Evaluation method of fatigue properties of metal materials

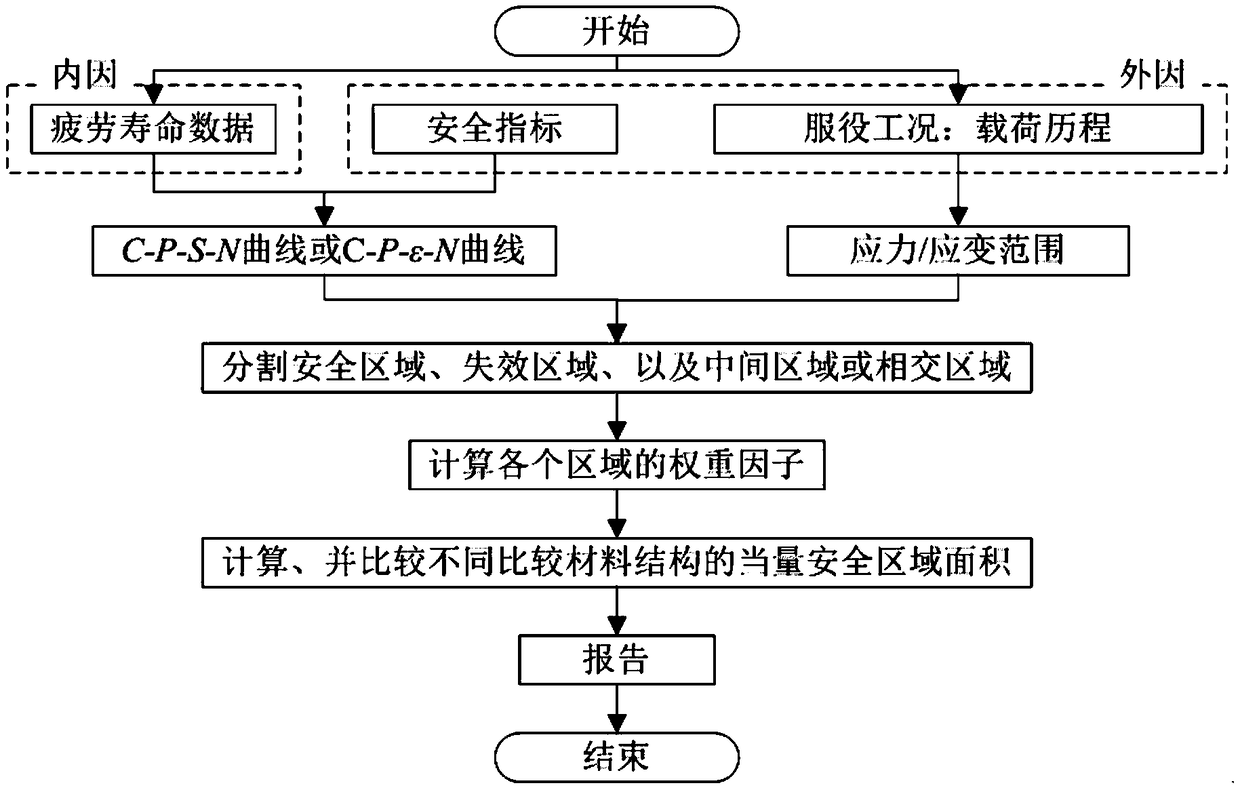

A technology for fatigue performance and metal materials, which is applied in the direction of analyzing materials, using repeated force/pulsation force to test the strength and strength characteristics of materials, etc. It can solve the problems of disregarding dispersion and no universal and feasible evaluation standards, etc., so as to achieve simple application , Evaluate the effect quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

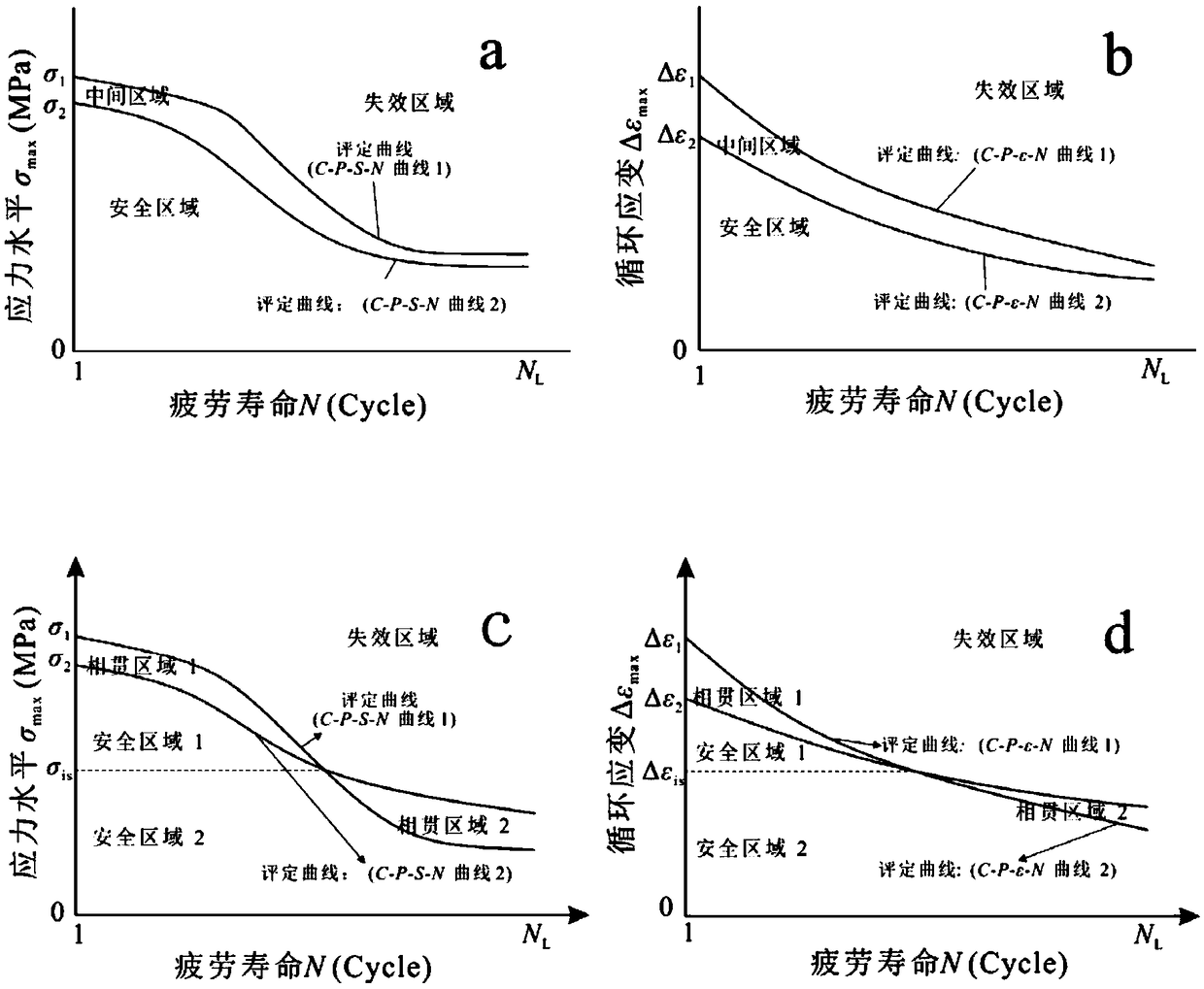

[0066] This example is to evaluate the fatigue performance of two cast aluminum alloys.

[0067] Conditions: Safety indicators are: confidence level 95%, survival rate 99%; life data are shown in Table 1 and Table 2; working stress is random load, and stress level obeys normal distribution σ max ~N(70,5 2 ), MPa.

[0068] Table 1 The service life of cast aluminum alloy ZL101A produced by Factory A

[0069]

[0070] Table 2 The service life of cast aluminum alloy ZL101A standard aluminum alloy produced by factory B

[0071]

[0072] The evaluation process is as follows:

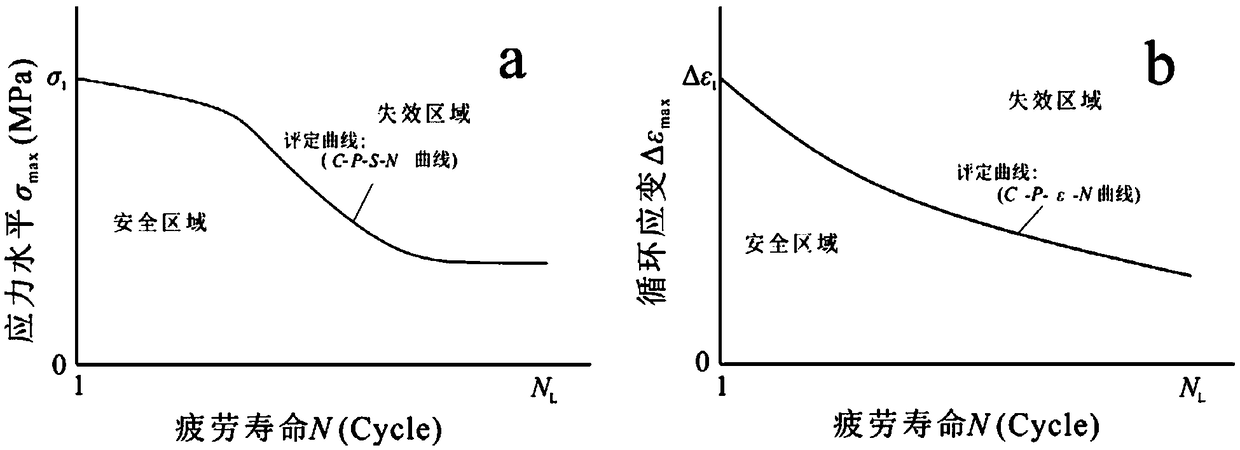

[0073] 1. Fitting fatigue life law C-P-S-N curve:

[0074] Based on fatigue life data points [Life N i,j , stress S i ], statistics of each stress level S i The lifetime distribution under:

[0075] 1.1 According to the formula (1), calculate the median logarithmic life under each stress level μ i :

[0076]

[0077] For the cast aluminum alloy ZL101A produced by Factory A: take the life cor...

Embodiment 2

[0125] The difference from Example 1 is that the two metal materials to be evaluated are tested at different strains ε i Fatigue life under N i,j , then based on the fatigue life data points [N i,j , ε i ], statistics of each cyclic strain ε i life distribution, and fit the fatigue life law C-P-ε-N curve (curve 1 and curve 2) of two kinds of materials; in each test and calculation process, all adopt material strain to replace the stress level in embodiment 1 . The output evaluation results are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com