Fuzzy random reliability evaluation method for pipeline with crack defect based on R6-FAD and BP-MCS

A BP-MCS, R6-FAD technology, applied in CAD numerical modeling, probabilistic CAD, stochastic CAD, etc., can solve the problem of not giving a unified value of safety margin, and achieve the effect of simplifying the randomization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

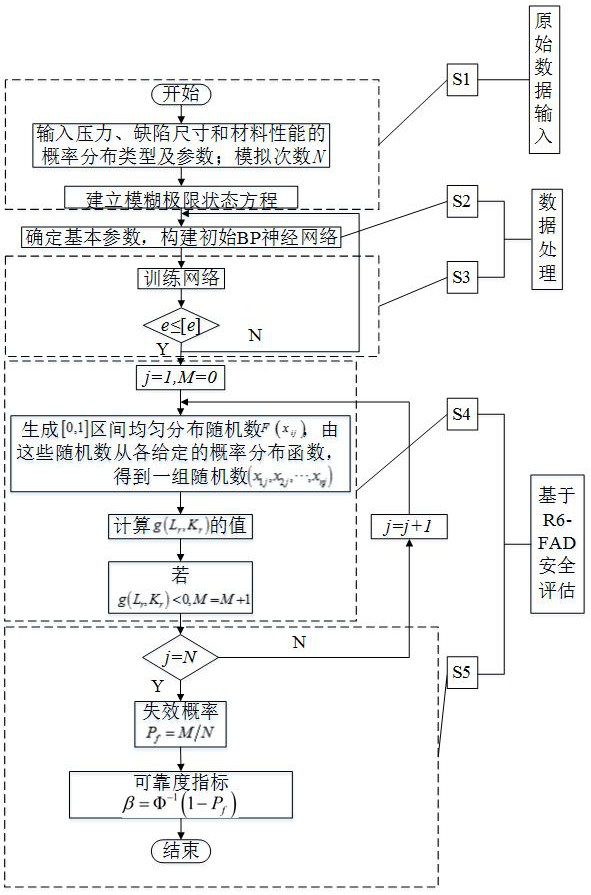

[0009] Such as figure 1 As shown, the present invention is based on R6-FAD and BP-MCS fuzzy random reliability evaluation method for pipelines containing crack defects, detailed steps: Step S1: input pipeline internal pressure and other actual working conditions external load, crack defect size and The probability distribution type and parameters of material properties and the maximum number of simulations N, establish the fuzzy limit state equation; step S2: data preprocessing, determine the basic parameters, and construct the initial BP neural network; step S3: train the neural network, when it can better approximate the fuzzy For the limit state equation, execute step S4, otherwise, return to step S2 to re-adjust the network; step S4: calculate j=1, M=0, generate [0,1] uniformly distributed random number F(x ij ), from these random numbers from each given probabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com