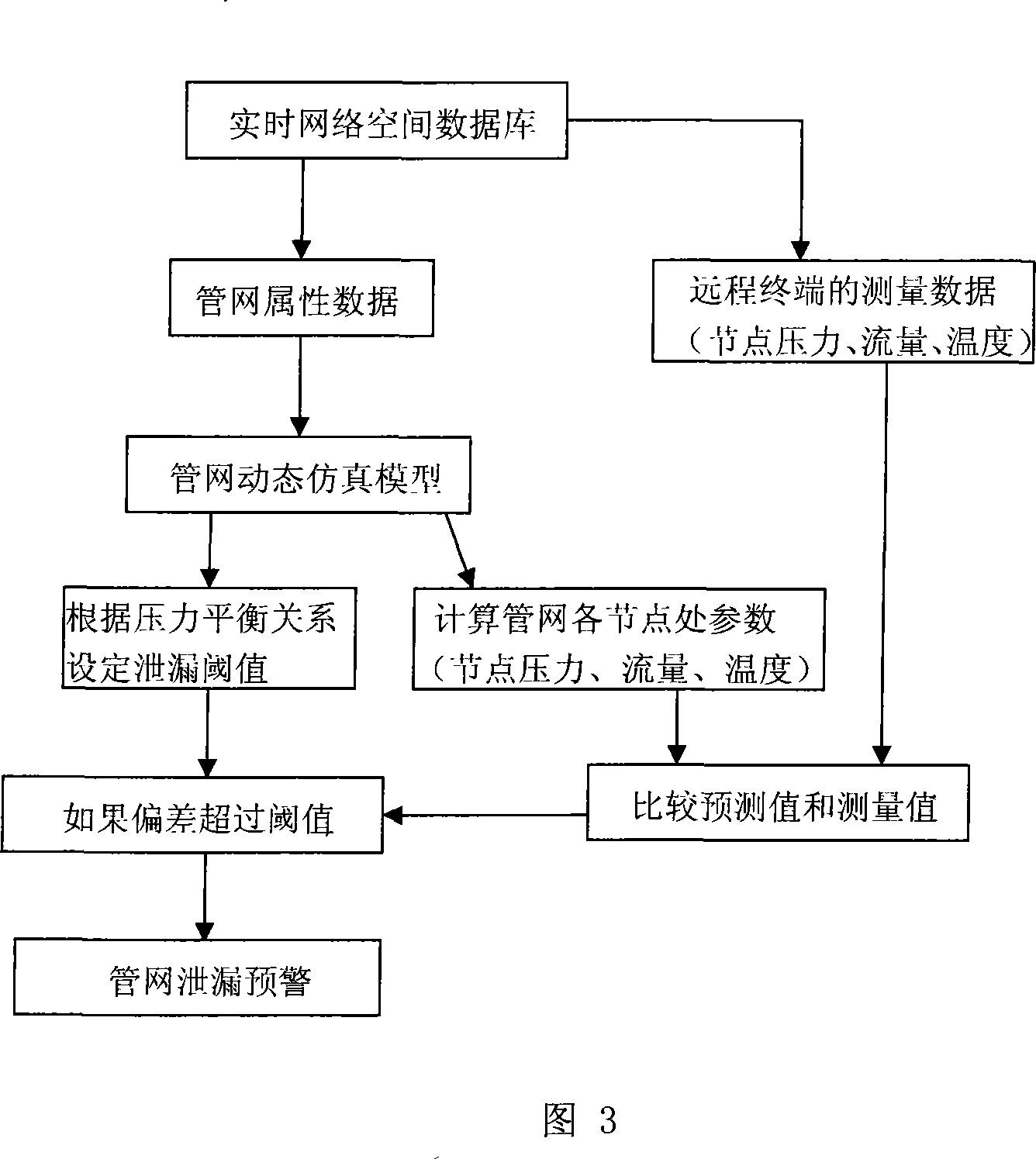

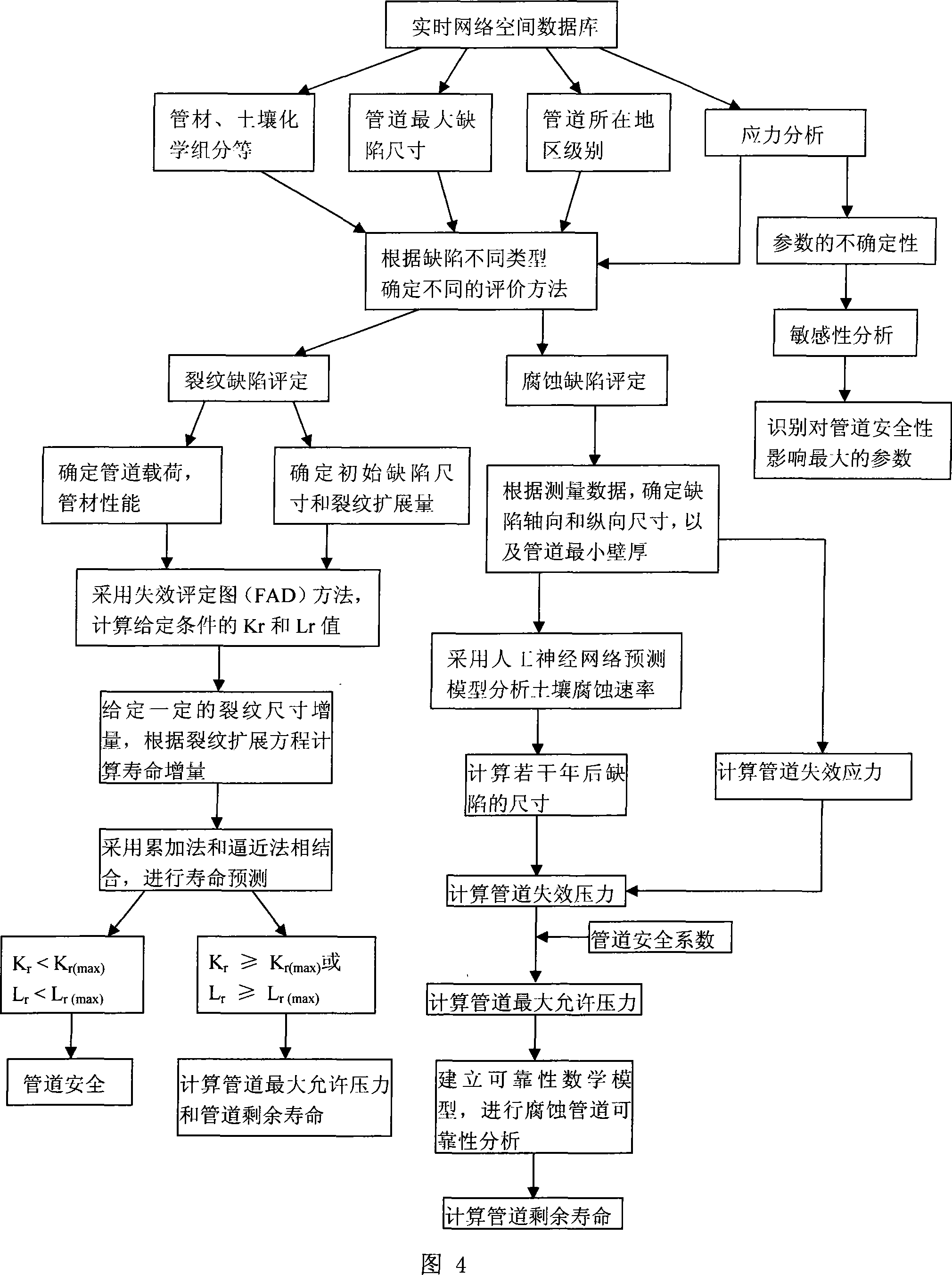

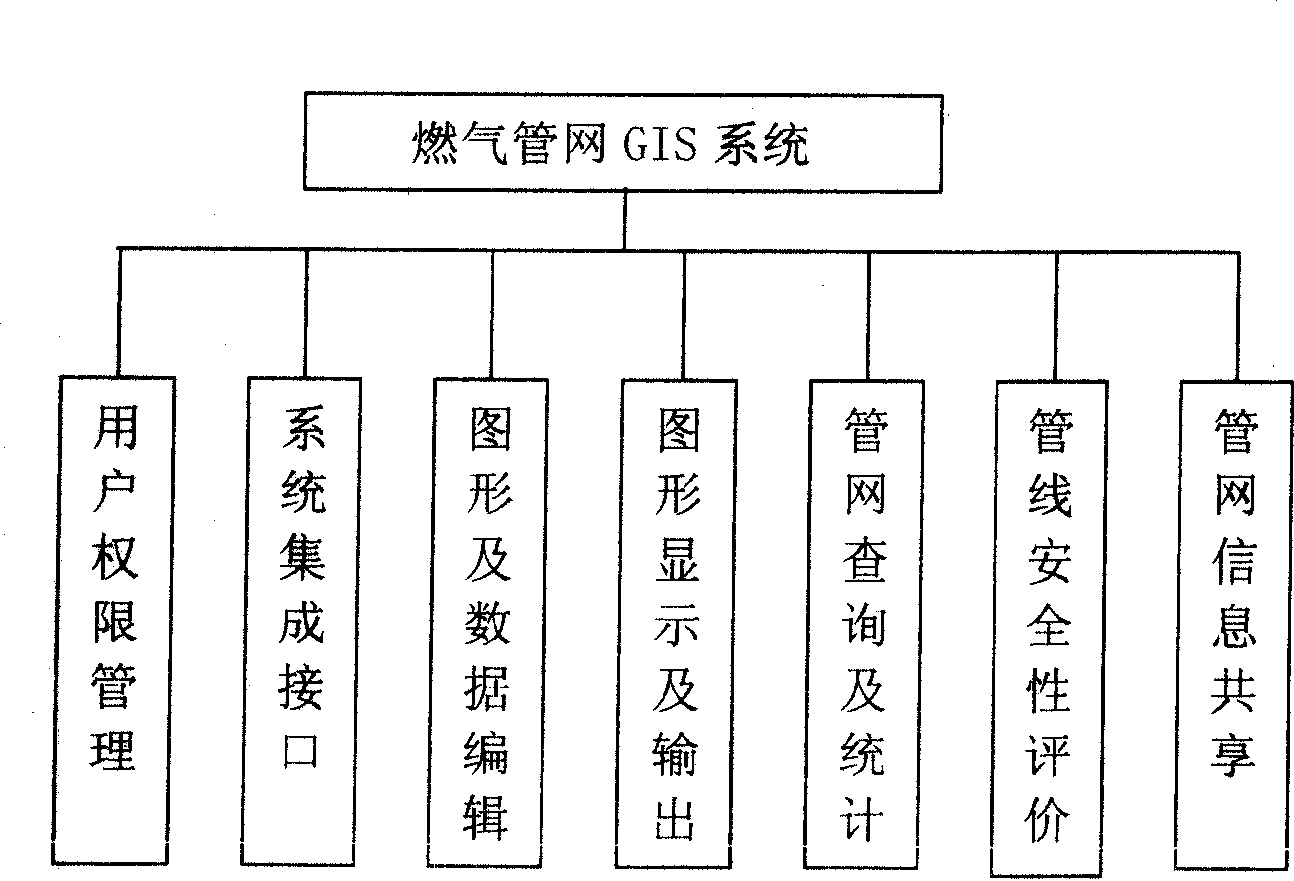

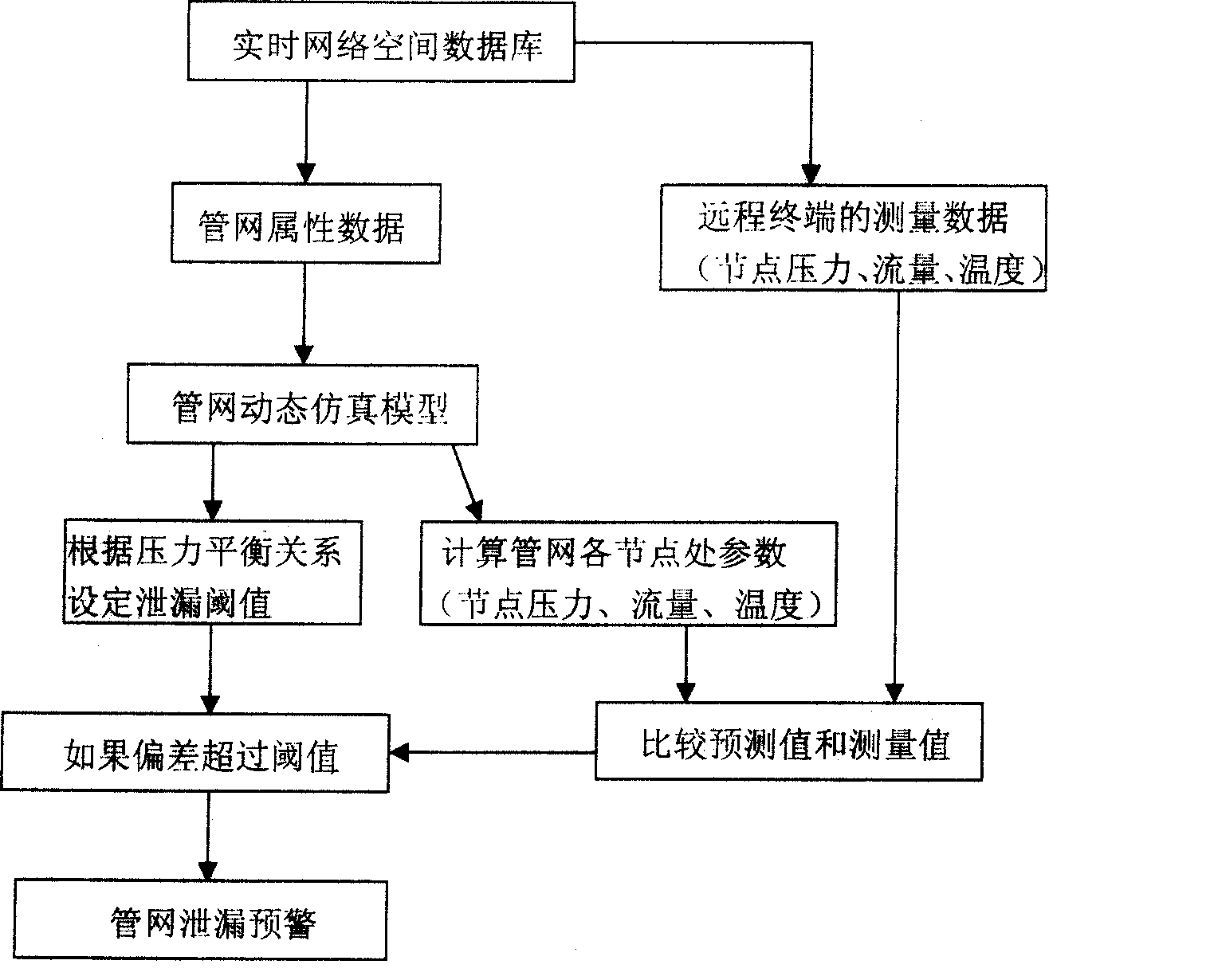

Gas pipe network accidents early warning method

InactiveCN101183249AAvoid major accidentsFlexible module configurationProgramme controlComputer controlFailure assessmentWorking pressure

The present invention belongs to the field of an automatic monitoring technology for city gas network, which relates to a warning method for gas network accident. The present invention comprises steps as follows: a gas network geographic information system is established; a gas network diagram which is drawn is read; a gas network attributing data and a spatial geographical data are read; the maximum allowable working pressure and the residual life time for the pipeline, including fault, are predicted by adopting the methods based on an invalid evaluation drawing and an artificial neural network; the real-time collection and automatic monitoring system of the gas network data is established; dynamic data, including the pressure of all pipeline nodes are collected real-timely; a dynamic or static alarming mechanism which real-timely monitors whether the pipeline in service leaks, operating pressure and service life is established. The gas network accident warning method provided by the present invention can effectively prevent serious gas accidents.

Owner:TIANJIN UNIV

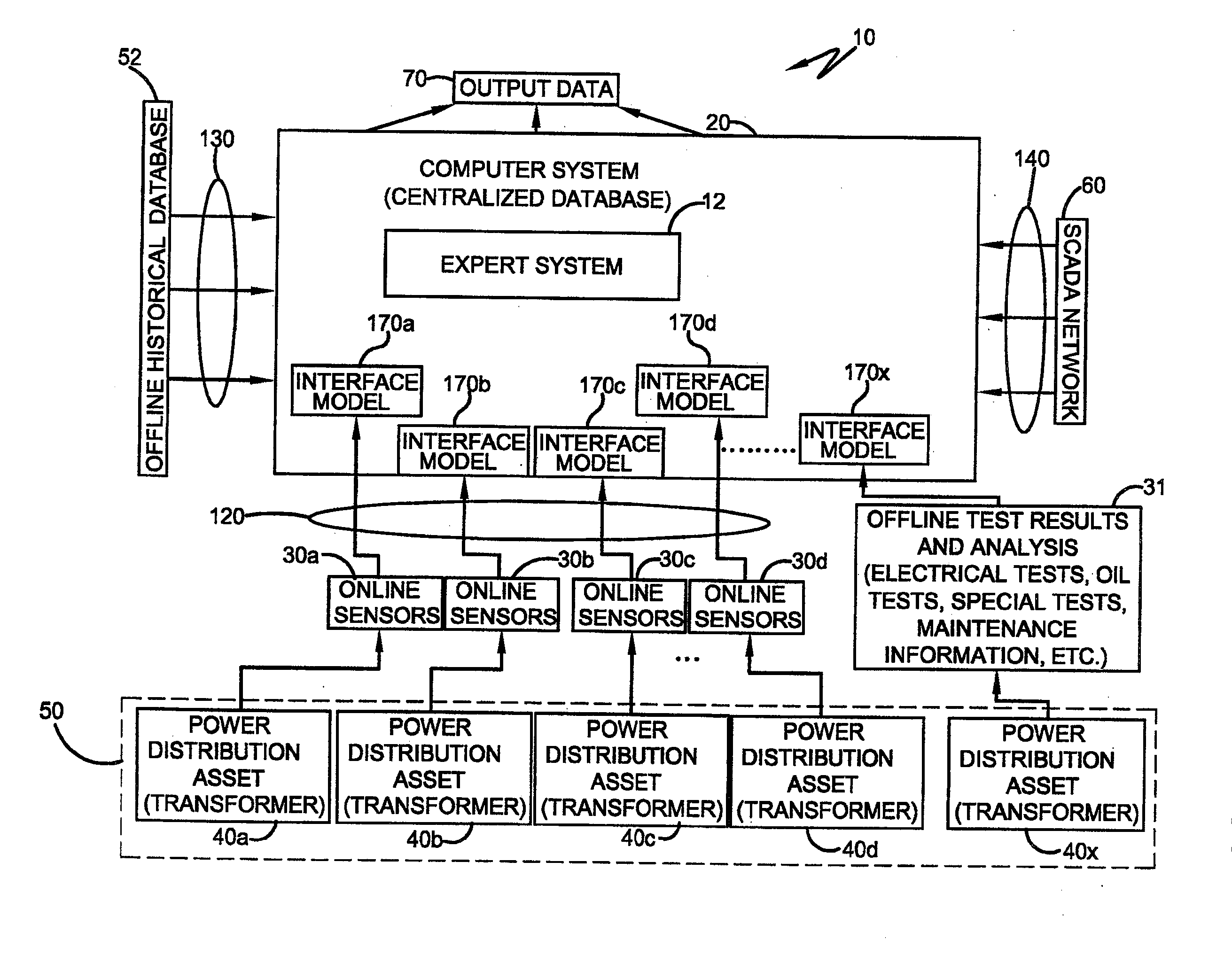

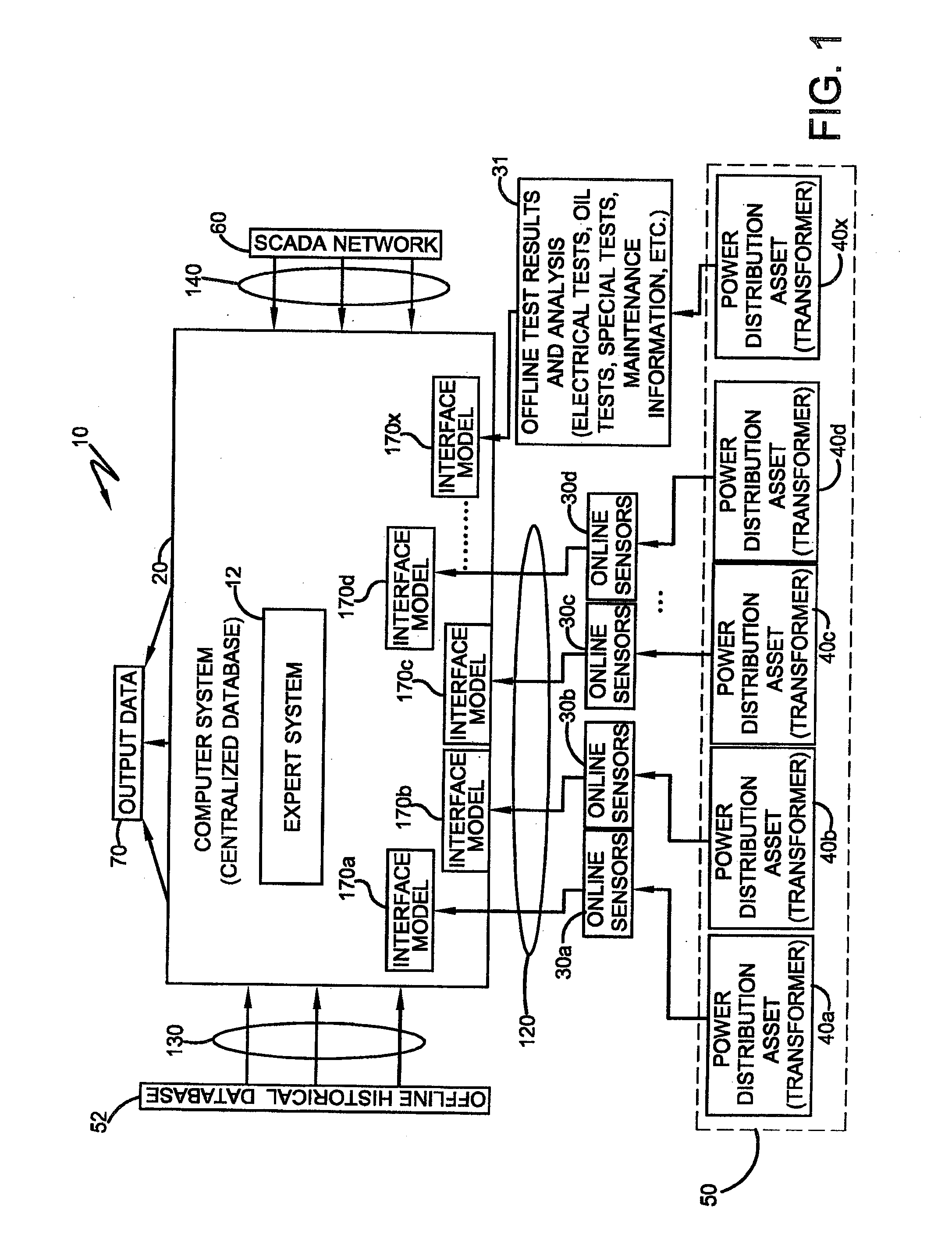

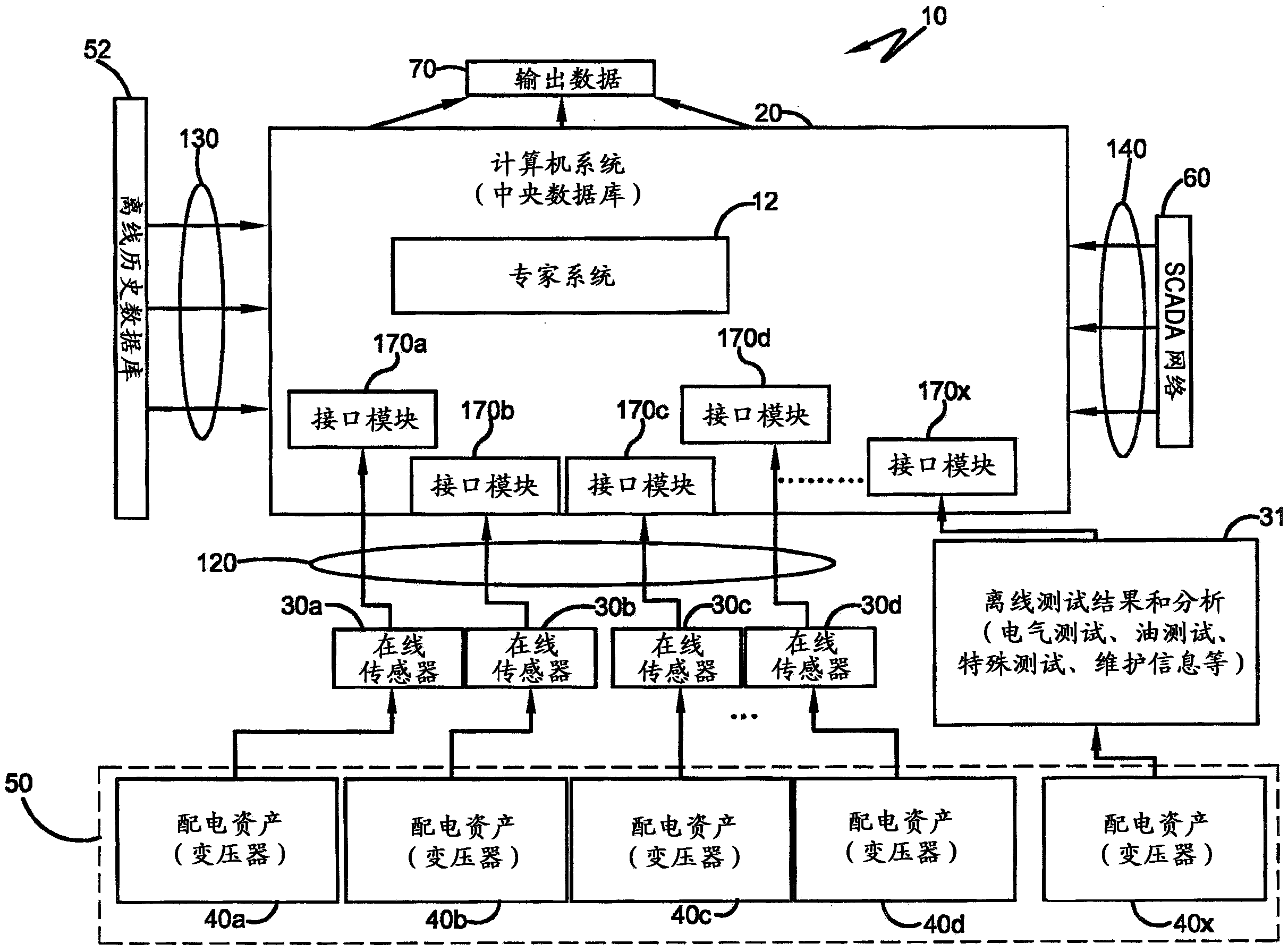

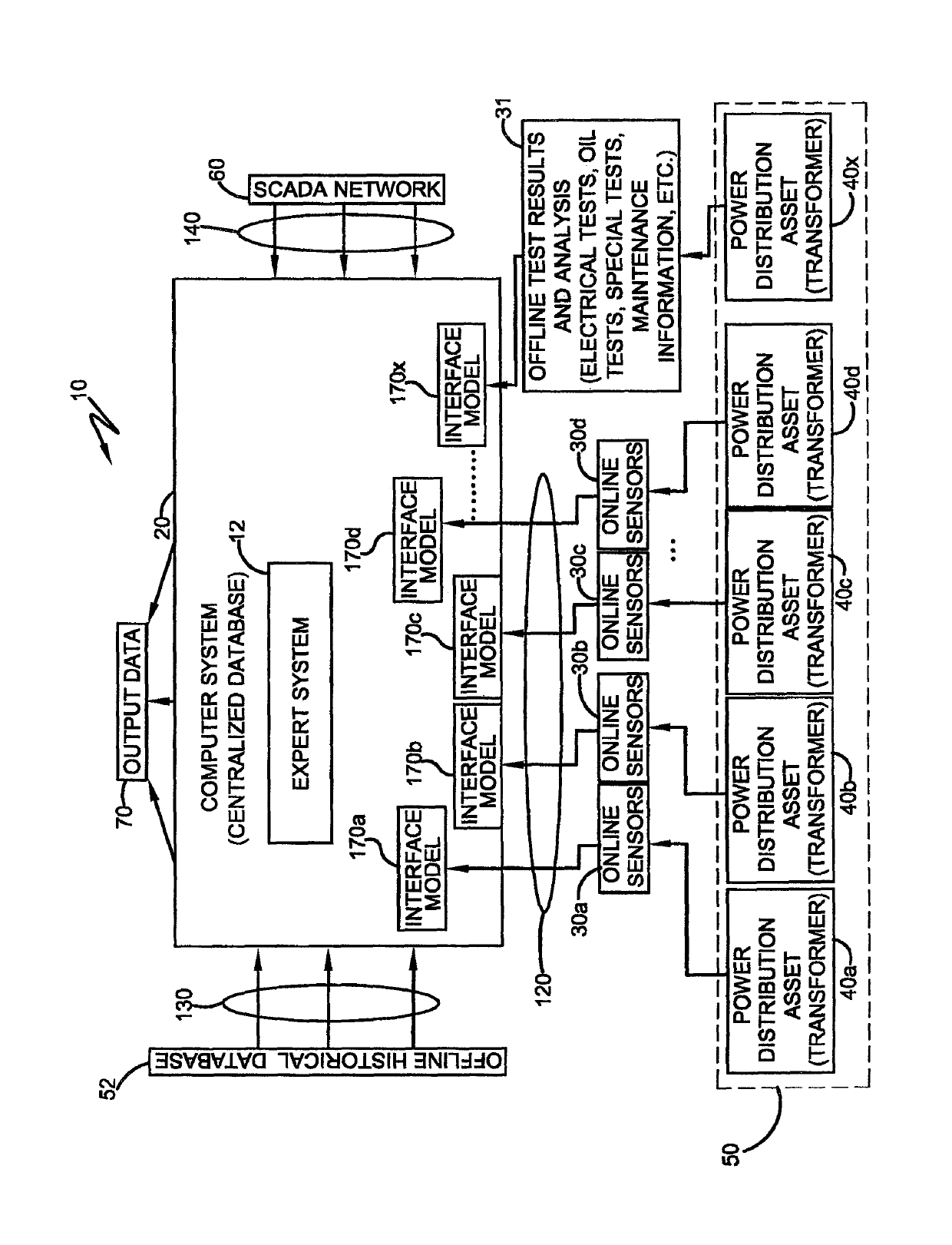

Dynamic assessment system for high-voltage electrical components

A dynamic assessment system for monitoring high-voltage electrical components, which includes a computer system that is configured to receive data from a plurality of on-line sensors configured to monitor various operating parameters associated with the operation of a plurality of electrical components such as a plurality of electrical transformers. The computer system is configured to automatically and continuously correlate the data from the on-line sensors with data from various off-line databases and supervisory networks associated with monitoring the operation of the power distribution network, so as to generate dynamic operating condition assessments, including risk of failure assessments, of each of the monitored electrical components.

Owner:HITACHI ENERGY SWITZERLAND AG

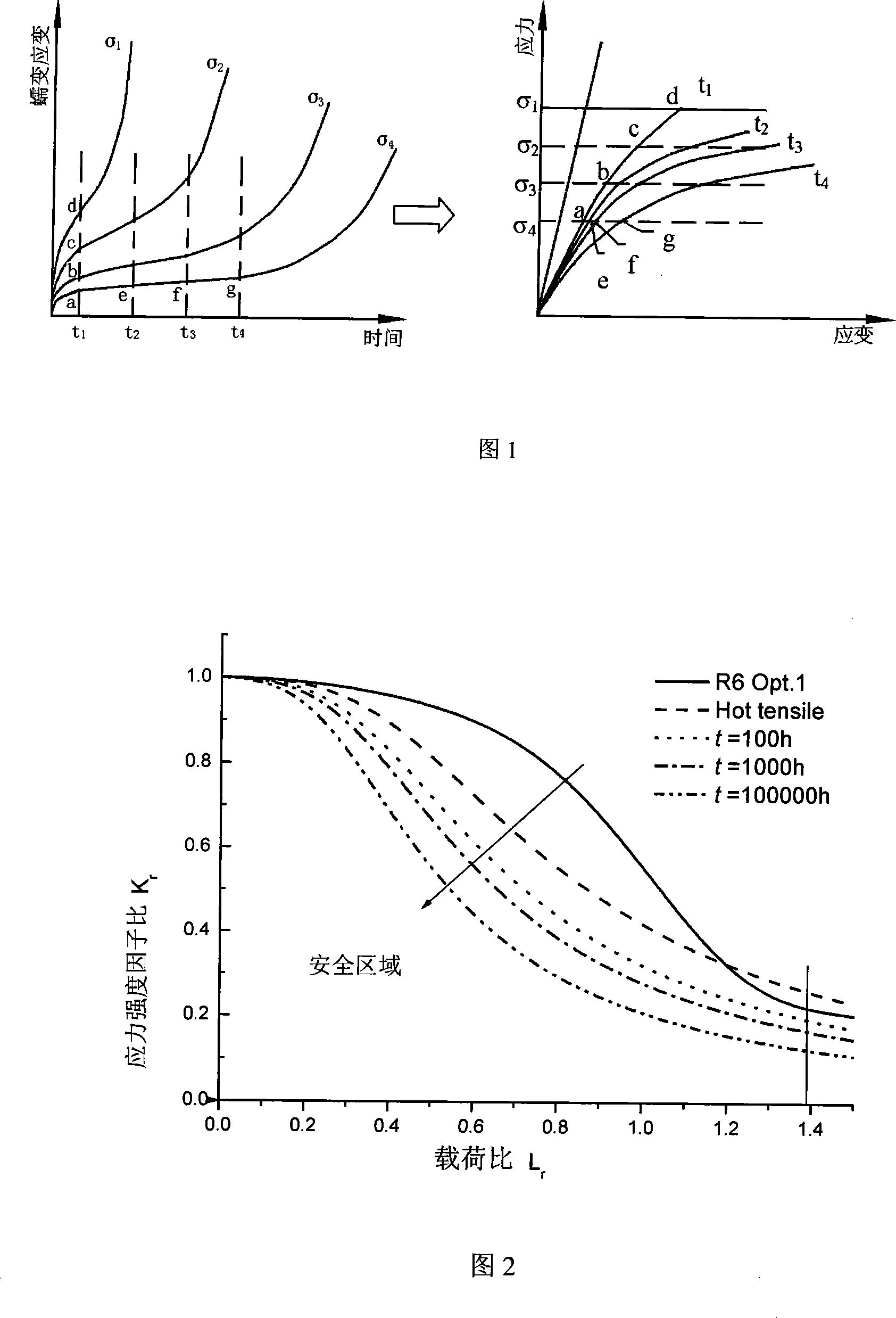

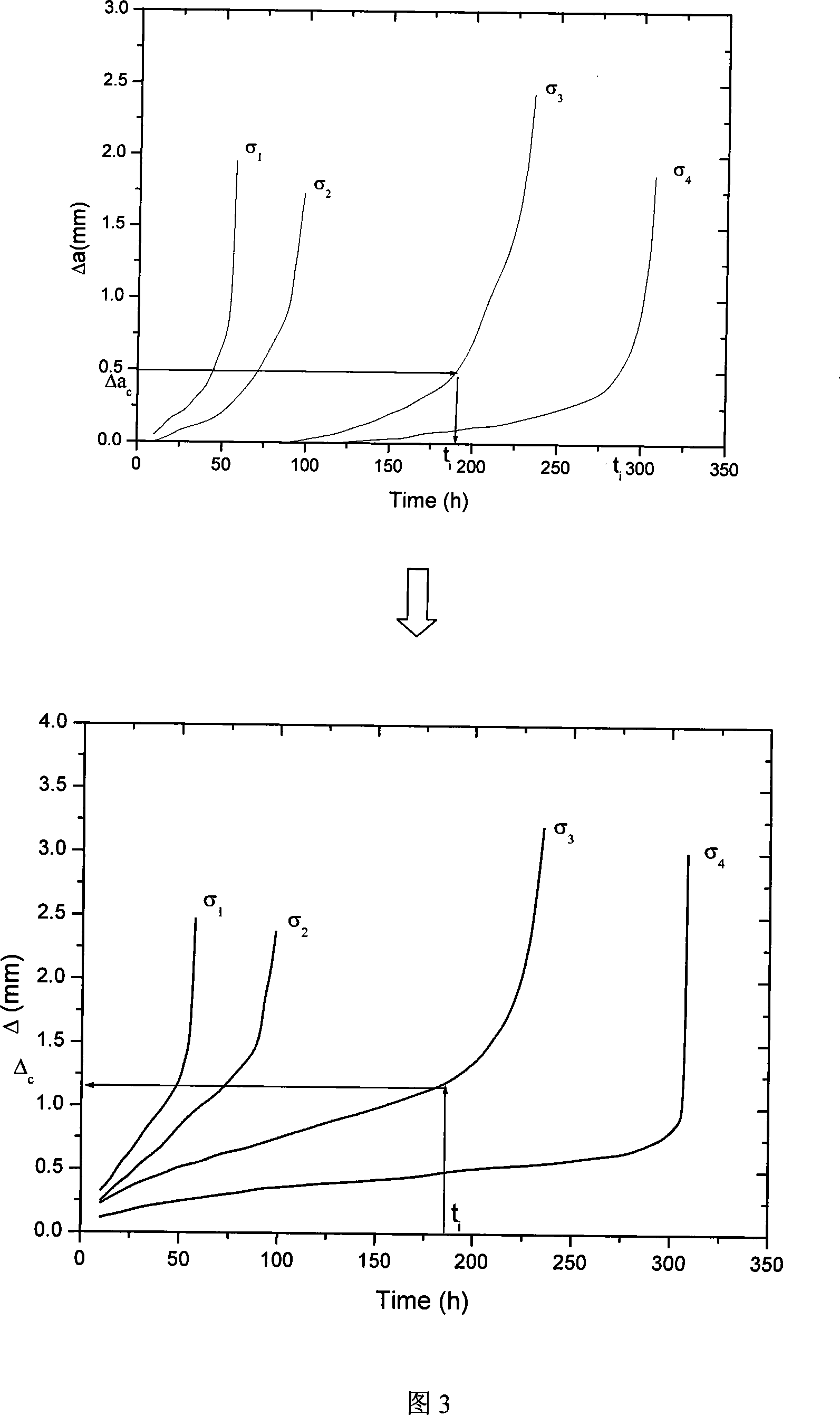

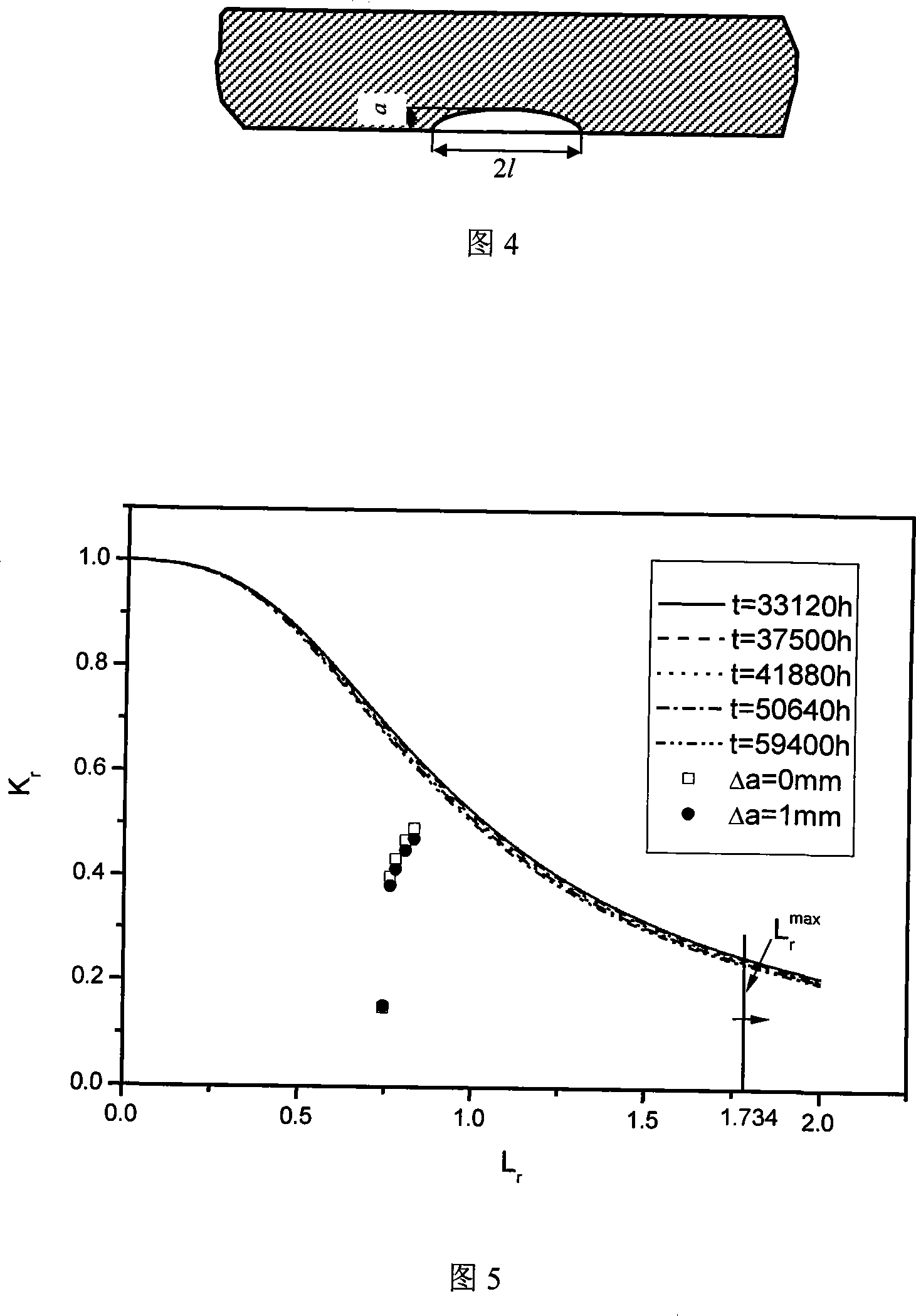

Safety evaluation method of high-temperature production facility or component defect

InactiveCN101178590AReasonable reflectionLow professional knowledge requirementProgramme controlComputer controlFailure assessmentCreep strain

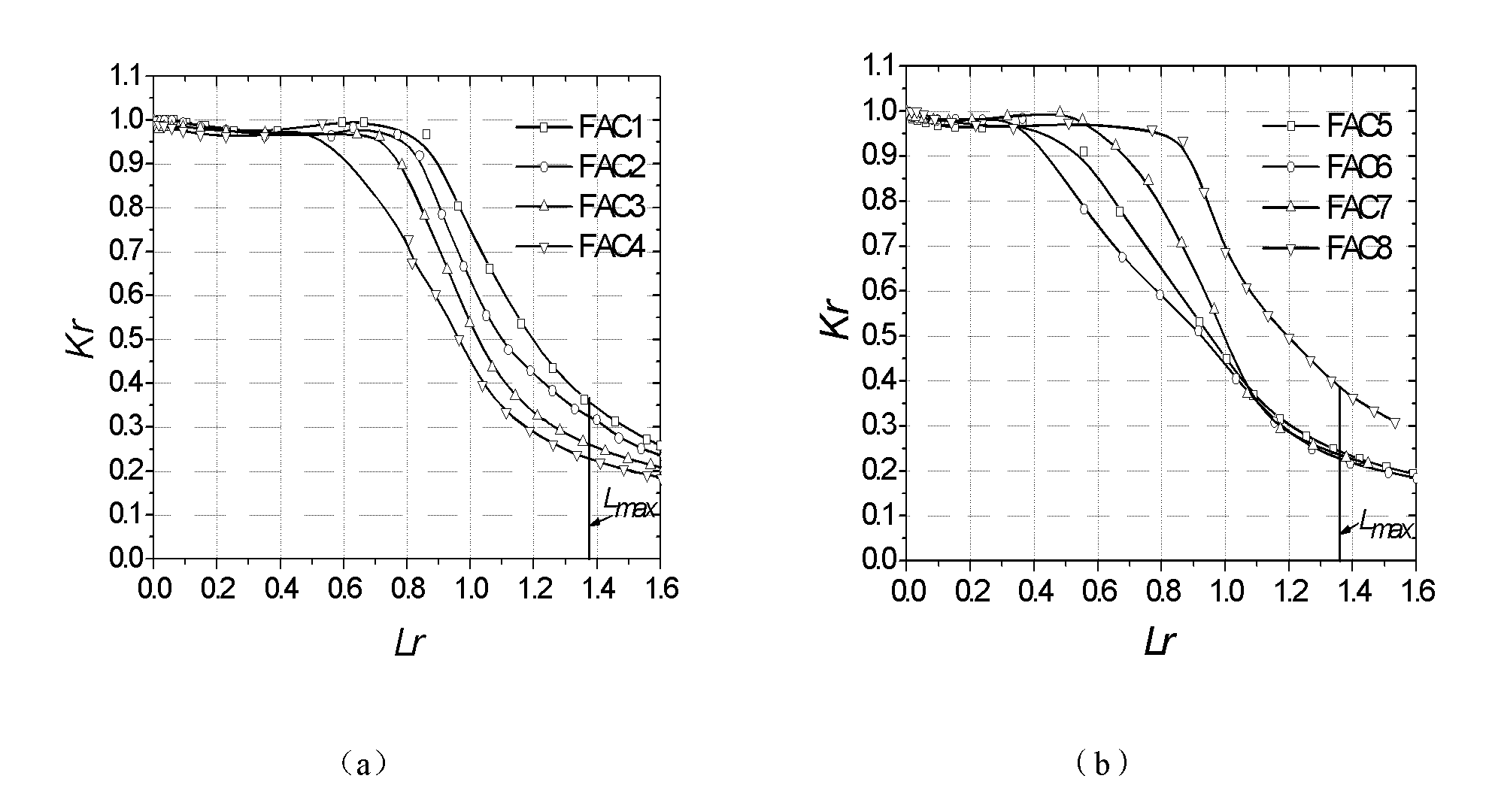

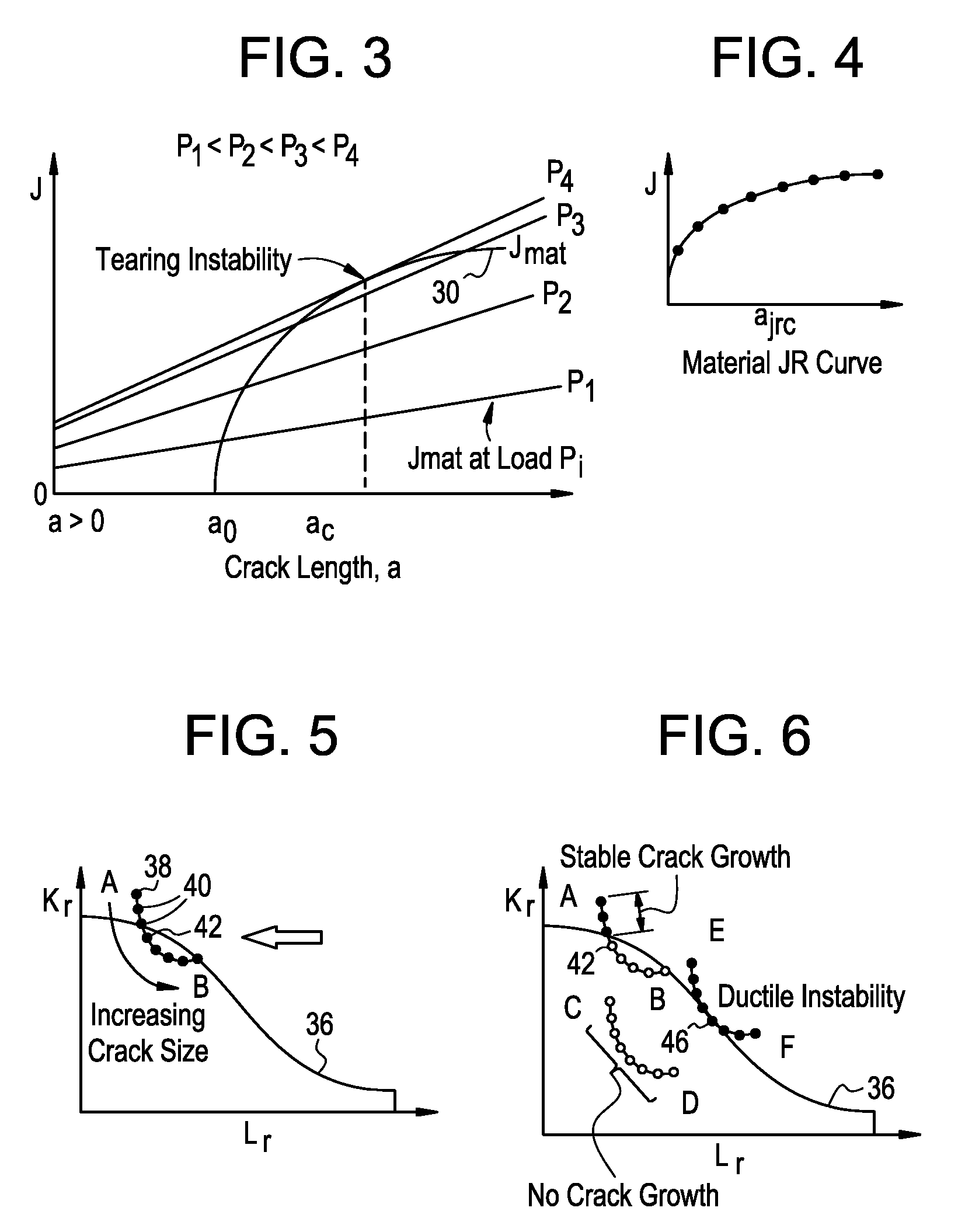

The invention discloses a safety evaluation method for the shortcomings of a high temperature production device or part, comprising the steps as follows: a creep strain-time curve of the material of the high temperature production device or part at a particular temperature is obtained, and an isochronous stress-strain curve corresponding to the particular time is established based on the creep strain-time curve; a failure assessment curve chart related to time is established; and a parameter Kr which can determine and reflect the cracking failure degree of the part and a parameter Lr which can determine and reflect the ultimate load failure degree of the part are counted; and finally the parameters(Kr and Lr) are put into the failure assessment chart as state points for comparing so as to determine the failure assessment point and judge the safety of the failure assessment point. The method can be used for analyzing the safety of the shortcomings during the production process and the use process of the high temperature production device or part, thereby avoiding unnecessary maintenance and premium, and further increasing the rationality of making maintenance plans for high temperature production devices.

Owner:EAST CHINA UNIV OF SCI & TECH

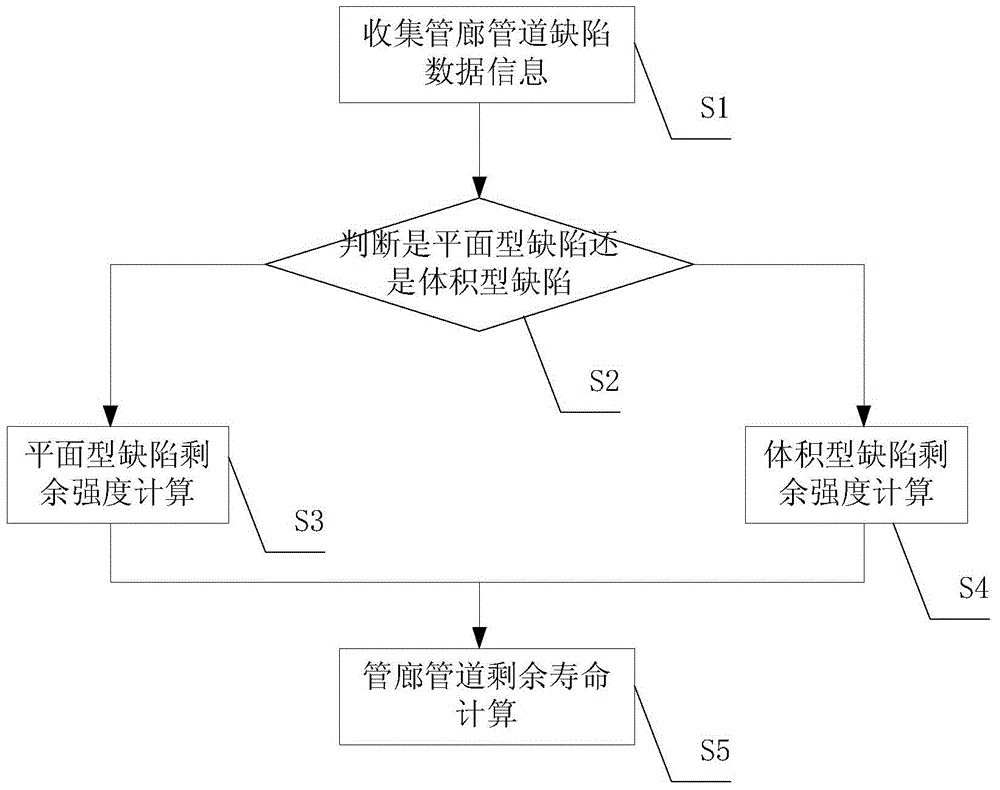

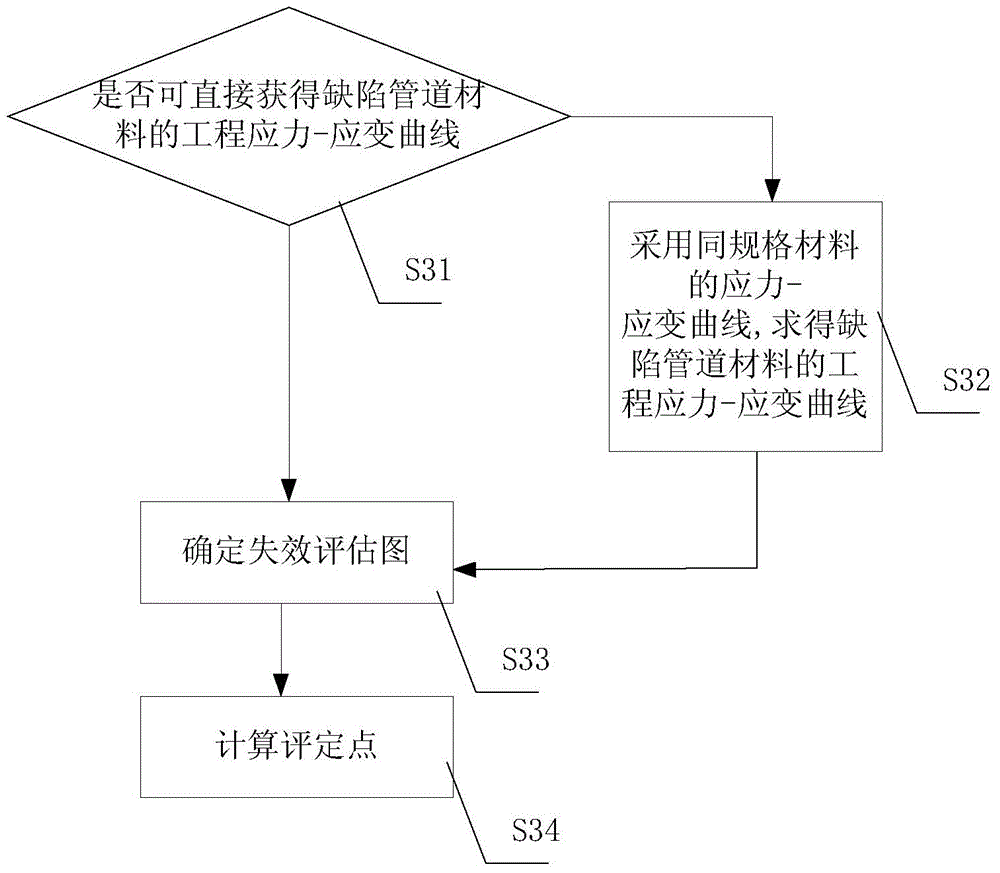

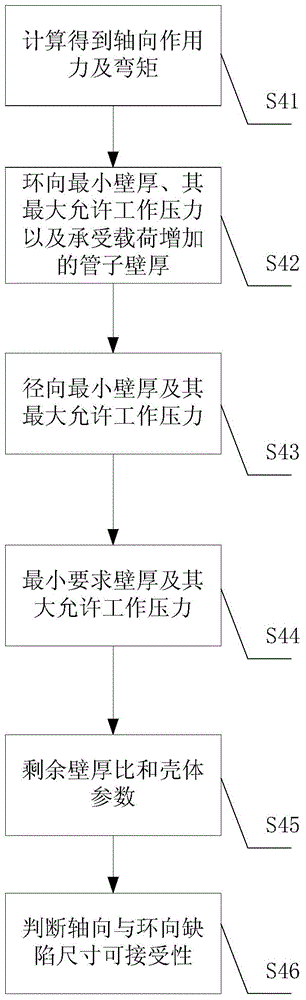

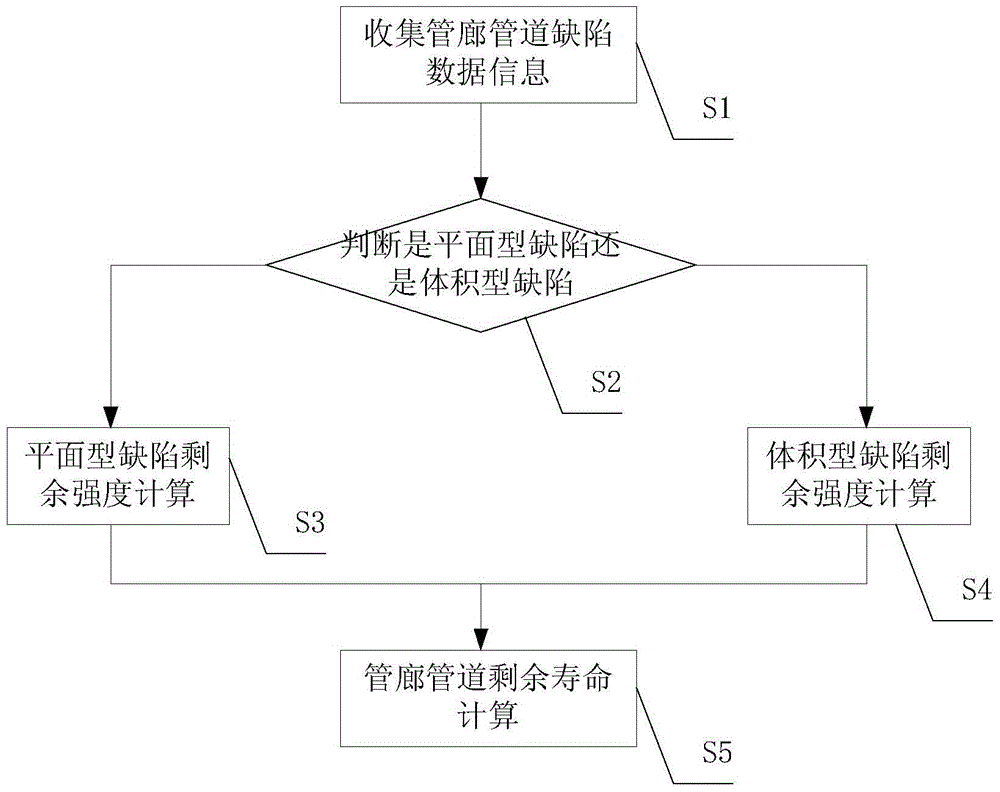

Residual intensity and residual life computing method for pipe gallery pipelines

ActiveCN104807966AGuaranteed safe operationSimple and fast operationMaterial analysisFailure assessmentNormal density

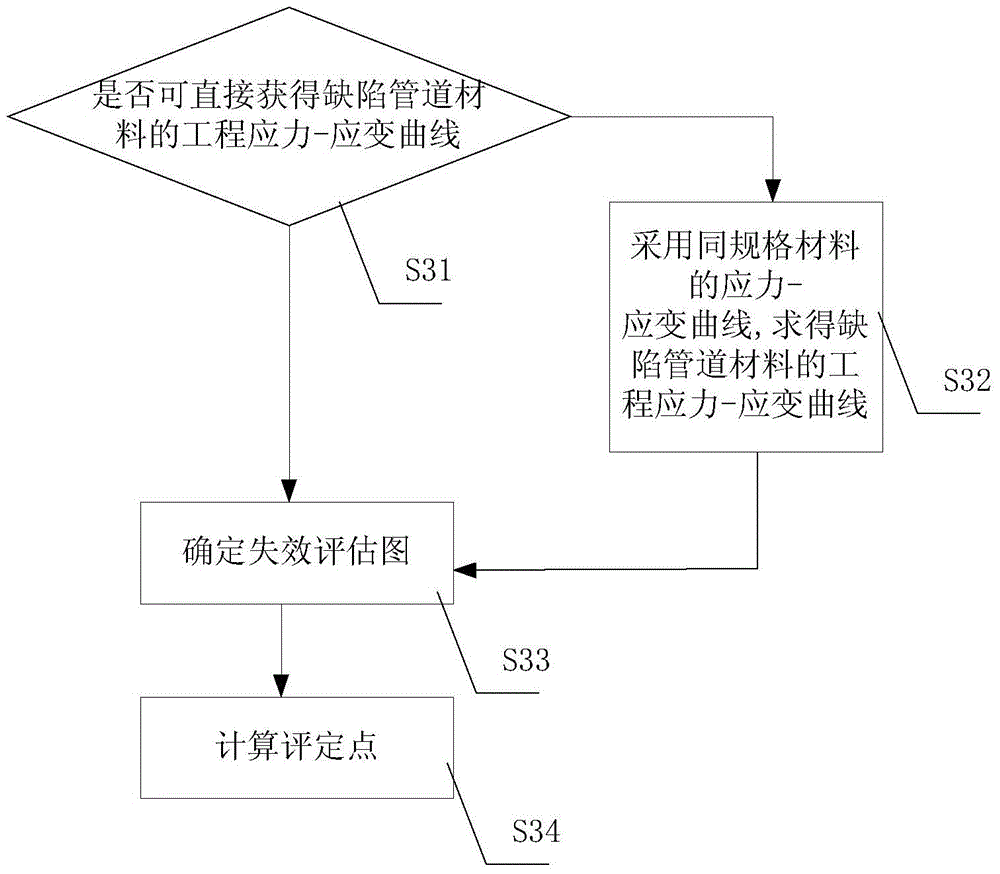

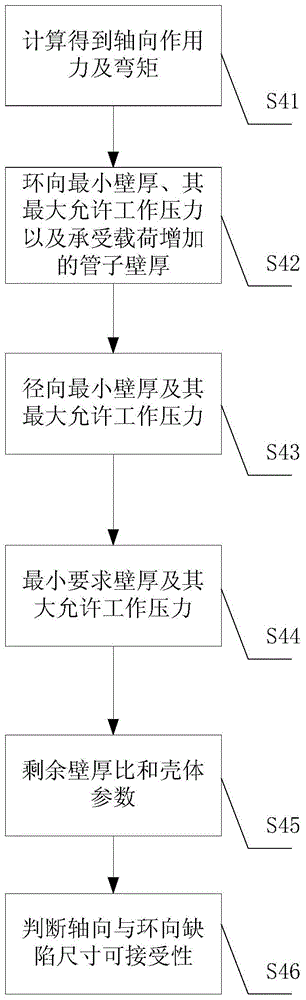

The invention discloses a residual intensity and residual life computing method for pipe gallery pipelines. The residual intensity and residual life computing method comprises the following steps: collecting the data information of defects of the pipe gallery pipelines; judging the defects are plane type defects or volume type defects; for the plane type defects, obtaining the engineering stress-strain curve of a defect pipeline material from the data information of the defects of the pipe gallery pipelines, determining a failure assessment diagram, and then computing assessment points to obtain the residual intensity of the pipe gallery pipelines; for the volume type defects, obtaining the design factors, the weld joint factors and the minimum measurement wall thickness from the data information of the defects of the pipe gallery pipelines, and obtaining the residual intensity of the pipe gallery pipelines through computing; computing basic numerical values according to the data information of the defects of the pipe gallery pipelines, and computing the residual lives of the pipe gallery pipelines according to a maximum value distribution probability density function, a reliability function, maximum corrosion depth point estimation and maximum likelihood estimation. Therefore, the residual intensity and residual lives of the pipelines in a pipe gallery area are effectively and accurately computed and predicted.

Owner:SHANGHAI CHEM IND PARK PUBLIC PIPE RACK

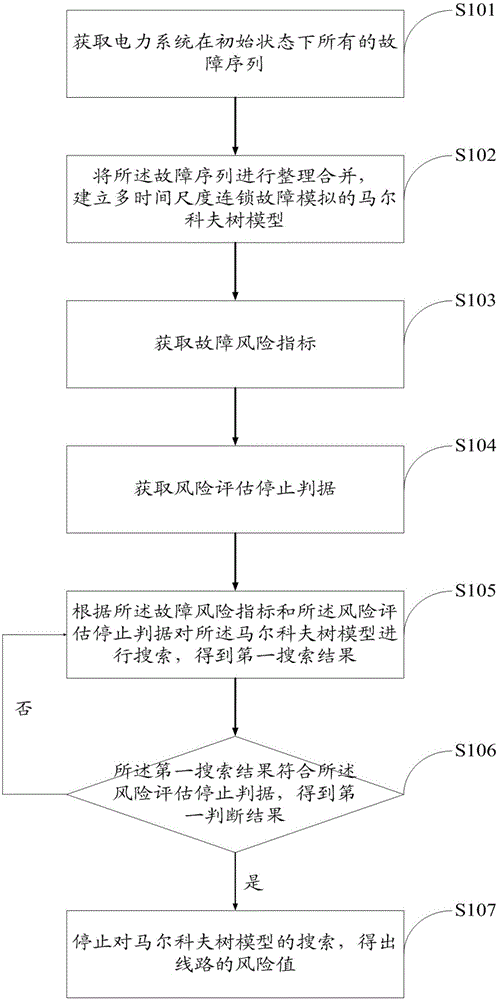

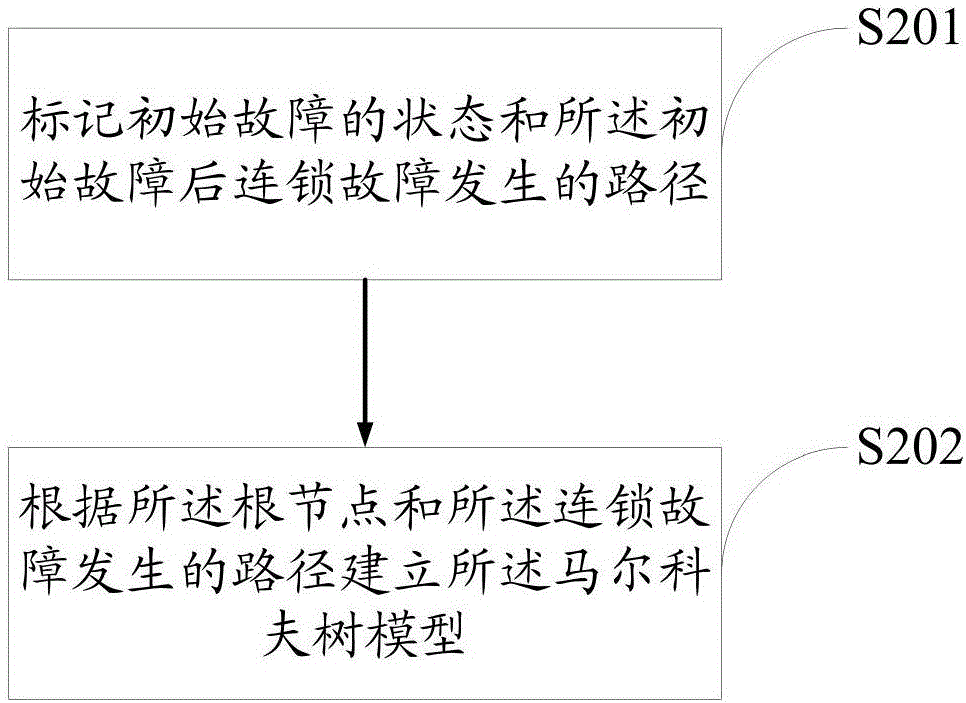

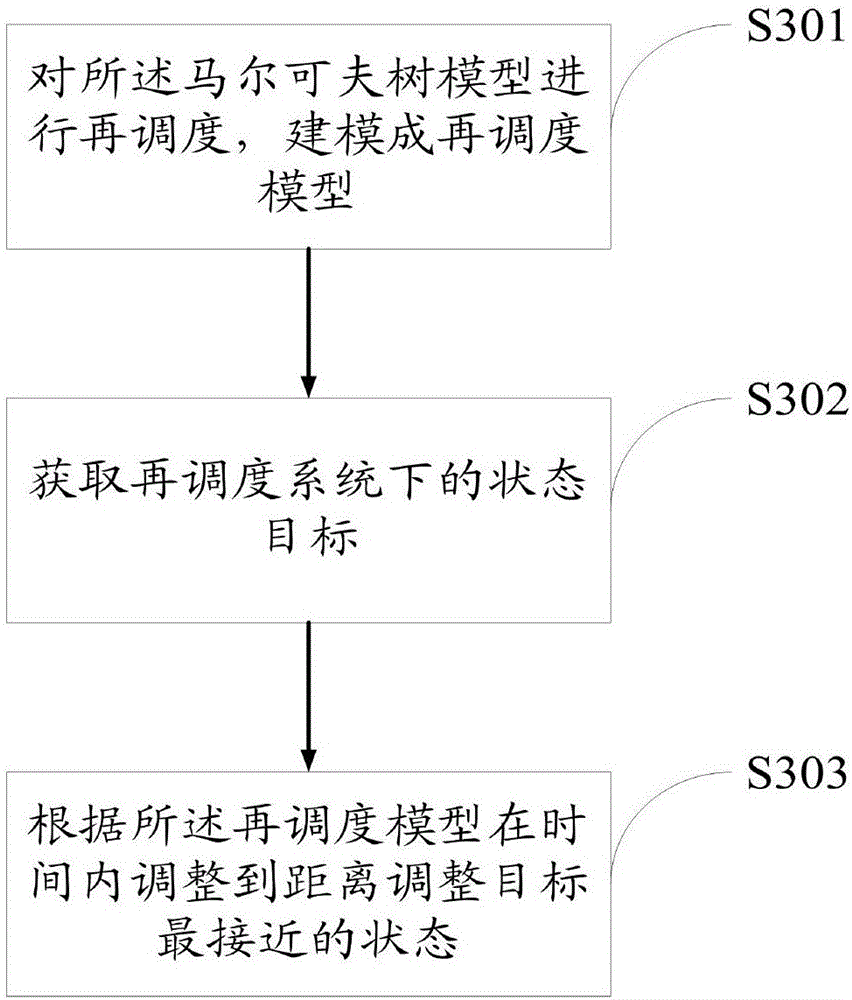

Power system cascading failure risk assessment method and power system cascading failure risk assessment system

The invention discloses a power system cascading failure risk assessment method and a power system cascading failure risk assessment system. The method comprises the following steps: acquiring all failure sequences of a power system in an initial state; sorting and combining all the failure sequences, and building a Markov tree model of multi-time-scale cascading failure simulation; acquiring failure risk indicators; acquiring a risk assessment stop criterion; searching for the Markov tree model according to the failure risk indicators and the risk assessment stop criterion to get a first search result; judging whether the first search result is in accordance with the risk assessment stop criterion to get a first judgment result; and when the first judgment result indicates that the first search result is in accordance with the risk assessment stop criterion, stopping searching for the Markov tree model, and getting the risk value of a line. By using the risk assessment method and the risk assessment system, maximum coverage of the possible development path space of cascading failure can be realized under the condition of limited computing resources, and therefore, the computation efficiency is improved significantly.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

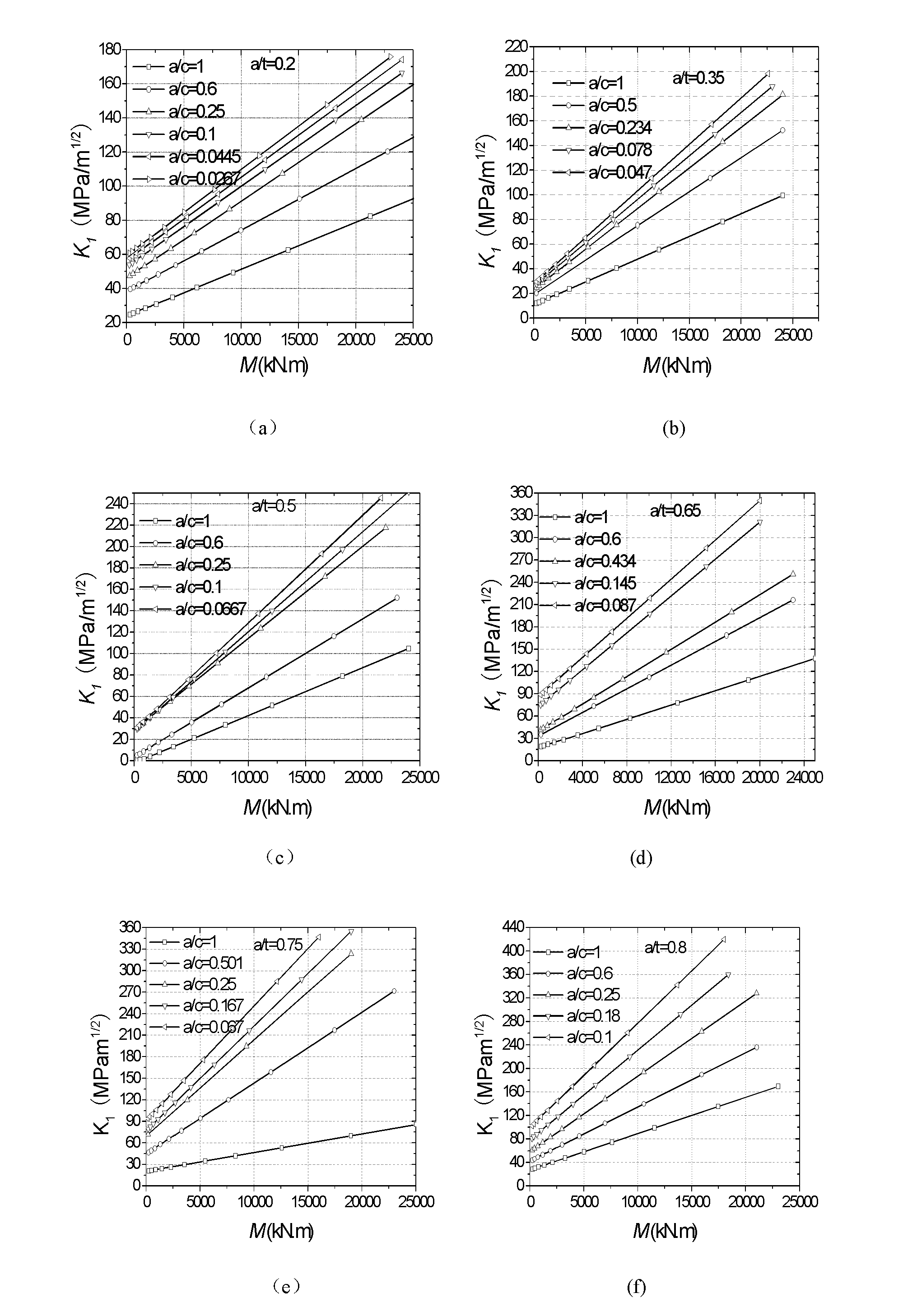

High-level assessment method for defects of welding joint area at piping safety end of pressure vessel of AP1000 nuclear reactor

ActiveCN102157211ASimplify Advanced AssessmentNuclear energy generationNuclear monitoringFailure assessmentUltimate load

The invention relates to a high-level assessment method for defects of a welding joint area at a piping safety end of a pressure vessel of an AP1000 nuclear reactor. The method comprises the following steps of: characterizing the detected dimensions of unpenetrated circumferential inner surface defects; establishing a failure assessment graph, wherein the failure assessment graph comprises the family of the failure assessment curves of the unpenetrated circumferential inner surface defects in the different dimensions, which are acquired on the basis of three-dimensional finite element calculation; selecting the failure assessment curves according to the dimensions of the defects; based on the three-dimensional finite element calculation, calculating the family of the curves that stress intensity factors change along an extra resultant bending moment at the deepest points of the unpenetrated circumferential inner surface defects in the different dimensions; determining the stress intensity factors according to the resultant bending moment and the dimensions of the defects; calculating a specific breaking strength parameter Kr; based on the three-dimensional finite element calculation, acquiring the family of the ultimate load bending moment curves of the unpenetrated circumferential inner surface defects in the different dimensions; determining ultimate load bending moments according to the dimensions of the defects; calculating a load ratio parameter Lr; and marking a calculated coordinate (Lr, Kr) on the failure assessment graph, and judging whether falling into an area which is encircled by the selected failure assessment curves, a vertical end line and coordinate axes or not.

Owner:EAST CHINA UNIV OF SCI & TECH

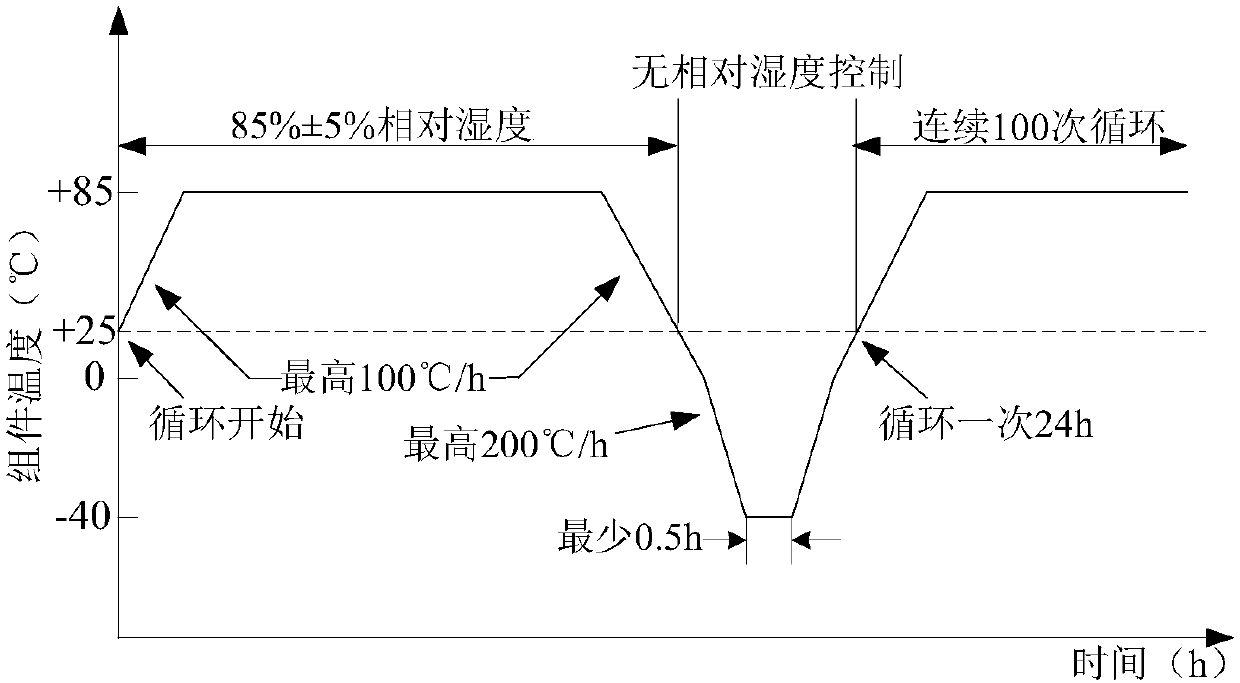

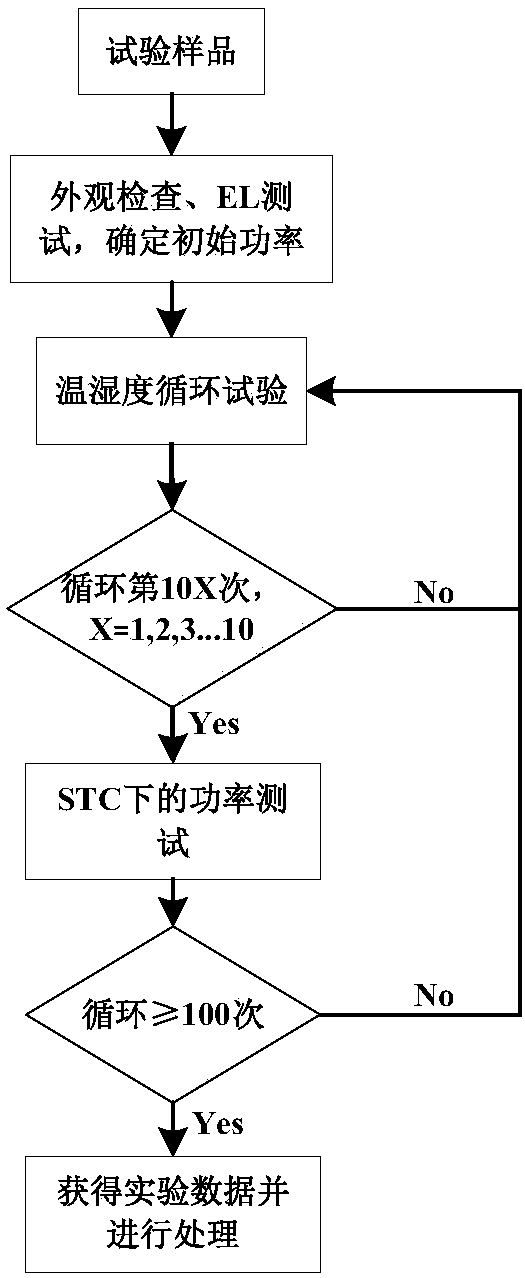

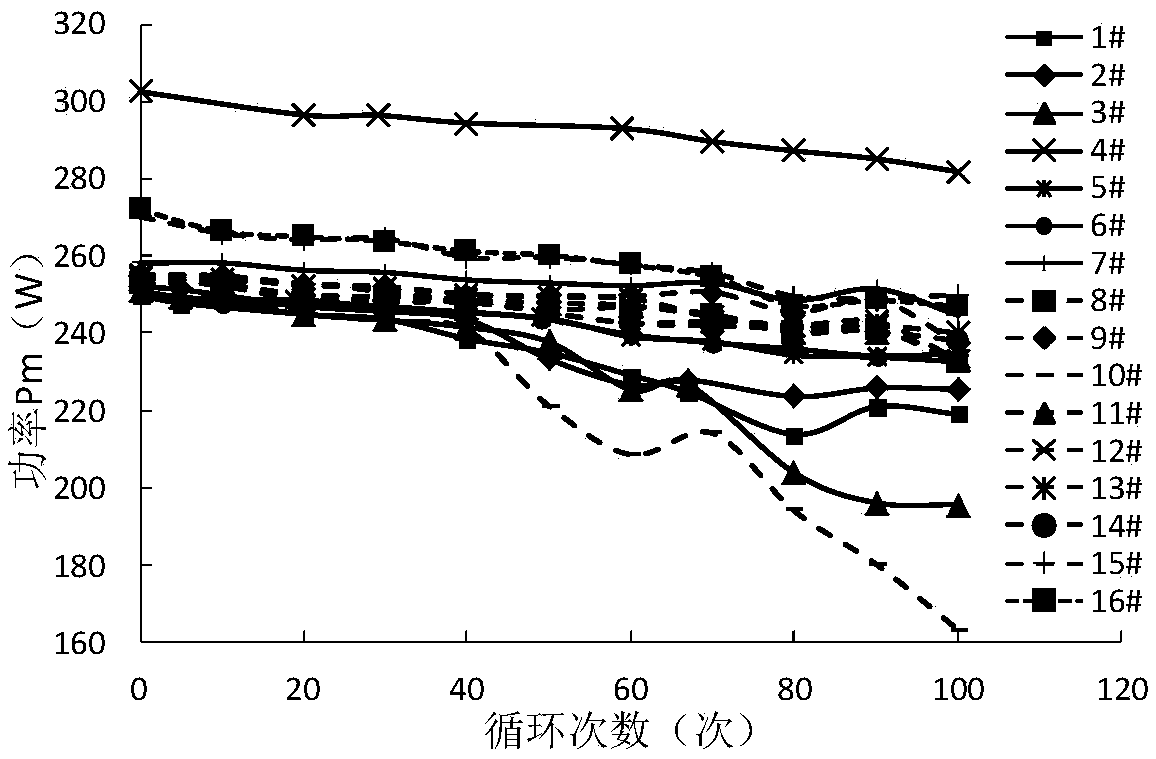

Photovoltaic module failure assessment and prediction method based on accelerated test chamber

InactiveCN107733366AChange the status quo of simple and single reliability evaluation method of accelerated testChange the simple and single status quoPhotovoltaic monitoringDesign optimisation/simulationFailure assessmentTest chamber

The invention discloses a photovoltaic module failure assessment and prediction method based on an accelerated test chamber. The failure probability of the module in different accelerated test stagesfor a prediction module can be assessed by using Weibull distribution and an obtained Weibull distribution function. The reliability of a photovoltaic module in a temperature and humidity circulationaccelerated test is assessed by using the Weibull distribution function, and the reliability of the module is assessed by using a reliability function for Weibull distribution. The current situation that the present reliability assessment method for a module accelerated test can be changed, the application of the reliability of the method for Weibull distribution in the module accelerated test andthe failure probability thereof is proposed through analysis for accelerated test data; and through the method, the failure probability of the photovoltaic module in different stages of the accelerated test can be obtained, and thus the reliability of the photovoltaic module in the accelerated test is assessed, so that certain reference significance is provided for predicting the service life ofthe photovoltaic module.

Owner:HOHAI UNIV CHANGZHOU

Method for detecting leak before rupture in a pipeline

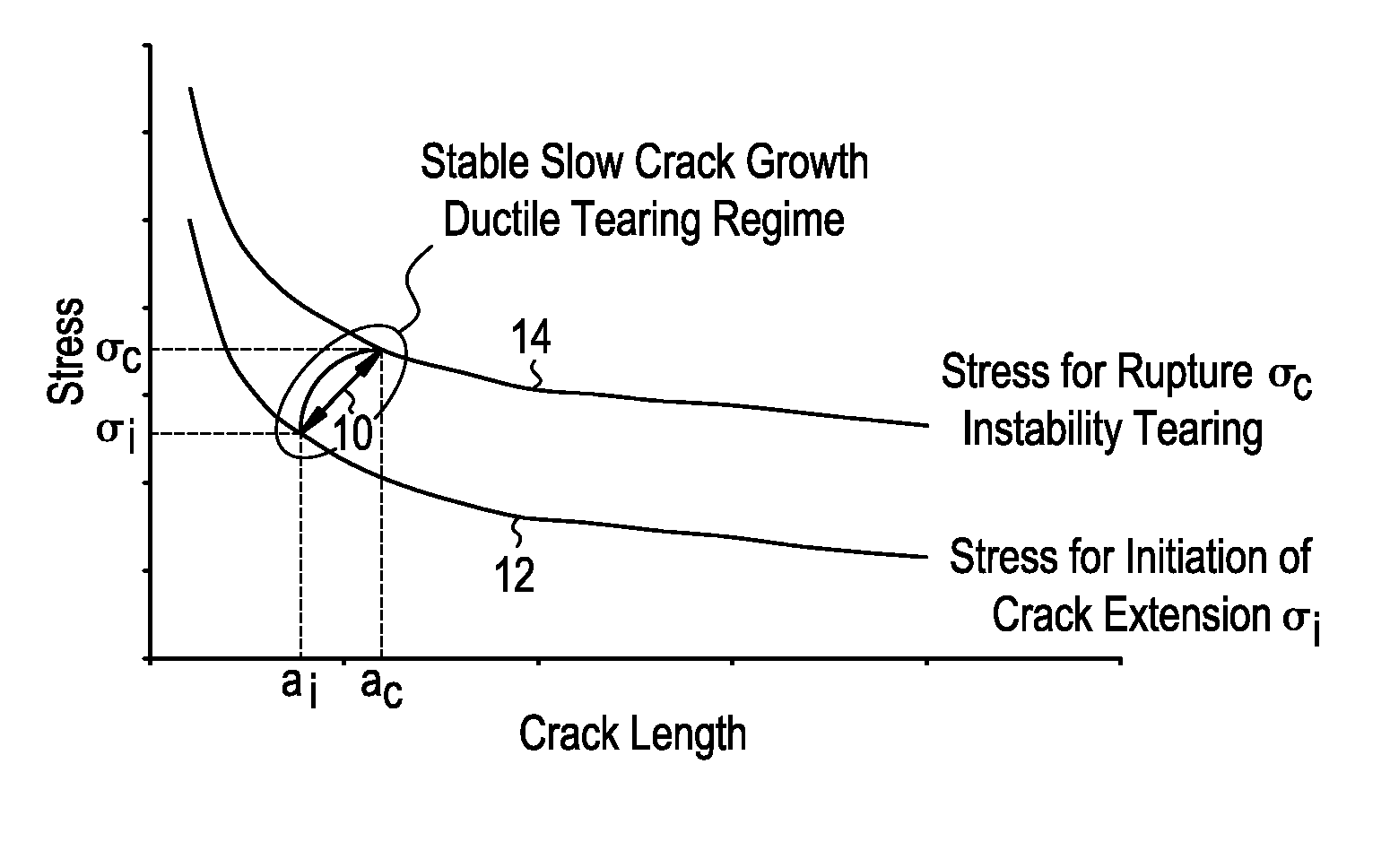

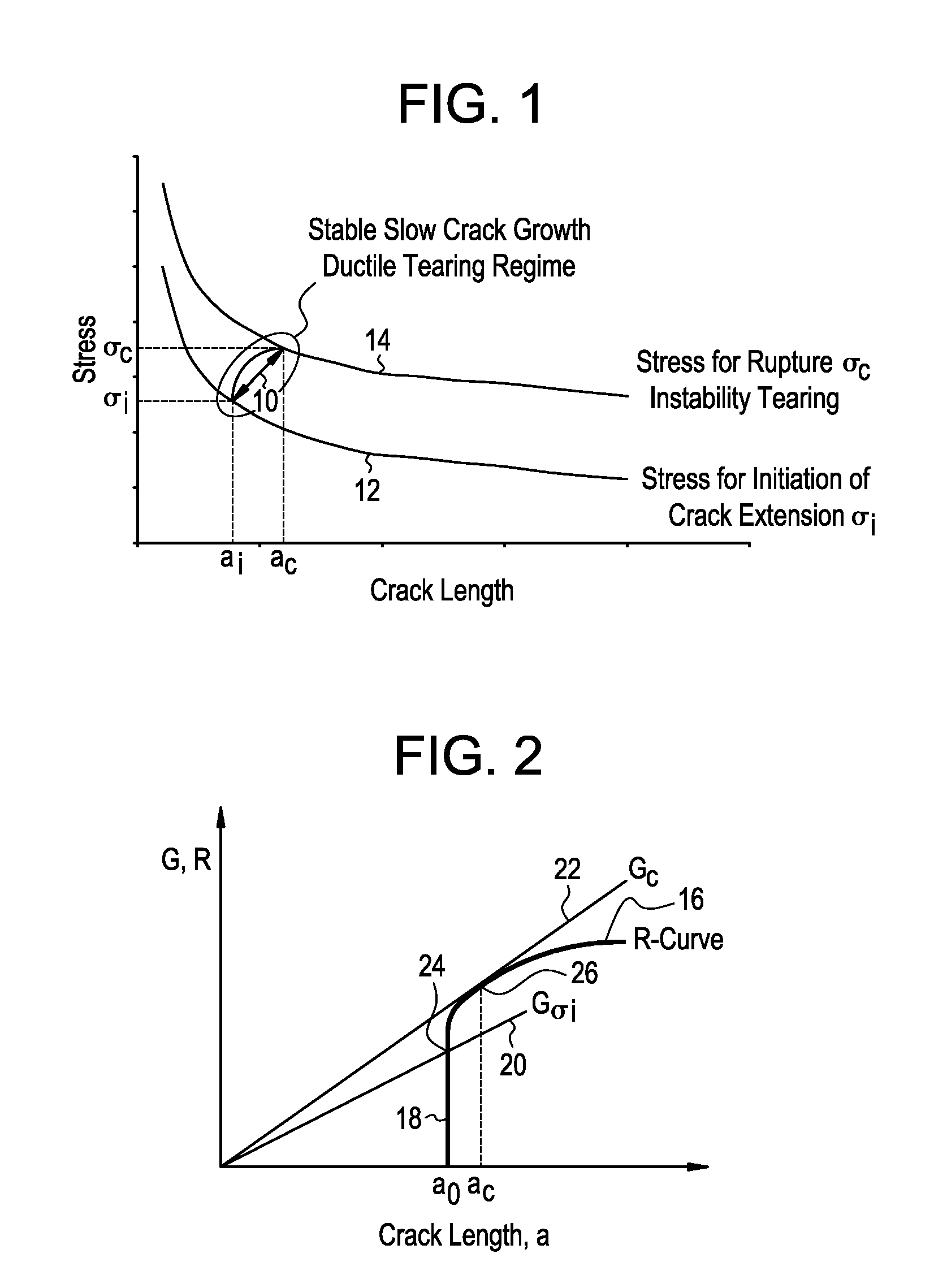

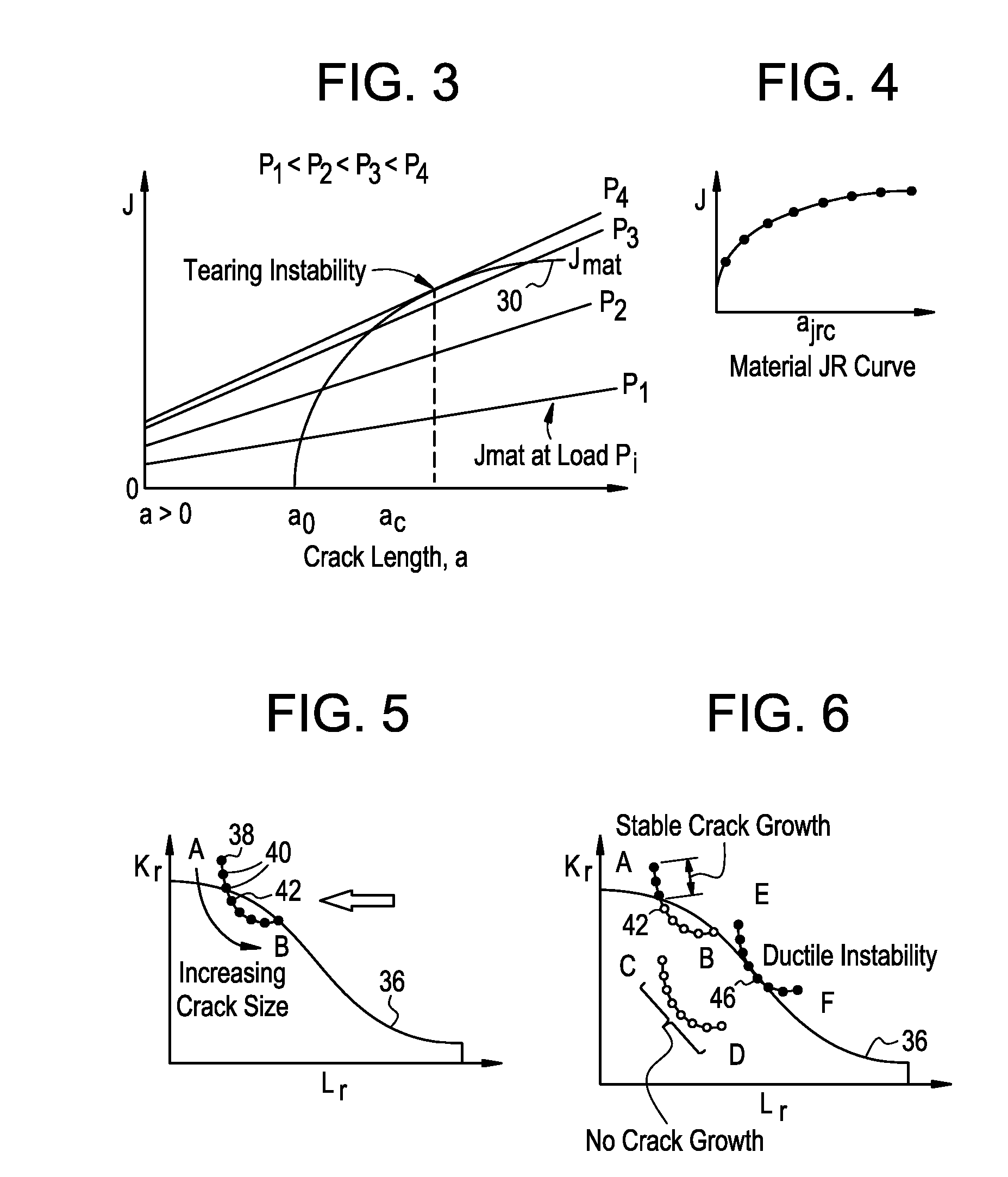

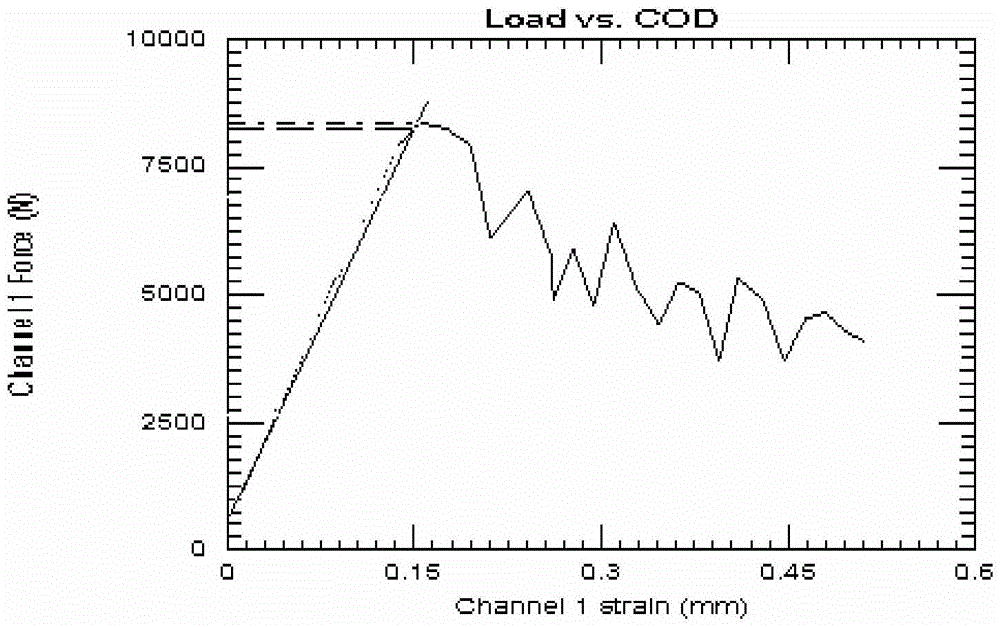

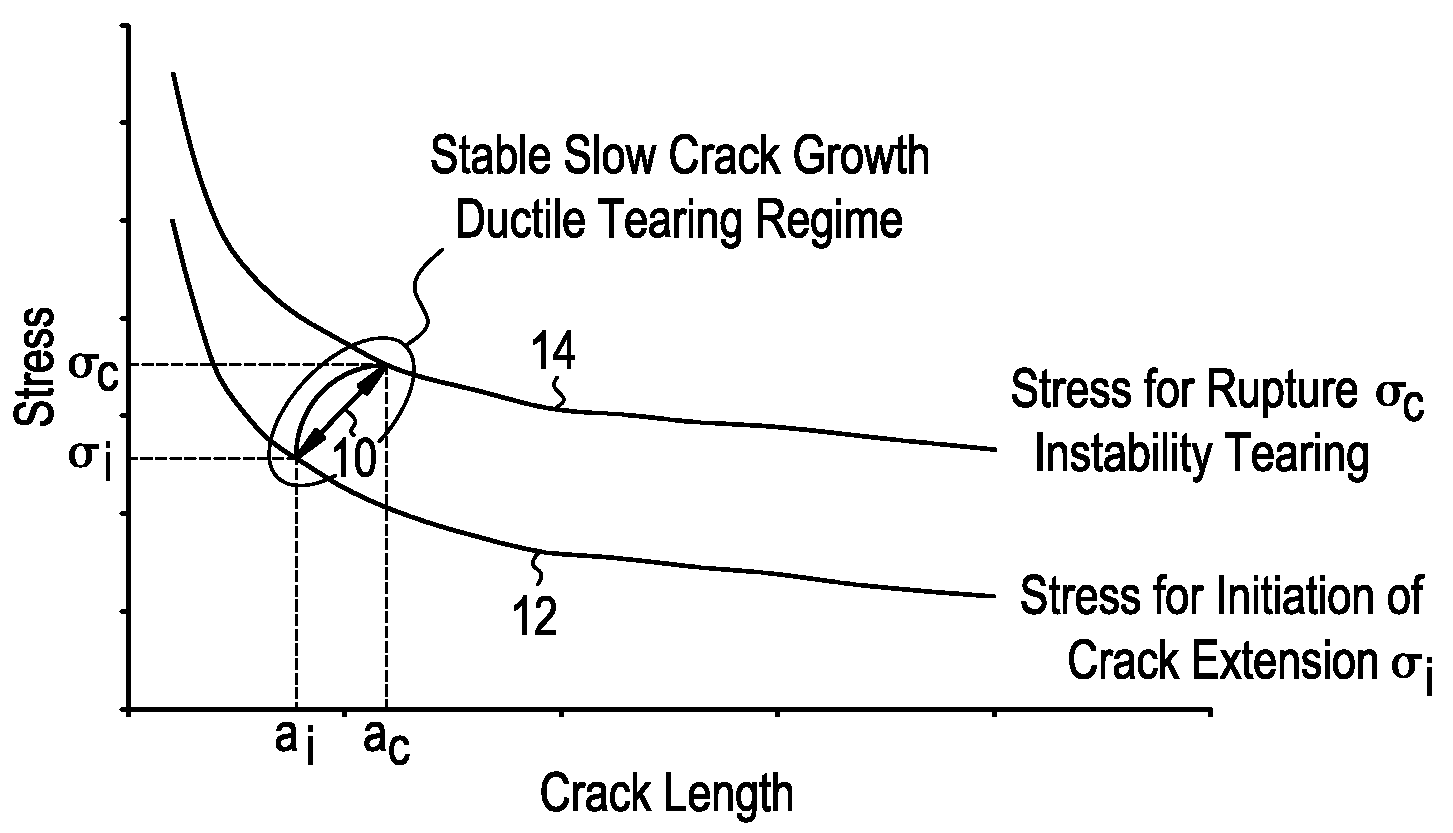

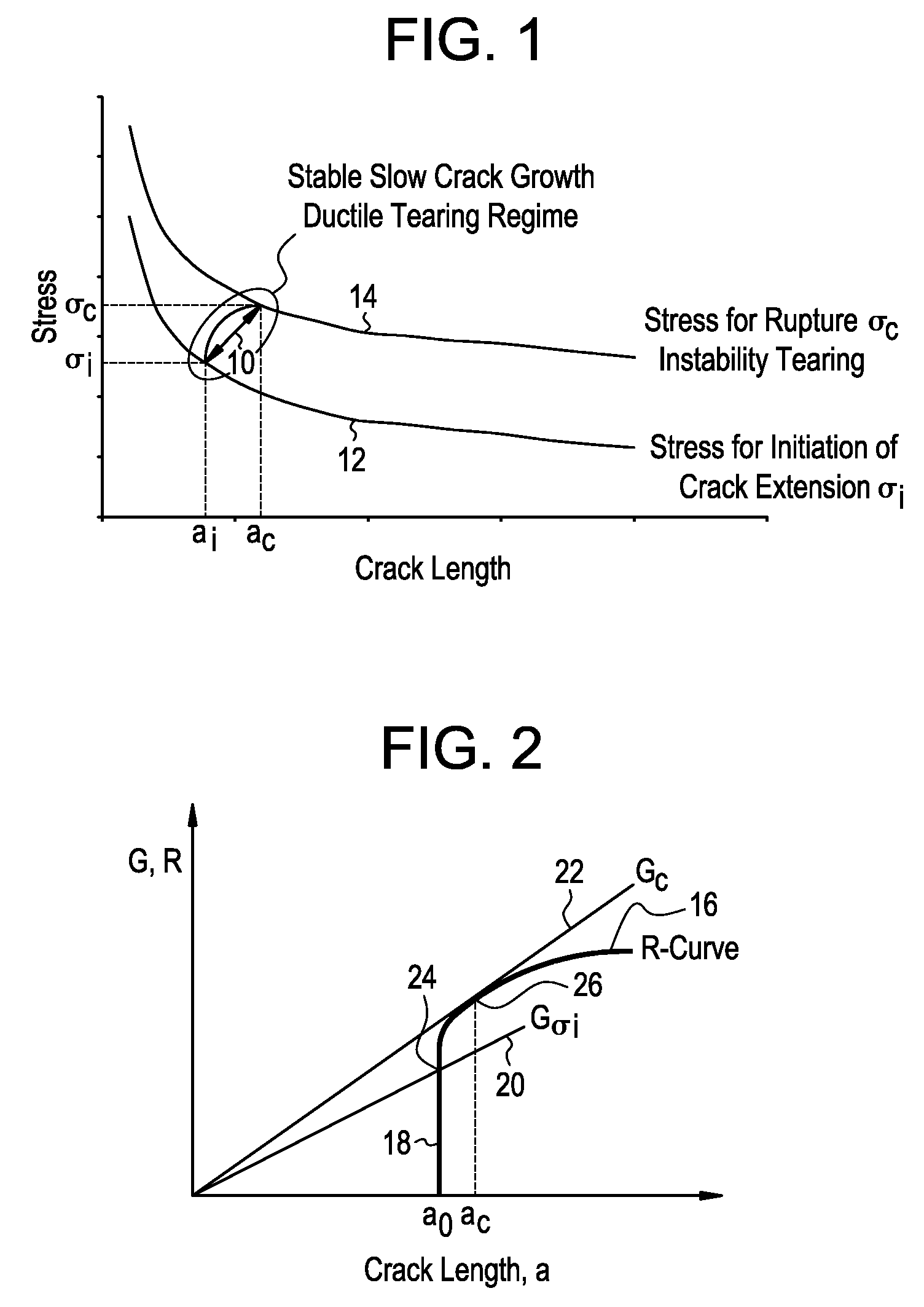

A method for leak-before-rupture assessment including using a failure assessment diagram (FAD) assessment curve from a crack initiation based FAD analysis to analyze a crack in a material; and using a ductile tearing analysis in conjunction with the FAD assessment curve to detect a crack exhibiting at least one of ductile tearing stability and tearing instability prone to rupture during growth of the crack.

Owner:GENERAL ELECTRIC CO

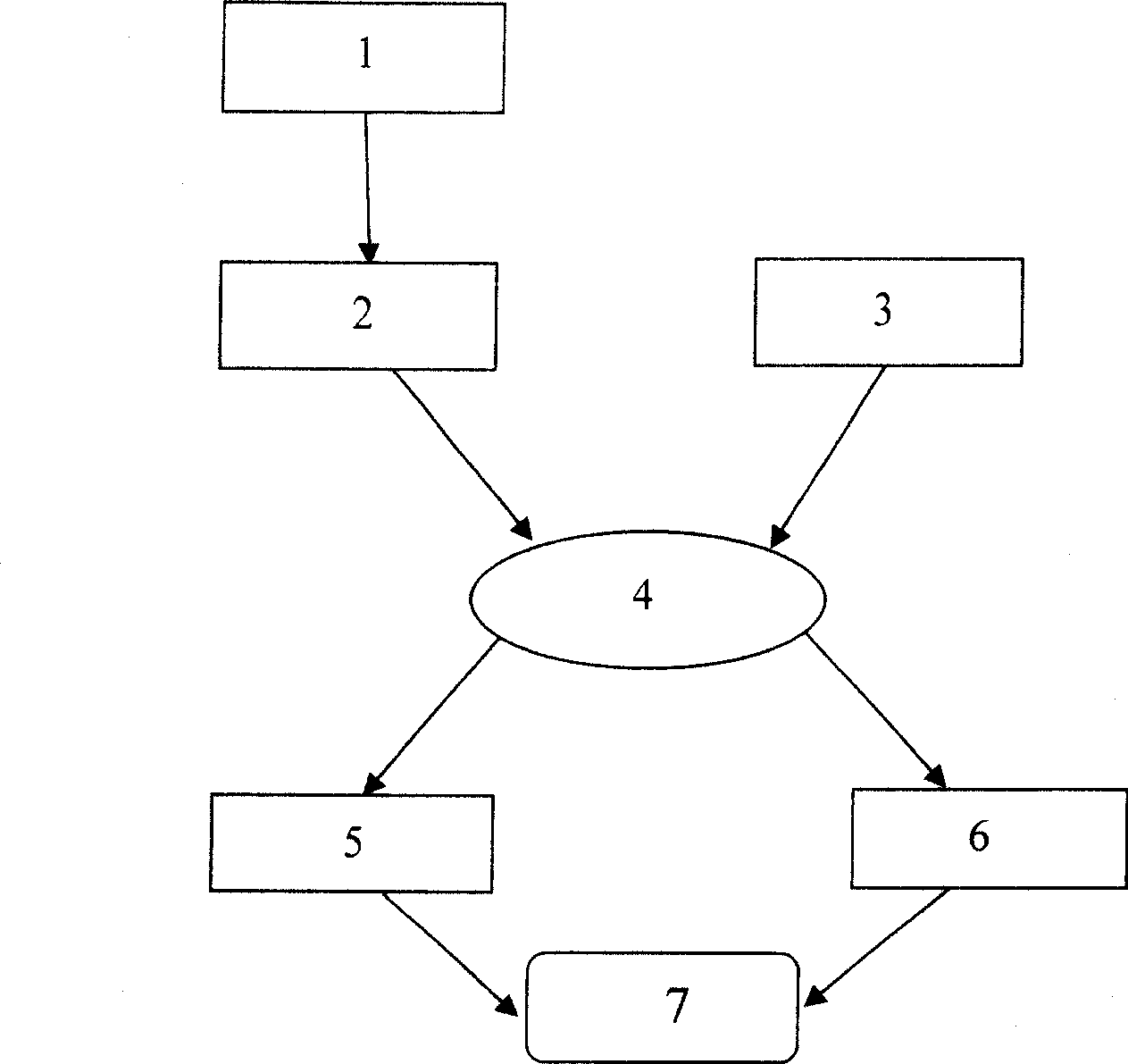

Reservoir group outlet structure failure assessment method based on Bayesian network

InactiveCN107330621AAnalytical scienceClimate change adaptationCharacter and pattern recognitionFailure assessmentSystem failure

The invention relates to a reservoir group outlet structure failure assessment method based on the Bayesian network. The reservoir group outlet structure failure assessment method includes the steps of establishing a Bayesian network topological structure, determining respective probability, calculating spillway system failure probability, and calculating the integral failure probability. The Bayesian network for failure probability determination is combined with a conventional event tree for determining stepped reservoir group spillway facility failure, and calculating the probability of downstream control step failure caused by upstream dam bursting flood is added as needed to form a complete Bayesian spillway facility failure assessment network. A reservoir group outlet structure failure is a complex multivariable system, and the assessment system can be used to analyze common cause failure and conduct backward inference. The assessment system can scientifically determine the value of information and determine whether new information needs to be acquired, so that the outlet structure failure analysis is gradually improved and becomes more scientific.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

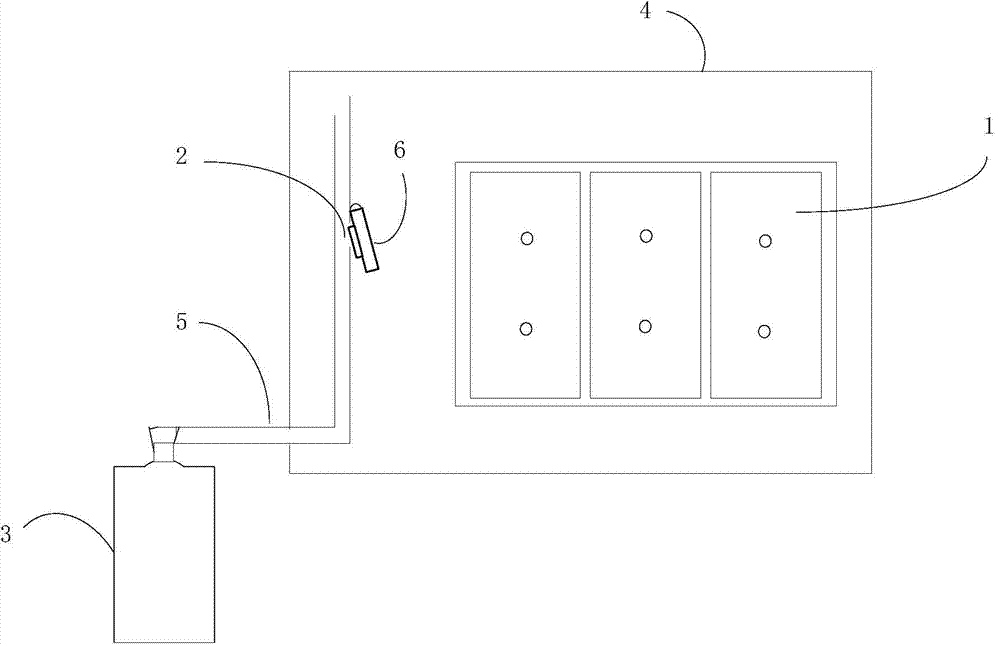

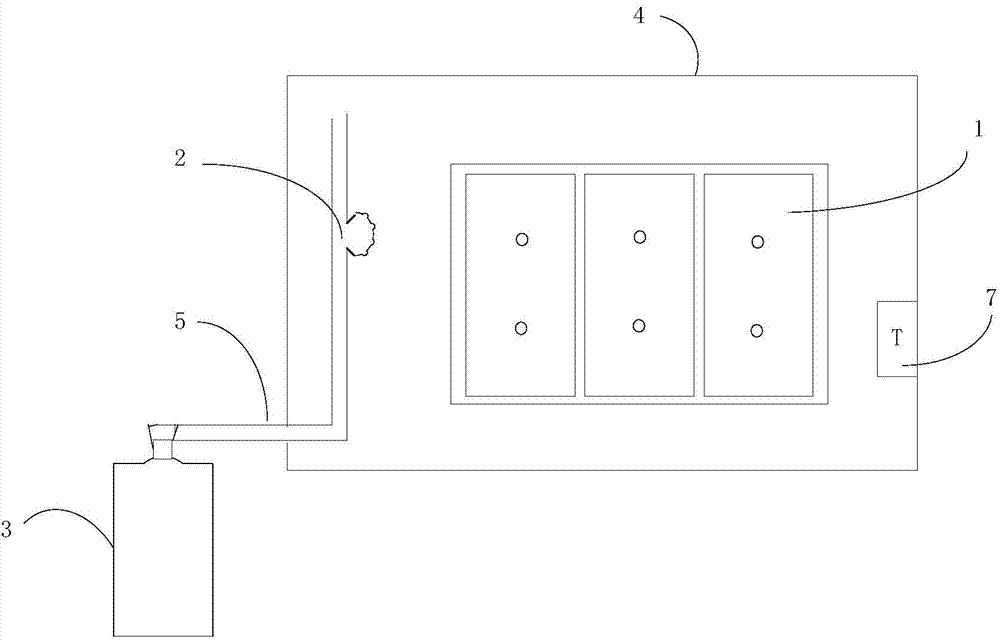

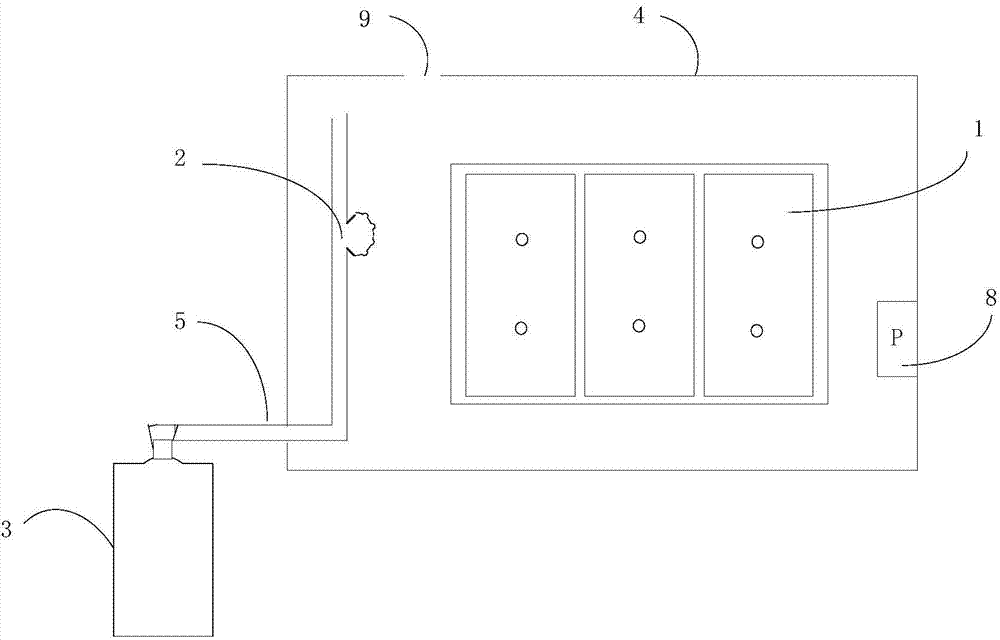

Cooling system of power battery pack for vehicle

The invention provides a cooling system of a power battery pack for a vehicle. The power battery pack comprises a power battery pack casing in which the power battery pack is positioned. The cooling system comprises a cooling liquid storing device, at least one nozzle and a cooling liquid pipeline which is used for connecting the cooling liquid storing device with the nozzle, wherein the nozzle is positioned in the power battery pack casing, faces the surface of the power battery pack and is started when a failure assessment parameter of the power battery pack meets a preset starting condition, so that a liquid in the cooling liquid storing device can be sprayed to the power battery pack. As the cooling system is used, a large amount of heat is adsorbed via liquid gasification, so that the power battery pack in failure can be cooled. Thus, the safety of the vehicle is ensured.

Owner:QOROS

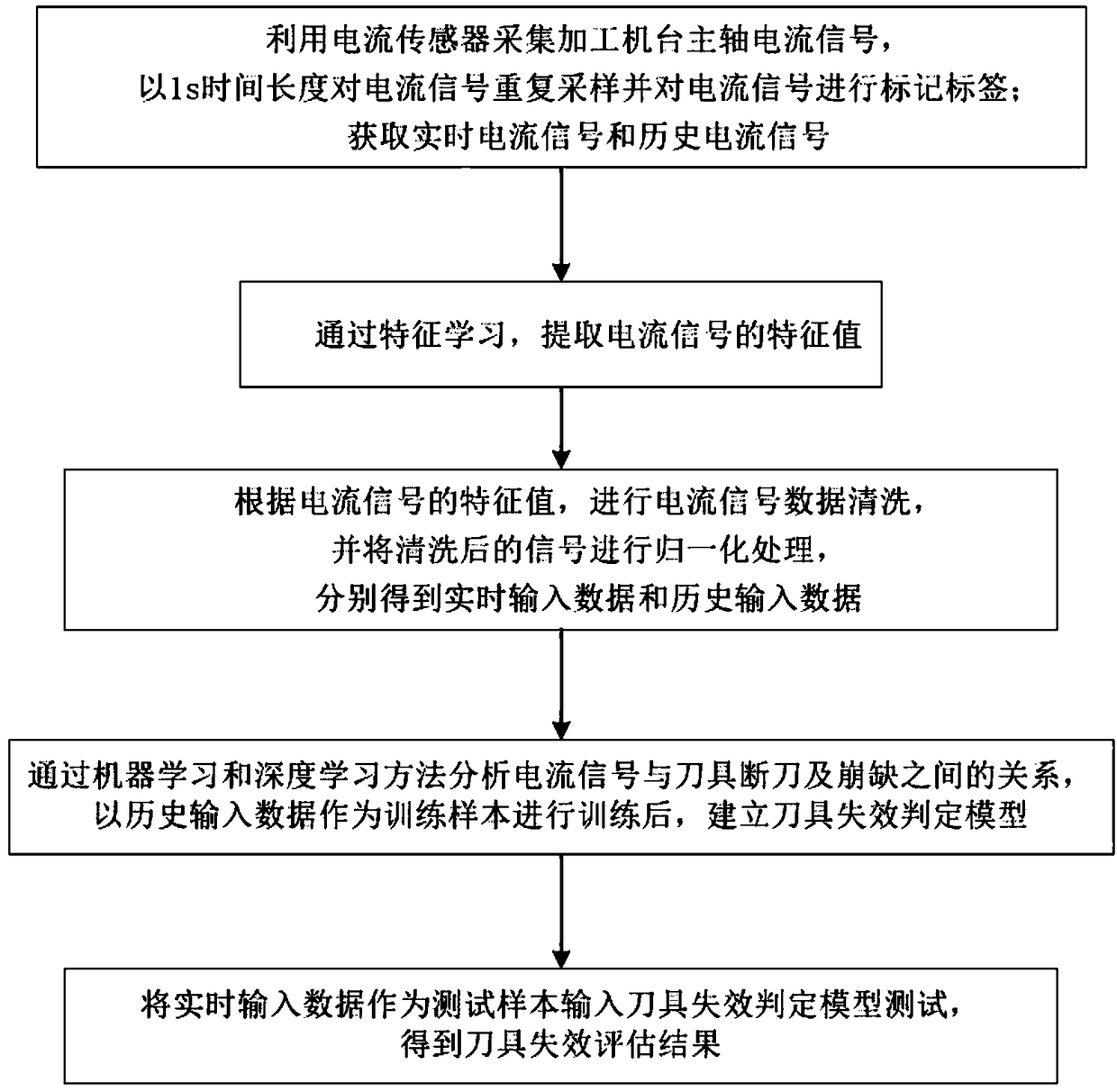

Judgement method for cutter failure

ActiveCN109262368ARealize online monitoringAchieve forecastMeasurement/indication equipmentsFailure assessmentPower flow

The invention discloses a judgement method for a cutter failure. The method comprises the steps that a current sensor is used for collecting a current signal of a main shaft of a processing machine table, and the current signal is repeatedly sampled with 1 s as time length, marked and labelled; through feature learning, a feature value of the current signal is extracted; according to the feature value of the current signal, current signal data is cleaned, the cleaned signal is subjected to normalization, and input data is obtained; through machine learning and depth learning methods, the relation between the current signal and cutter breaking and cracks is analyzed, the input data is used as a training sample for training, and then a cutter failure judgement model is established; the inputdata is used as a testing sample to be input into the cutter failure judgement model testing, and a cutter failure assessment result is obtained. According to the judgement method for the cutter failure, cutter wear can be effectively monitored and predicted online in real time, the cutter failure states of various related factors including cutter breaking and edge cracking are predicted in advance, hidden safety dangers in the production process are greatly reduced, and the finished product rate of products is increased.

Owner:CHENGDU UNION BIG DATA TECH CO LTD

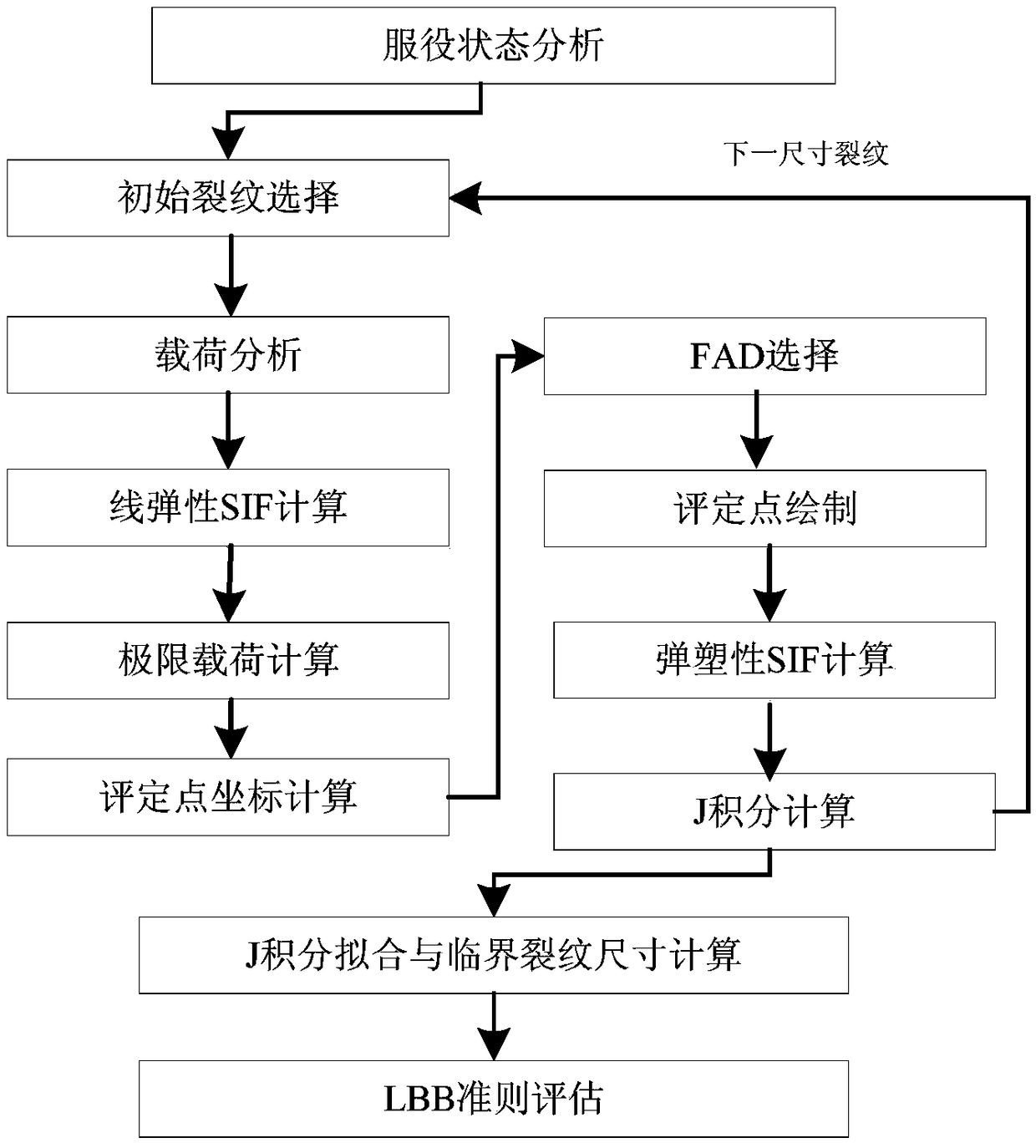

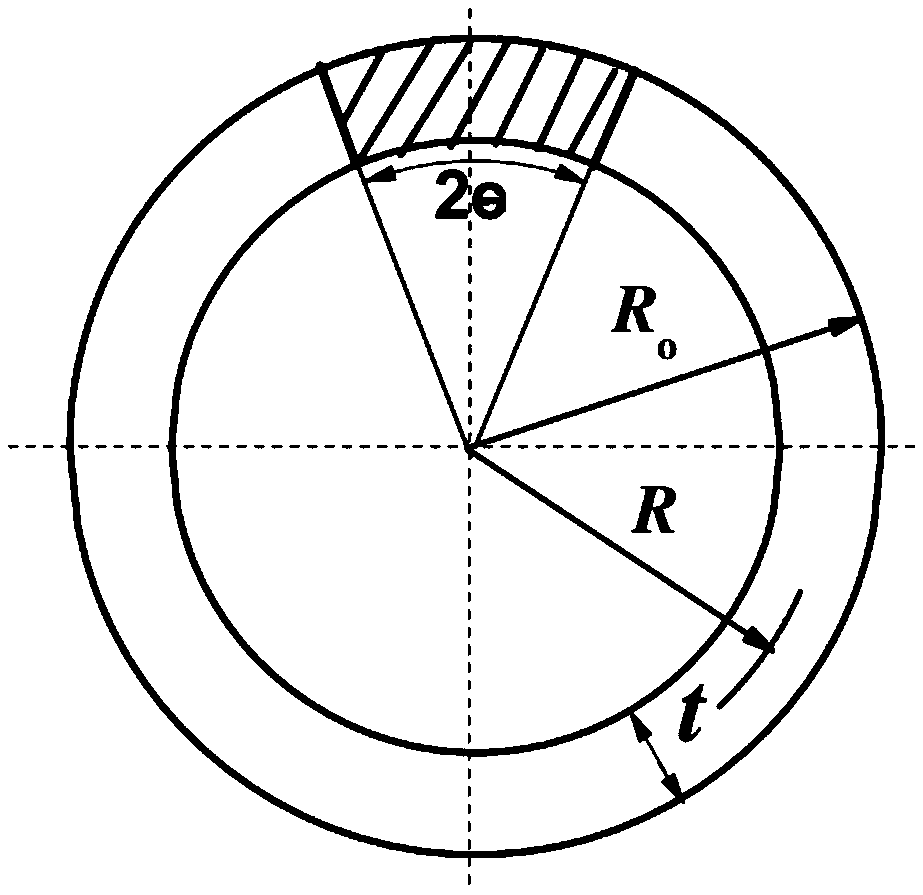

Leak before burst analysis method based on failure assessment diagram

ActiveCN108710721ADesign optimisation/simulationSpecial data processing applicationsFailure assessmentElement model

The present invention relates to a leak before burst (LBB) analysis method based on a failure assessment diagram (FAD). The method comprises the following steps: (a) service state analysis; (b) initial crack selection; (c) load analysis; (d) line elastic stress intensity factor (SIF) calculation; (e) ultimate load analysis; (f) evaluation point coordinate calculation; (g) FAD selection; (h) evaluation point drawing; (i) elastoplastic SIF calculation; (j) J-integral calculation; (k) calculation and fitting of the J-integral of different cracks; (l) calculation of the structural failure criticalcrack size; (m) calculation of the structural critical leakage crack size; and (n) LBB criterion evaluation. According to the method provided by the present invention, based on the FAD theory, defects that the theoretical basis of elastoplastic analysis in the existing norms is insufficient, the existing J-integral calculation manual has a limited application scope, the finite element modeling analysis process is complicated, and the processes for calculating the structural failure critical crack size and the structural critical leakage crack size are complicated, and the like are overcome, and a FAD-based LBB analysis basis is provided.

Owner:SUZHOU NUCLEAR POWER RES INST +4

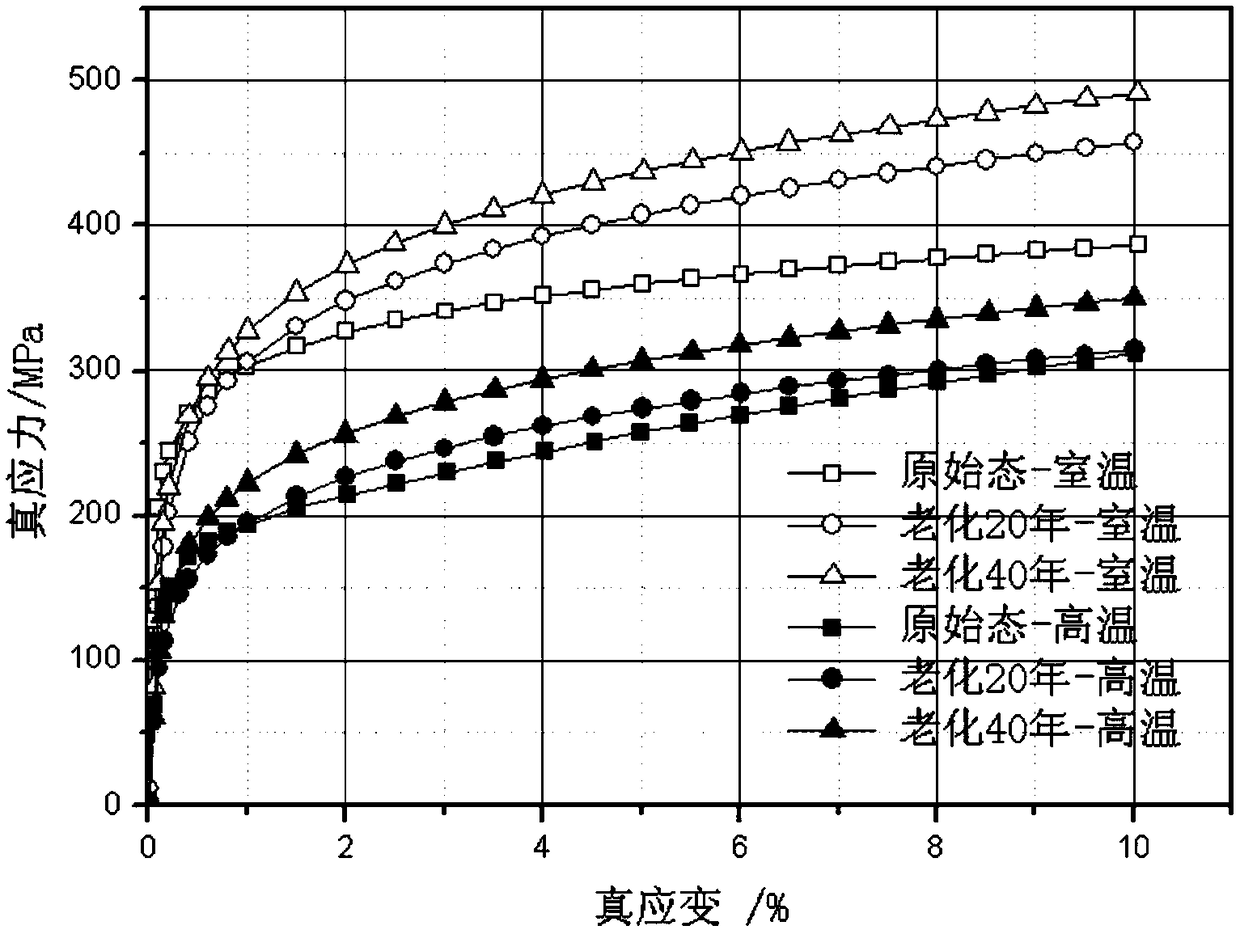

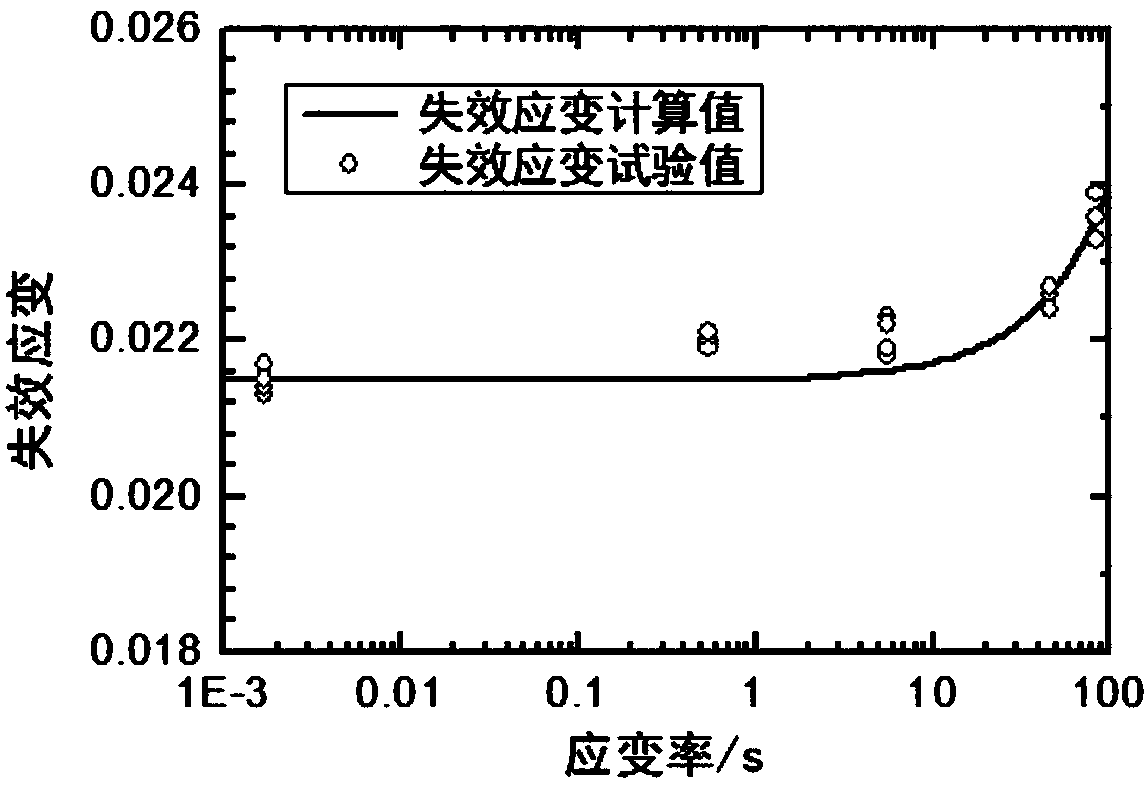

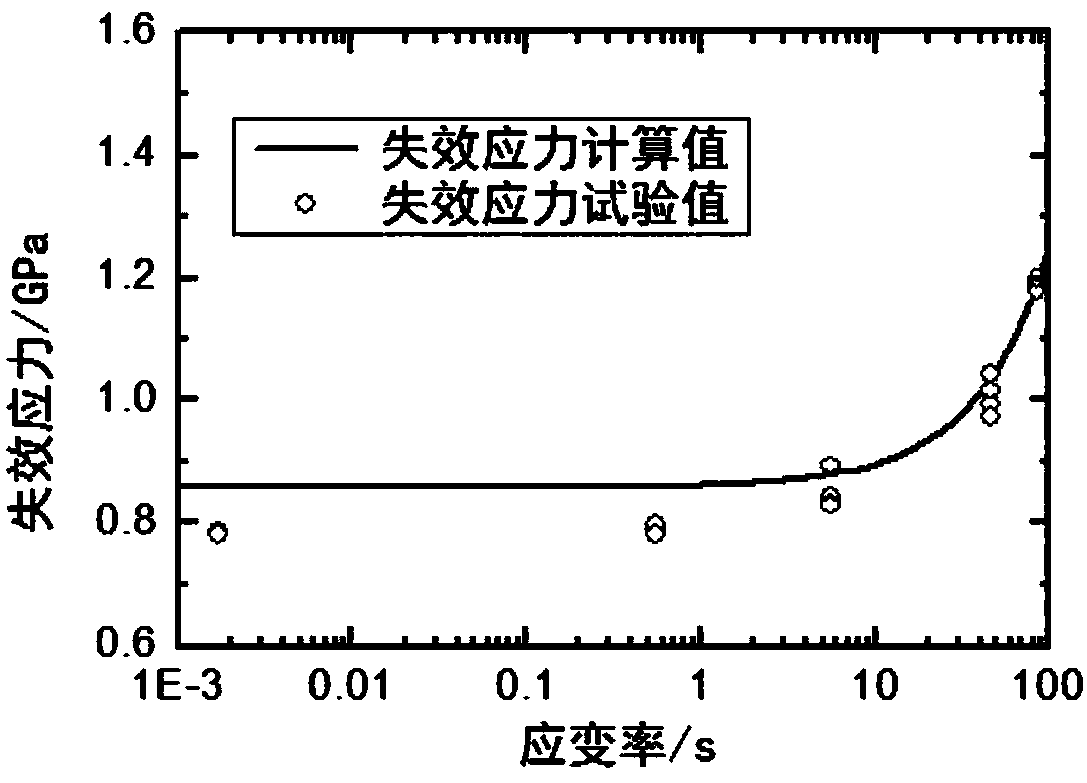

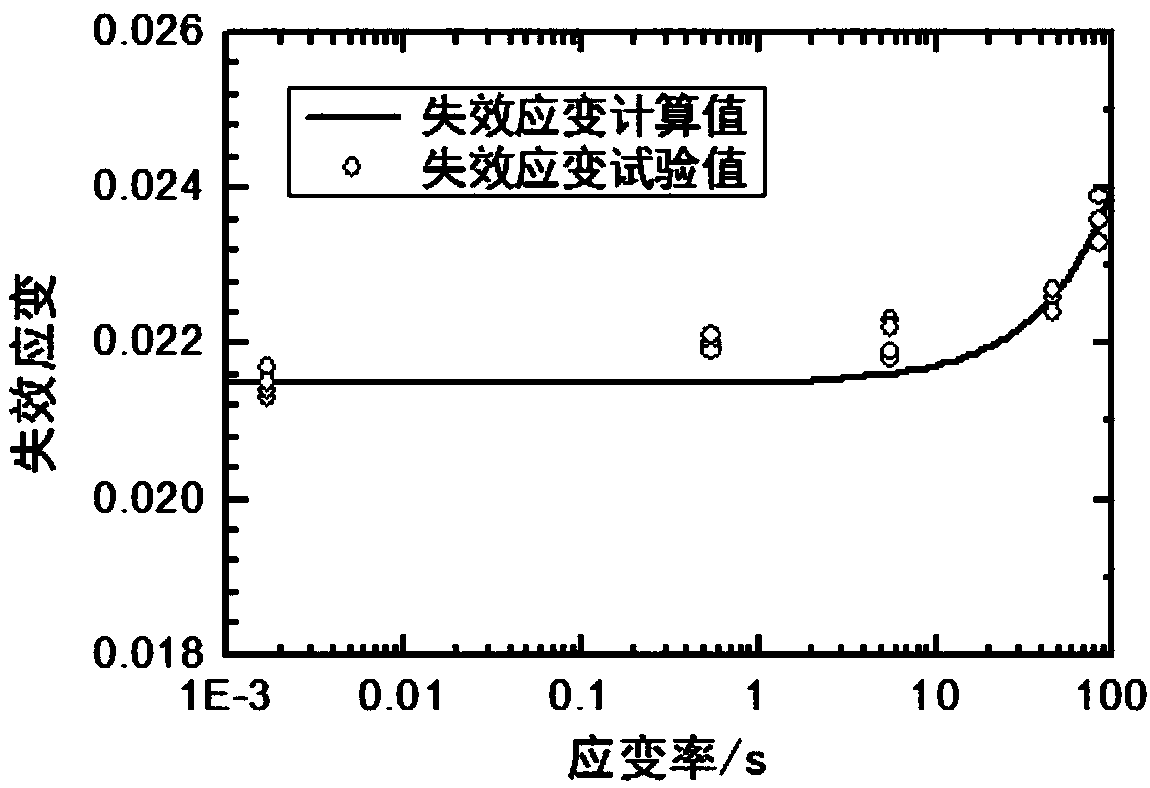

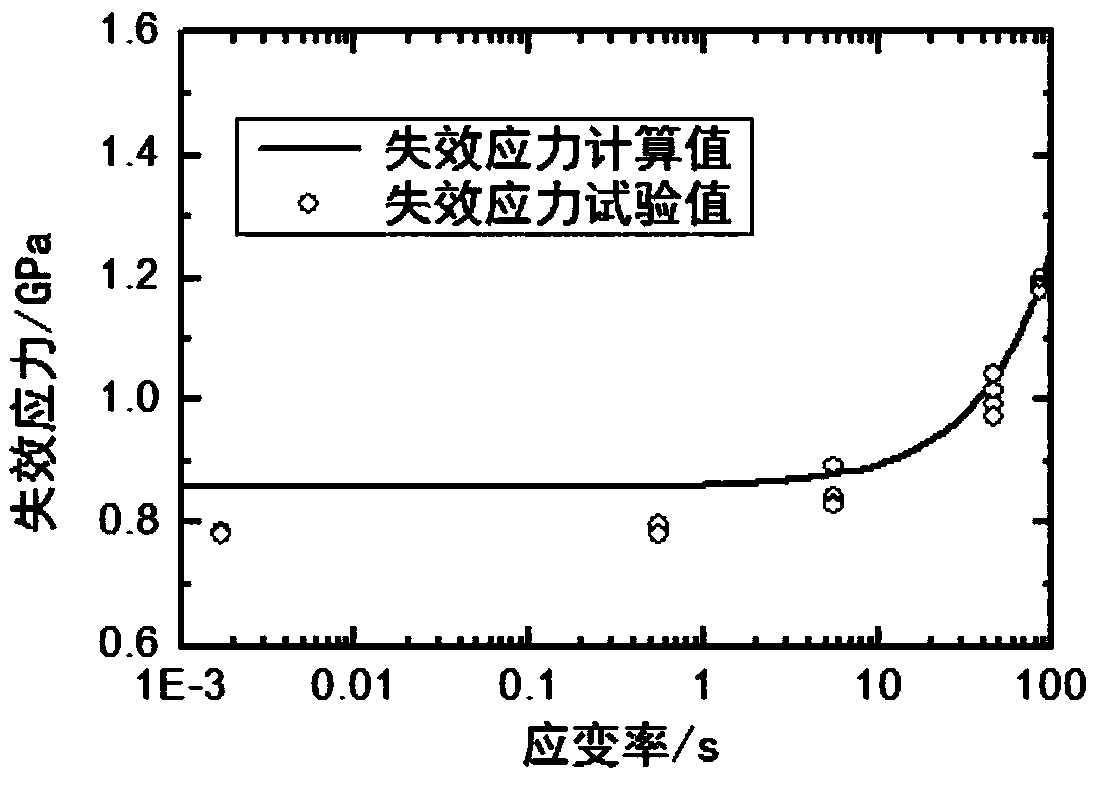

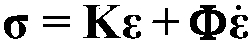

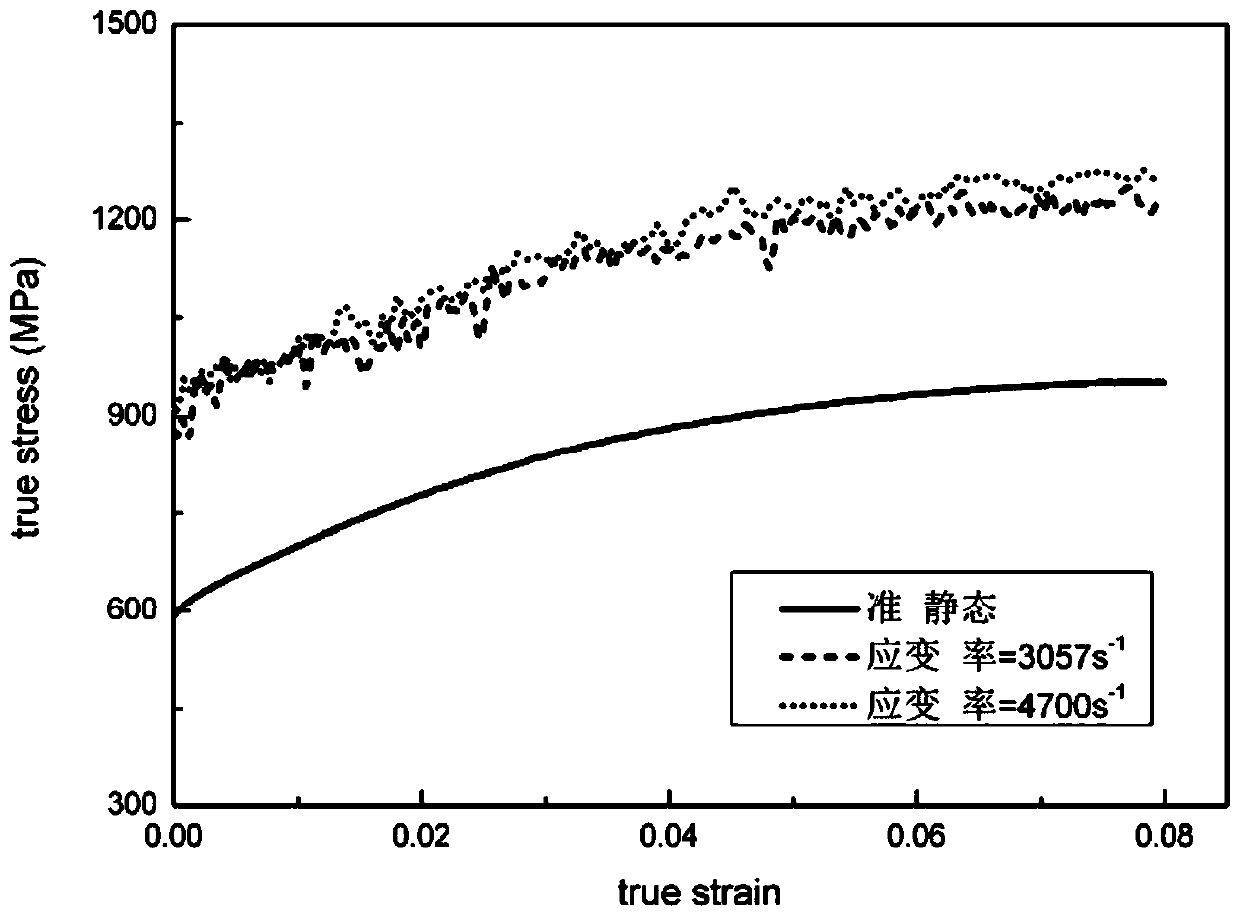

Dynamic stretching failure assessment method for fiber reinforced composite material

ActiveCN108549743AAccurately analyze tensile failure behaviorAnalyzing Tensile Failure BehaviorDesign optimisation/simulationSpecial data processing applicationsFailure assessmentDynamic stretching

The invention provides a dynamic stretching failure assessment method for a fiber reinforced composite material. For the problem of lack of a theoretical basis due to no consideration of a strain rateeffect and dependency on test data in correction in an existing fiber reinforced composite material failure assessment method, based on an energy density theory, the strain rate effect of the fiber reinforced composite material under the action of a dynamic load is considered, and derivation is performed to obtain a strain rate related distortion energy density equation of the material under theaction of the dynamic stretching load; the method can accurately analyze a stretching failure behavior of the fiber reinforced composite material under the action of the dynamic load; a large amount of dynamic tests are avoided; and the reliable assessment method is provided for design of various fiber reinforced composite structures.

Owner:SOUTHEAST UNIV

Dynamic assessment system for high-voltage electrical components

A dynamic assessment system for monitoring high-voltage electrical components, which includes a computer system that is configured to receive data from a plurality of on-line sensors configured to monitor various operating parameters associated with the operation of a plurality of electrical components such as a plurality of electrical transformers. The computer system is configured to automatically and continuously correlate the data from the on-line sensors with data from various off-line databases and supervisory networks associated with monitoring the operation of the power distribution network, so as to generate dynamic operating condition assessments, including risk of failure assessments, of each of the monitored electrical components.

Owner:HITACHI ENERGY LTD

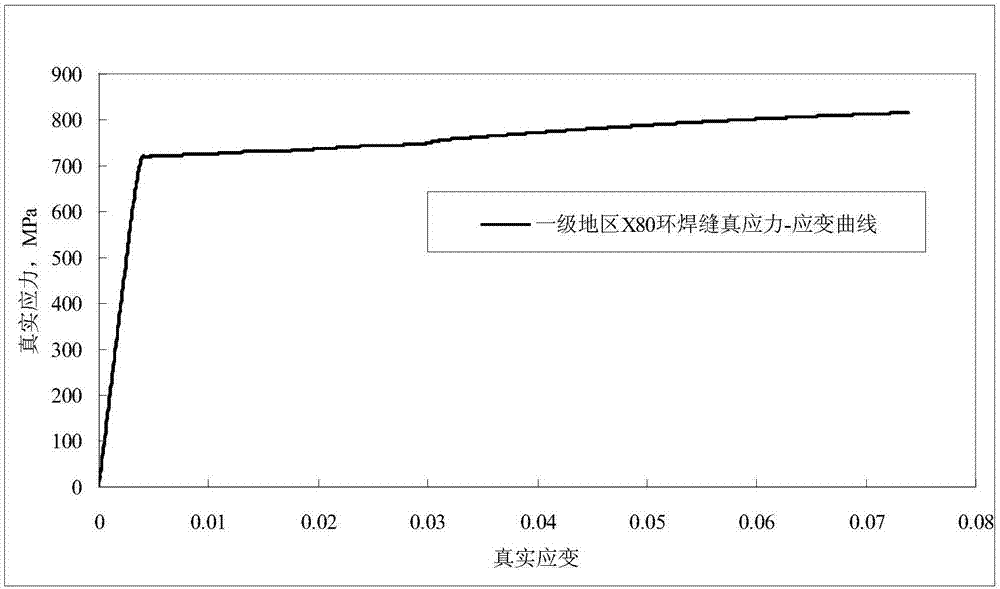

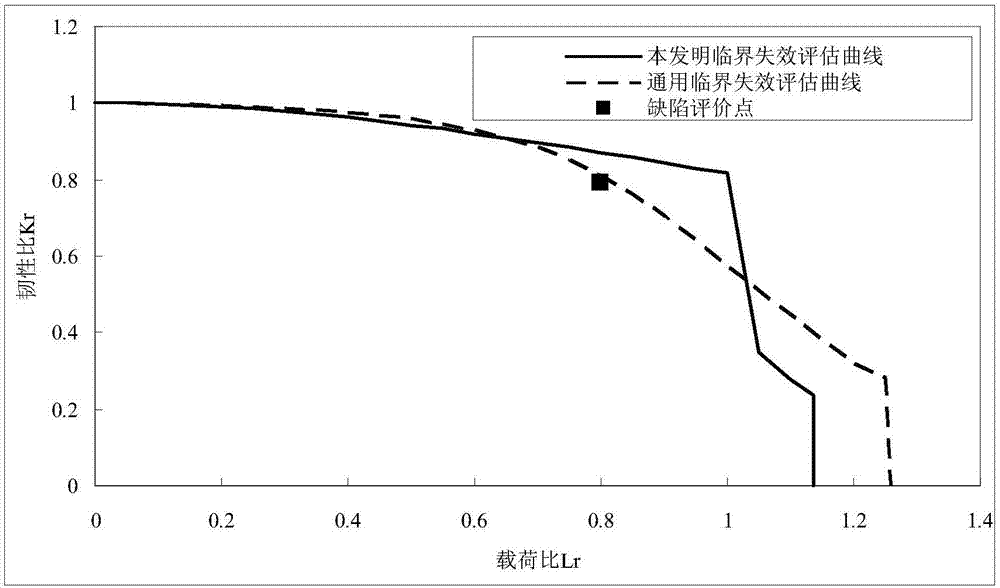

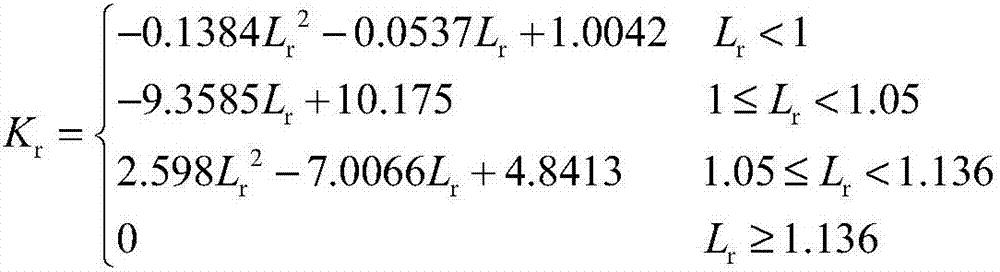

Evaluation method used for residual intensity of X80 pipeline circumferential weld crack type defect

InactiveCN107451394AThe critical failure assessment curve is close to the actualEasy to operateSpecial data processing applicationsInformaticsResidual strengthFailure assessment

The invention discloses an evaluation method used for the residual intensity of an X80 pipeline circumferential weld crack type defect. The evaluation method comprises the following steps that: 1) calculating the loading ratio of an X80 pipeline to be evaluated, and calculating the ductility ratio of the X80 pipeline to be evaluated, wherein the X80 pipeline to be evaluated is provided with the circumferential weld crack type defect; 2) according to the loading ratio and the ductility ratio of the X80 pipeline to be evaluated, drawing a data point in a coordinate system; and 3) constructing the critical failure assessment curve of an X80 pipeline circumferential weld sample, inserting the critical failure assessment curve of the X80 pipeline circumferential weld sample into a coordinate system in the 2), and evaluating the residual intensity of the circumferential weld crack type defect of the X80 pipeline to be evaluated according to the critical failure assessment curve of the X80 pipeline circumferential weld sample and the position relationship of the data point in the 2). By use of the method, the evaluation of the residual intensity of the X80 pipeline circumferential weld crack type defect can be realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

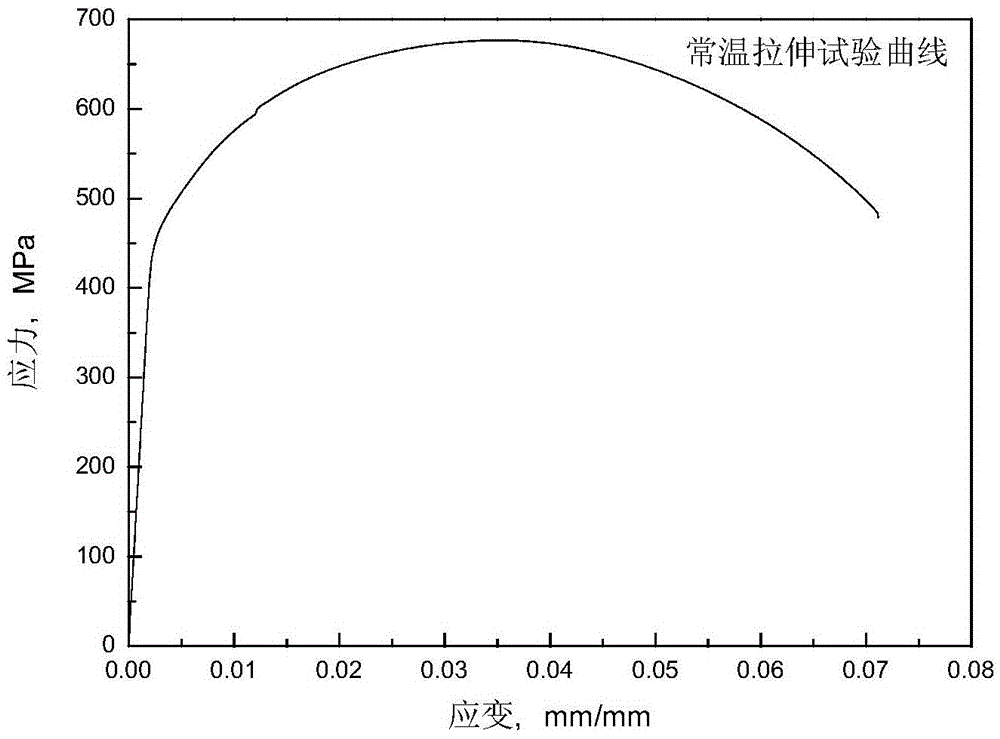

Method for assessing structural integrity of high-temperature and high-pressure welded member

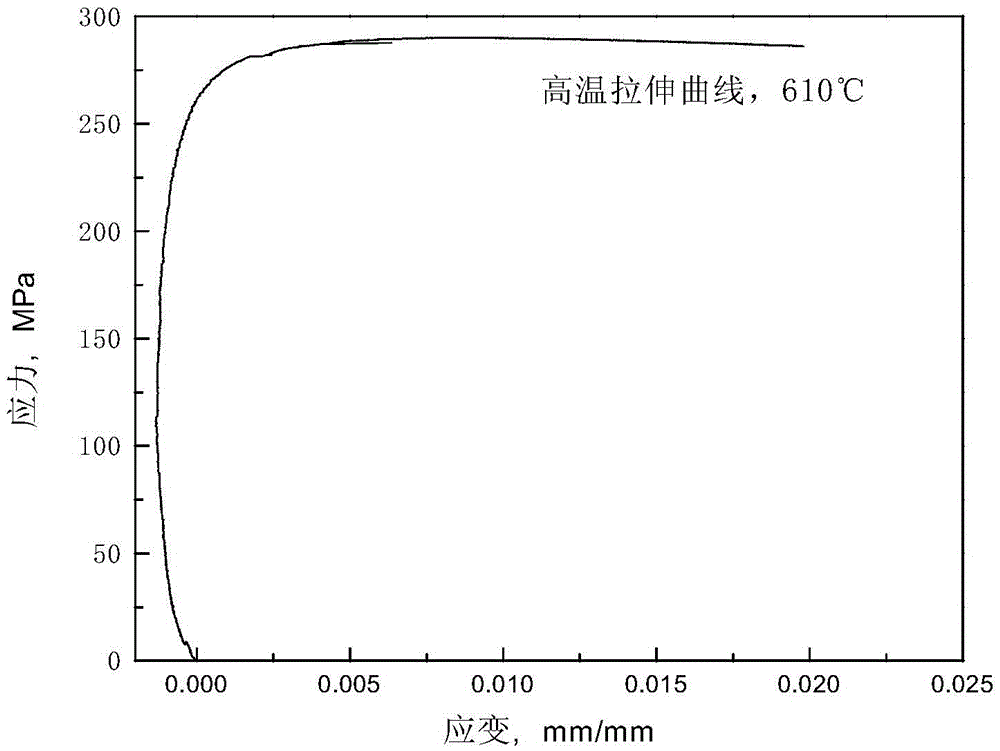

InactiveCN105651606ASafety Assessment ScienceSafety assessment is accurateMaterial analysis by electric/magnetic meansMaterial strength using tensile/compressive forcesFailure assessmentStress–strain curve

The invention relates to a method for assessing the structural integrity of a high-temperature and high-pressure welded member. The method comprises the following steps that (a) mechanical performance testing is conducted on a joint material of the welded member at normal temperature and high temperature; (b) crack propagation rate testing under the creep-fatigue and fatigue-creep interaction effect is conducted on the joint of the welded member in a high-temperature temperature to obtain crack propagation characteristics represented by high-temperature breakage parameters; (c) SEM is adopted to analyze the fracture of the joint of the welded member so as to determine a failure mode of a test sample and select corresponding high-temperature breakage parameters; (d) an isochronous stress-strain curve of the joint of the welded member is established; (e) the ratio value of a stress intensity factor to fracture toughness serves as a vertical coordinate and the ratio value of an applied load to a plastic collapse load serves as a horizontal ordinate to establish a failure assessment curve about the correlation between the joint material of the welded member and time, and an assessment area of the failure assessment curve is divided into a safety area and a failure area to perform structural safety assessment. Therefore, the obtained safety evaluation is more scientific and accurate.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Method for detecting leak before rupture in a pipeline

A method for leak-before-rupture assessment including using a failure assessment diagram (FAD) assessment curve from a crack initiation based FAD analysis to analyze a crack in a material; and using a ductile tearing analysis in conjunction with the FAD assessment curve to detect a crack exhibiting at least one of ductile tearing stability and tearing instability prone to rupture during growth of the crack.

Owner:GENERAL ELECTRIC CO

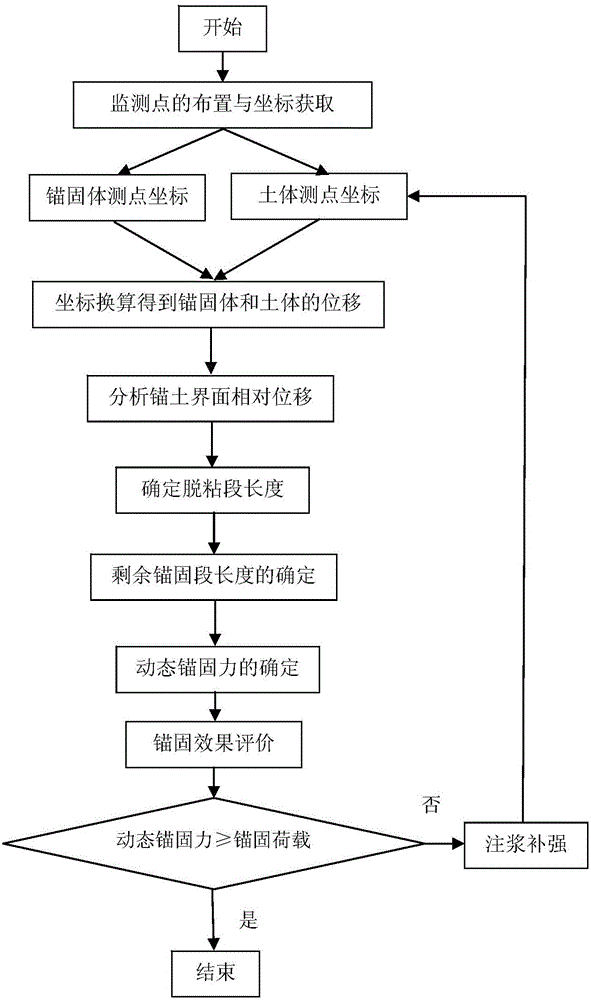

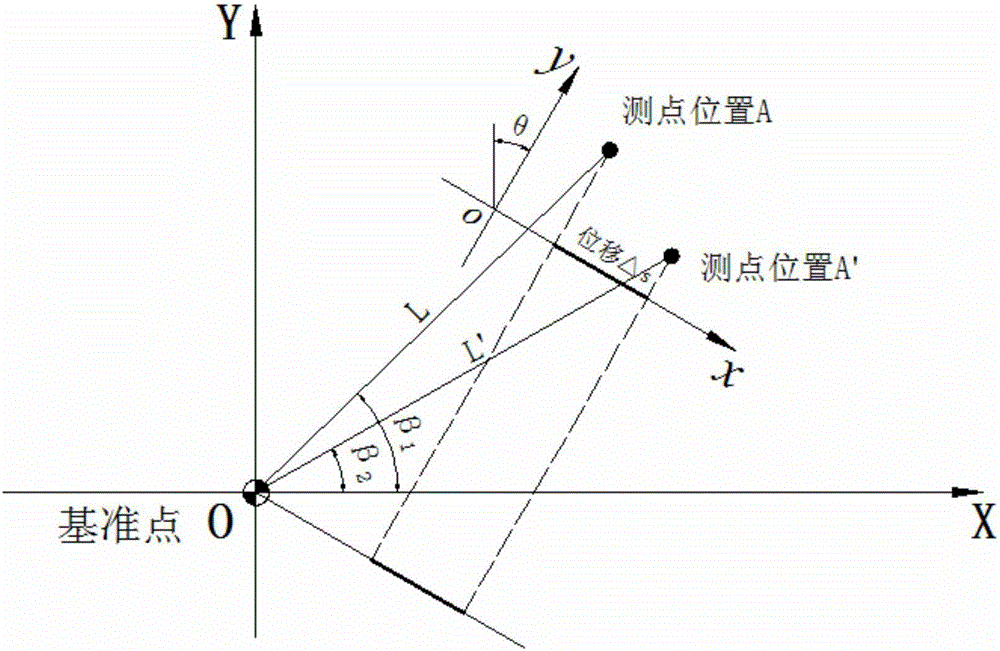

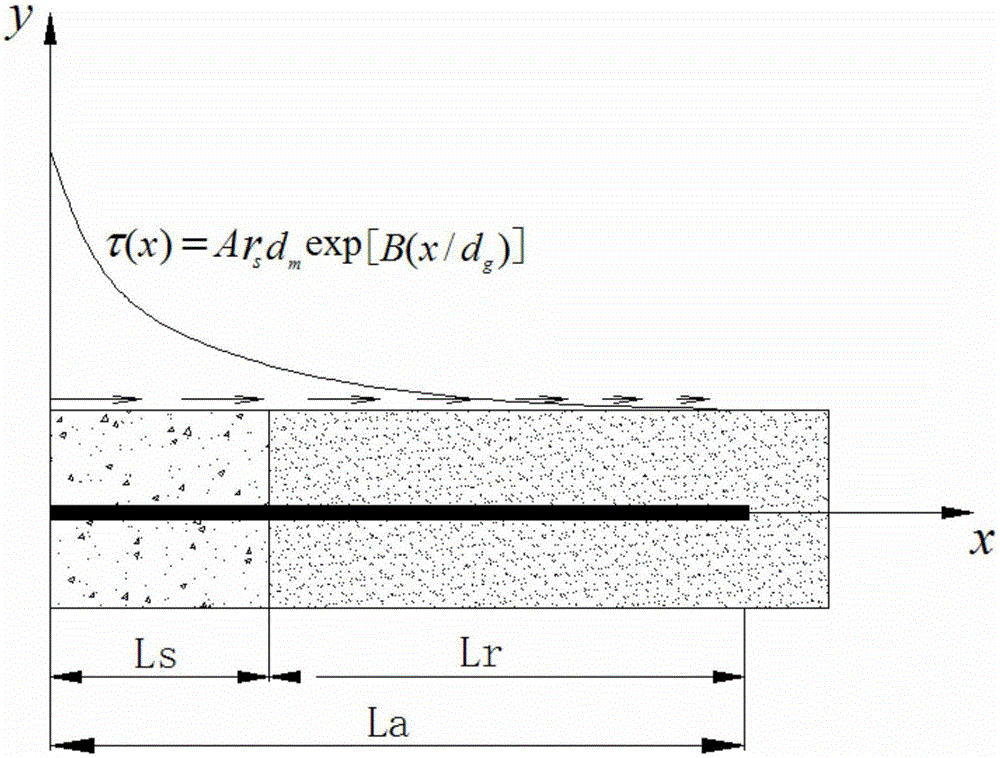

Method for measuring full-length cohesive soil anchorage de-bonding length and dynamic anchorage force

ActiveCN106638718AEffective dynamic monitoringImprove environmental adaptabilityFoundation testingBulkheads/pilesUltrasound attenuationFailure assessment

The invention discloses a method for measuring full-length cohesive soil anchorage de-bonding length and dynamic anchorage force. The measuring method is mainly characterized in that based on advantageous shear failure characteristics of an anchorage soil interface, a de-bonding length change value of an anchorage structure is determined according to a total displacement composition of an anchorage body when a rod body is completely coupled with the anchorage body, anchorage soil interface shearing stress index attenuation characteristics and slippage failure assessment thereof, and dynamic anchorage force is further obtained. The method can be used for performing dynamic monitoring, anchorage effect assessment and anchorage reinforcement on anchorage force, so that disasters are reduced; moreover, a monitoring process and a calculating process are clear, operation is simple and convenient, environmental adaptation is strong and cost is low, so that the problem that anchorage force fixation as well as a complex dynamic monitoring technology thereof and reinforcing grouting amount depend on experience is overcome, and better theoretical significance and a higher economic value are shown, and therefore, practice can be guided better.

Owner:HUNAN INSTITUTE OF ENGINEERING

Evaluation method of fatigue properties of metal materials

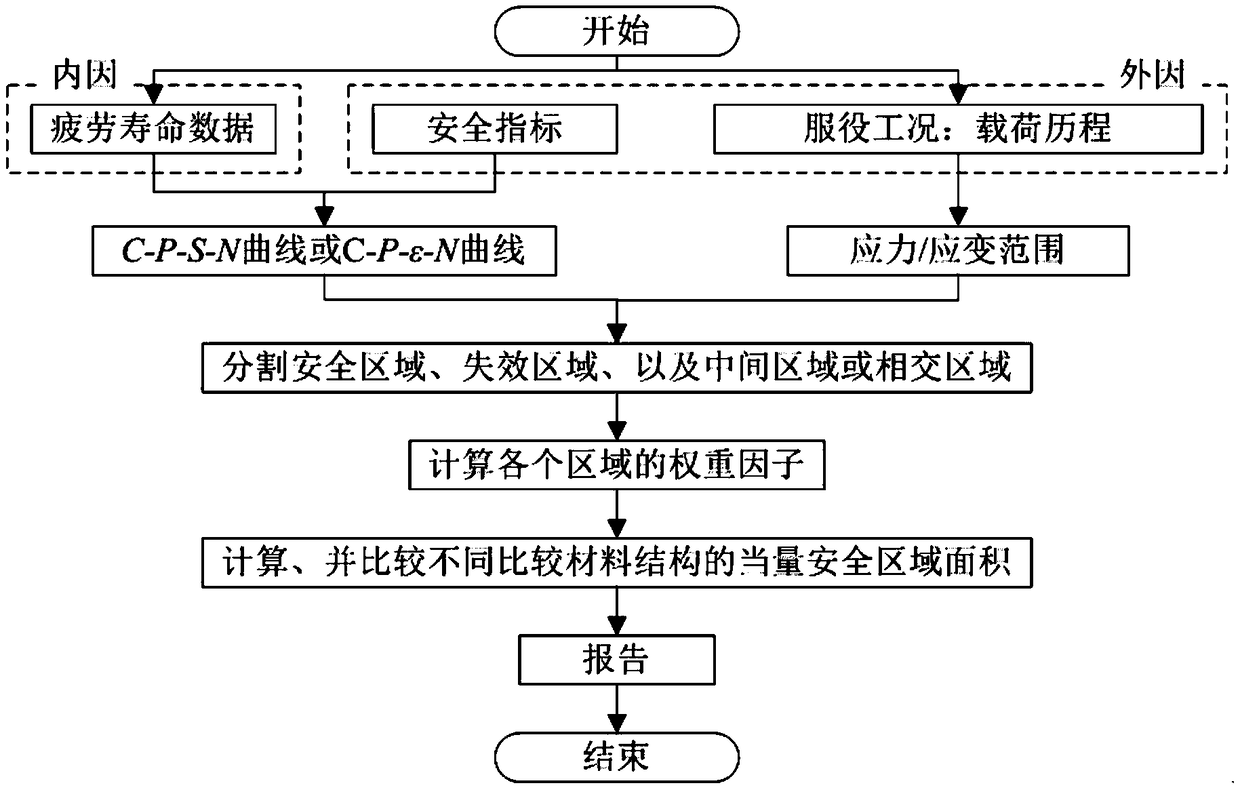

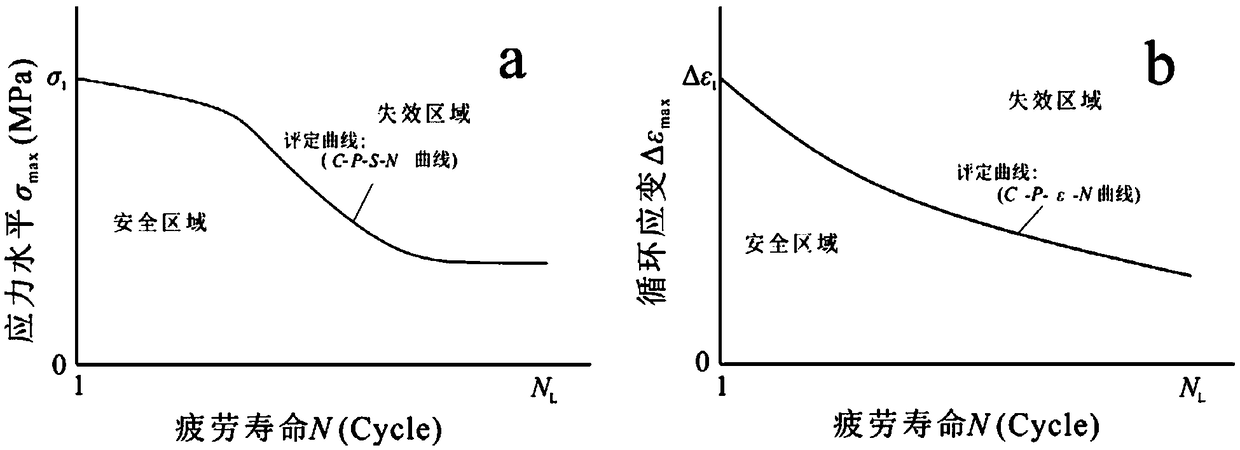

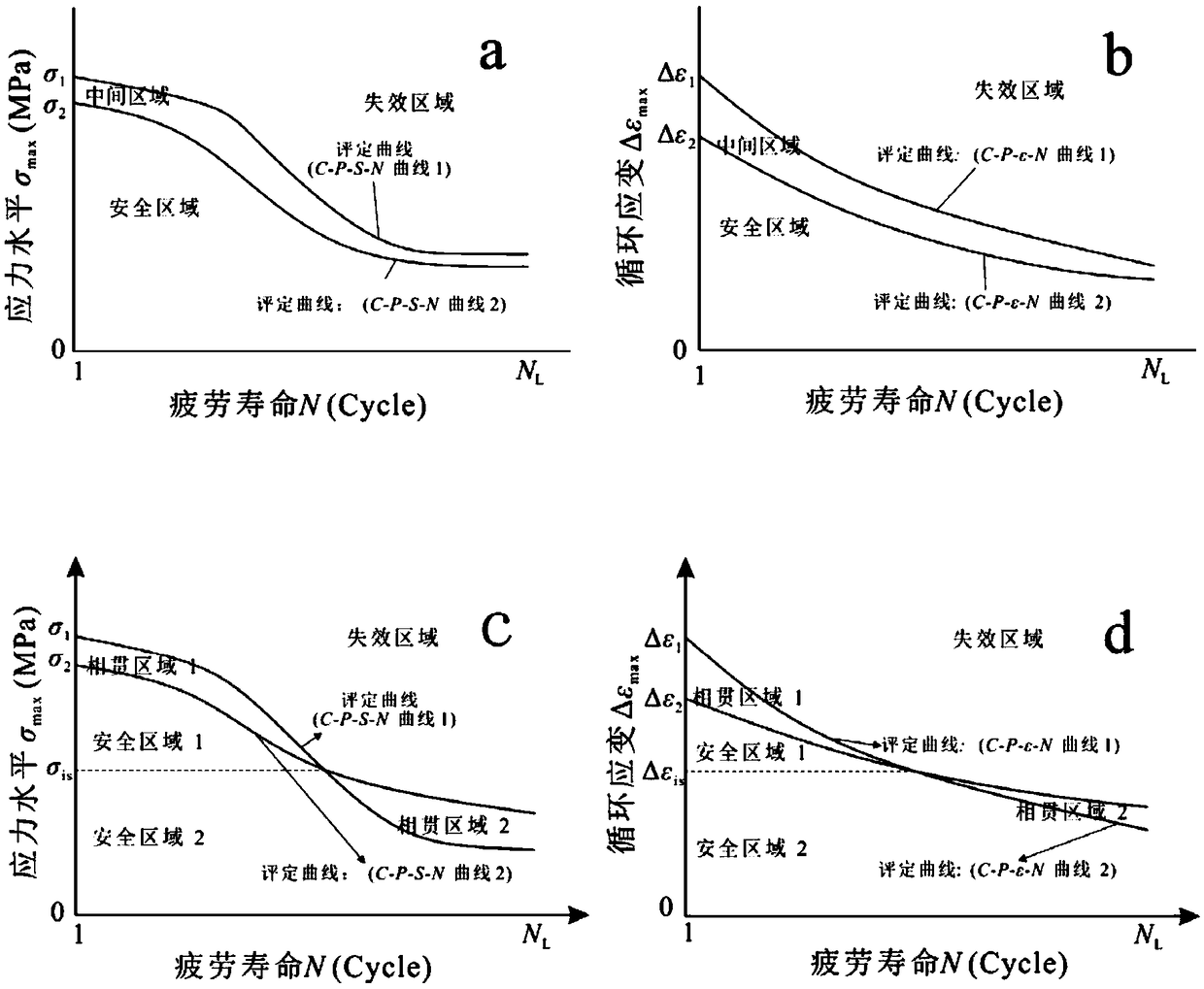

ActiveCN108871981ASolving Dispersion ProblemsSolve the problem of not being able to make a direct comparisonMaterial strength using repeated/pulsating forcesSafety indexFailure assessment

The invention discloses an evaluation method of the fatigue properties of metal materials, and belongs to the technical field of material science and engineering application. The evaluation method ischaracterized in that based on material fatigue life data, a service working condition and safety indexes, a fatigue failure evaluation curve is developed, a safety region, a failure region and an intermediate region or an intersecting region can be divided by a stress / strain range, and the fatigue properties of different materials can be compared through calculation of equivalent safety area. According to a technology disclosed by the invention, the problems that the fatigue properties of different materials are scattered, and direct comparison cannot be carried out are solved; the new technology has the advantages that the evaluation is rapid and the application is simple, and can be widely applied to compare and evaluate the fatigue properties of different metal materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A Calculation Method for Residual Strength and Remaining Life of Pipes in Pipe Gallery

ActiveCN104807966BGuaranteed safe operationSimple and fast operationMaterial analysisNormal densityResidual strength

The invention discloses a residual intensity and residual life computing method for pipe gallery pipelines. The residual intensity and residual life computing method comprises the following steps: collecting the data information of defects of the pipe gallery pipelines; judging the defects are plane type defects or volume type defects; for the plane type defects, obtaining the engineering stress-strain curve of a defect pipeline material from the data information of the defects of the pipe gallery pipelines, determining a failure assessment diagram, and then computing assessment points to obtain the residual intensity of the pipe gallery pipelines; for the volume type defects, obtaining the design factors, the weld joint factors and the minimum measurement wall thickness from the data information of the defects of the pipe gallery pipelines, and obtaining the residual intensity of the pipe gallery pipelines through computing; computing basic numerical values according to the data information of the defects of the pipe gallery pipelines, and computing the residual lives of the pipe gallery pipelines according to a maximum value distribution probability density function, a reliability function, maximum corrosion depth point estimation and maximum likelihood estimation. Therefore, the residual intensity and residual lives of the pipelines in a pipe gallery area are effectively and accurately computed and predicted.

Owner:SHANGHAI CHEM IND PARK PUBLIC PIPE RACK

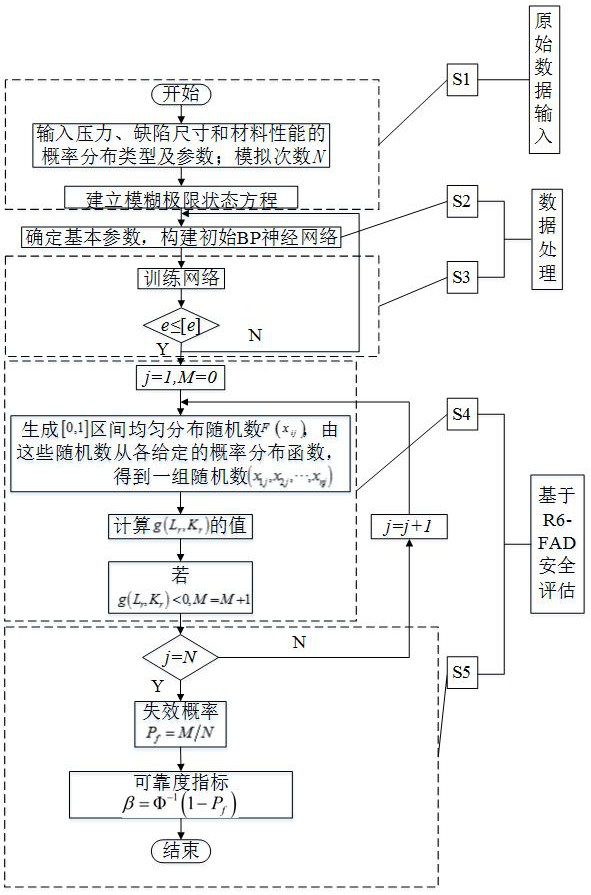

Fuzzy random reliability evaluation method for pipeline with crack defect based on R6-FAD and BP-MCS

InactiveCN112949190AImprove simulation accuracySimplify the randomization process of fuzzy reliabilityDesign optimisation/simulationNeural architecturesFailure assessmentAlgorithm

The invention discloses an R6-FAD and BP-MCS-based fuzzy random reliability evaluation method for a pipeline with crack defects, and the method combines a BP neural network and Monte Carlo simulation based on a failure evaluation diagram of an R6 specification, and is applied to the fuzzy random reliability evaluation of the pipeline with the crack defects. The method mainly comprises the following steps: step 1, inputting probability distribution types and parameters of actual working condition load, crack defect size and material performance and maximum simulation times N, and establishing a fuzzy limit state equation; 2, determining basic parameters, and constructing an initialized BP neural network; 3, training a neural network to ensure that the neural network can better approach a fuzzy limit state equation; and 4, random sampling being carried out, and a Monte Carlo principle being used to calculate a failure probability and a reliability index. According to the method, the fuzzy reliability randomization process can be simplified, and a numerical solution with relatively high simulation precision can be obtained; meanwhile, the fuzzy random coupling uncertainty of the structure is considered, the method is better in line with engineering practice, and the method has guiding significance for safety assessment of the structure.

Owner:SOUTHWEST PETROLEUM UNIV

Gas pipe network accidents early warning method

InactiveCN100492233CAvoid major accidentsFlexible module configurationProgramme controlComputer controlFailure assessmentWorking pressure

The present invention belongs to the field of an automatic monitoring technology for city gas network, which relates to a warning method for gas network accident. The present invention comprises steps as follows: a gas network geographic information system is established; a gas network diagram which is drawn is read; a gas network attributing data and a spatial geographical data are read; the maximum allowable working pressure and the residual life time for the pipeline, including fault, are predicted by adopting the methods based on an invalid evaluation drawing and an artificial neural network; the real-time collection and automatic monitoring system of the gas network data is established; dynamic data, including the pressure of all pipeline nodes are collected real-timely; a dynamic or static alarming mechanism which real-timely monitors whether the pipeline in service leaks, operating pressure and service life is established. The gas network accident warning method provided by the present invention can effectively prevent serious gas accidents.

Owner:TIANJIN UNIV

Dynamic assessment system for high-voltage electrical components

A dynamic assessment system for monitoring high-voltage electrical components, which includes a computer system that is configured to receive data from a plurality of on-line sensors configured to monitor various operating parameters associated with the operation of a plurality of electrical components such as a plurality of electrical transformers. The computer system is configured to automatically and continuously correlate the data from the on-line sensors with data from various off-line databases and supervisory networks associated with monitoring the operation of the power distribution network, so as to generate dynamic operating condition assessments, including risk of failure assessments, of each of the monitored electrical components.

Owner:HITACHI ENERGY LTD

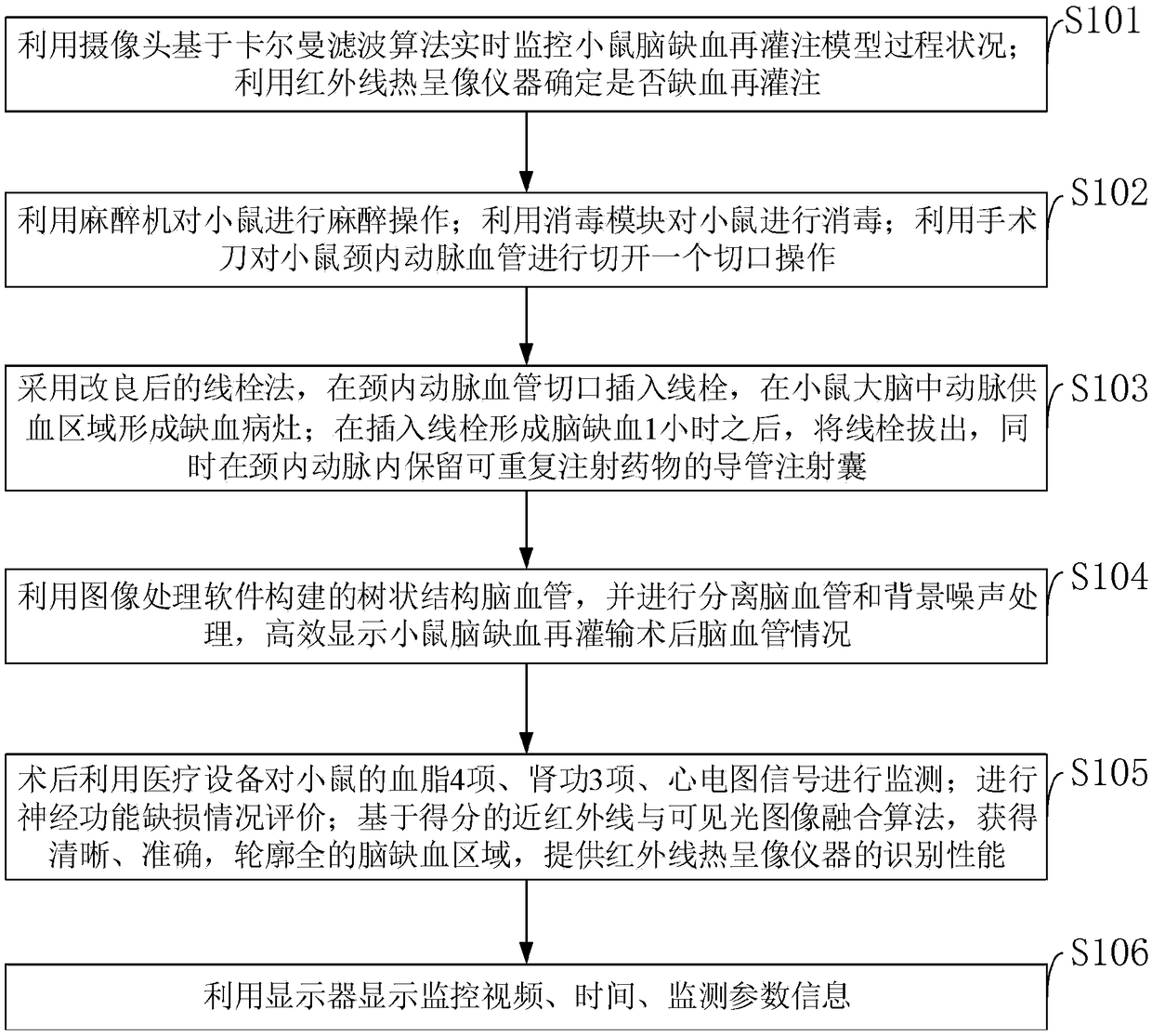

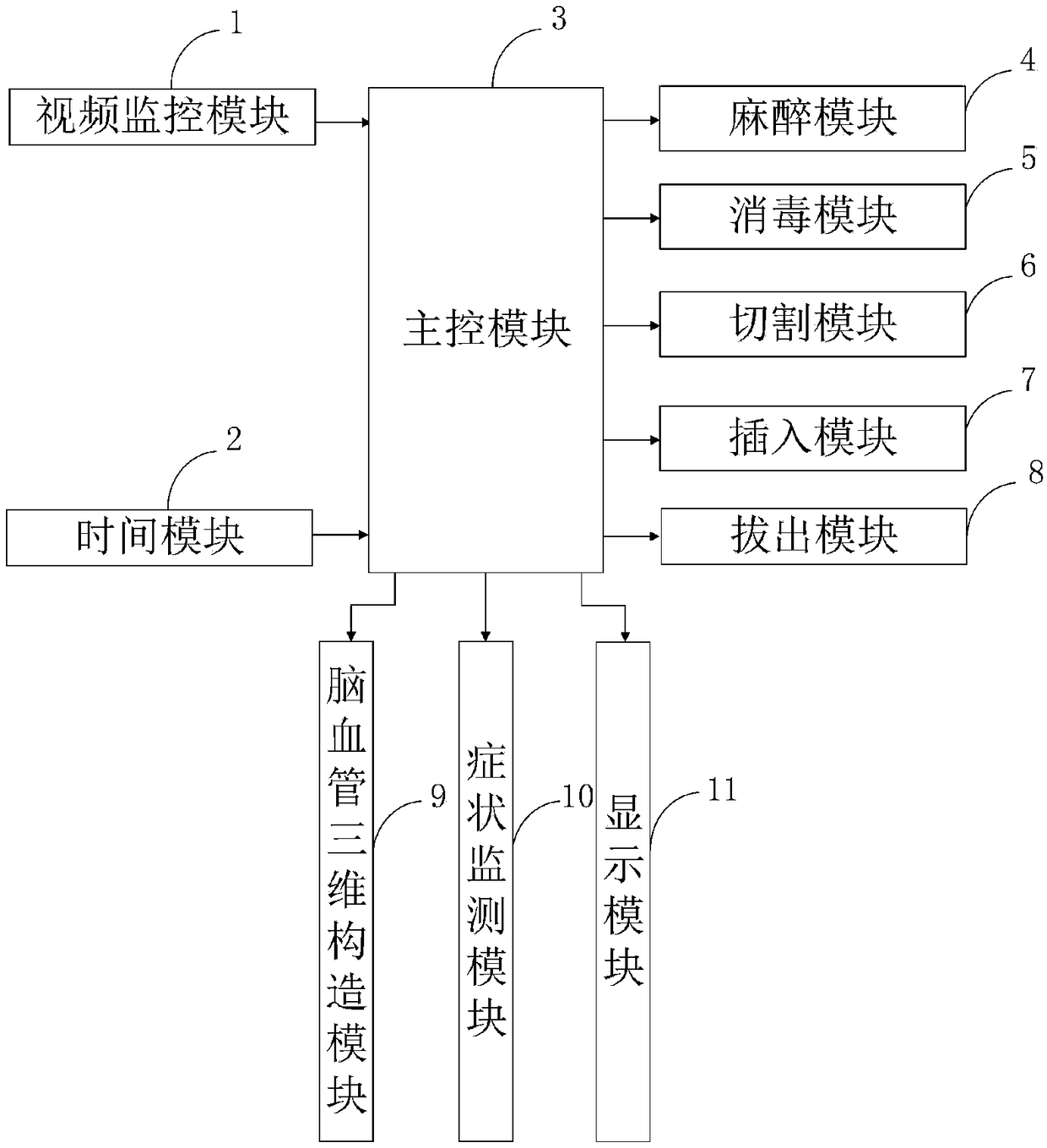

Mouse cerebral ischemia reperfusion model optimization and failure assessment method

InactiveCN109480791AEffective segmentationAccurate extraction of fine structuresMedical imagingCatheterVideo monitoringFailure assessment

The invention belongs to the technical field of mouse cerebral ischemia reperfusion models and discloses a mouse cerebral ischemia reperfusion model optimization and failure assessment method. A mousecerebral ischemia reperfusion model optimization and failure assessment system comprises a video monitoring module, a time module, a master control module, an anesthesia module, a sterilization module, a cutting module, an insertion module, a pulling-out module, a cerebral blood vessel three-dimensional structure module, a symptom monitoring module and a display module. By the cerebral blood vessel three-dimensional structure module for displaying cerebral blood vessel conditions after mouse cerebral ischemia reperfusion, effectiveness in division of cerebral blood vessel thick branches can be achieved, and cerebral blood vessel tiny structures can be extracted accurately. In addition, by intraoperative monitoring of vital signs including the body temperature, pulse, breath and blood pressure, the mouse survival rate is increased; by the postsurgical symptom monitoring module, quantitative assessment of neurological function damages after mouse cerebral ischemia reperfusion can be given, and important significance to cerebral arterial thrombosis prevention, curative effect assessment and the like is achieved.

Owner:徐州矿务集团总医院

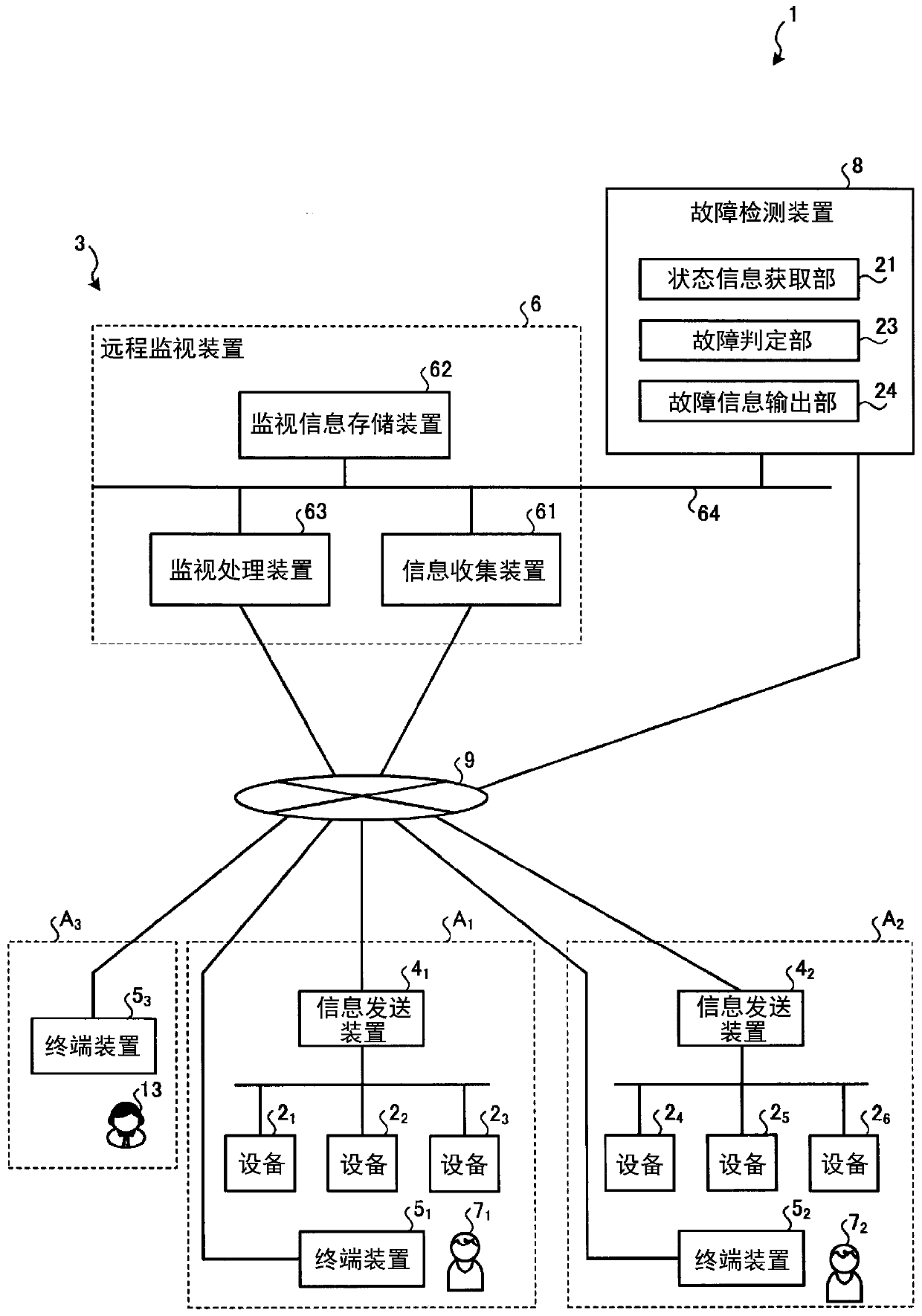

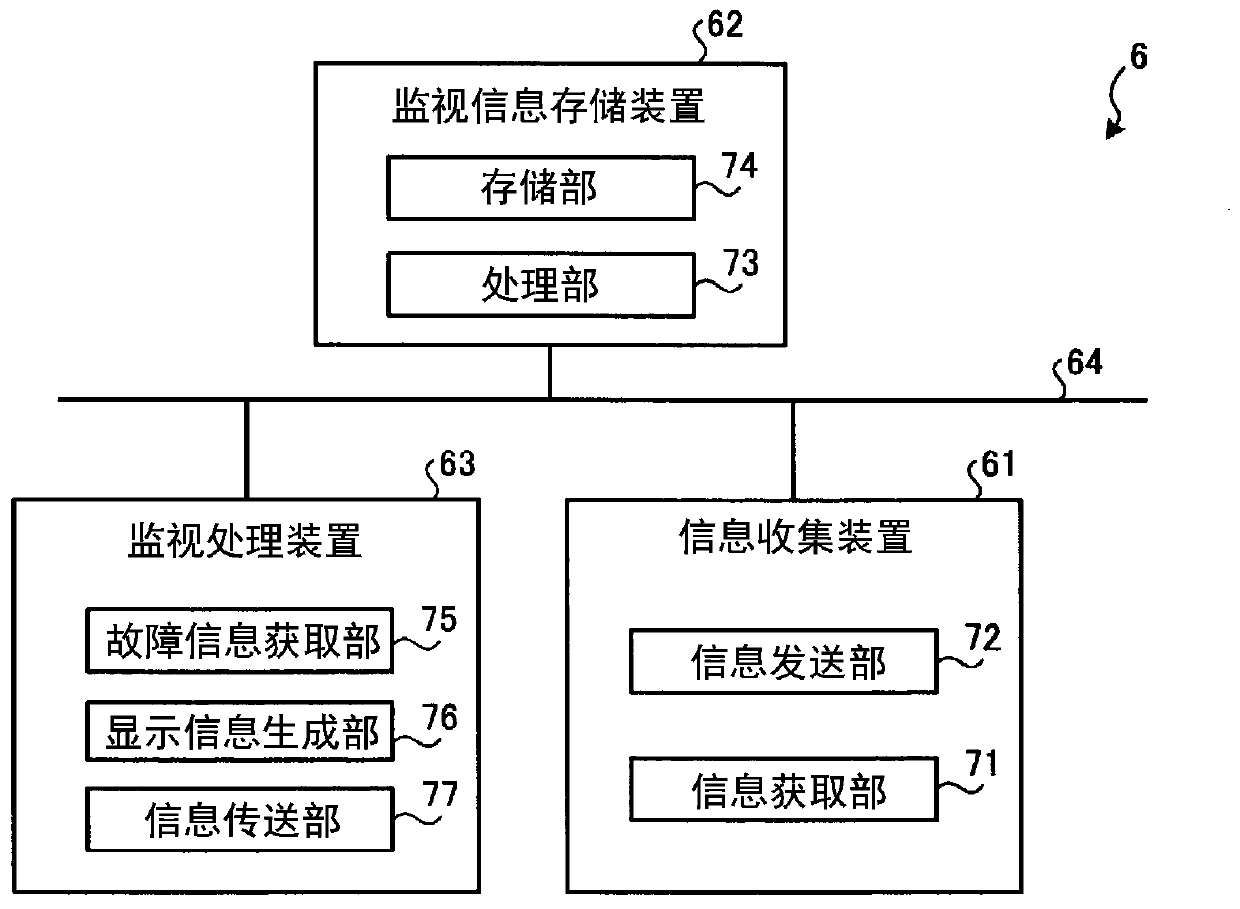

Failure sensing device, monitoring and control system, and failure sensing method

PendingCN111556992AReduce the burden onTelemetry/telecontrol selection arrangementsTesting/monitoring control systemsFailure assessmentControl system

Provided is a failure sensing device (8) comprising a state information acquisition part (21), a failure assessment part (23), and a failure information output part (24). The state information acquisition part (21) acquires, from a remote monitoring system (3) for monitoring remotely disposed facilities (21-26), state information indicating the state of the remote monitoring system (3). On the basis of the state information acquired by the state information acquisition part (21), the failure assessment part (23) assesses a failure of the remote monitoring system (3), and generates failure information indicating details of the assessed failure. The failure information output part (24) outputs the failure information generated by the failure assessment part (23).

Owner:MITSUBISHI ELECTRIC CORP

A Dynamic Tensile Failure Evaluation Method for Fiber Reinforced Composite Materials

ActiveCN108549743BAccurately analyze tensile failure behaviorAnalyzing Tensile Failure BehaviorDesign optimisation/simulationSpecial data processing applicationsFailure assessmentEnergy based

Owner:SOUTHEAST UNIV

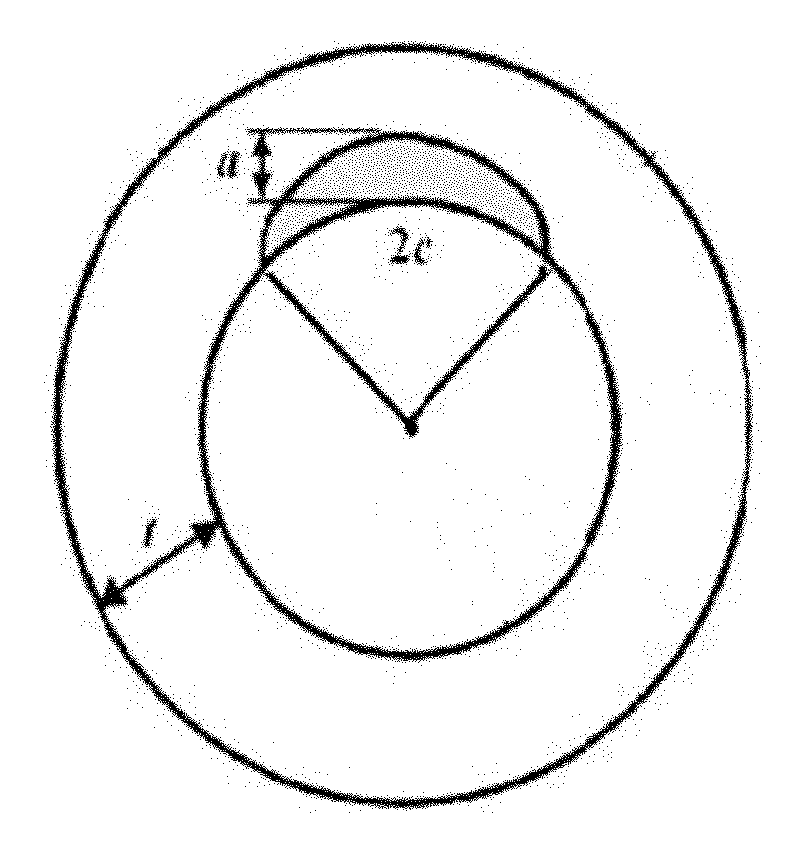

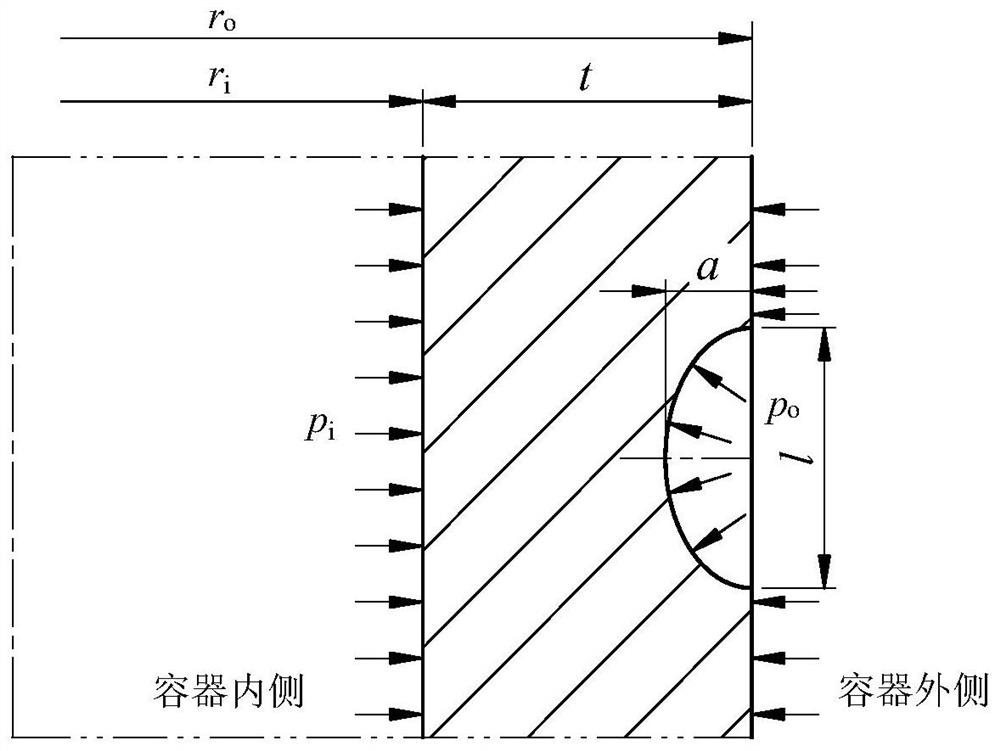

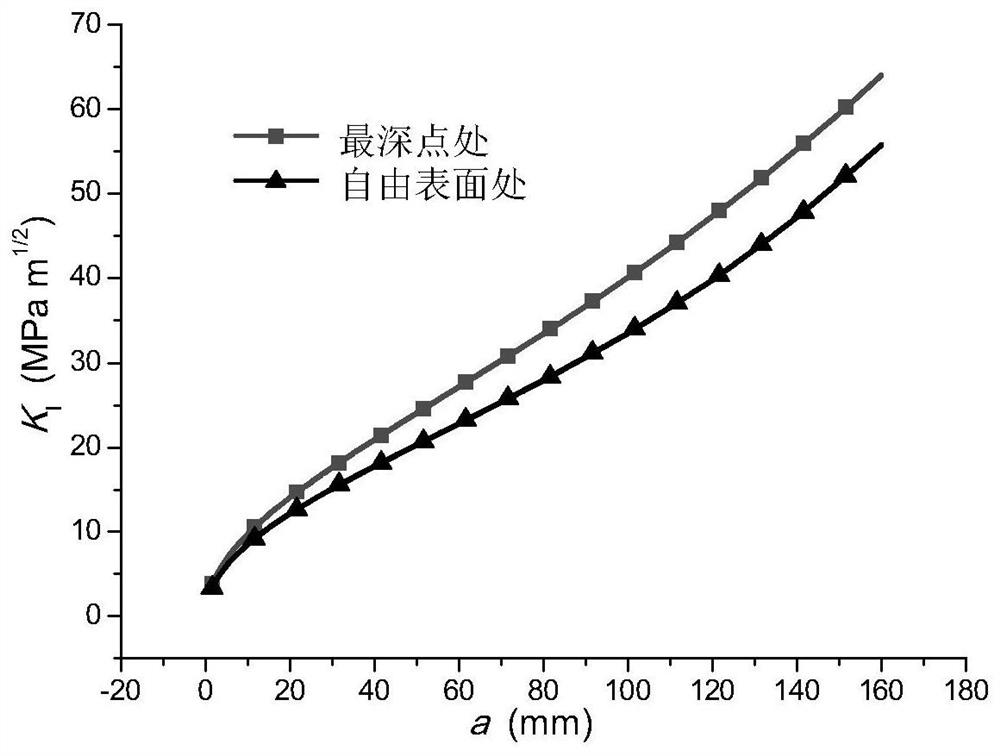

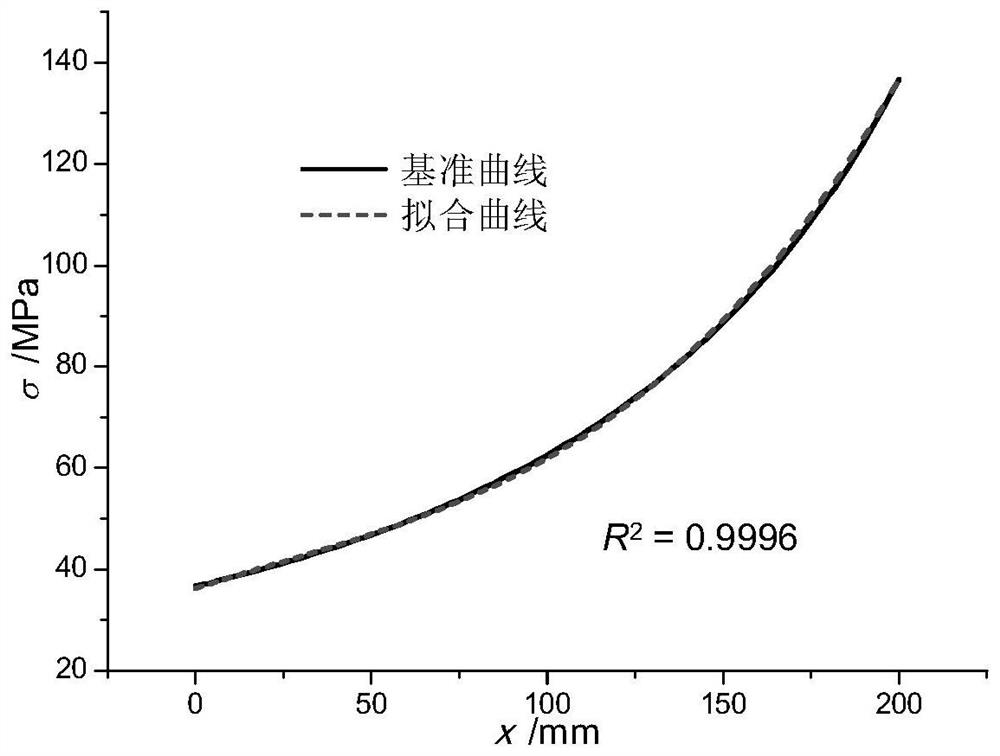

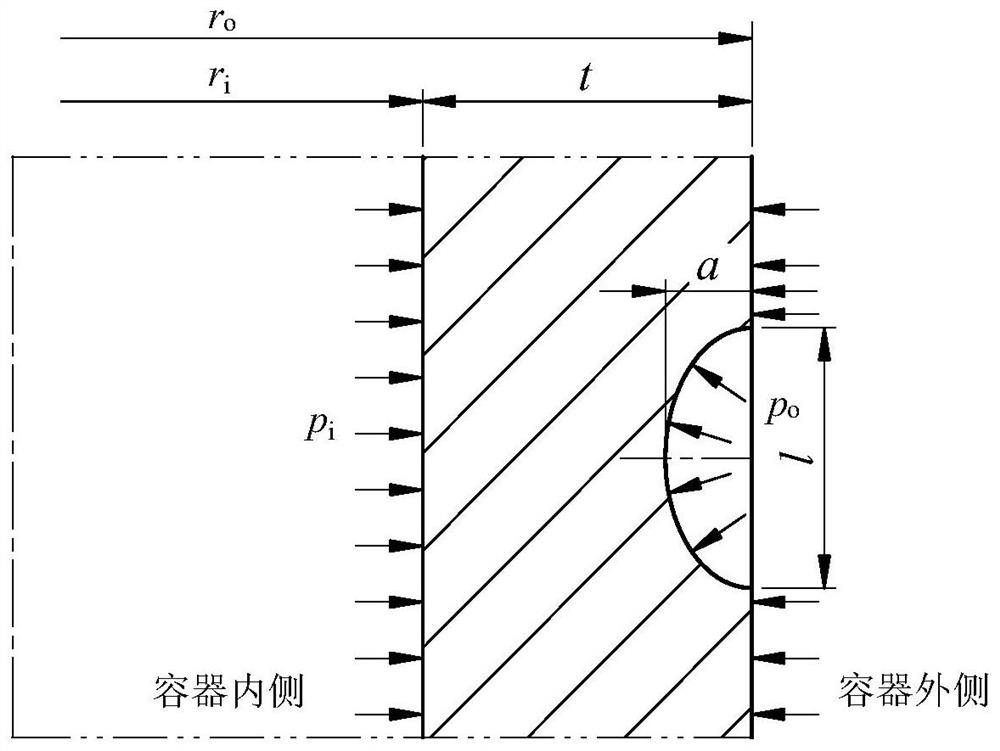

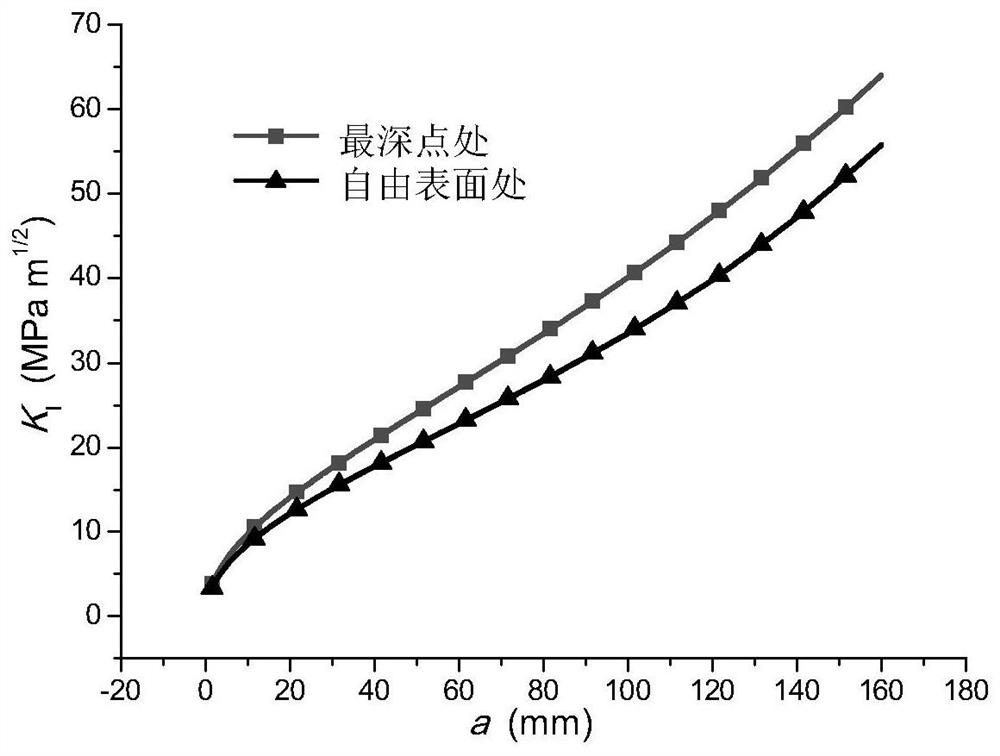

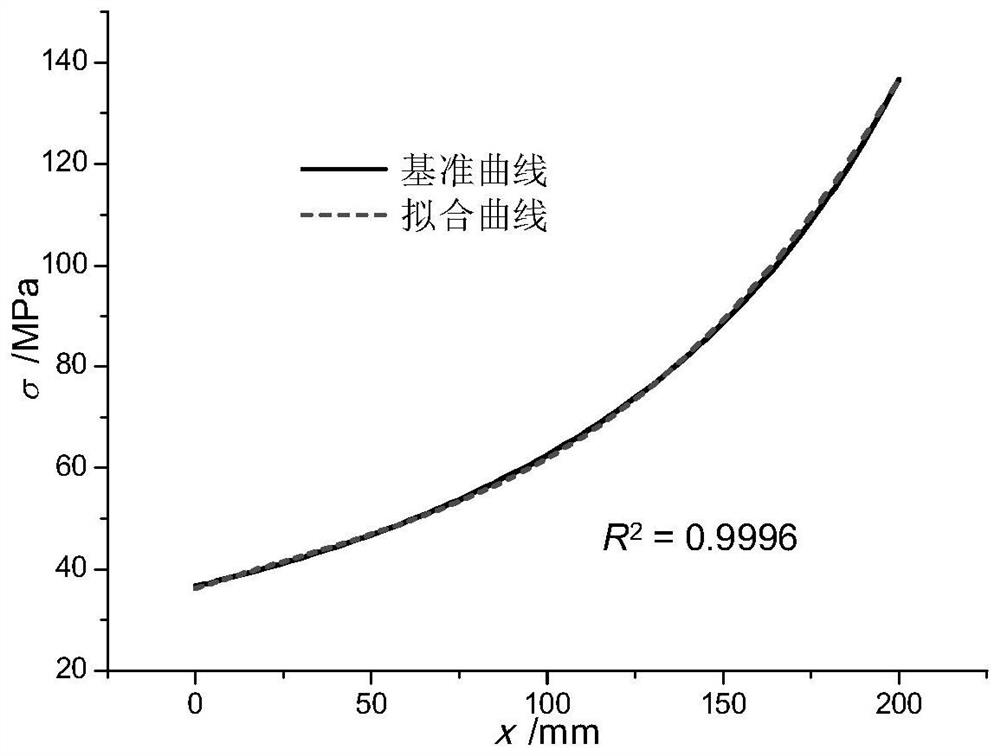

Calculation method of stress intensity factor for axial-radial cracks in outer wall of ultra-high pressure vessel

ActiveCN113176142BConvenient App CalculationImprove accuracyNuclear energy generationMaterial strength using tensile/compressive forcesUltra high pressureFailure assessment

The invention relates to the technical field of ultra-high pressure vessel design and development and fatigue failure assessment calculation, in particular to a method for calculating stress intensity factors of axial-radial cracks on the outer wall of an ultra-high pressure vessel. The invention includes the following steps: determining the structural parameters of the ultra-high pressure vessel, measuring the shape parameters of the axial-radial cracks, and determining the load condition of the cylinder; fitting the stress distribution perpendicular to the plane where the cracks are located; calculating the required simulated Calculate another fitting coefficient under the current crack shape; calculate the crack shape coefficient at the deepest point of the current crack and near the free surface; calculate the stress intensity factor K I . While ensuring the accuracy of the calculation results, the present invention can realize the fast, concise and written calculation of the stress intensity factor of the axis-radial semi-elliptical crack on the outer wall of the cylinder only through formulas, without relying on finite elements Calculation software and professional mathematical analysis software are more suitable for engineering applications.

Owner:HEFEI GENERAL MACHINERY RES INST +1

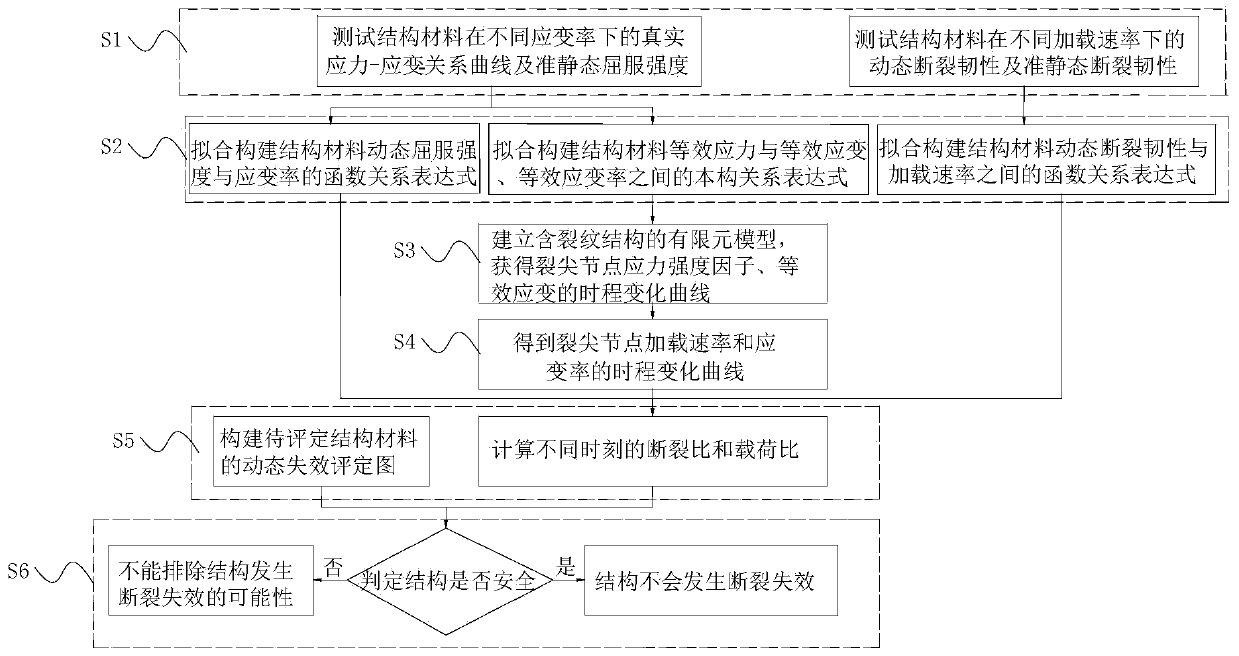

A Dynamic Fracture Evaluation Method for Structures Containing Crack-like Defects

ActiveCN108225915BImplementation of failure assessmentMaterial strength using tensile/compressive forcesNODALFailure assessment

The invention relates to an assessment method of a dynamic fracture containing a crack-like defect structure. The method comprises the steps of testing a relation curve of a true stress sigma true-true strain epsilon true of a structural material under different strain rates, and quasi-static yield strength sigma y; testing dynamic fracture toughness KId and quasi-static fracture toughness KIC ofthe structural material under different loading rates; fitting and building a relation between dynamic yield strength sigma yd and the strain rates, a constitutive relation among an equivalent stresssigma eq, an equivalent strain epsilon eq and an equivalent strain rate, and a relation between the dynamic fracture toughness KId and the loading rates, thus obtaining a time course change curve of astress intensity factor KI and the equivalent strain epsilon eq of a crack tip node containing the crack structure, and a time course change curve of the loading rates and the strain rates of the crack tip node; calculating fracture ratios Kr and load ratios Lr at different moments, building a dynamic failure assessment diagram, and comparing the (Lr, Kr) obtained through calculation as assessment points with a failure assessment curve. The assessment method of the dynamic fracture containing the cracklike defect structure provided by the invention has the advantages that the influence of thestrain rates and the loading rates borne on the material at the crack tip position under the dynamic load action is introduced, so that the failure assessment of the dynamic fracture containing the cracklike defect structure is realized.

Owner:HEFEI GENERAL MACHINERY RES INST +1

A multi-scenario distributed information control system based on the Industrial Internet of Things

ActiveCN113485268BEnables quantitative deviation analysisMeet processing needsTotal factory controlProgramme total factory controlInformatizationFailure assessment

The invention discloses a multi-scenario distributed informatization control system based on the Industrial Internet of Things, which includes a scene distribution acquisition module, a scene parameter analysis module, a waste processing simulation module, a scene correlation evaluation module, a tracking calibration module and an information management and control platform. The management and control platform adjusts the processing parameters and process environment parameters associated with the comprehensive fault evaluation coefficient greater than the threshold of the fault evaluation coefficient. degree coefficient and the correlation coefficient between each processing procedure, comprehensively evaluate the comprehensive failure evaluation coefficient of each processing procedure affected by the previous processing procedure, and track the processing parameters and processing parameters in each related processing procedure through the numerical value of the comprehensive failure assessment coefficient The process environment parameters are used to optimize the control of post-processing parameters and process environment parameters, and have the characteristics of intelligent and information-based tracking and control.

Owner:深圳市壹佰度科技有限公司

Method for calculating stress axial-radial crack stress intensity factor of outer wall of ultrahigh pressure vessel cylinder

ActiveCN113176142AConvenient App CalculationImprove accuracyNuclear energy generationMaterial strength using tensile/compressive forcesStress distributionFailure assessment

The invention relates to the technical field of ultrahigh pressure vessel design and development and fatigue failure evaluation calculation, in particular to a method for calculating an axial-radial crack stress intensity factor of the outer wall of an ultrahigh pressure vessel cylinder. The method comprises the following steps: determining structural parameters of an ultrahigh pressure vessel, measuring shape parameters of axial-radial cracks, and determining a load working condition of a cylinder; fitting stress distribution perpendicular to a plane where the crack is located; calculating a required fitting coefficient; calculating another fitting coefficient under the current crack shape; calculating crack shape coefficients at the deepest point of the current crack and the position close to the free surface; and calculating a stress intensity factor KI. According to the method, the accuracy of a calculation result can be ensured, meanwhile, rapid, concise and written calculation of the axial-radial semi-elliptical crack stress intensity factor of the outer wall of the cylinder can be achieved only through a formula, finite element calculation software and professional mathematical analysis software do not need to be relied on, and the method is more suitable for engineering application.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com