Patents

Literature

44 results about "Dynamic stretching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamic stretching is a form of stretching beneficial in sports utilizing momentum from form, static-active stretching strength and the momentum from static-active stretching strength, in an effort to propel the muscle into an extended range of motion not exceeding one's static-passive stretching ability. Anything beyond this range of motion becomes ballistic stretching. It is a type of stretching while moving. This form of stretching prepares the body for physical exertion and sports performance. In the past it was the practice to undertake static stretching before exercise. Dynamic stretching increases range of movement, blood and oxygen flow to soft tissues prior to exertion. Increasingly coaches and sports trainers are aware of the role in dynamic stretching in improving performance and reducing the risk of injury.

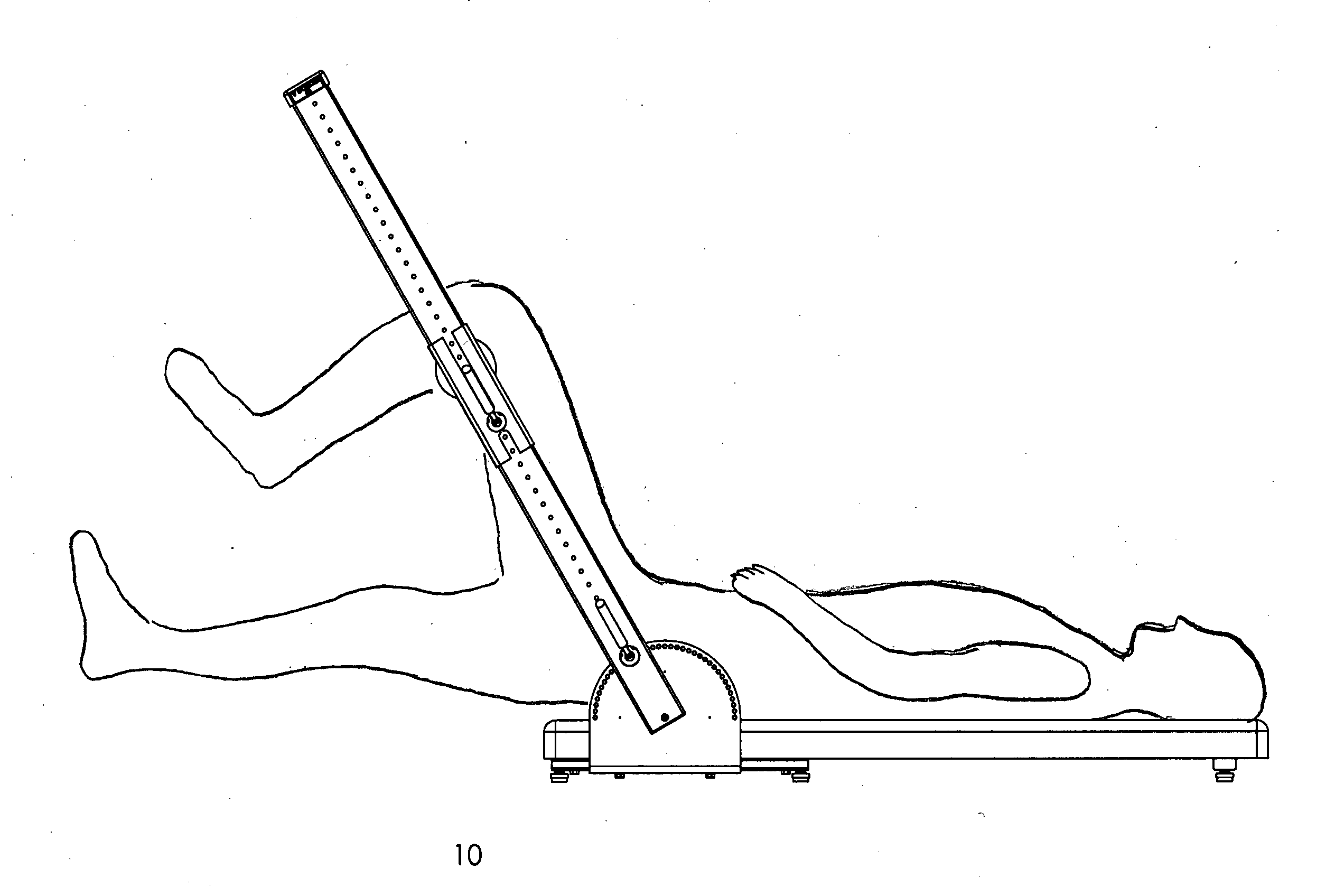

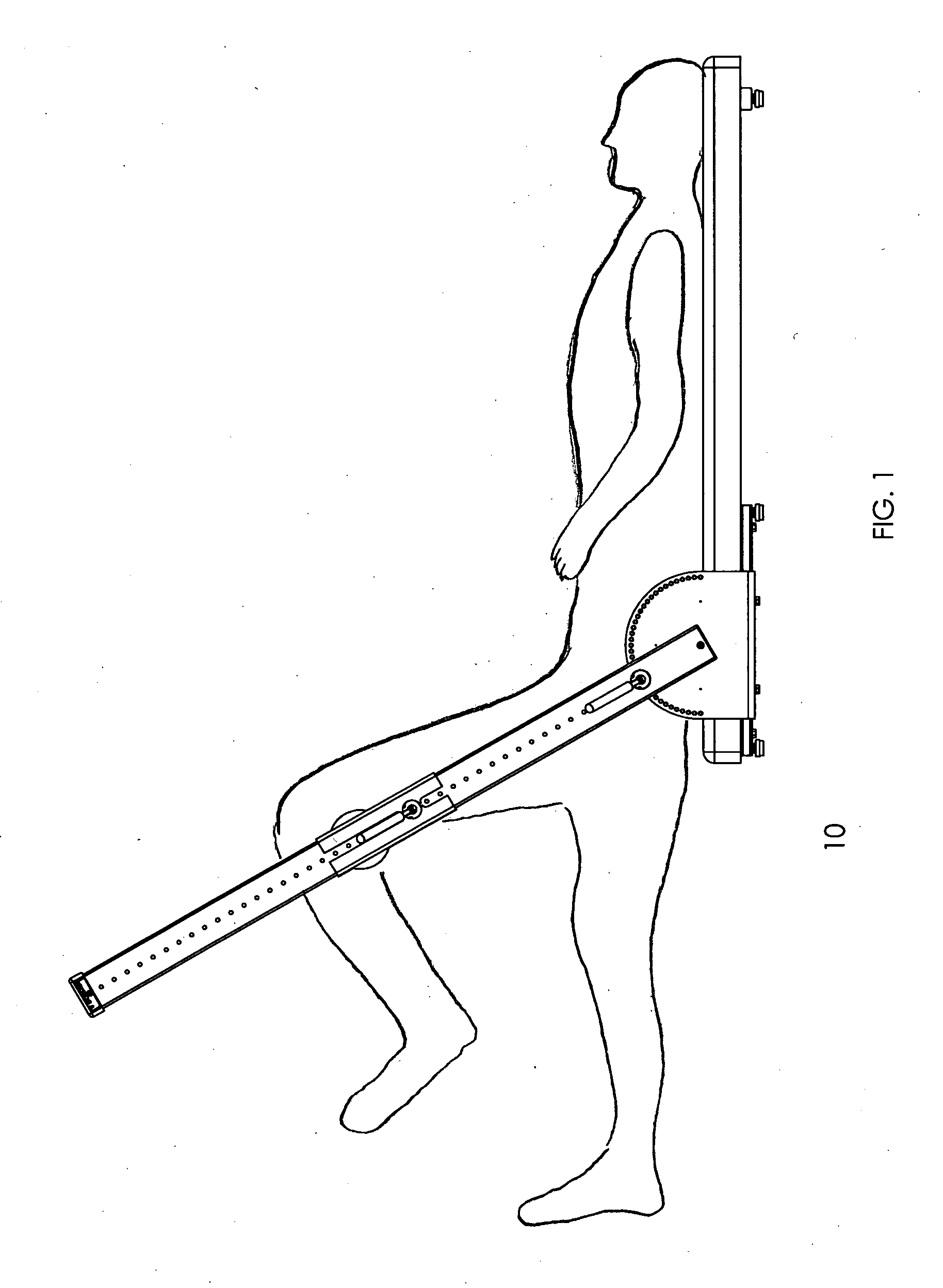

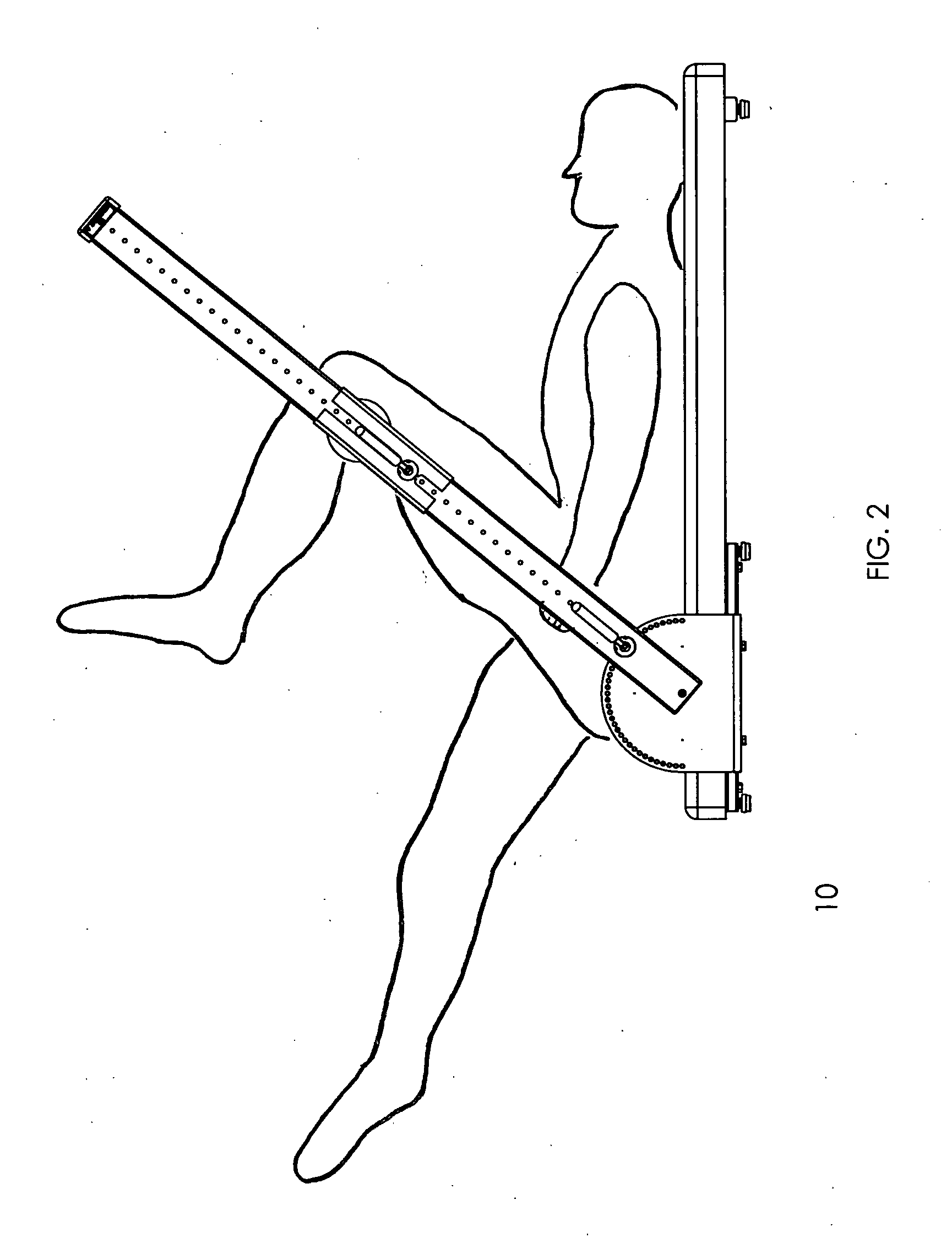

Leg Stretching Machine For Simultaneously Stretching All Stride Muscles And Method Of Using

InactiveUS20130225378A1Overcomes stretching fatigueStretch excessivelySpace saving gamesStiltsStride lengthEngineering

A muscle-stretching machine designed to provide the user with an easy method of functional and dynamic stretching and also provide the user with flexibility feedback information as to the performance of the stretch, with regards to the included angle between the two legs. A user of the muscle stretching machine can set the roller pad along any point along the back of the user's leg and set the angle the roller pad makes with the floor, so that the angle exceeds the users stride length. The user then lies on their back on the cushioned surface; places one leg on the roller pad and the other leg is allowed to hang down. If the roller pad is set at an angle that exceeds the users stride length, then the leg not on the pad will not contact the floor. As a result, when the free leg drops all the muscles in the user's stride are stretched.

Owner:BUREK DENIS E

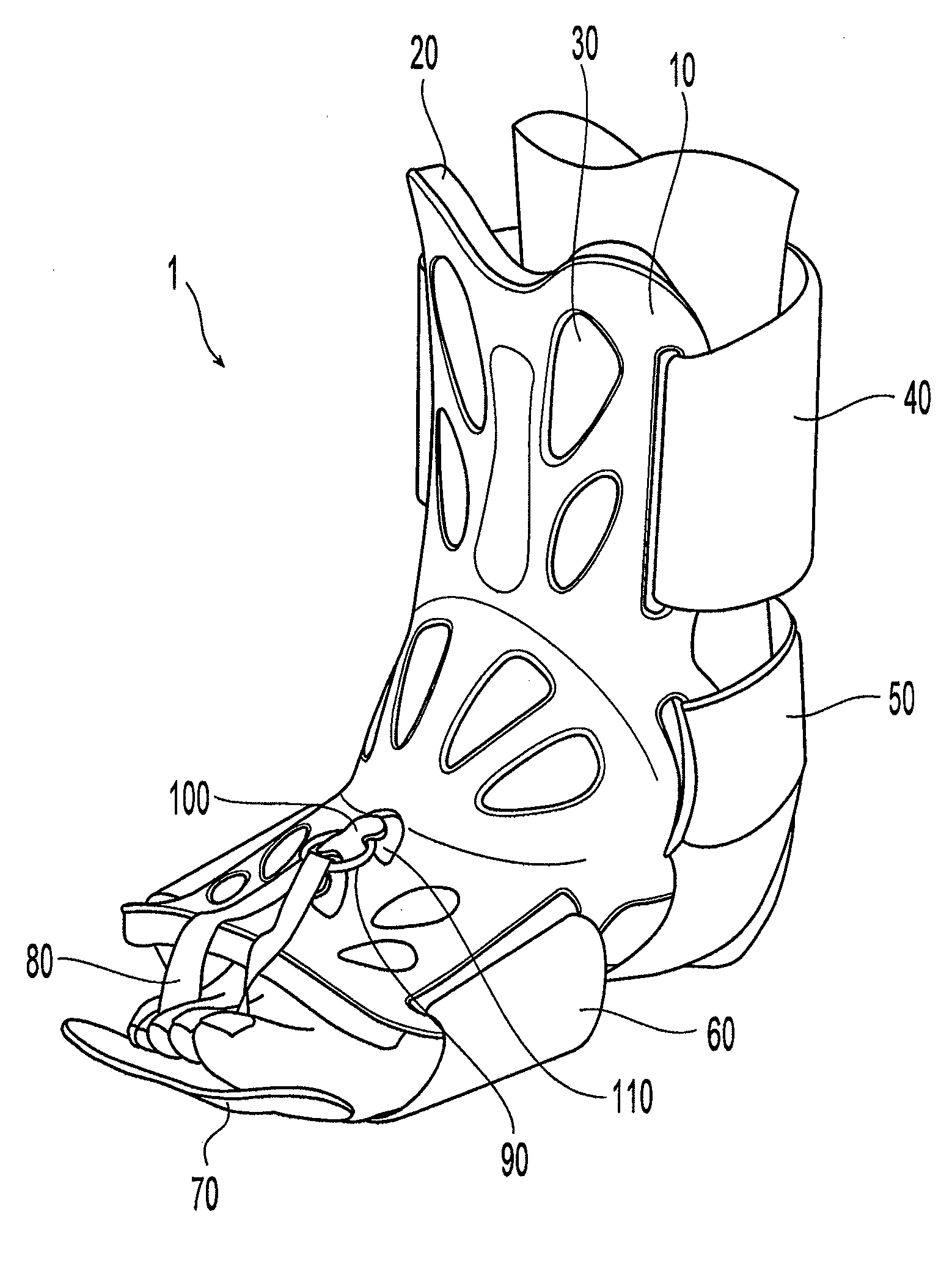

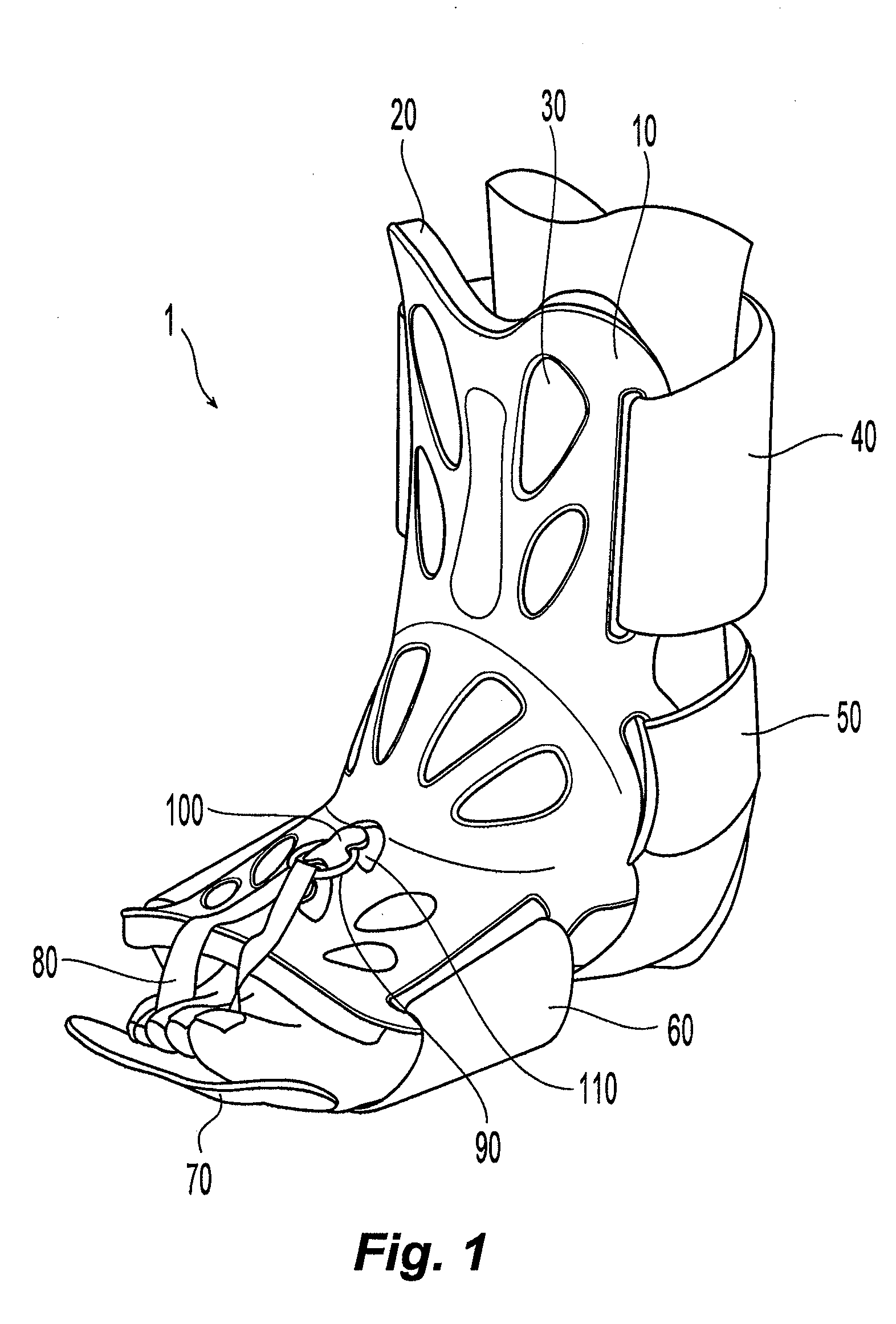

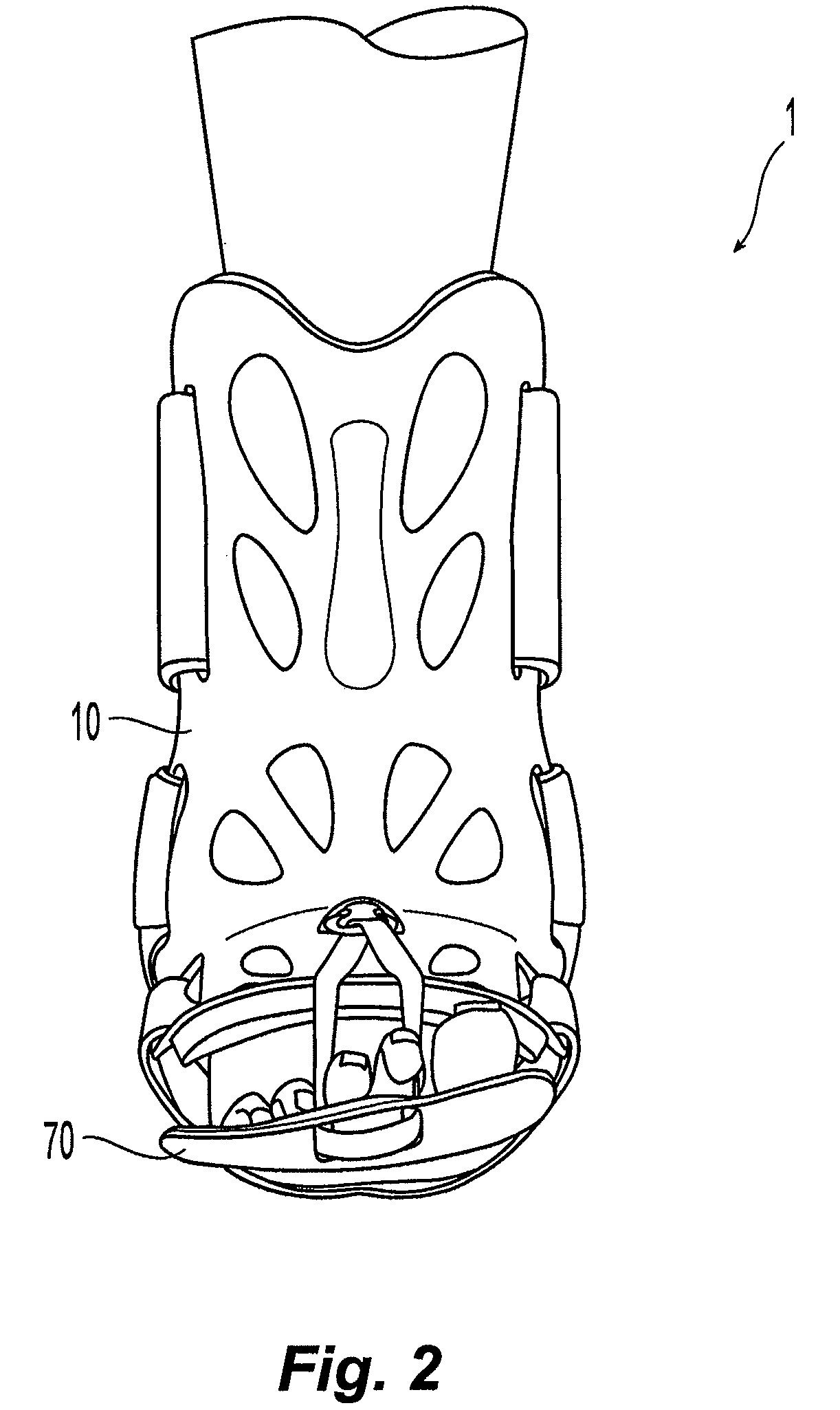

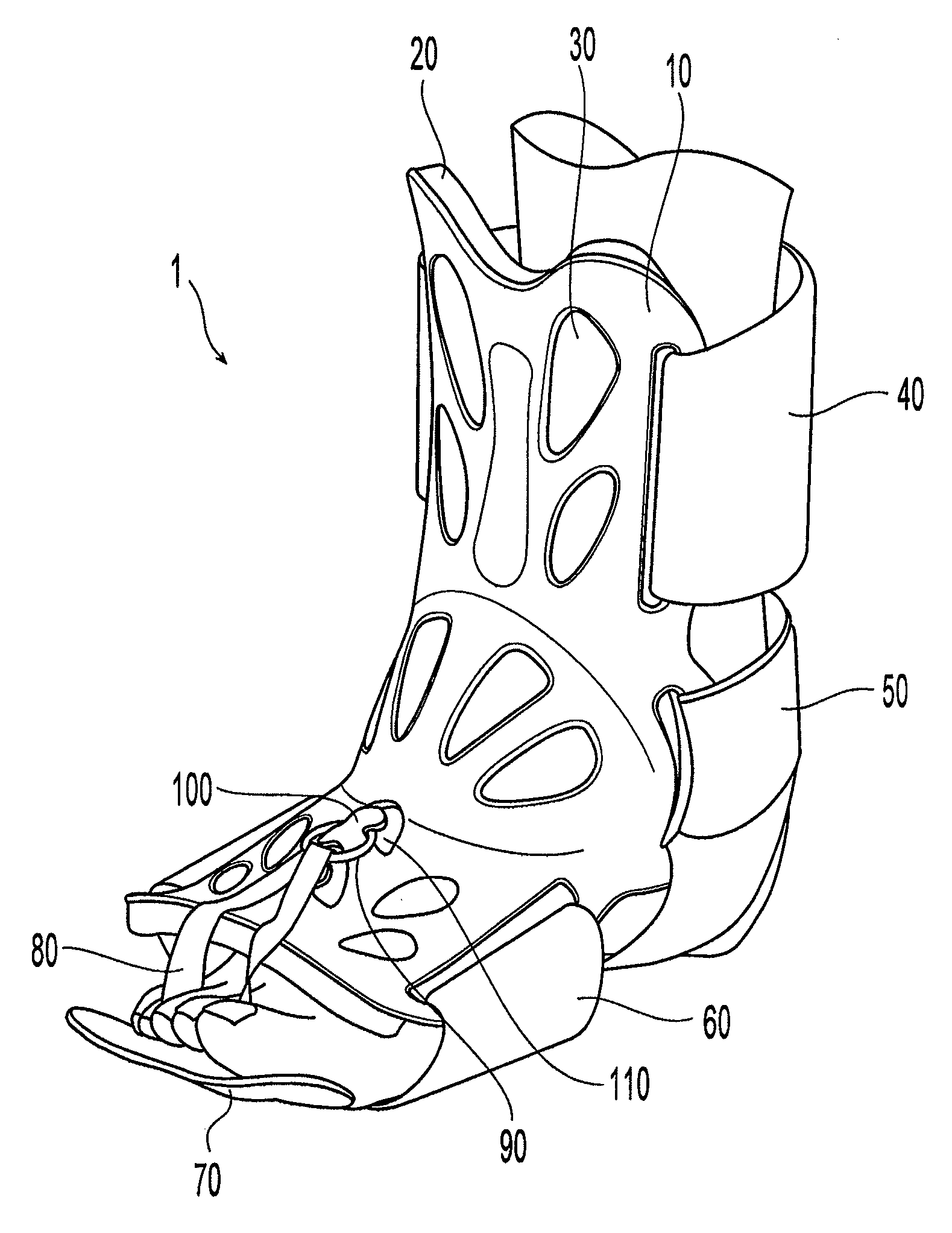

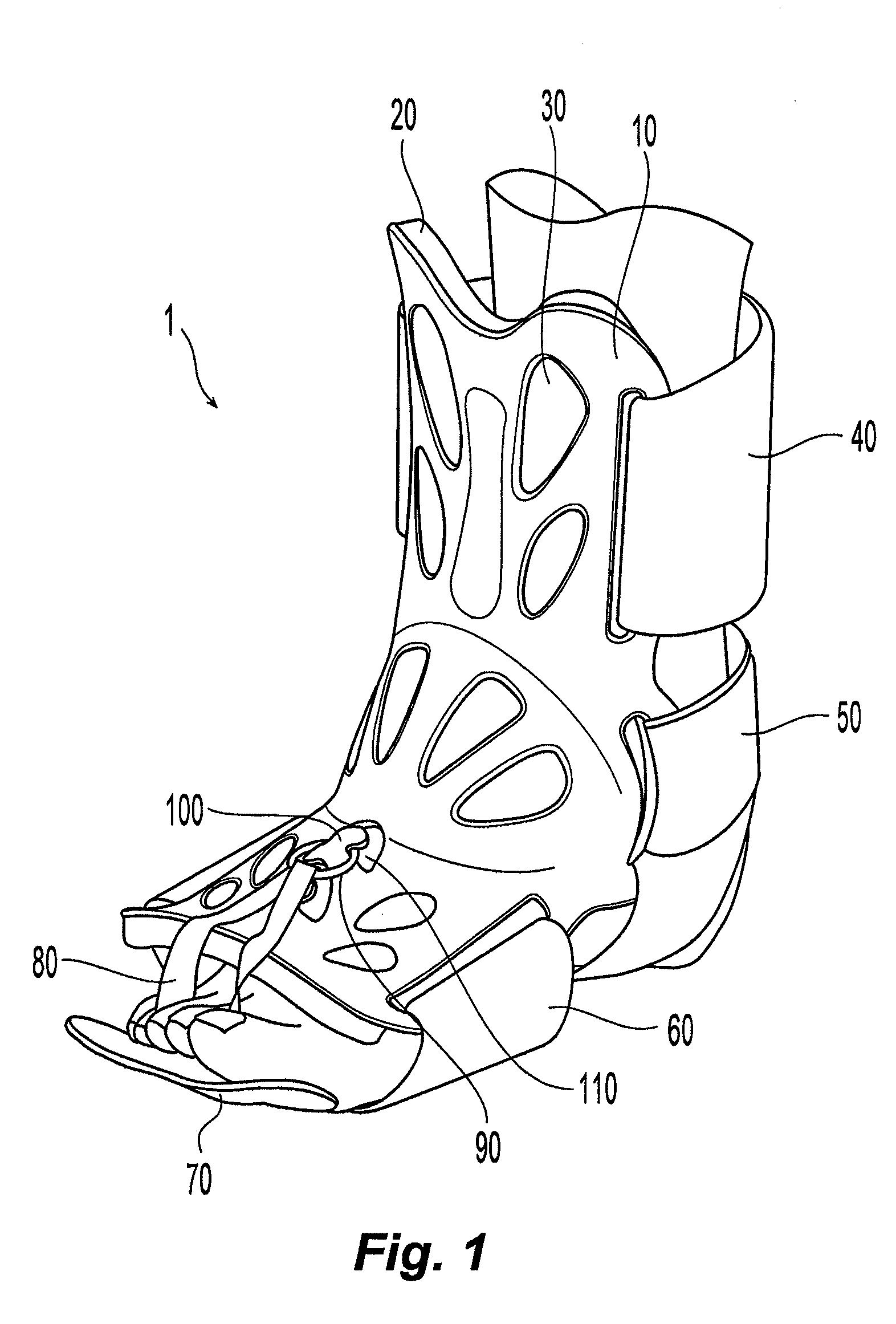

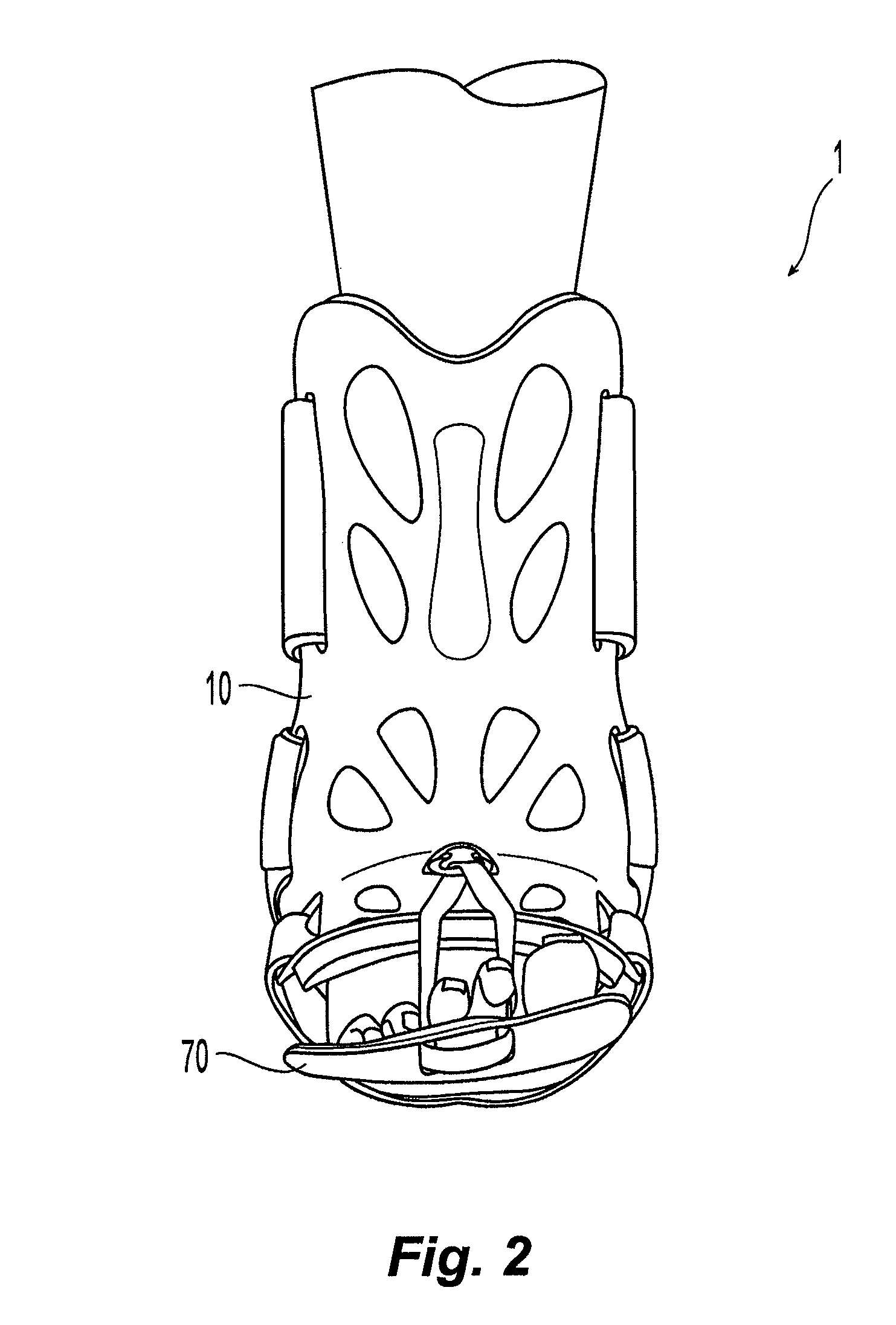

Night splint with digital dorsiflexion

ActiveUS20090264803A1Relieve symptomsReduce loadRestraining devicesNon-surgical orthopedic devicesLow loadDynamic stretching

A night splint for a user's foot having a frame member and a toe retainer that is releasably connected to the frame member. The toe retainer is configured to dorsiflex at least one toe of the user to allow for a dynamic stretch of the plantar fascia and to provide a low load stretch of the Achilles tendon, plantar fascia tendon, deep flexor muscles and calf muscles to relieve symptoms of plantar fasciitis.

Owner:DARCO INT

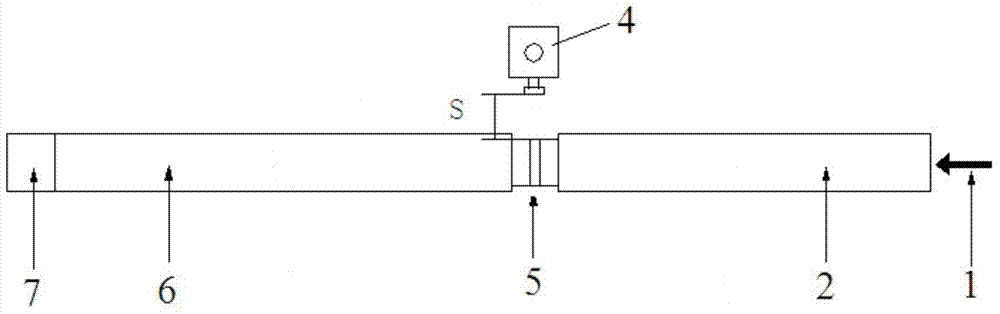

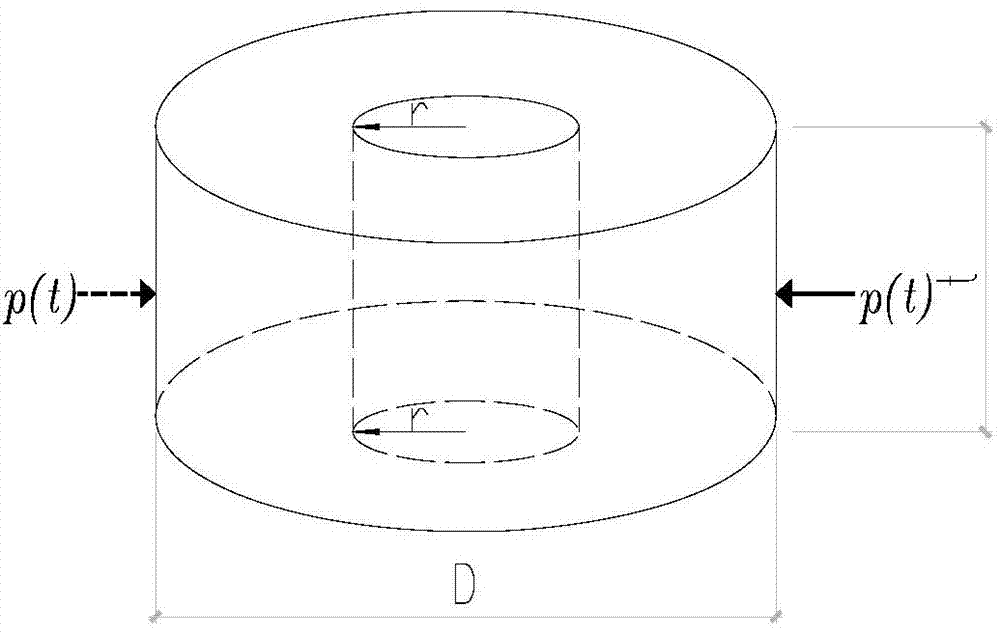

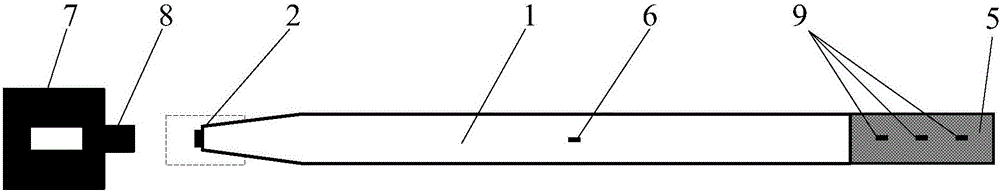

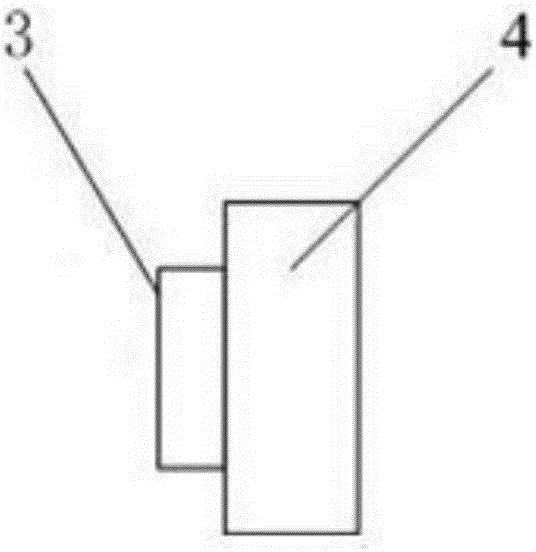

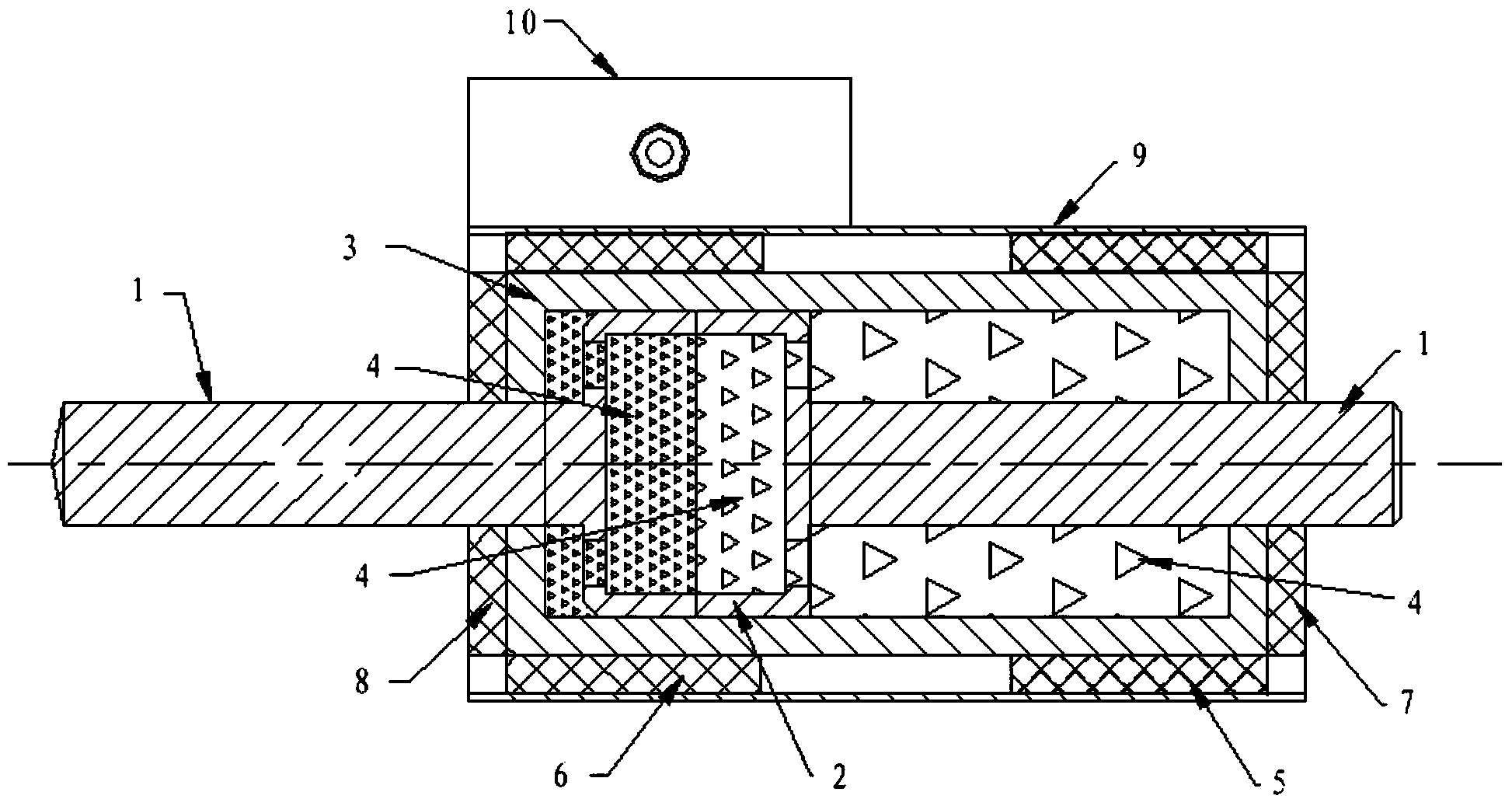

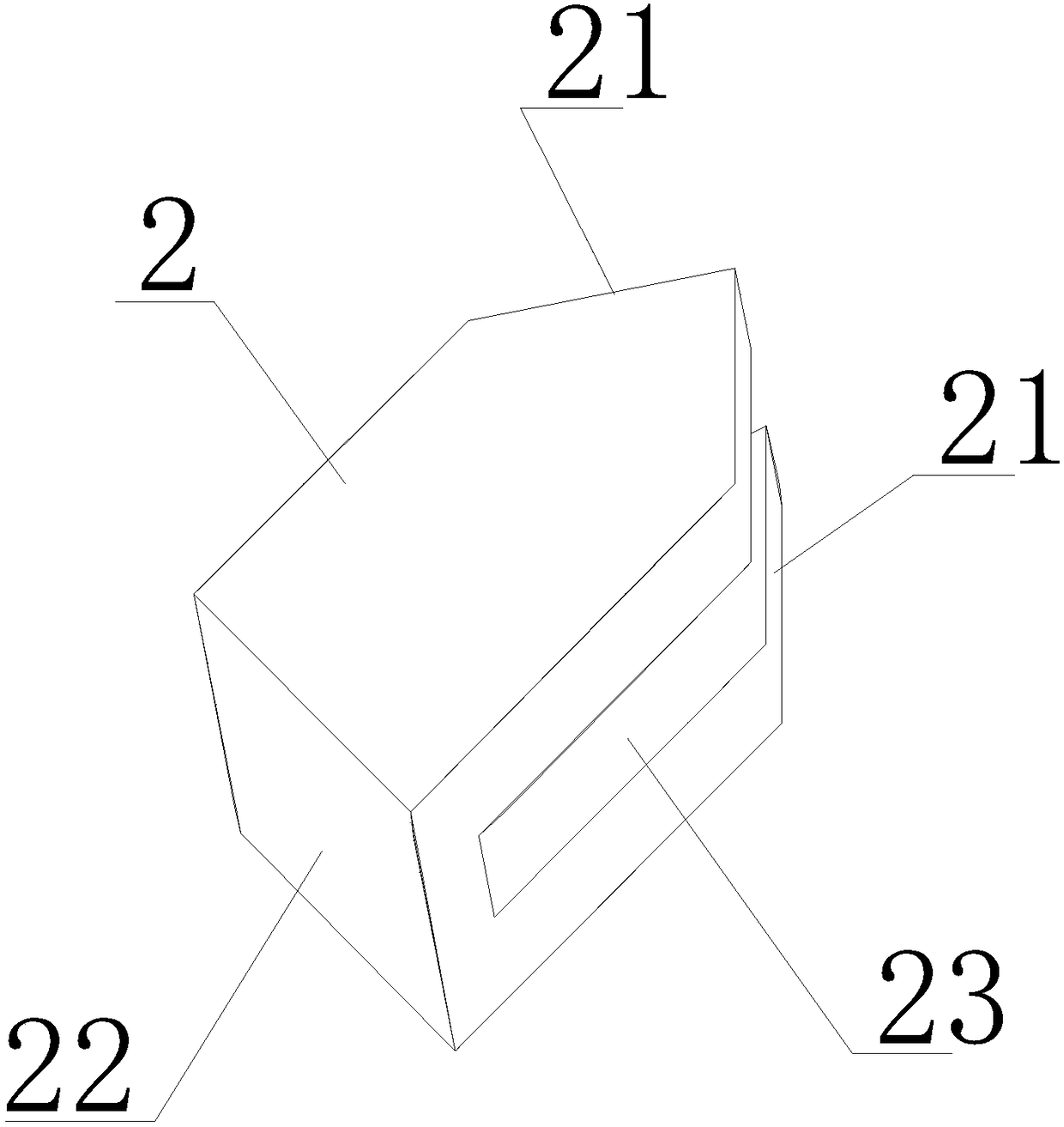

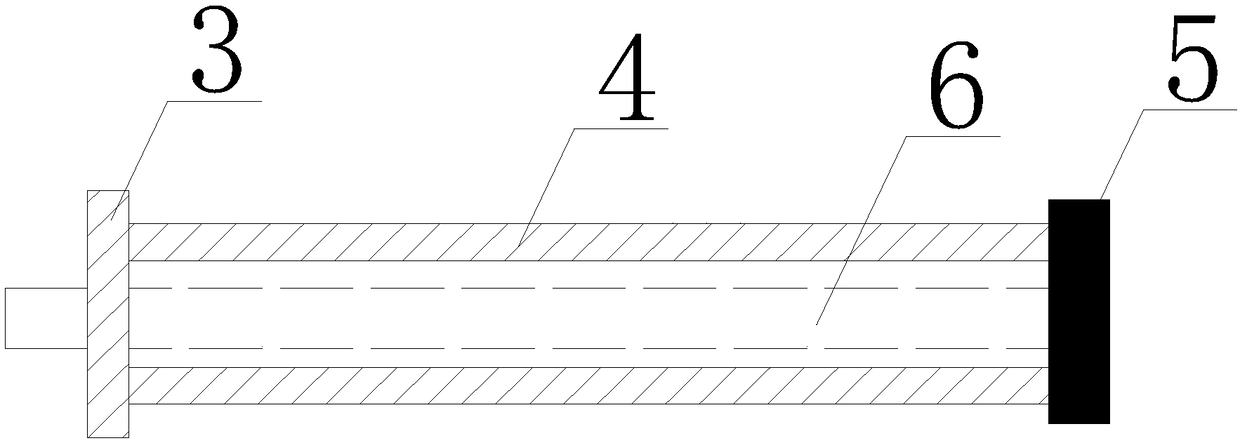

Measurement device and method for dynamic stretching crack propagation speed of fragile material

ActiveCN103792151AHigh measurement accuracyPrecisely determine when the extension startsMaterial strength using single impulsive forceMeasurement deviceStop time

The invention discloses a measurement device for the dynamic stretching crack propagation speed of a fragile material. The measurement device comprises an SHPB (split Hopkinson pressure bar) device, a specimen and a high-speed camera, wherein a round through hole is preformed in the center of the specimen, and the specimen is clamped between an incident rod and a transmission rod of the SHPB device; the high-speed camera is installed on an axis of the round through hole of the specimen. The measurement method comprises the following steps: applying impact load to the specimen by utilizing the SHPB device so as to enable a material to be cracked; meanwhile, shooting an image on the surface of the specimen in real time, confirming the crack starting and stopping time according to the record of the image, measuring the length of the crack actually, and calculating the dynamic stretching crack propagation speed. The measurement device and method provided by the invention can control the dynamic stretching crack propagation direction of the fragile material, and also can precisely confirm the crack propagation starting and stopping time, effectively improve the measurement precision of dynamic stretching crack propagation speed of the fragile material, and provide a novel conveniently operated, rapid, convenient, simple and effective method for confirming the dynamic stretching crack propagation speed of the rock-type fragile material under the impact load effect.

Owner:CENT SOUTH UNIV

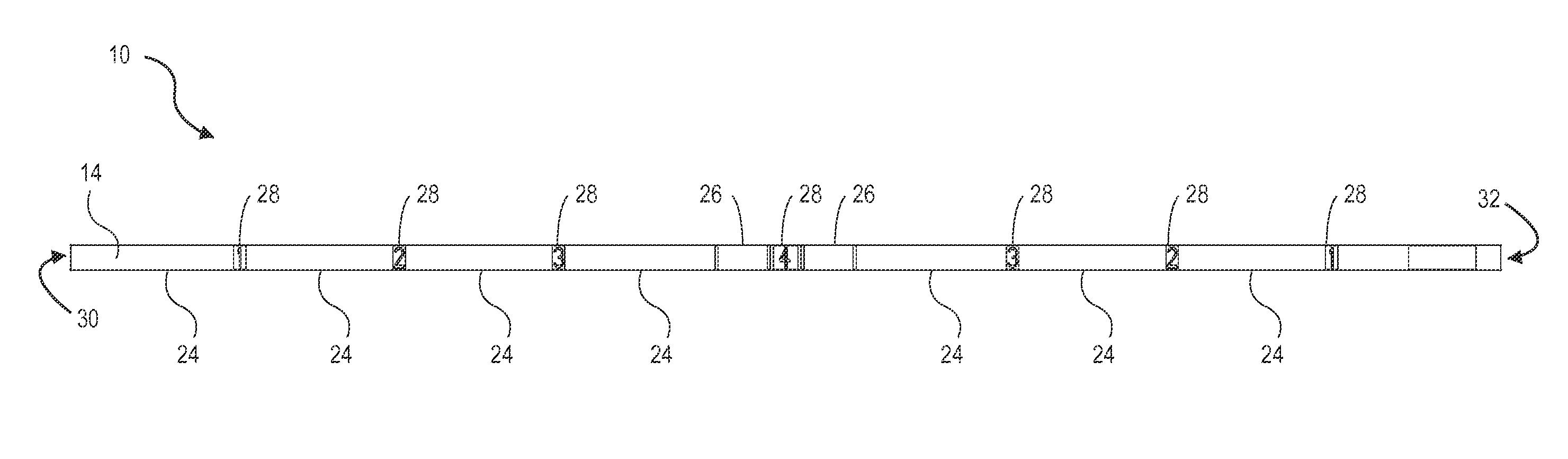

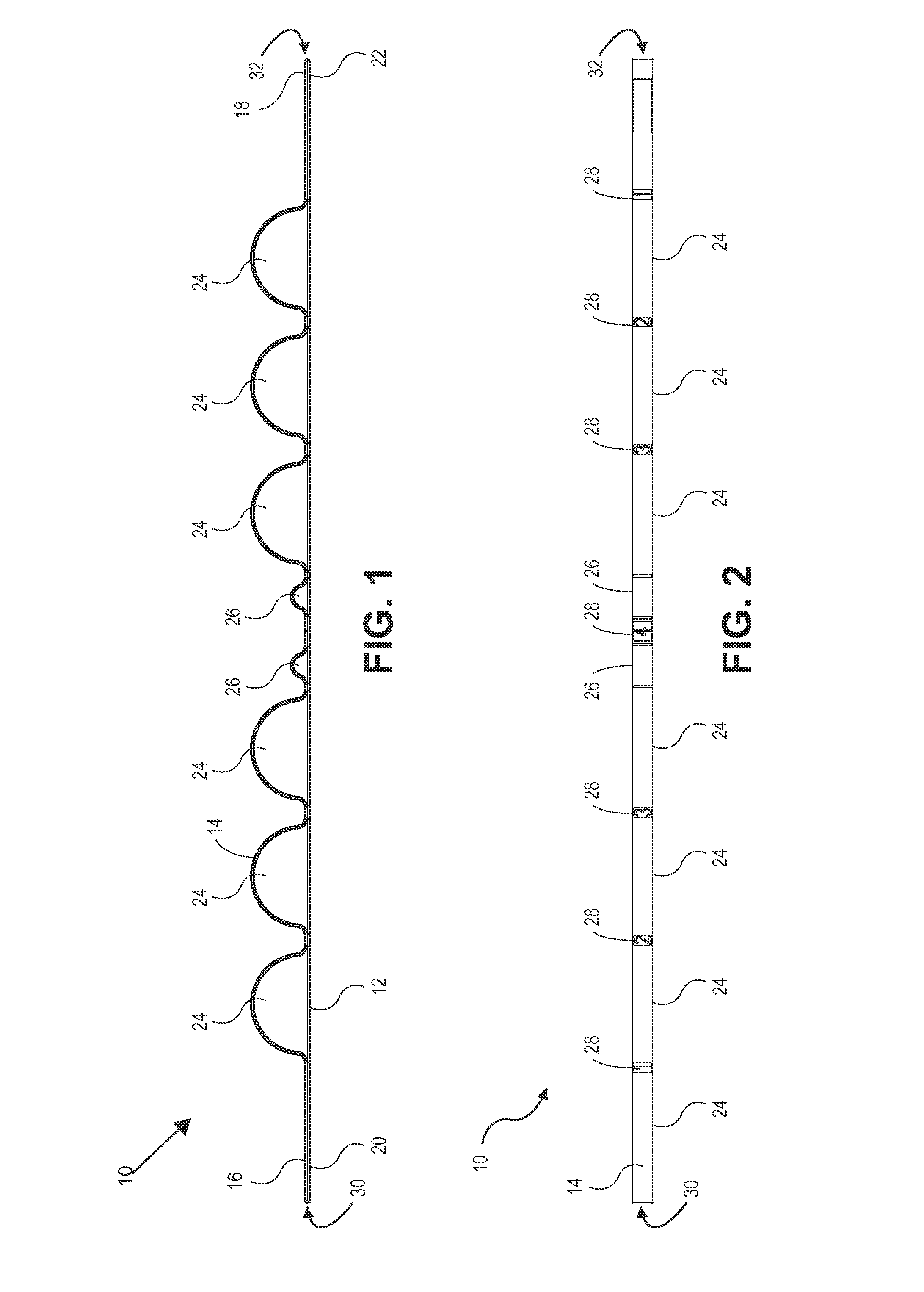

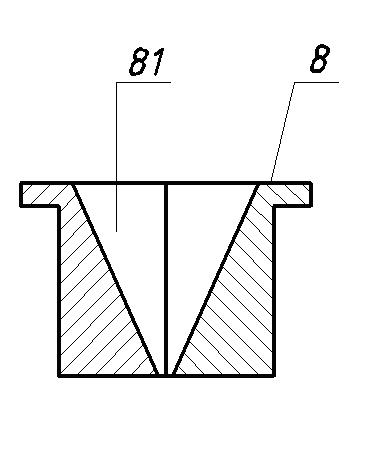

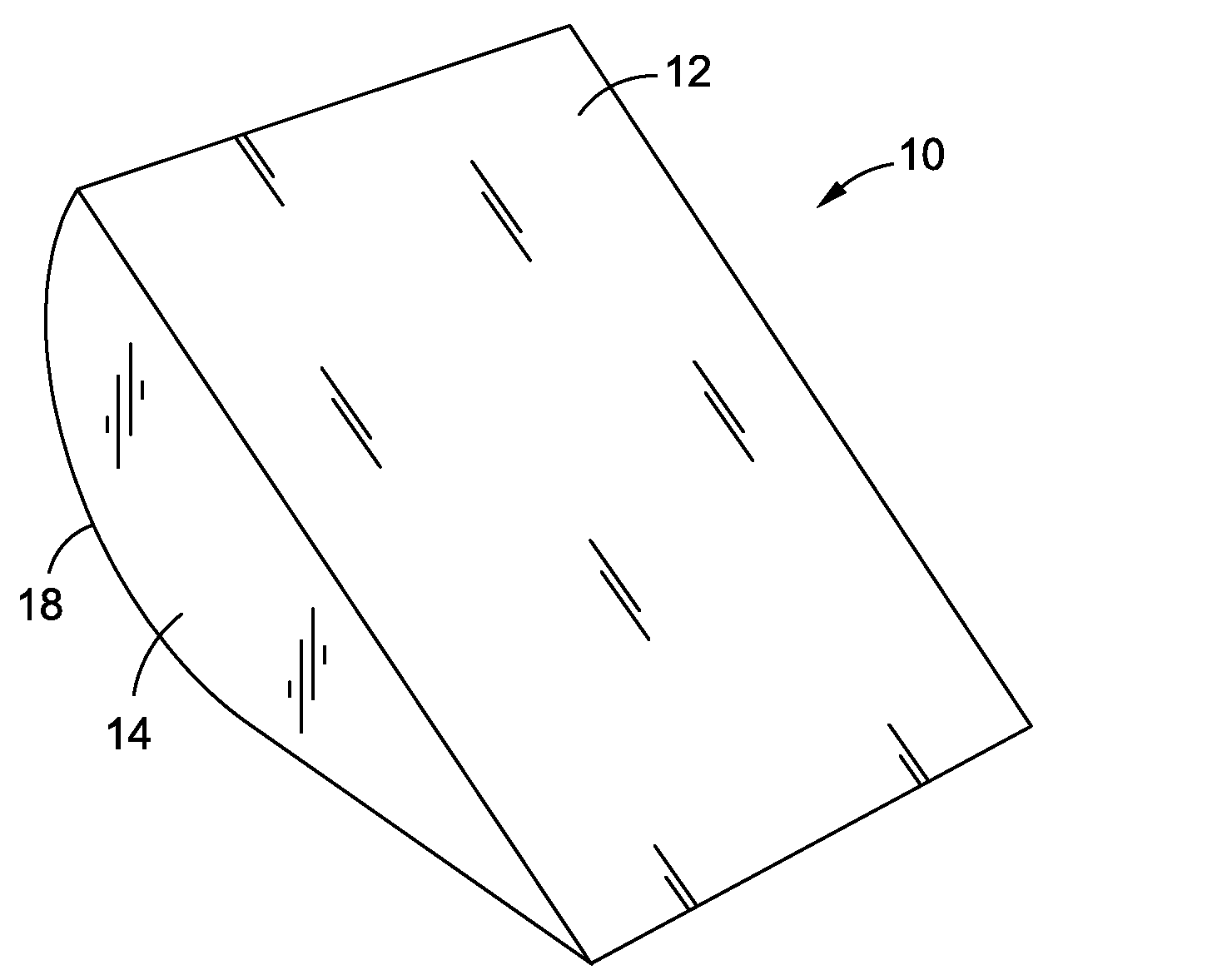

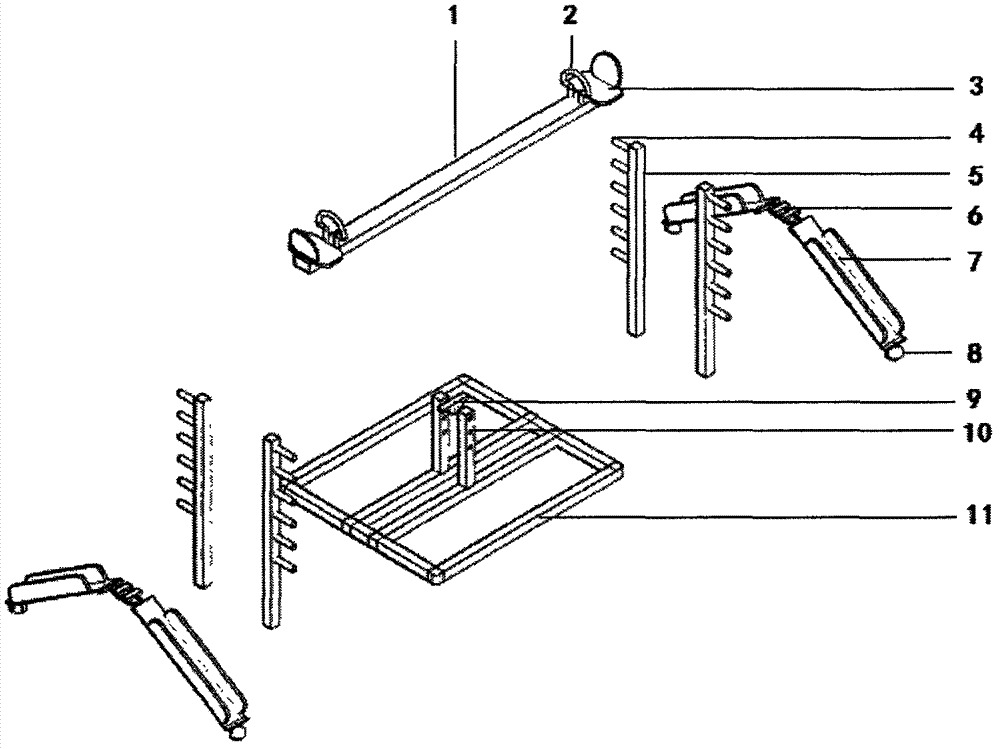

Stretch Strap

The present invention provides in some embodiments, a device for stretching muscles having a series of loops. The device can be formed from strips of elastic material periodically joined in order to form loops. More particularly, a top portion of elastic material can be laid on top of a bottom portion of elastic material. The top and bottom portions of materials can be joined in a variety of ways. A user of the device can engage different body parts with the loops and use the device to facilitate a dynamic stretch of a muscle. Dynamic stretching involves active contraction of the muscle prior to the stretch.

Owner:HYGENIC INTANGIBLE PROPERTY HLDG

Material mechanical property in-situ test instrument and method under high-temperature complex mechanical load

ActiveCN110579404AEasy maintenancePrevent oxidationMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesFatigue loadingScientific instrument

The invention, which belongs to the field of precise scientific instruments, relates to a material mechanical property in-situ test instrument and method under a high-temperature complex mechanical load. A support frame module of the instrument is used for realizing stable support and effective vibration isolation of each functional module of the instrument. A high-frequency fatigue loading moduleis used for realizing high-frequency fatigue loading of a tested sample. A static and dynamic mechanical load loading module is used for realizing combined loading of static and dynamic stretching / compressing / bending loads of the tested sample. A high / low-temperature loading module is used for realizing variable temperature environment loading on the tested sample from a low temperature to a hightemperature. An in-situ monitoring module can integrate a surface deformation damage measurement assembly, a three-dimensional strain measurement assembly, a microstructure measurement assembly and an internal damage detection assembly according to actual test requirements to realize parallel accurate in-situ measurement of a micromechanics behavior, a deformation damage mode and a performance evolution law of the tested sample. The material mechanical property in-situ test instrument and method have advantages of complex load environment, rich test content, high measurement precision and thelike.

Owner:JILIN UNIV

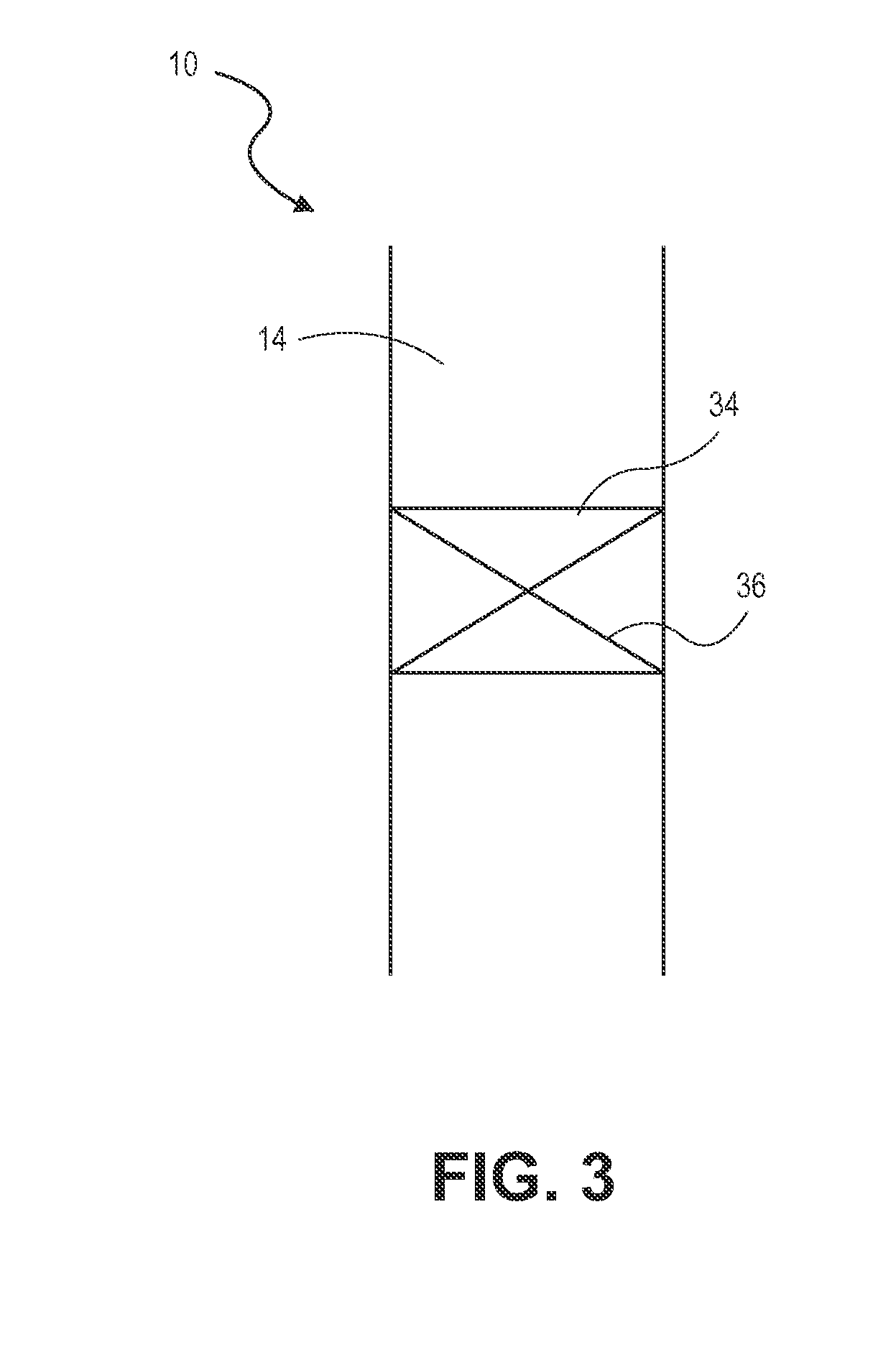

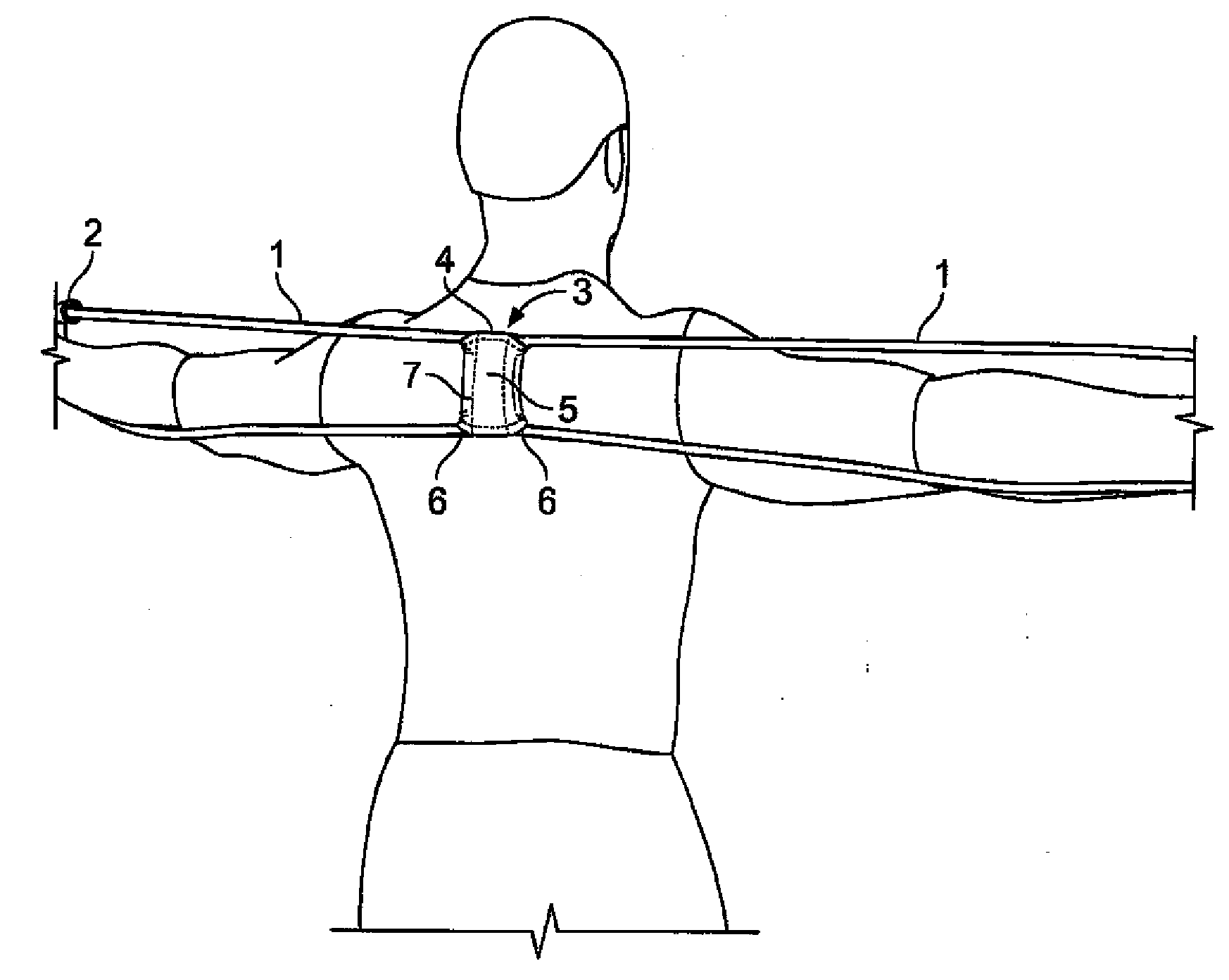

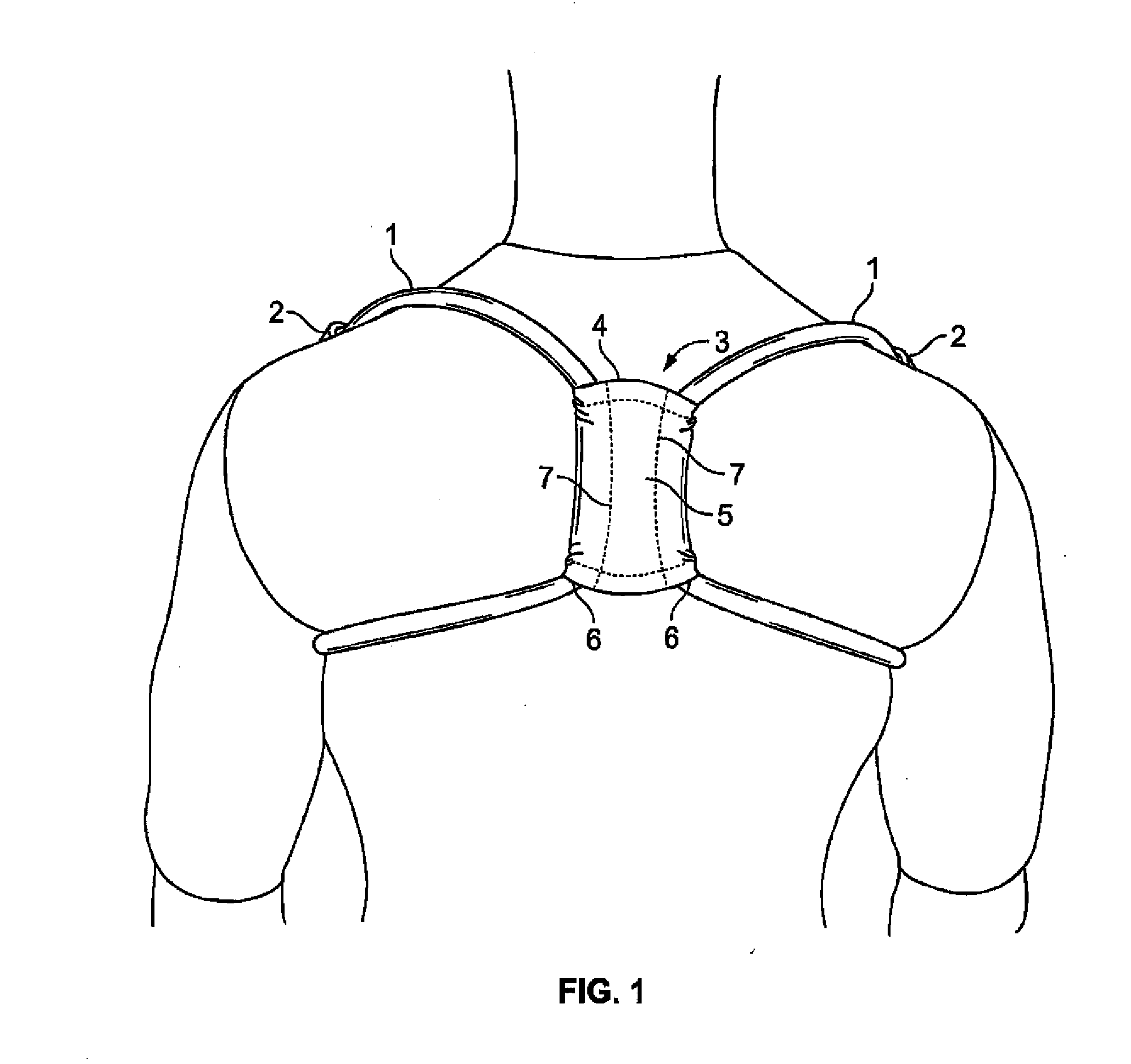

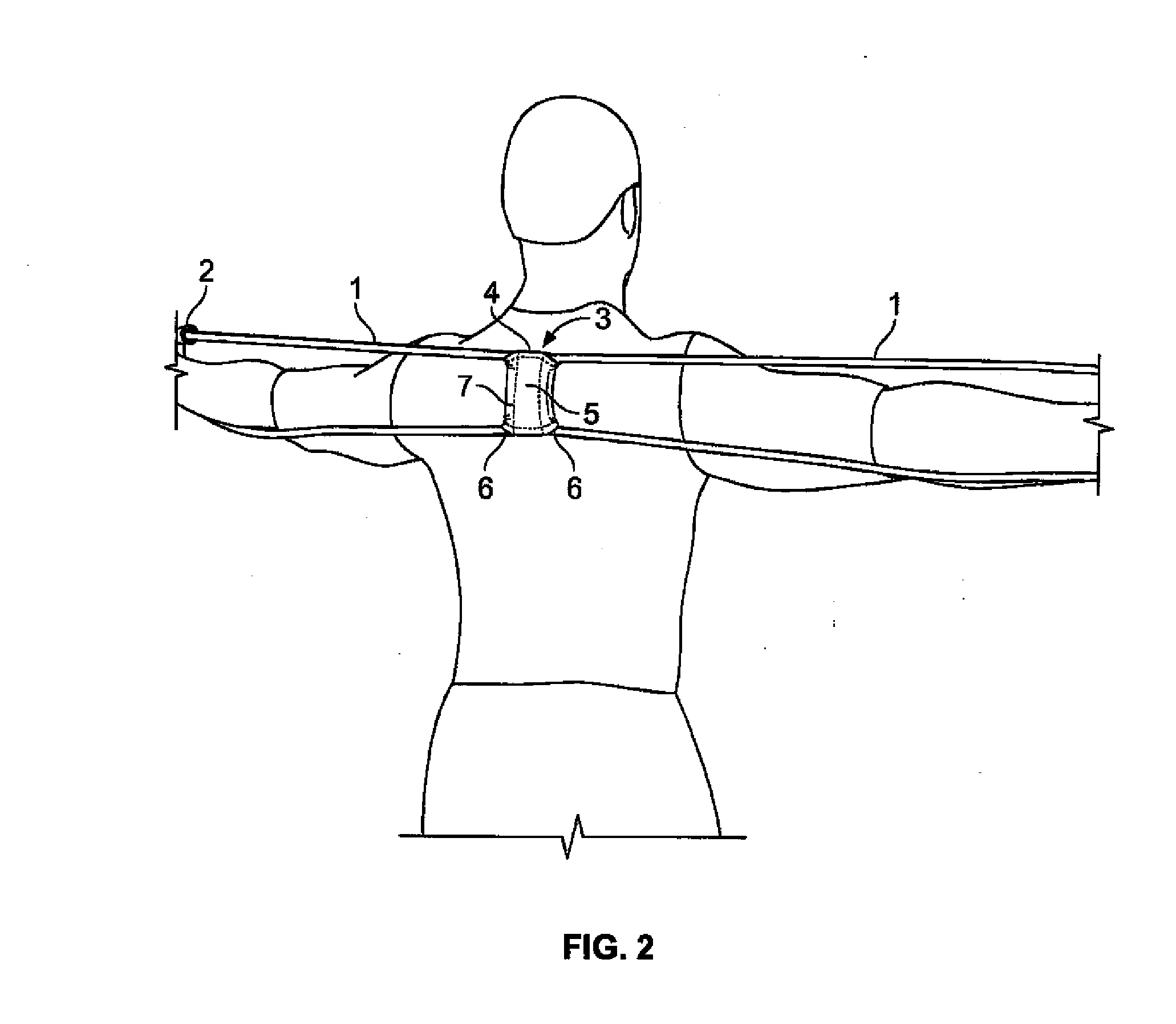

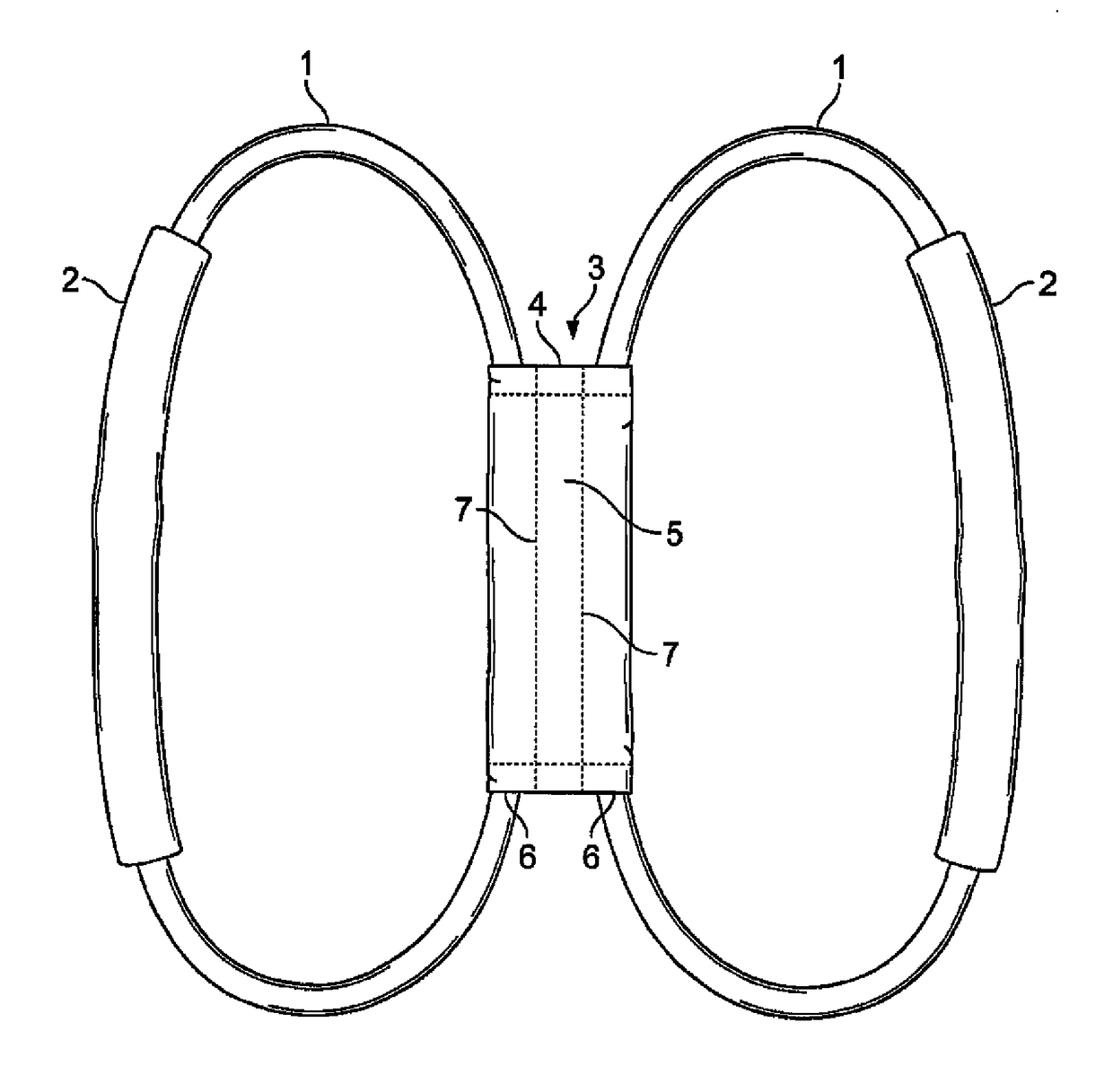

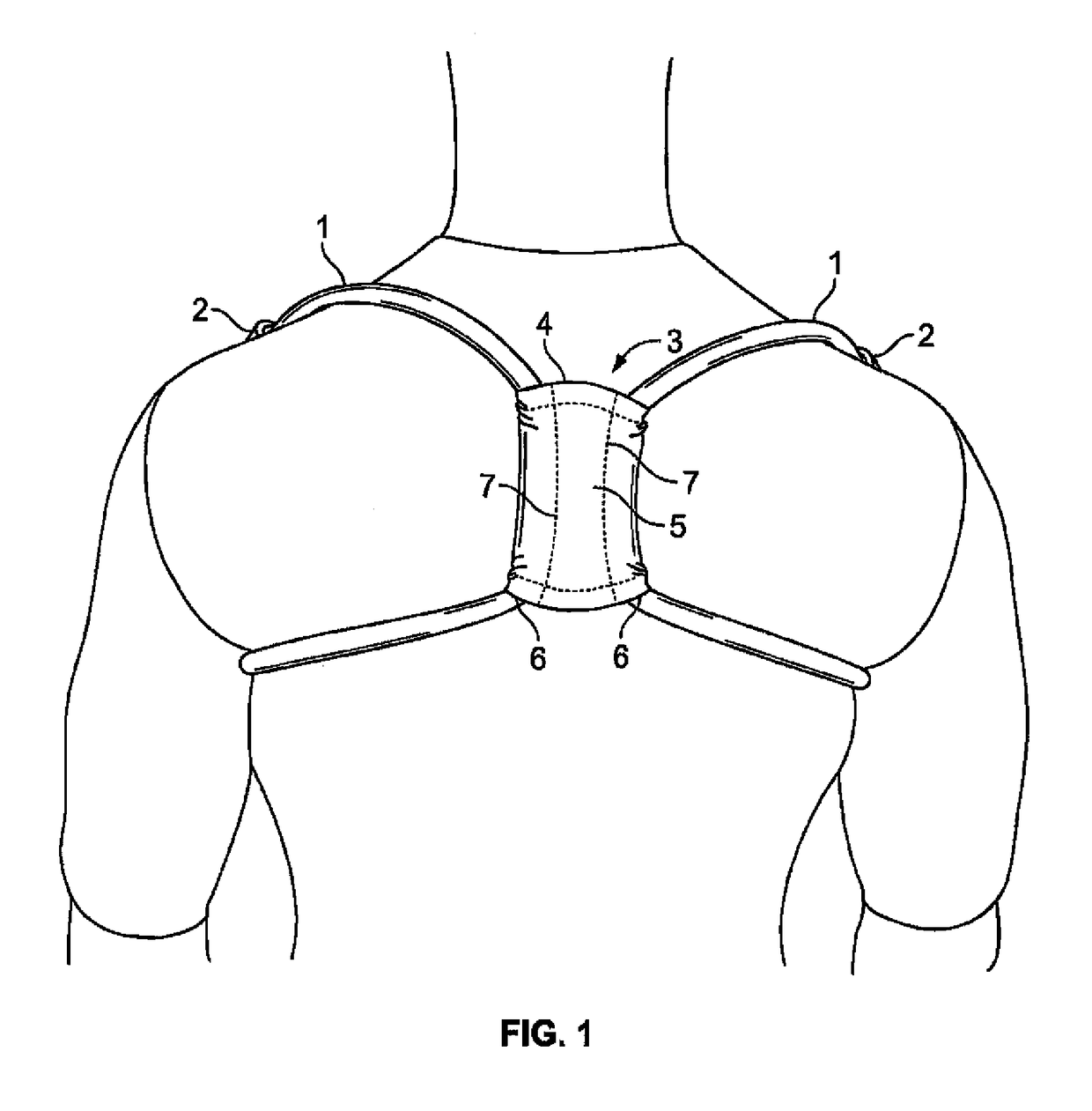

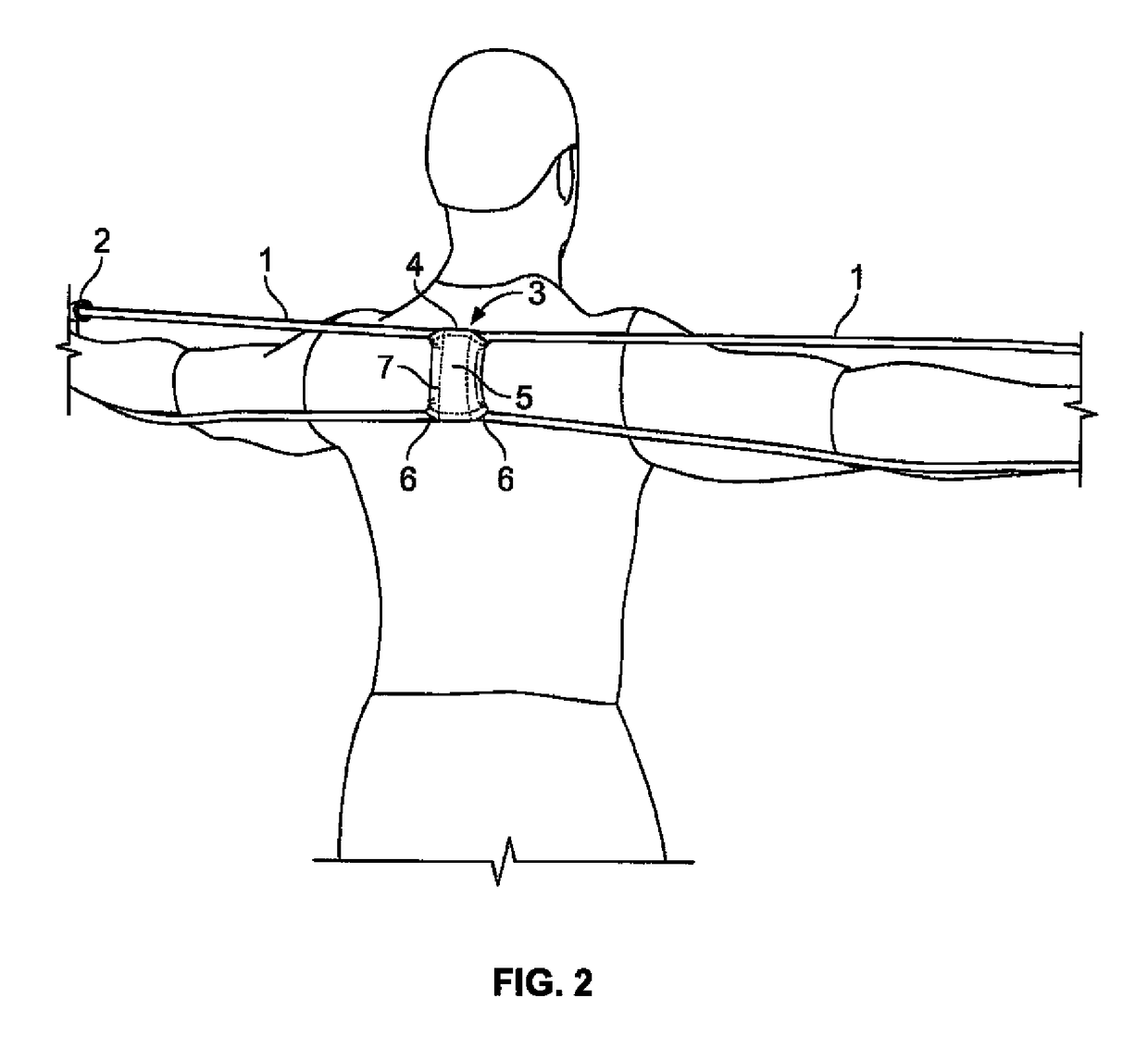

Dynamic stretching, strengthening and stabilization device for postural correction and retraining

ActiveUS20140371039A1Passive resistanceResilient force resistorsOrthopedic corsetsClosed loopEngineering

A dynamic stretching, strengthening and stabilization device is provided for postural correction and retraining. The device has a pair of closed loop resistance tubes and a central harness member which positions the closed loop resistance tubes roughly in the form of a FIG. 8. Each loop of the resistance tube is sized to accommodate the arm and shoulder of the user. The device may be used in a stabilization mode or stretching / strengthening mode, and transitions easily between these modes to correct and retrain the user's posture.

Owner:POSTURE PERFECTOR

Dynamic stretching, strengthening and stabilization device for postural correction and retraining

ActiveUS9592418B2Passive resistanceResilient force resistorsOrthopedic corsetsClosed loopEngineering

A dynamic stretching, strengthening and stabilization device is provided for postural correction and retraining. The device has a pair of closed loop resistance tubes and a central harness member which positions the closed loop resistance tubes roughly in the form of a FIG. 8. Each loop of the resistance tube is sized to accommodate the arm and shoulder of the user. The device may be used in a stabilization mode or stretching / strengthening mode, and transitions easily between these modes to correct and retrain the user's posture.

Owner:POSTURE PERFECTOR

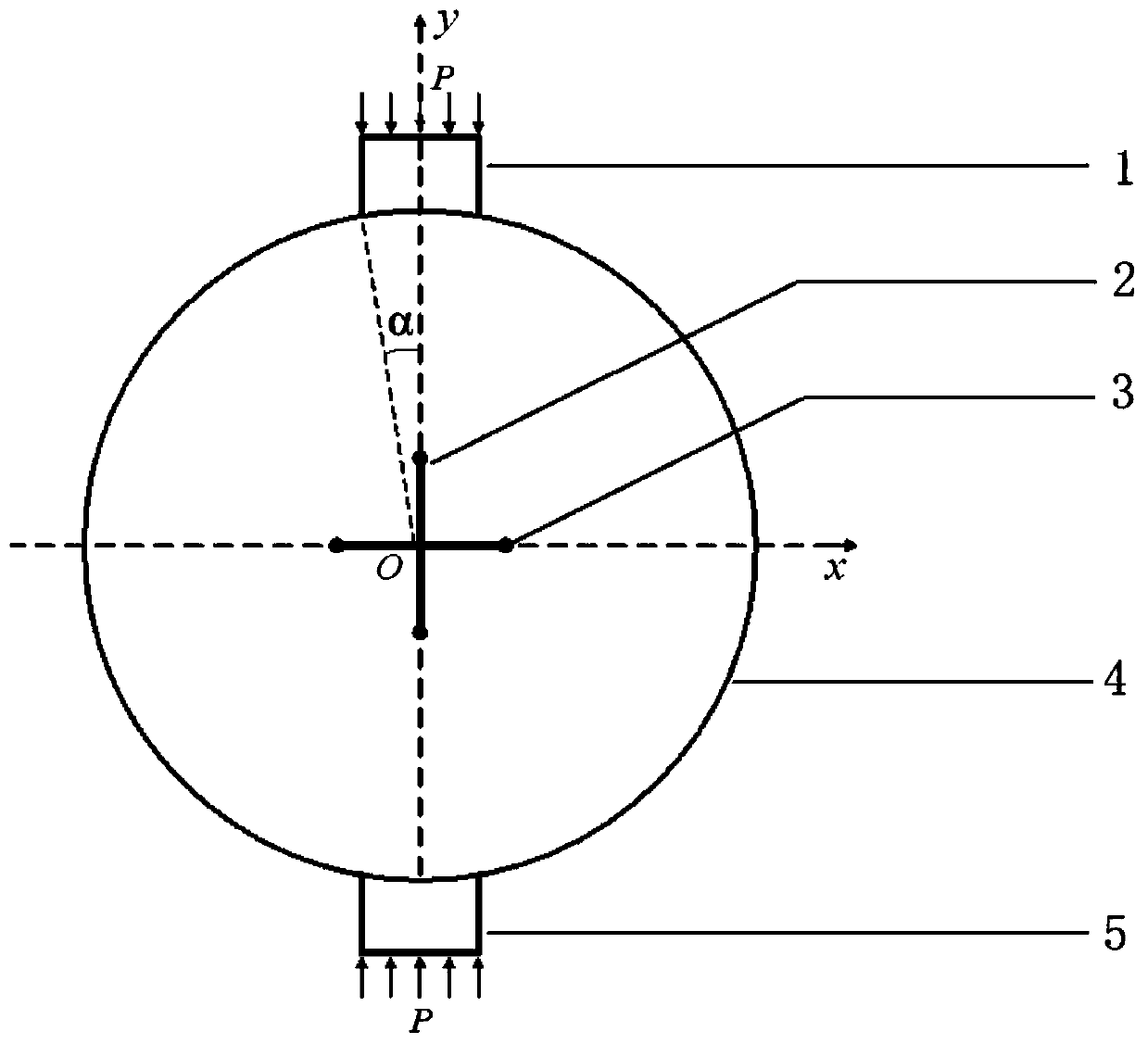

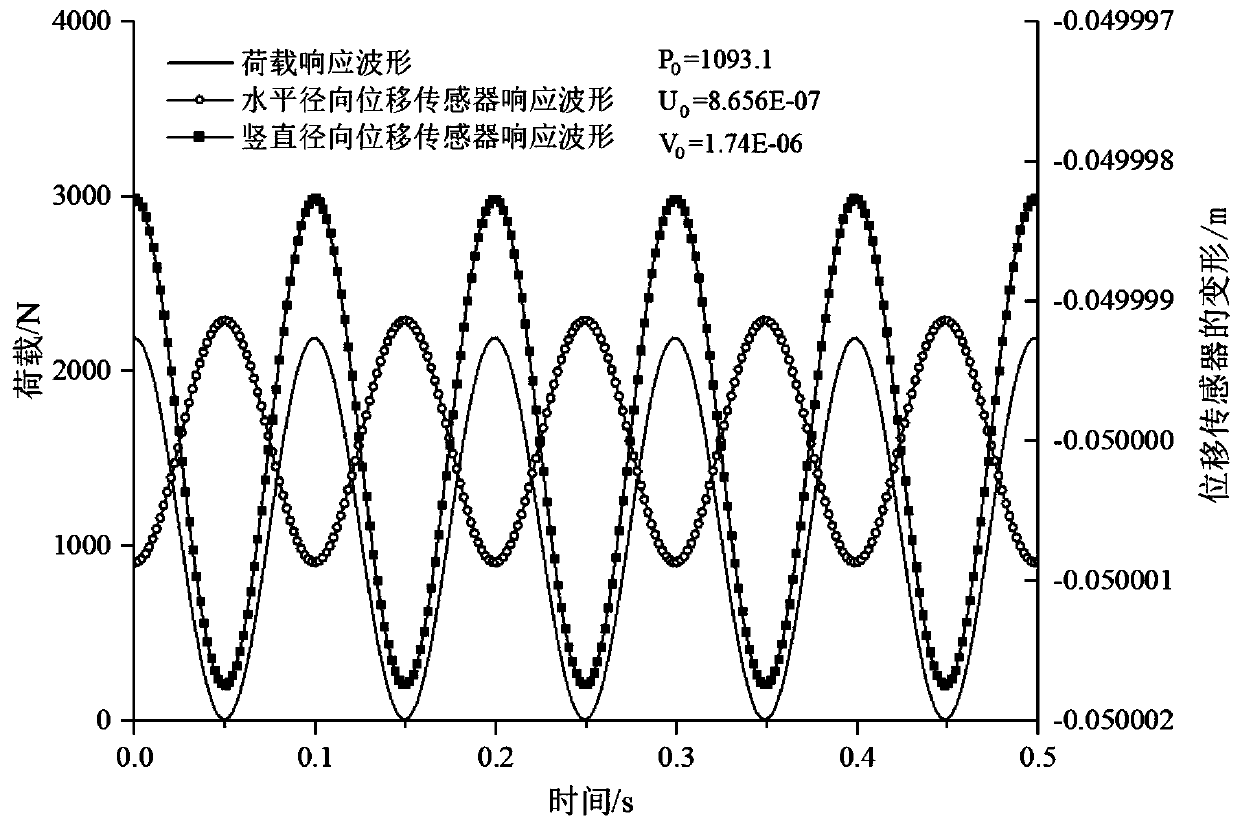

Synchronous test method for asphalt mixture dynamic stretching, compression modulus and Poisson's ratio

ActiveCN110174308AAccurate evaluationComprehensive evaluationMaterial strength using tensile/compressive forcesRelational modelPresent method

The present invention discloses a synchronous test method for asphalt mixture dynamic stretching, compression modulus and Poisson's ratio. The method places the asphalt mixture split test piece in a split metal fixture of a loading test system, installs a horizontal radial displacement sensor and a vertical radial displacement sensor on end surface of the test piece, and applies a vertical dynamiccompression load to the test piece at a prescribed temperature and frequency. According to Hooke's law under a two-dimensional plane stress state of the split test, the present method deduces an analytical expression of the dynamic compression modulus and dynamic stretching modulus of the asphalt mixture, according to a relationship model between the dynamic compression modulus and the Poisson'sratio, through the method of simultaneously determination of the dynamic compression modulus, the dynamic stretching modulus and Poisson's ratio of the asphalt mixture, the method greatly improves test efficiency and accuracy, and is beneficial to further scientifically and reliably evaluate dynamic response characteristics of the asphalt mixture under the two-dimensional stress conditions, and has good application and promotion value.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

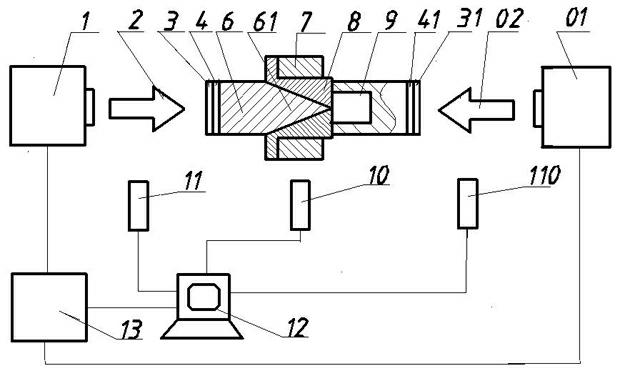

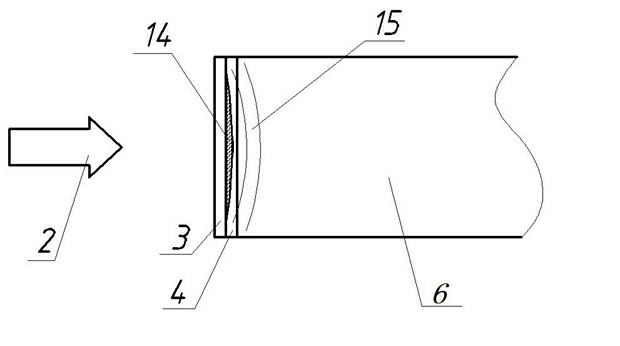

Device and method for hoop tensile test based on laser impact biaxial loading

InactiveCN102128755AControl strain rateRealize the loadStrength propertiesDynamic stretchingTensile testing

The invention relates to a material dynamic tensile mechanical property test and belongs to the technical field of a material dynamic tensile mechanical property test. By using an intense laser pulse-induced impact wave as a loading condition, the material achieves a high strain rate; and different strain rates can be loaded by changing the laser pulse width and laser energy. A device comprises ahigh-power pulse laser (13), a laser head A (1), a laser head B (01), a restraining layer A (3), a restraining layer B (31), an absorbing layer A (4), an absorbing layer B (41), a loading rod A (6), a loading rod B (9), a cylindrical driving ring (8), a laser interferometer (10), a trigger A (11), a trigger B (110) and a computer (12). The device provided by the invention can be used for researching the dynamic tensile property of the material under the condition of different strain rates. The loading process is simple, the influencing factors are few, the calculation process is simple and the test cost is low.

Owner:JIANGSU UNIV

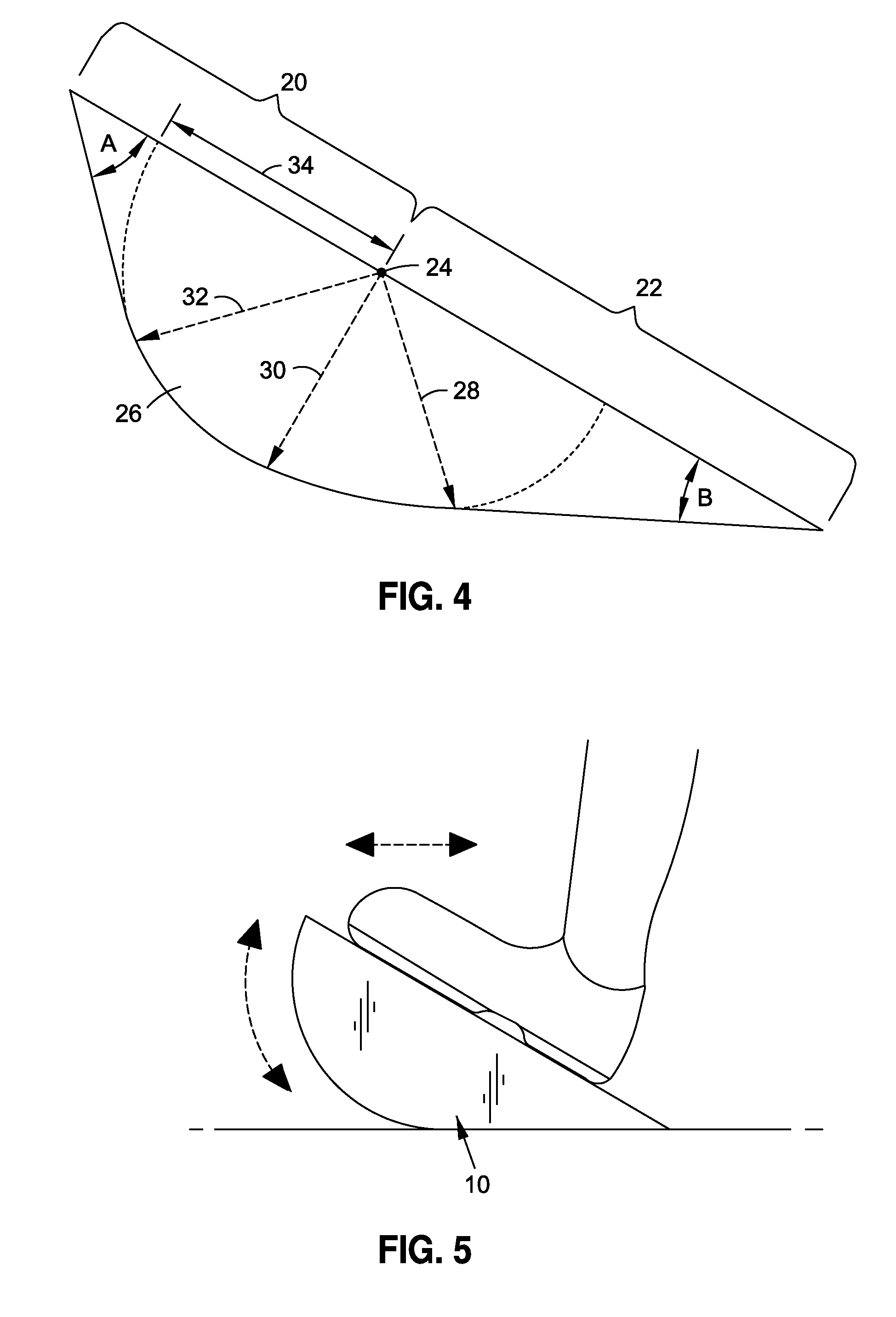

Lower extremity exercise wedge

A lower extremity exercise device for performing strengthening exercises for the calf muscles, as well as for performing static or dynamic stretching of the calf muscles. The device is preferably configured to have a generally wedge-shape positionable upon a flat surface. The wedge defines an upper, inclined platform surface for receiving the foot of a user, and has a rounded base portion having an asymmetric, gradually increasing radius to allow the user's foot to smoothly roll or rotate the device forward when pushed thereagainst. In use, the device allows for natural, relative rotations between the forefoot pivot-point and the ankle joint in the sagittal plane.

Owner:HARKINS GEORGE CHRISTOPHER

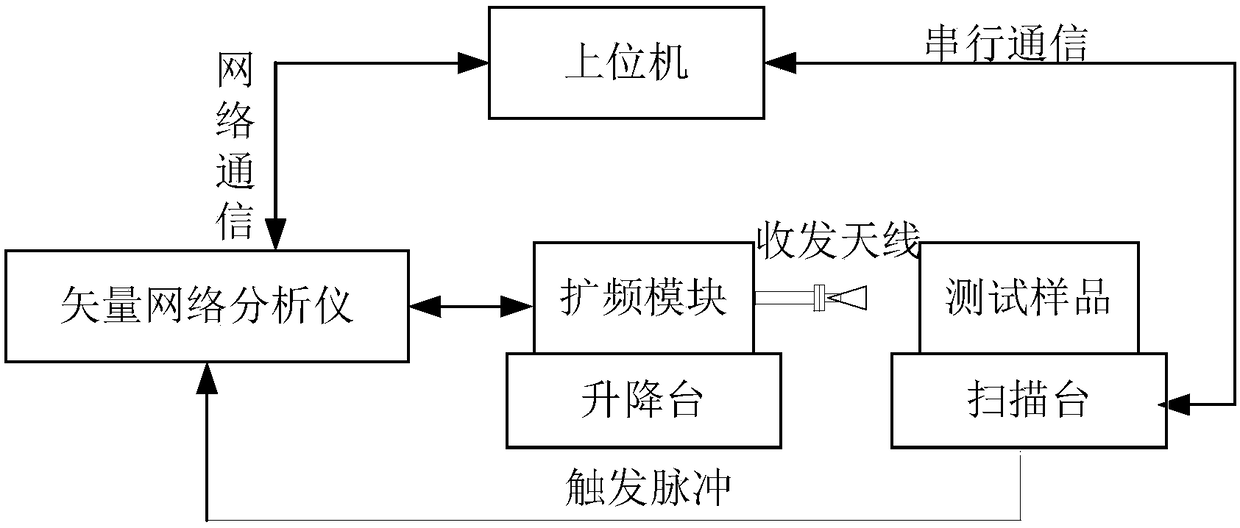

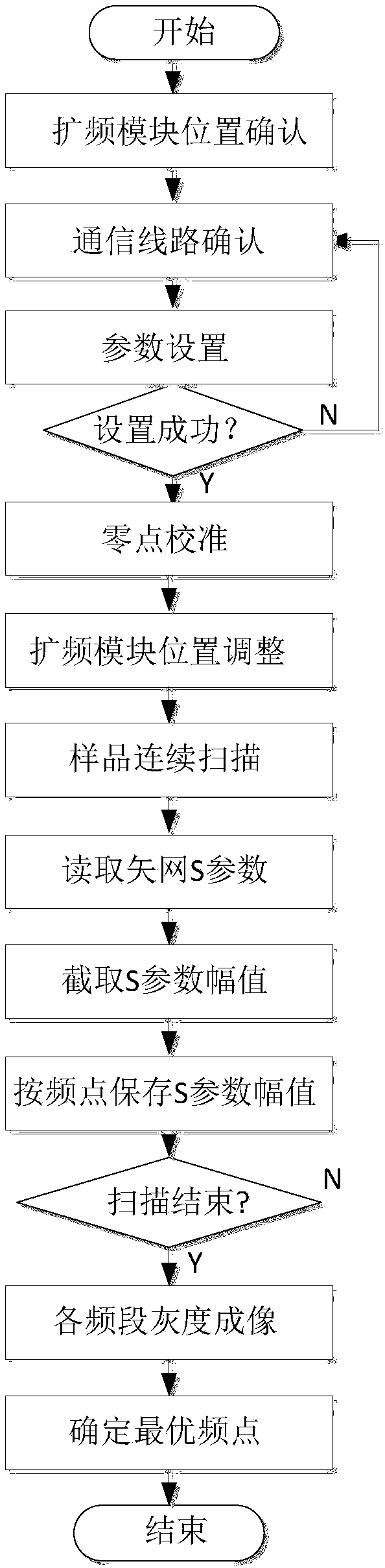

Terahertz continuous wave scanning imaging system and method

ActiveCN108267462AExpandable and flexibleHigh degree of automationMaterial analysis by optical meansMaterial analysis by transmitting radiationDynamic stretchingTest sample

The invention discloses a Terahertz continuous wave scanning imaging system and method. The system comprises a vector network analyzer which is connected to a frequency spread module, a scanning stageand an upper computer separately, and the scanning stage is connected to the upper computer; the frequency spread module is placed on a lifting table, and the lifting table is used for adjusting thehorizontal and vertical position of the frequency spread module away from a test sample; the test sample is fixed to the scanning stage; the upper computer scans parameters, sends a scanning order andcontrols movement of the scanning stage by configuring test samples; the upper computer completes parameter setting of the vector network analyzer, reading of S parameters and test sample scanning imaging display. Accordingly, the upper computer does not need to perform interactive communication with the scanning stage to obtain position coordinates of sampling points, the upper computer obtainsgrayscale images through the methods such as line scanning point number control, data rearrangement and gray value dynamic stretching, the communication link is simplified, the system scanning time isshortened, and the imaging efficiency is improved.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

Dynamic damage experimental method based on dynamic tensile strain rate serving as single variable

InactiveCN105954120AClose to the research purposeReduce research difficultyMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceTensile strainExperimental methods

The invention provides a dynamic damage experimental method based on the dynamic tensile strain rate serving as a single variable, and relates to the field of impact dynamics. The dynamic damage experimental method includes S1, producing a plurality of flying sheets; S2, producing a plurality of sample targets, wherein the thickness difference value between a first sample target body and a second sample target body of each sample target is the same; S3, corresponding the flying sheets to the sample targets one to one to form a plurality of impact experiment groups, wherein the ratios of the thicknesses of the flying sheets in the impact experiment groups to the total thicknesses of the sample target bodies are the same, and the sums of the thicknesses of the flying sheets in the impact experiment groups and the total thicknesses of the sample target bodies are different; S4, performing impact experiments on the impact experiment groups; S5, measuring post-impact data and analyzing results. The dynamic damage experimental method has the advantages that the difficulty in strain rate effect theoretical analysis can be remarkably lowered, and the method is more suitable for research on dynamics processes and rules in the early stage of dynamic strain damage evolution.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

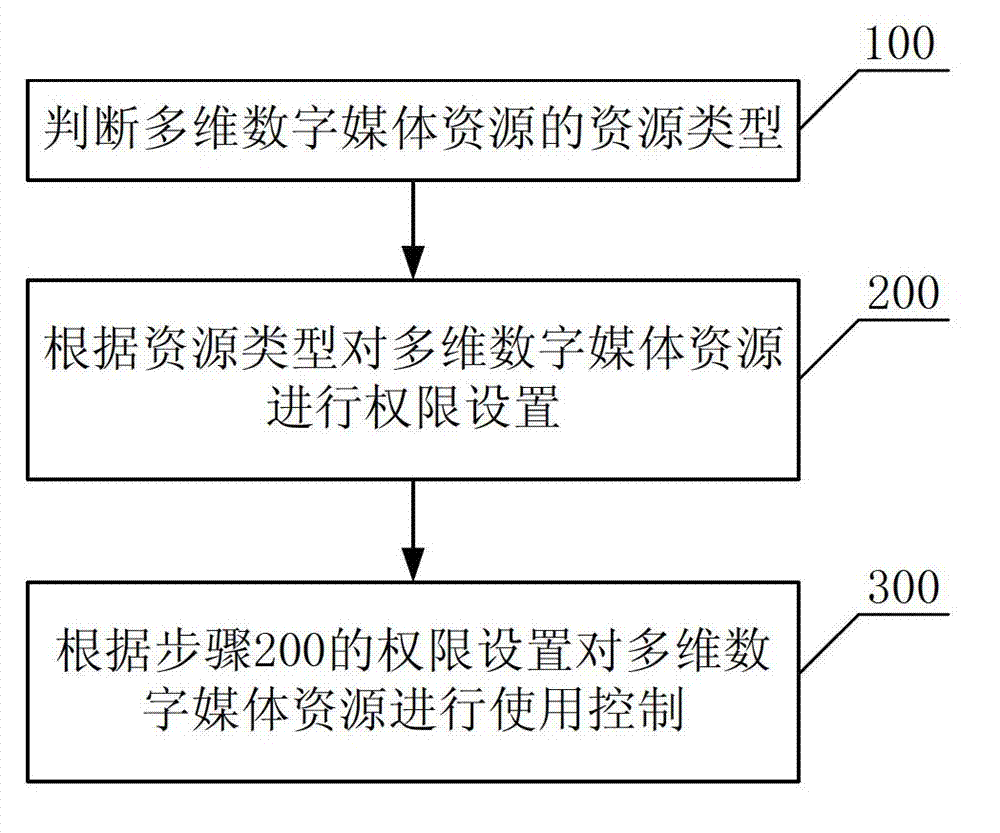

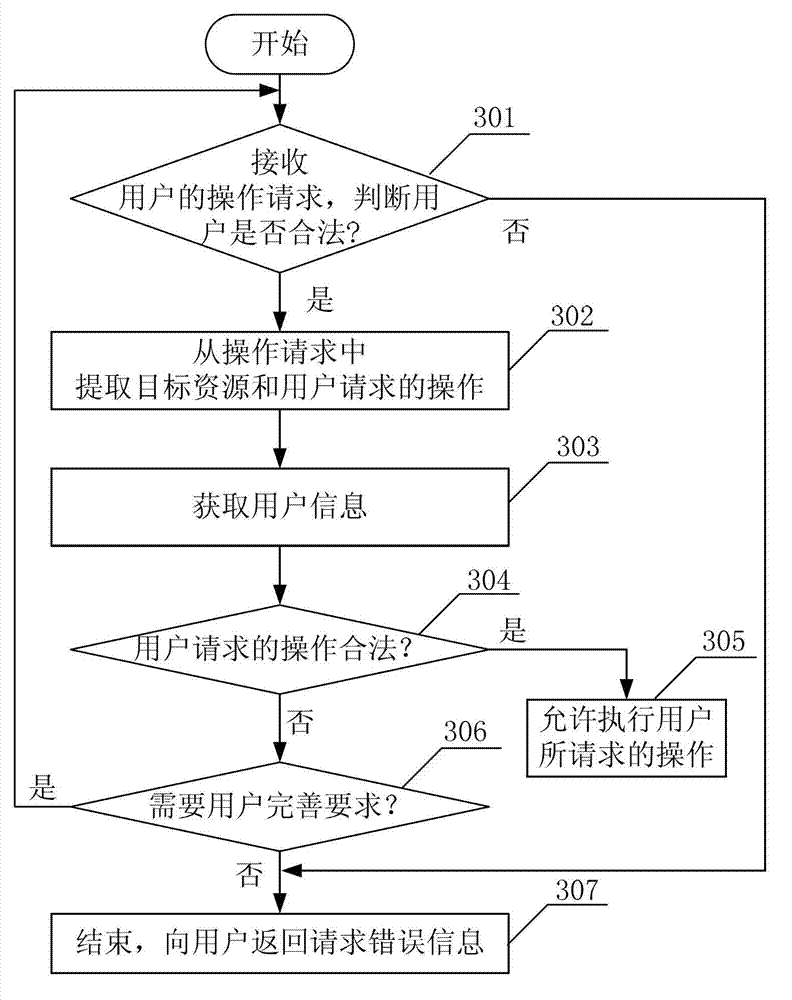

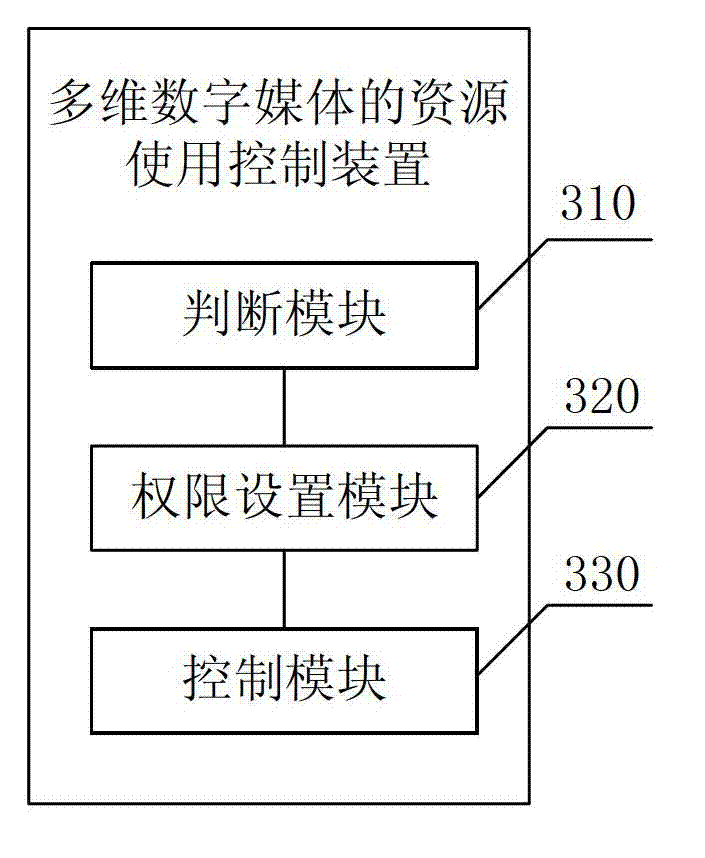

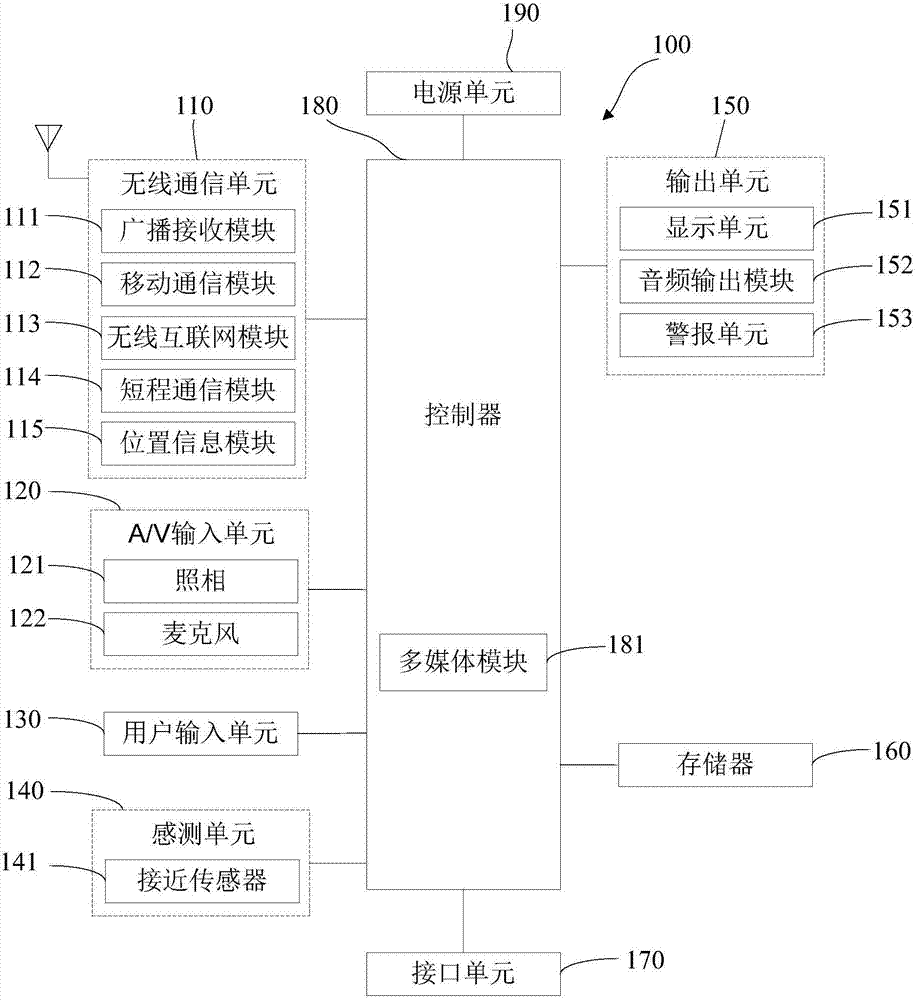

Resource use control method and resource use control device of multi-dimensional digital media

ActiveCN102902898AImprove processing efficiencyImprove user experienceProgram/content distribution protectionPersonalizationSecurity properties

The invention relates to a resource use control method and a resource use control device of multi-dimensional digital media. The resource use control method of the multi-dimensional digital media includes judging resource types of resources of the multi-dimensional digital media, conducting permission setting on the resource of the multi-dimensional digital media according to the resource types and conducting use control on the resource of the multi-dimensional digital media according to the permission setting. The permission setting comprises operation permission of the multi-dimensional digital media and attributes that the operation permission corresponds to. The method and the device can describe operation of information in the multi-dimensional digital media and with different particle sizes and safety attributes and constraint conditions, prerequisite conditions, personalized customization and the like of the operation, resolve permission dynamic stretching caused by object extraction, recombination or interaction and permission dynamic adjusting problems caused by personalized customization, greatly improve data processing efficiency and improve use experience of a user.

Owner:INST OF INFORMATION ENG CAS +1

Method and apparatus for measuring dynamic stretch rigidity of outer panel of automobile component

ActiveCN104769411AIncreased dynamic tensile stiffnessIncreased Dynamic Tensile RigidityMaterial strength using steady bending forcesOptical apparatus testingDynamic stretchingEngineering

Owner:JFE STEEL CORP

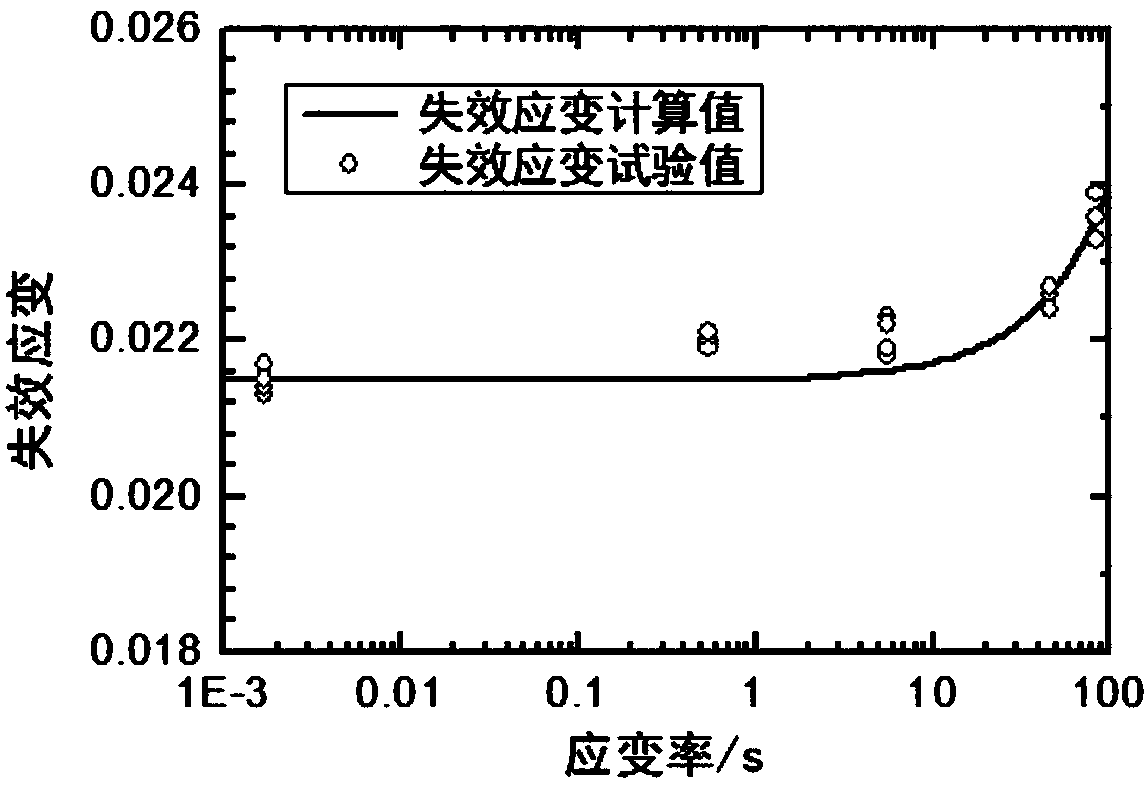

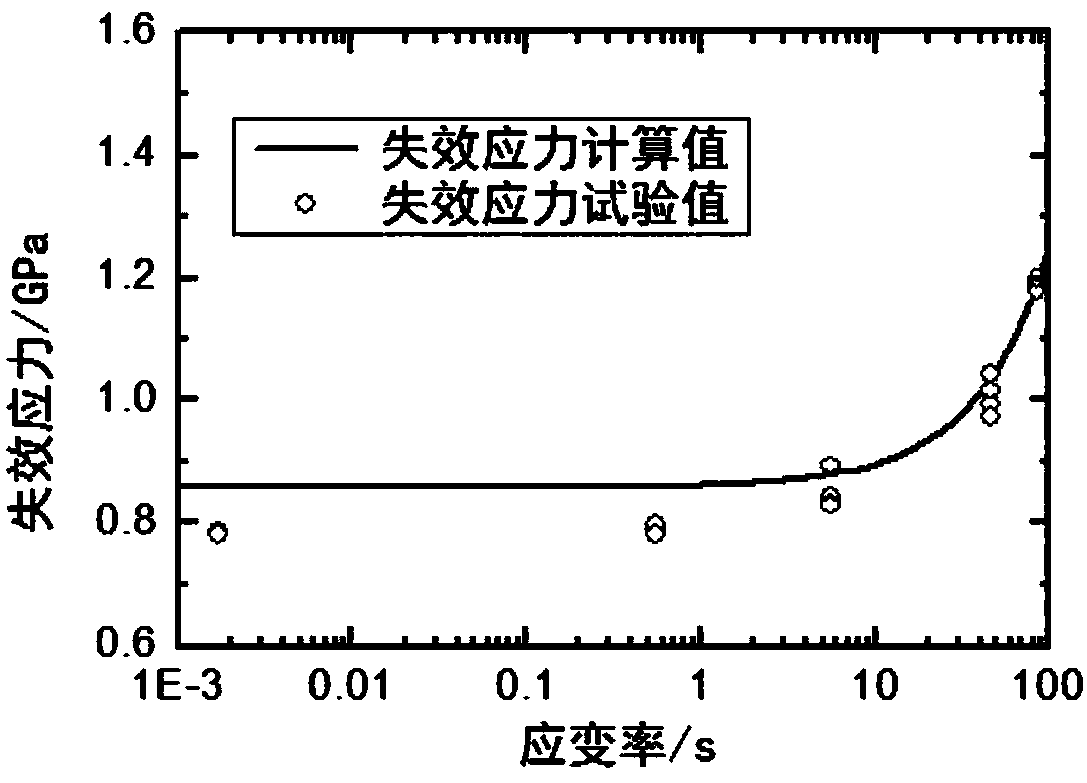

Dynamic stretching failure assessment method for fiber reinforced composite material

ActiveCN108549743AAccurately analyze tensile failure behaviorAnalyzing Tensile Failure BehaviorDesign optimisation/simulationSpecial data processing applicationsFailure assessmentDynamic stretching

The invention provides a dynamic stretching failure assessment method for a fiber reinforced composite material. For the problem of lack of a theoretical basis due to no consideration of a strain rateeffect and dependency on test data in correction in an existing fiber reinforced composite material failure assessment method, based on an energy density theory, the strain rate effect of the fiber reinforced composite material under the action of a dynamic load is considered, and derivation is performed to obtain a strain rate related distortion energy density equation of the material under theaction of the dynamic stretching load; the method can accurately analyze a stretching failure behavior of the fiber reinforced composite material under the action of the dynamic load; a large amount of dynamic tests are avoided; and the reliable assessment method is provided for design of various fiber reinforced composite structures.

Owner:SOUTHEAST UNIV

Image generation device and method, and terminal

ActiveCN106993134AEasy to getTelevision system detailsColor television detailsComputer graphics (images)Dynamic stretching

The invention discloses an image generation device and method, and a terminal. The device comprises an extraction module, a determination module, and a blurring processing module, wherein the extraction module is used for extracting a foreground area and a background area from an area to be photographed; the determination module is used for determining a subject in the foreground area; and the blurring processing module is used for carrying out dynamic stretching and blurring operation on the subject and the background area in the area to be photographed, so that a photographed picture is obtained. The device and method and the terminal provided by the invention have the advantages that the technical problem in the prior art that acquisition of a dynamic picture is too complicated is solved, and the technical effect that the dynamic picture can be simply and efficiently acquired is achieved.

Owner:NUBIA TECHNOLOGY CO LTD

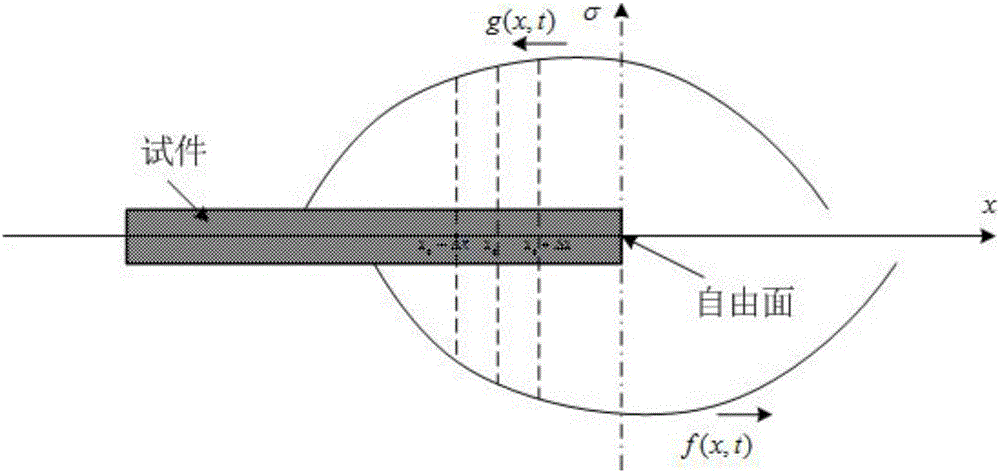

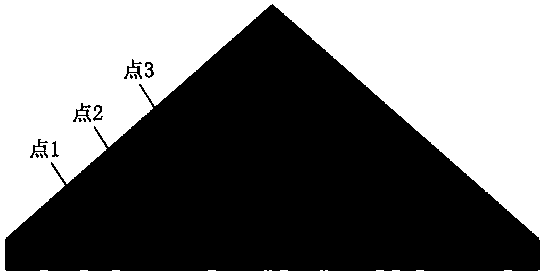

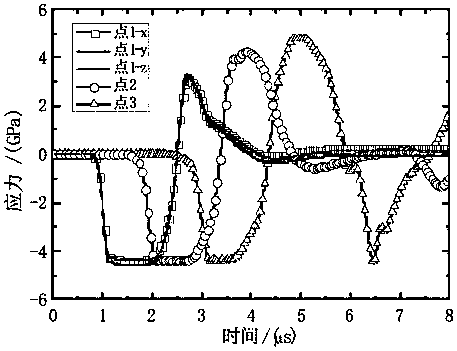

Measuring and determining method for spall strength of quasi-brittle material at high strain rate

The invention discloses a dynamic spall tensile test method for a quasi-brittle material based on a Hopkinson principle. The method has the advantages that isosceles triangle-like incident waves obtained by virtue of a shaping technology can help a spall test and other dynamic tensile test methods to establish a relationship on the aspect of the data interpretation when the spall sample reaches a constant-strain-rate deformation state and a uniform tensile stress state. The amplitude of the isosceles triangle-like incident wave can be adjusted by virtue of fine pulse shaping, while the duration of the waves can be adjusted by changing a length of a collision rod. By virtue of the characteristics, the novel technique is suitable for the spalling application of different materials and different sizes.

Owner:POWERCHINA XIBEI ENG +1

Experiment method taking dynamic tensile stress amplitude value as variable and impact experiment device

InactiveCN105784512AIndividual change controlEliminate distractionsPreparing sample for investigationStrength propertiesClassical mechanicsDynamic stretching

The invention provides an experiment method taking a dynamic tensile stress amplitude value as a variable and an impact experiment device and relates to the field of impact dynamics. The experiment method taking the dynamic tensile stress amplitude value as the variable comprises the following steps: S1. preparing a plurality of sample targets; S2. preparing a plurality of flying plate groups, wherein each flying plate group comprises a first flying plate layer and a second flying plate layer which is collided with the corresponding sample target; the first flying plate layers are fitted with the second flying plate layers and the resistance of each first flying plate layer is smaller than that of each second flying plate layer; S3. forming an impact experiment group by corresponding each flying plate group to one sample target; and S4. carrying out a collision experiment on each impact experiment group. In an experiment, experiment data of spallation caused by the single variable, which is controlled by the change of the dynamic tensile stress amplitude value, is only acquired, and the difficulty of theoretical analysis of a tensile stress amplitude value effect can be remarkably reduced. The invention further provides the impact experiment device.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

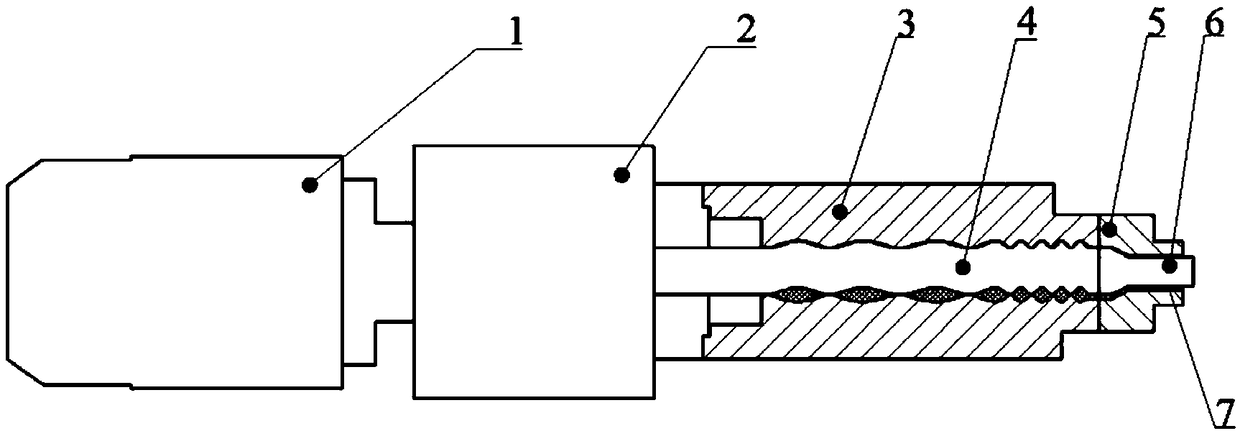

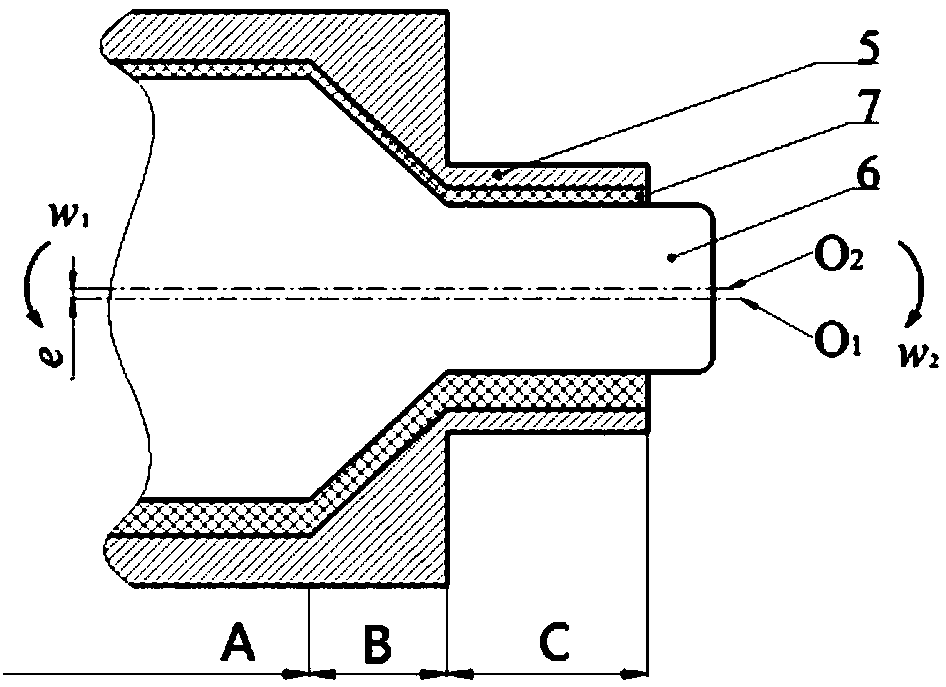

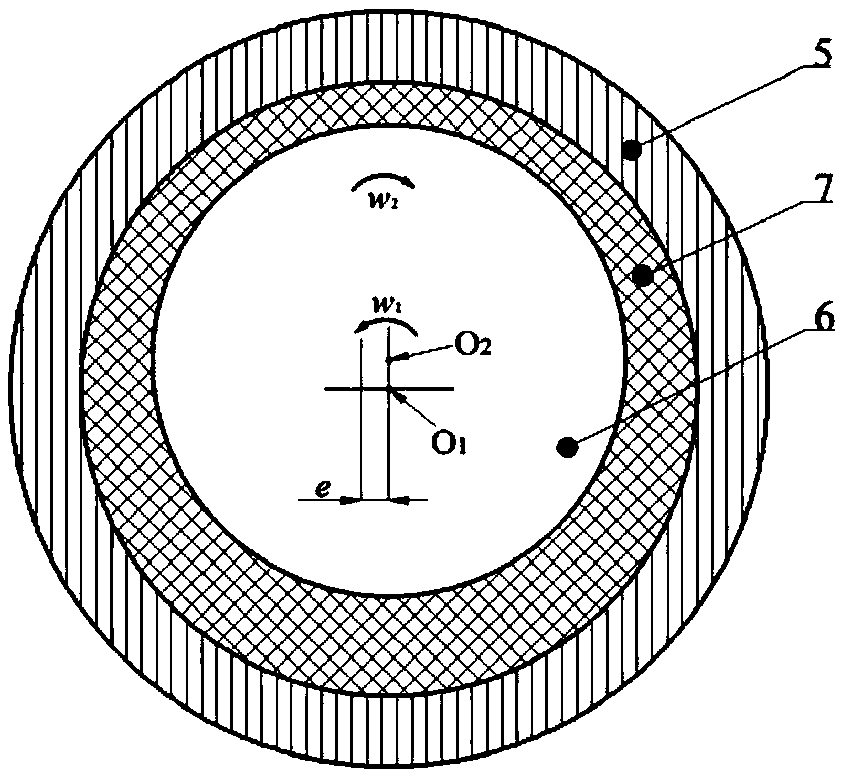

Dynamic stretching-based ultra-high molecular weight polymer rolling forming method

The invention relates to a dynamic stretching-based ultra-high molecular weight polymer rolling forming method. An extensional rheology extruder is used for molten plasticizing of an ultra-high molecular weight polymer raw material and is used for transporting the ultra-high molecular weight polymer raw material to a rolling forming die head based on dynamic stretching, melt firstly forms a large-diameter tubular blank having a non-uniform wall thickness in the rolling forming die head, the non-uniform tubular blank is continuously stretched and compressed in the circumferential direction andthe axial direction under the radial rolling action of an eccentric rotating mandrel to be uniform or to trend to uniform, a converging flow path of the rolling forming die head also enables the tubular blank to extend in the axial direction, and finally the tubular blank is rolled into a tubular blank having a uniform wall thickness. The method overcomes the extrusion molding machining problems that ultra-high molecular weight polymer is sensitive to shearing, small in processing temperature range, poor in processing fluidity and the like. The invention further relates to dynamic stretching-based ultra-high molecular weight polymer rolling forming equipment. The equipment is suitable for mass production of ultra high molecular weight polymer pipes, sheets, fibers and membrane products. The dynamic stretching-based ultra-high molecular weight polymer rolling forming method and equipment belong to the field of ultra-high molecular weight polymer extrusion processing.

Owner:SOUTH CHINA UNIV OF TECH

Night splint with digital dorsiflexion

A night splint for a user's foot having a frame member and a toe retainer that is releasably connected to the frame member. The toe retainer is configured to dorsiflex at least one toe of the user to allow for a dynamic stretch of the plantar fascia and to provide a low load stretch of the Achilles tendon, plantar fascia tendon, deep flexor muscles and calf muscles to relieve symptoms of plantar fasciitis.

Owner:DARCO INT

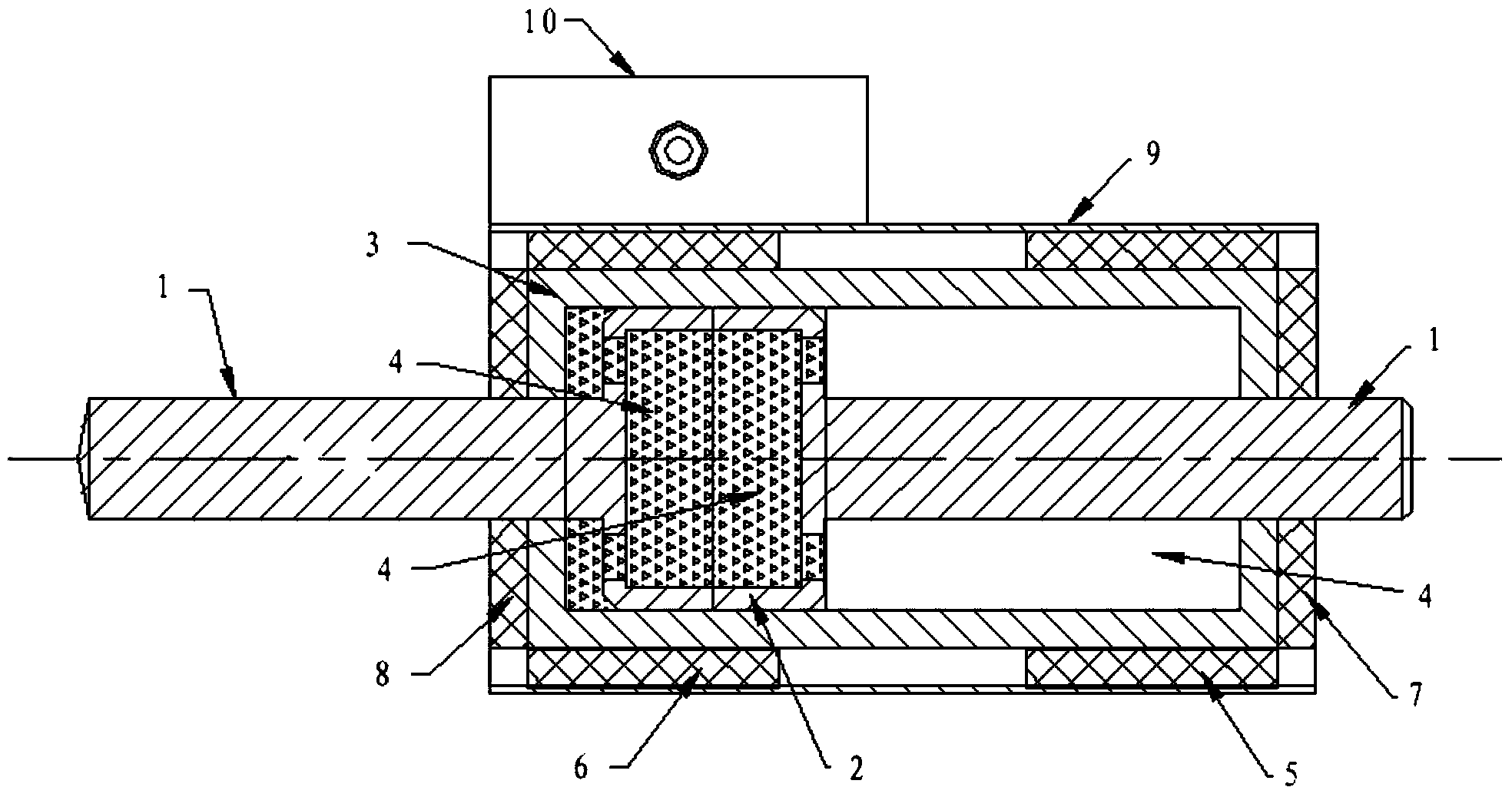

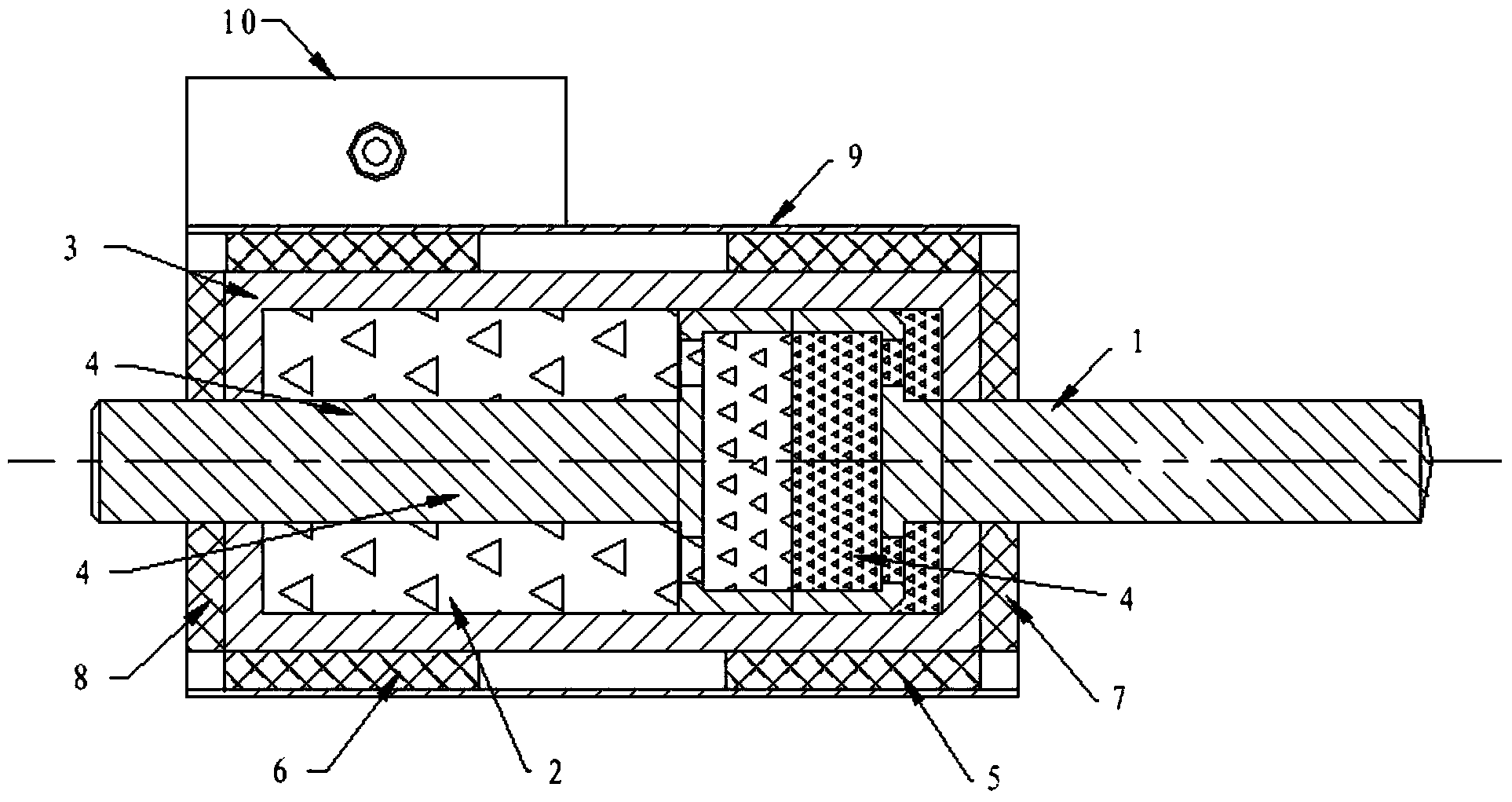

Magnetofluid-driven straight reciprocating motion structure and application method thereof

ActiveCN103953608AReduce volumeSimple operation structureFluid-pressure actuatorsReciprocating motionDynamic stretching

The invention discloses a magnetofluid-driven straight reciprocating motion structure and an application method thereof. The magnetofluid-driven straight reciprocating motion structure is characterized by comprising a cylinder body, wherein a dynamic shrinking coil and a dynamic stretching coil are symmetrically arranged on the upper side and the lower side of the cylinder body; a dynamic shrinking planar coil and a dynamic stretching planar coil are symmetrically arranged on the left side and the right side of the cylinder body; a piston is arranged in the cylinder body; the piston is connected with a piston rod; a piston cavity for allowing magnetofluid to be stored and flow is formed in the piston; a drainage hole for allowing the magnetofluid to flow when the magnetofluid is changed in the storage and flowing process is formed in the piston; terminals of the dynamic shrinking coil, the dynamic stretching coil, the dynamic shrinking planar coil and the dynamic stretching planar coil are connected with a power supply and a control switch circuit. The magnetofluid-driven straight reciprocating motion structure and the application method thereof are economic and practical in product manufacturing, simple in operation structure, small in volume of an application system, and energy-saving and low in energy consumption.

Owner:JINAN YOUBAI ELECTRONICS TECH

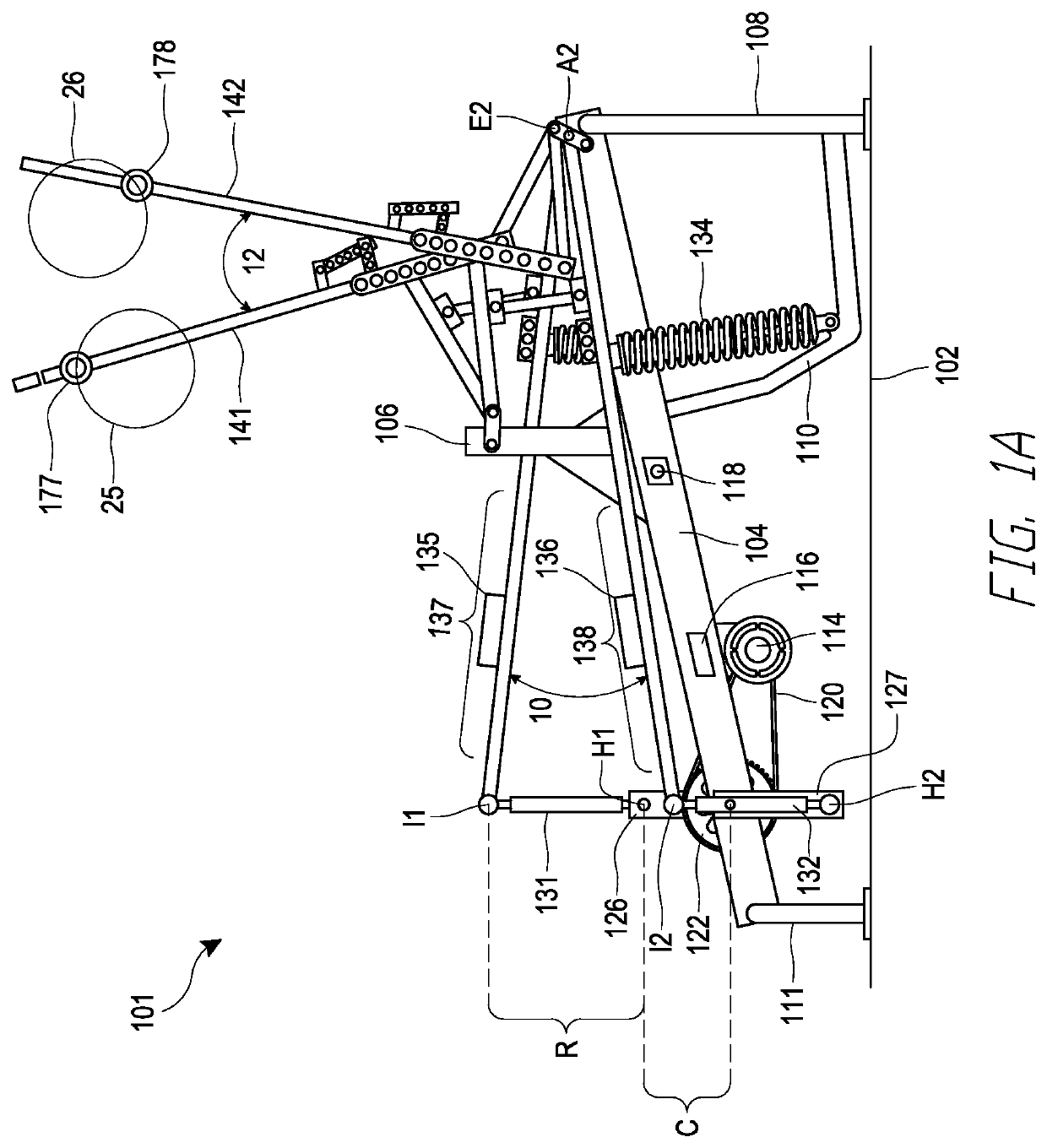

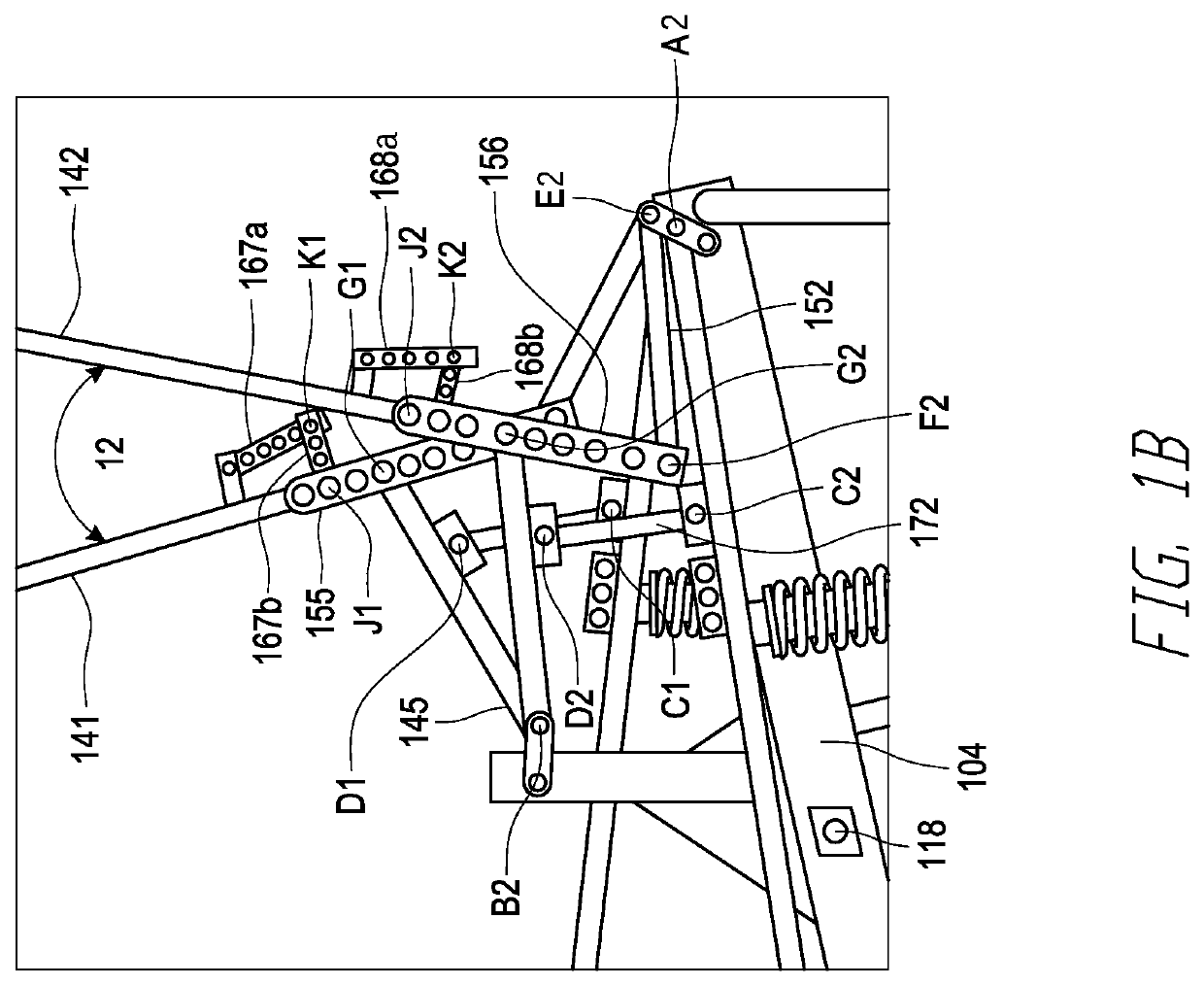

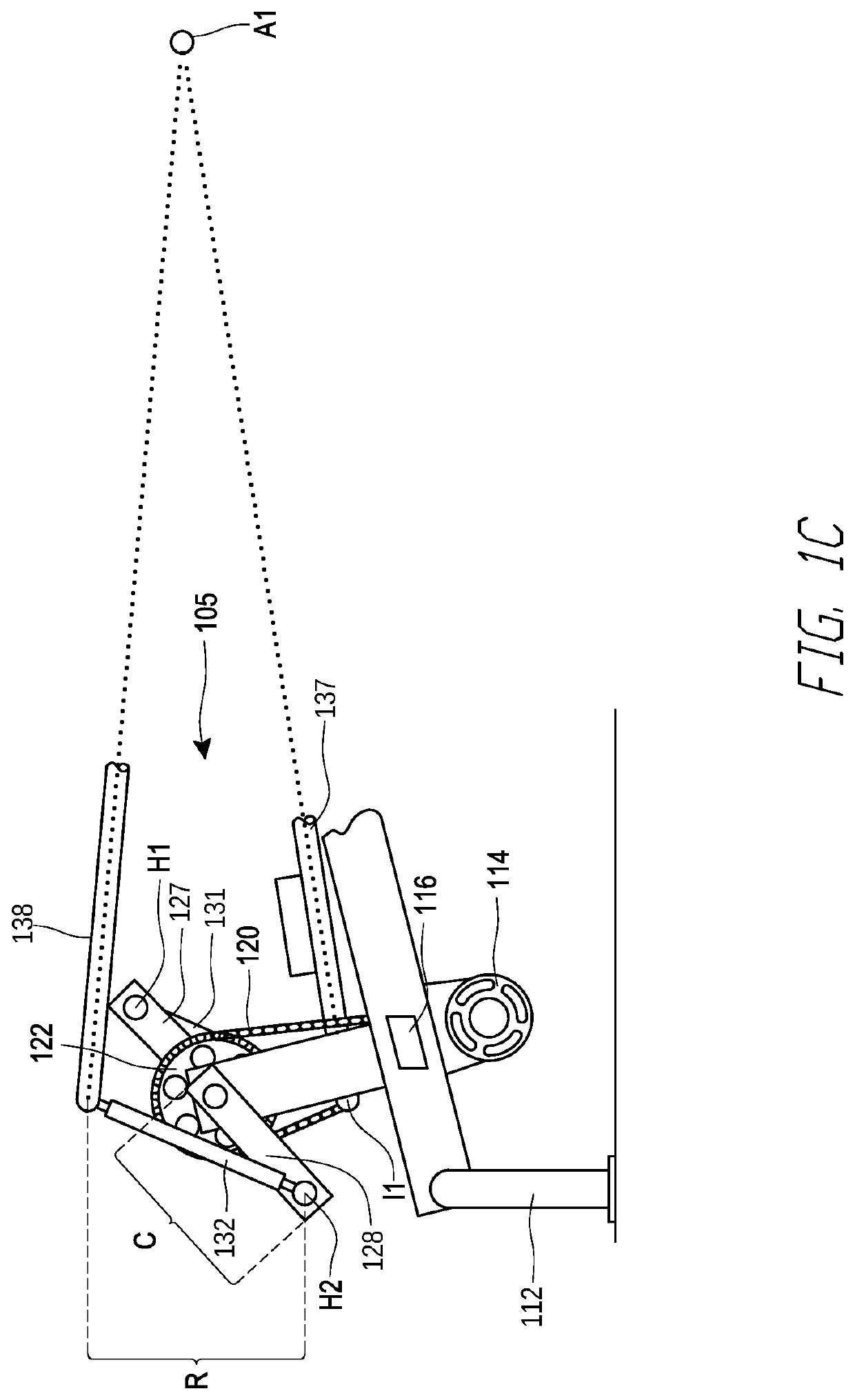

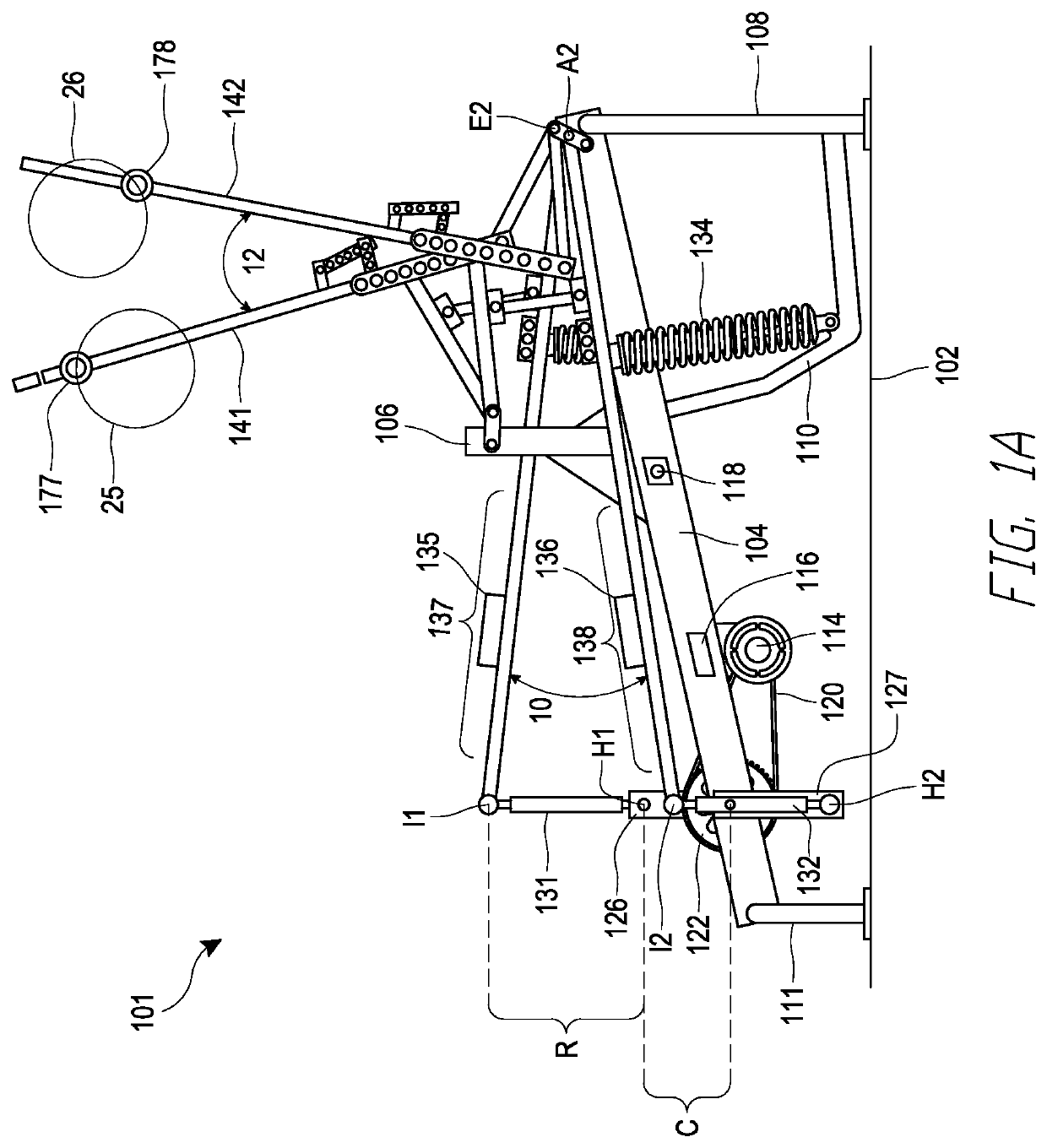

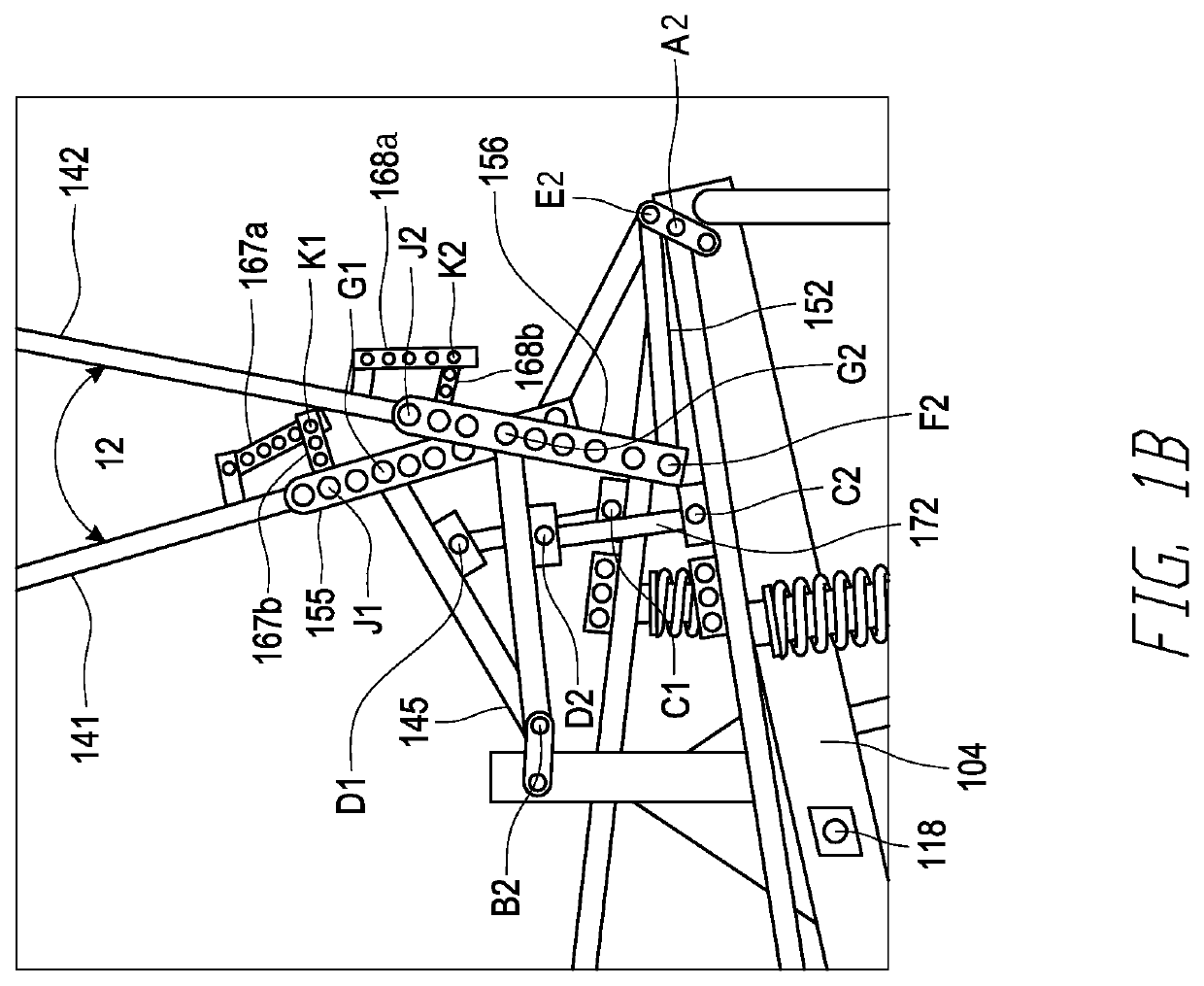

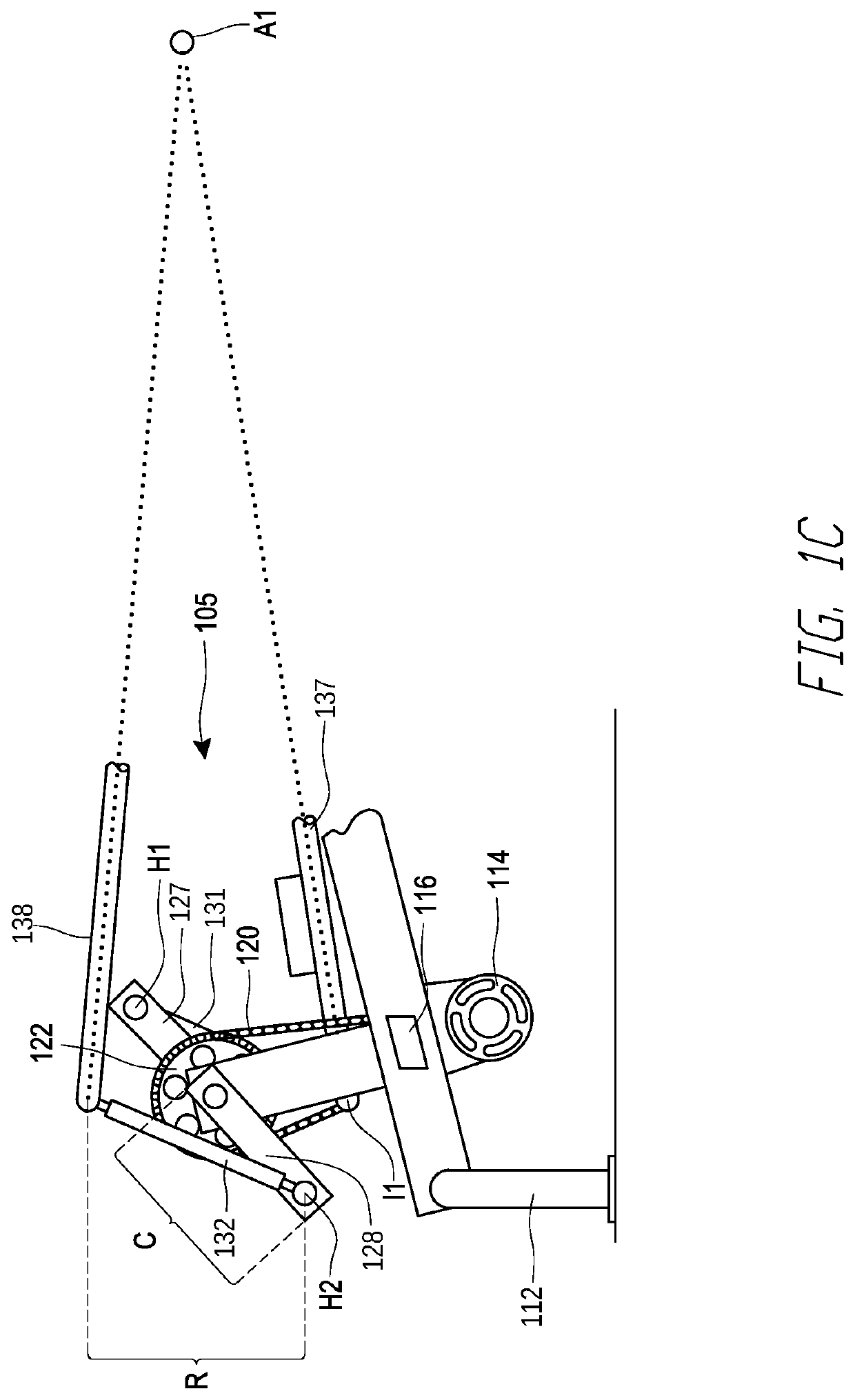

Guided movement exercise machine

ActiveUS20190344112A1Improve powerImprove efficiencyMuscle exercising devicesMovement coordination devicesStrength trainingDynamic stretching

An exercise machine can include a frame, one or more platform arms that can be driven by a motor or a hydraulic system, and one or more handle arms that can be grasped by the user's hands. The exercise machine can guide the user through movement that actively flexes and extends portions of a user's body while the user exercises to provide, for example, dynamic stretching and cardio benefits while achieving strength training.

Owner:PHILLIPS HARRY J

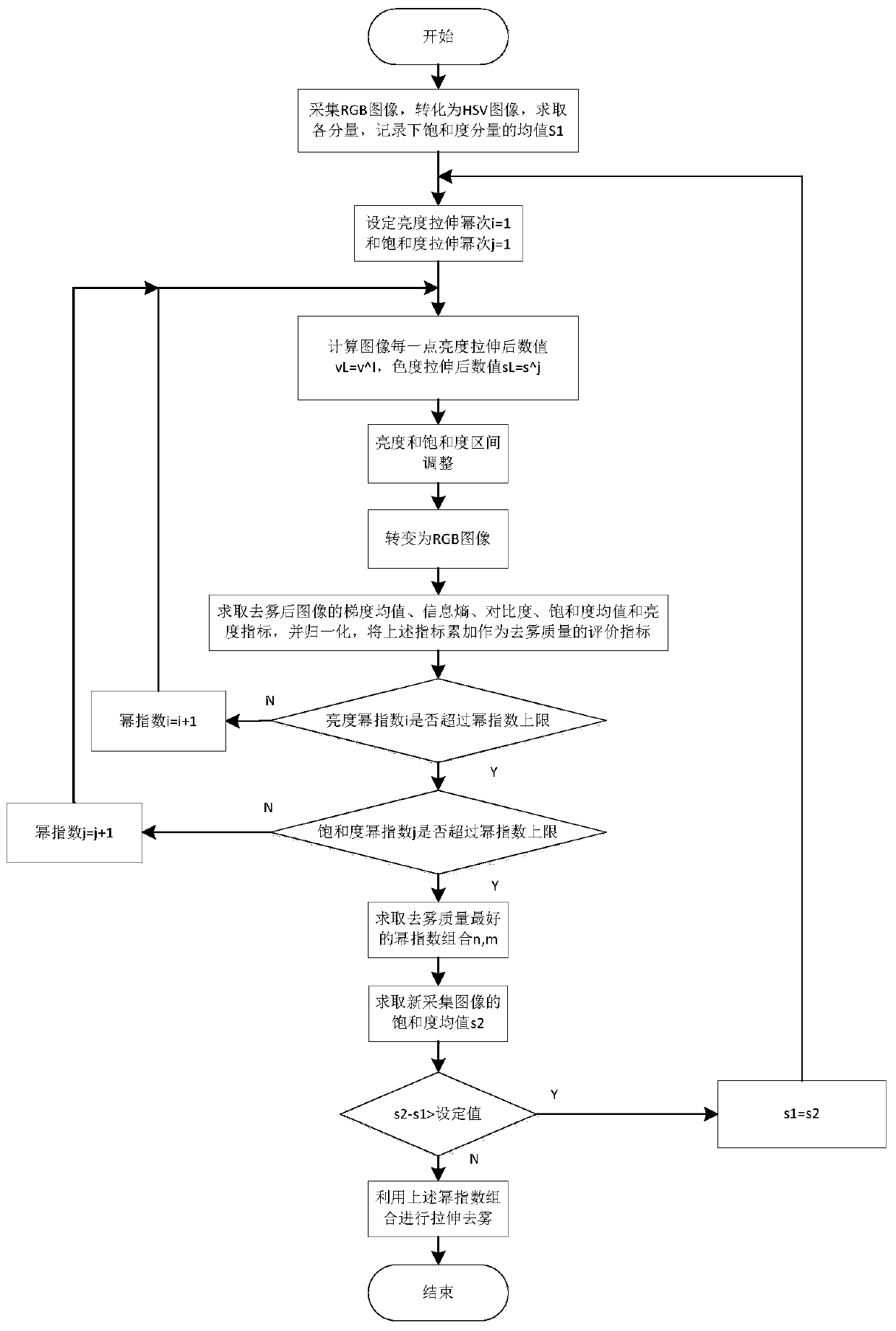

Defogging method based on image enhancement

ActiveCN110223253AChroma does not affectExpand rangeImage enhancementImage analysisRgb imageDynamic stretching

The invention discloses a defogging method based on image enhancement, and the method comprises the steps: carrying out the HSV transformation of a color foggy image, and obtaining the components of brightness, chromaticity, and saturation; performing power operation on the brightness component and the saturation component respectively, and performing dynamic stretching on the brightness componentand the saturation component after operation; synthesizing the stretched brightness component and saturation component with the original chroma component into an RGB image, and converting the RGB image into a grayscale image; solving corresponding image parameters, calculating a normal distribution function value to serve as a brightness index, and adding all the normalized indexes to serve as the evaluation of the defogging effect of each combination; selecting the power exponent corresponding to the tensile combination with the best evaluation index as the power exponent of the subsequent defogging power operation; and then, operating the tensile combination evaluation algorithm again, and searching the changed optimal power exponent combination. Aiming at the influence of fog on the image, the optimal power exponent of the brightness component and the saturation component is determined by calculating the power drawing of the brightness component and the saturation component and evaluating the defogged image.

Owner:JIANGSU UNIV OF SCI & TECH

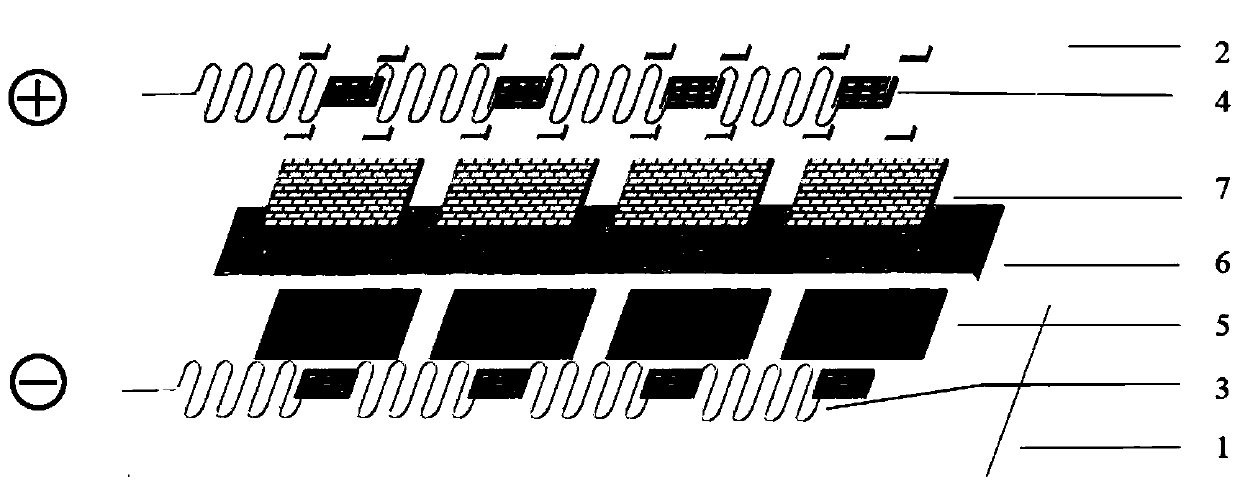

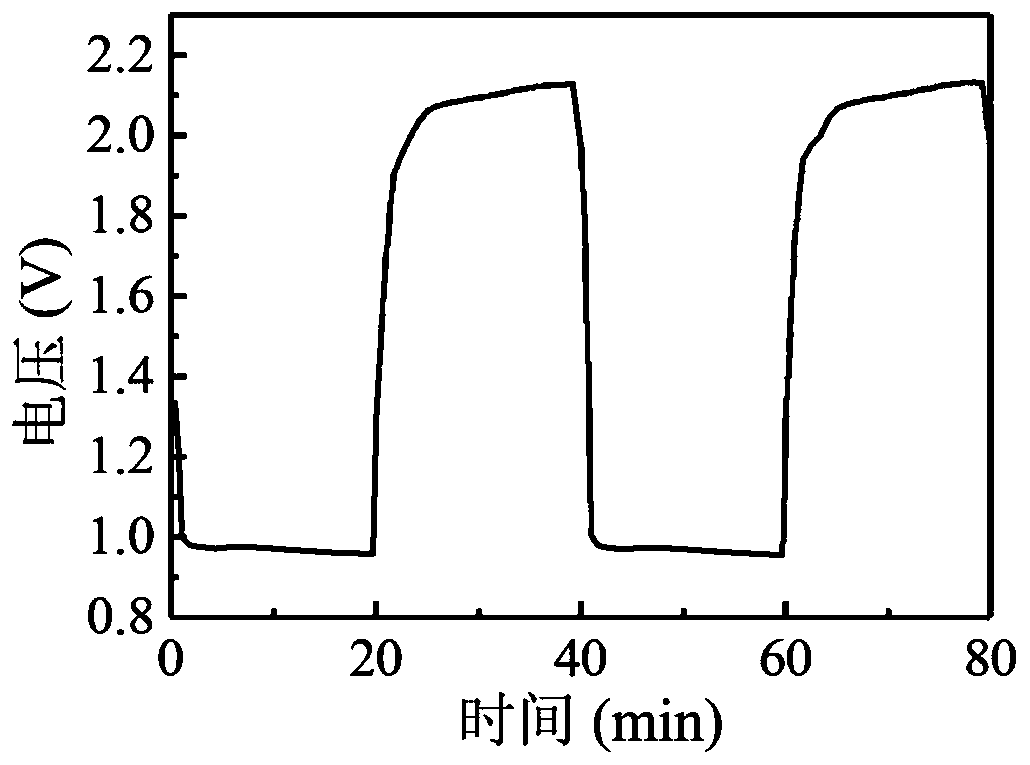

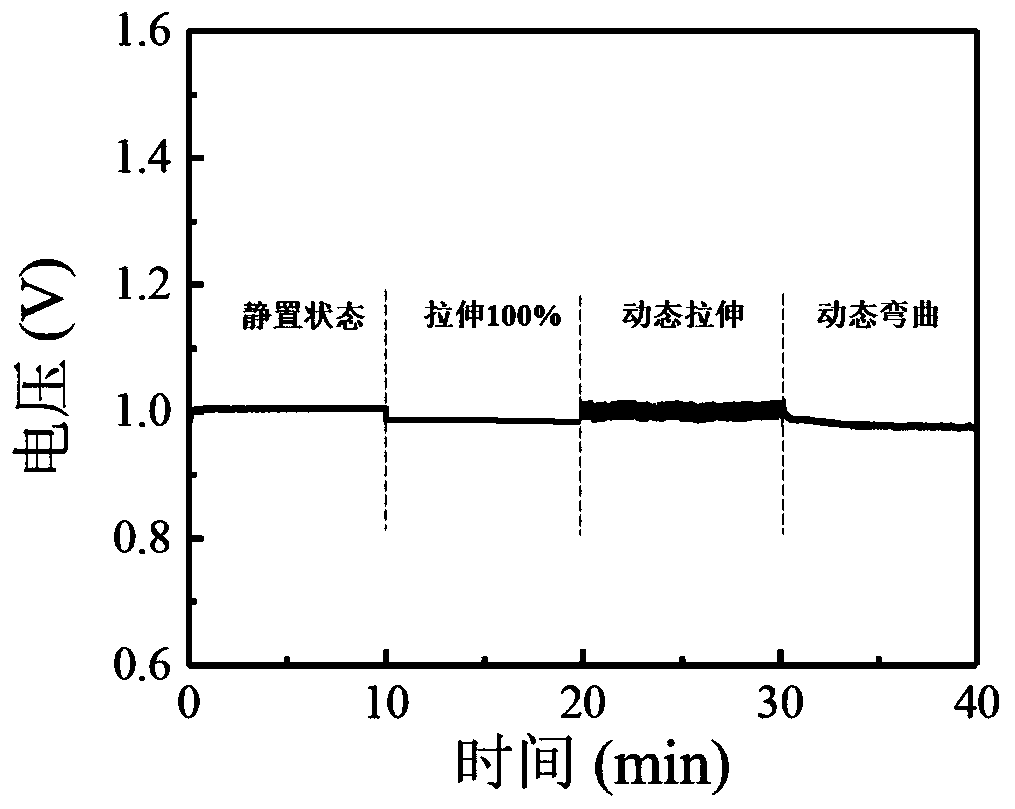

Stretchable zinc air battery array and preparation method thereof

InactiveCN109841930AAchieve stretching effectImprove discharge performanceFuel and primary cellsPrimary cell electrodesPolymer electrolytesModified carbon

The invention belongs to the field of intelligent energy storage devices, in particular to a stretchable zinc air battery array and a preparation method thereof. The preparation method comprises the steps of: firstly, embedding a snakelike line copper wire circuit in a silicone rubber mold; secondly, binding a zinc foil piece and a modified carbon cloth to specific positions of the snakelike linecopper wire circuit to form an array and serve as a negative electrode and a positive electrode of a battery respectively; thirdly, separating the zinc foil piece and the modified carbon cloth by means of a polymer electrolyte film; and finally sealing edges to obtain the stretchable zinc air battery array. The stretchable zinc air battery array is rechargeable, has good bendability and stretchability, and stably discharges during the dynamic stretching and bending process. The battery array can be sewn on clothes, and thus has a good application prospect in the field of wearable equipment.

Owner:TIANJIN UNIV

Material dynamic damage evolution experiment method of high temporal-spatial resolution

ActiveCN109975135AConvenient researchConvenient inspectionMaterial strength using single impulsive forceImage resolutionWave form

The invention discloses a material dynamic damage evolution experiment method of a high temporal-spatial resolution. A flying sheet is controlled to hit against a large head end surface of a cone sample. After impact, a flying sheet impact compression wave and a sample impact compression wave are generated to large head surfaces of the flying sheet and the cone sample. When a sample compression wave front reaches a conical surface of the cone sample, oblique reflection is performed to form a sample sparse wave, simultaneously, a flying sheet sparse wave is spread towards a small head end direction in plane wave form in the cone sample, and forms a flying sheet sparse wave front. The sample sparse wave and the flying sheet sparse wave front encounter in the cone sample, and generate stretching stress and damages, and finally form a spall damage surface parallel to a cone bus as time goes on. The method has advantages that material dynamic stretching damage and destroy information underdifferent impulse conditions after single loading can be acquired; and a characteristic of the high temporal-spatial resolution is possessed, which is beneficial to study of a spall strength criteriontheory and investigation of microscopic damage evolution physical image information in the sample.

Owner:NINGBO UNIV

Dynamic test apparatus for rubber pipeline, and test method thereof

PendingCN107515164AIncrease flexibilityIncrease diversityInvestigating material ductilityMaterial strength using repeated/pulsating forcesTorsion testDynamic stretching

The invention relates to a dynamic test apparatus, and concretely relates to a dynamic test apparatus for a rubber pipeline, and a test method thereof. The apparatus comprises a bending dolly, a dolly guide rail, and a bending device, a stretching device and a torsion device which are respectively arranged on the ground, the stretching device and the torsion device are respectively positioned at two sides of the bending device, the dolly guide rail arranged on the ground is arranged between the stretching device and the torsion device, and the dolly guide rail is provided with the bending dolly which can slide back and forth. The test method comprises a dynamic bending test technology, a dynamic stretching test technology and a dynamic torsion test technology. Every test device is provided with two corresponding hydraulic oil cylinders, so the flexibility and the diversity of the whole dynamic test apparatus are improved, and the phenomenon of insufficient power of the rubber pipeline during the dynamic test is avoided.

Owner:T RUBBER

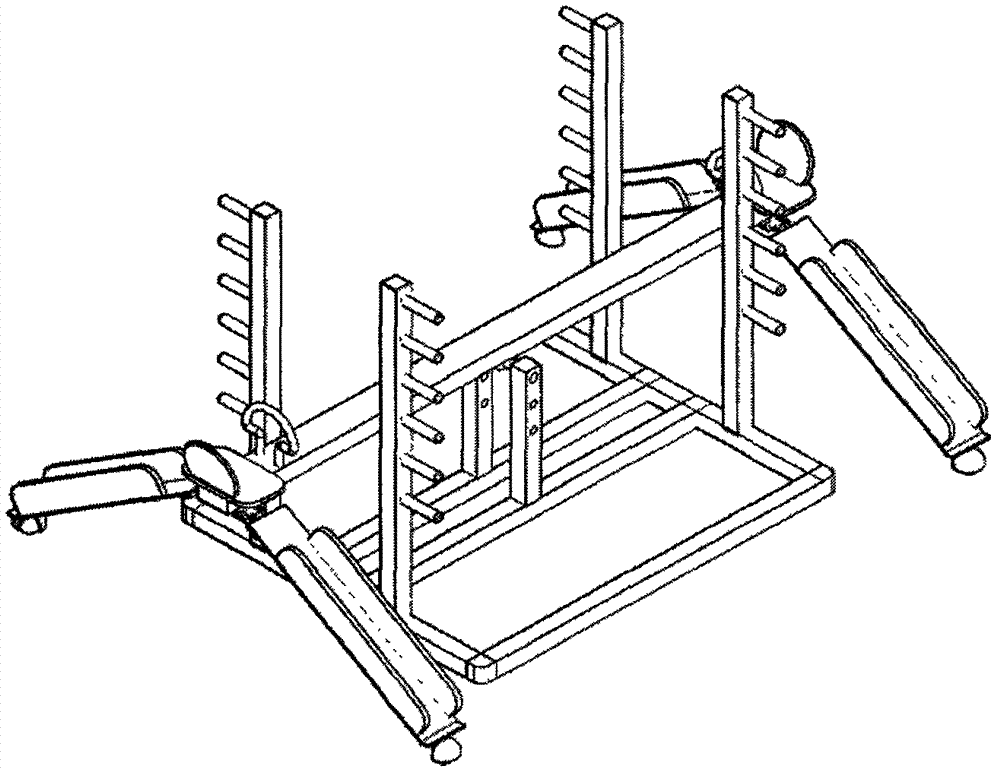

Seesaw-type double split training device

InactiveCN102728028AEntertainingSatisfy the playful natureGymnastic exercisingSee-sawsCouplingDynamic stretching

Owner:EASTERN GANSU UNIVERSITY +1

Guided movement exercise machine

ActiveUS11033767B2Stretched to limitIncrease strainMovement coordination devicesMuscle exercising devicesSimulationDynamic stretching

An exercise machine can include a frame, one or more platform arms that can be driven by a motor or a hydraulic system, and one or more handle arms that can be grasped by the user's hands. The exercise machine can guide the user through movement that actively flexes and extends portions of a user's body while the user exercises to provide, for example, dynamic stretching and cardio benefits while achieving strength training.

Owner:PHILLIPS HARRY J

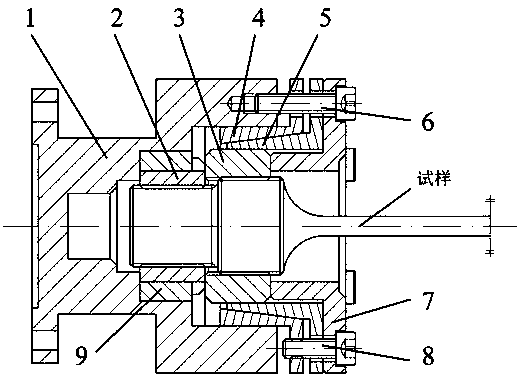

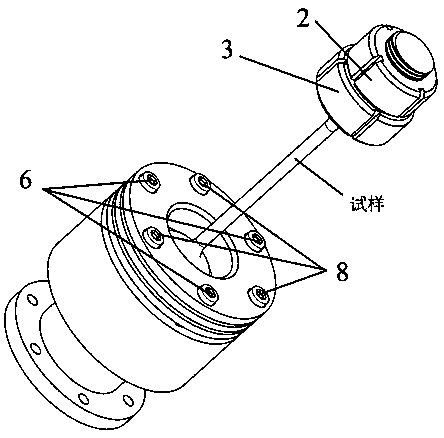

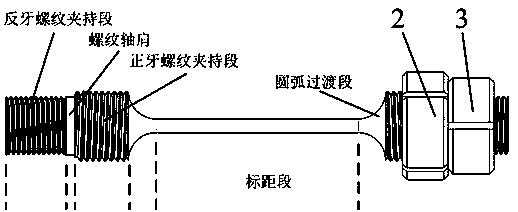

Stretch-twist combined fixture based on forward thread structure and reverse thread structure

The invention relates to a stretch-twist combined fixture based on a forward thread structure and a reverse thread structure and belongs to the field of material testing technologies. Through the combined fixture, reliable clamping of a sample can be completed in quasi-static and high-frequency dynamic stretch-twist combined loading material tests, and high-frequency dynamic loading includes but not limited to zero-crossing loading. The combined fixture comprises a fixture shell part, a clamping part and an expansion part, wherein the rear end of a fixture cup seat in the shell part is connected with a stretch-twist combined sensor through a flange; the clamping part is composed of two nuts which are unequal in diameter and opposite in rotating direction, and the clamping part is connectedwith the fixture cup seat through a flat key pair and the expansion part; and the expansion part is used for adjusting the locking degree of the inner-end nut. The combined fixture has the advantagesthat the sample can be clamped in a mechanical connection mode under quasi-static and high-frequency dynamic stretch-twist combined loading conditions; and the combined fixture is good in universality, low in cost and convenient to maintain and further has an important prospect of application in extremely high and low-temperature environments and a limited space.

Owner:JILIN UNIV

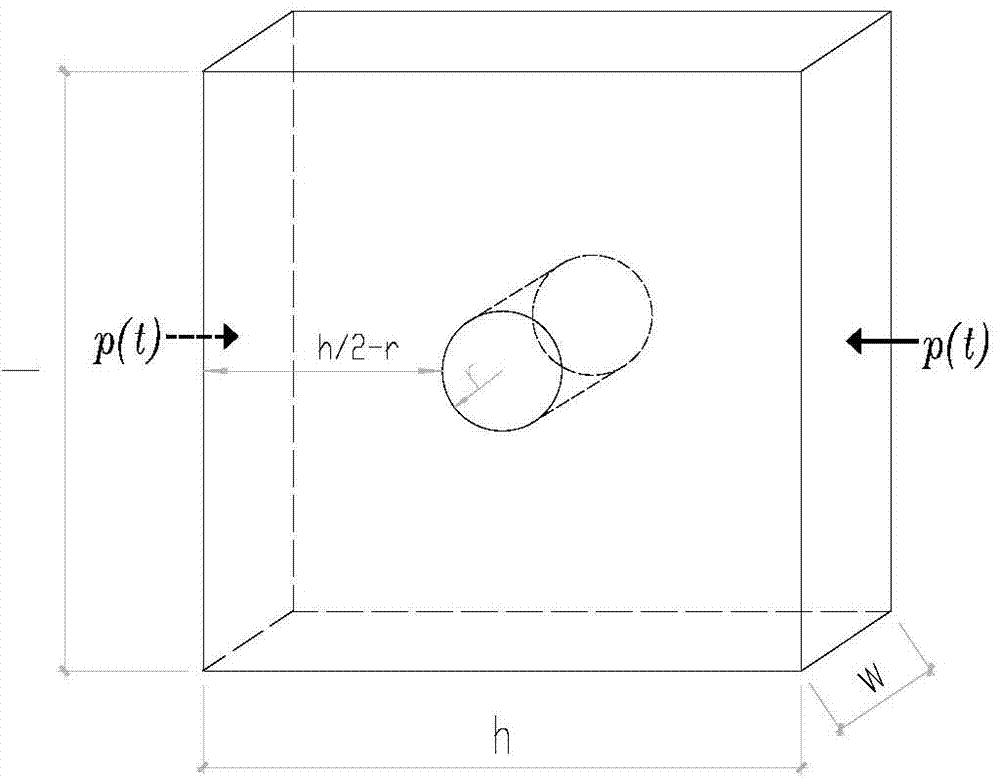

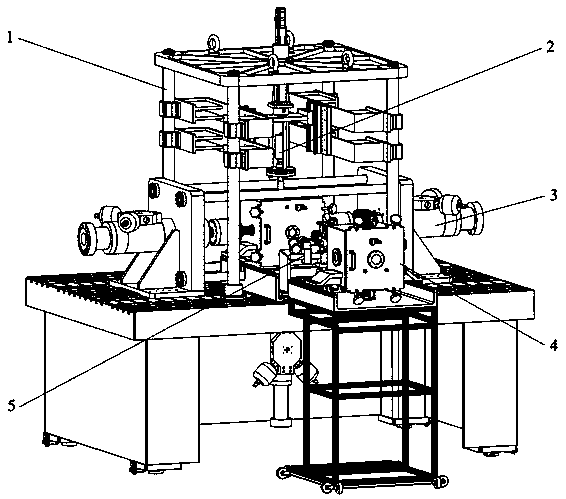

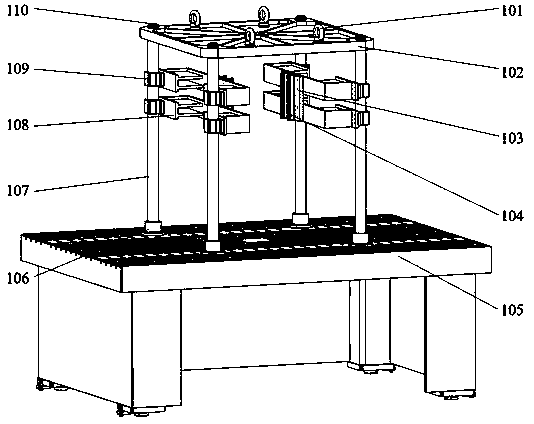

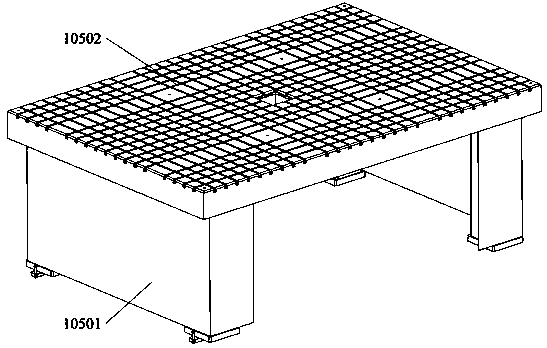

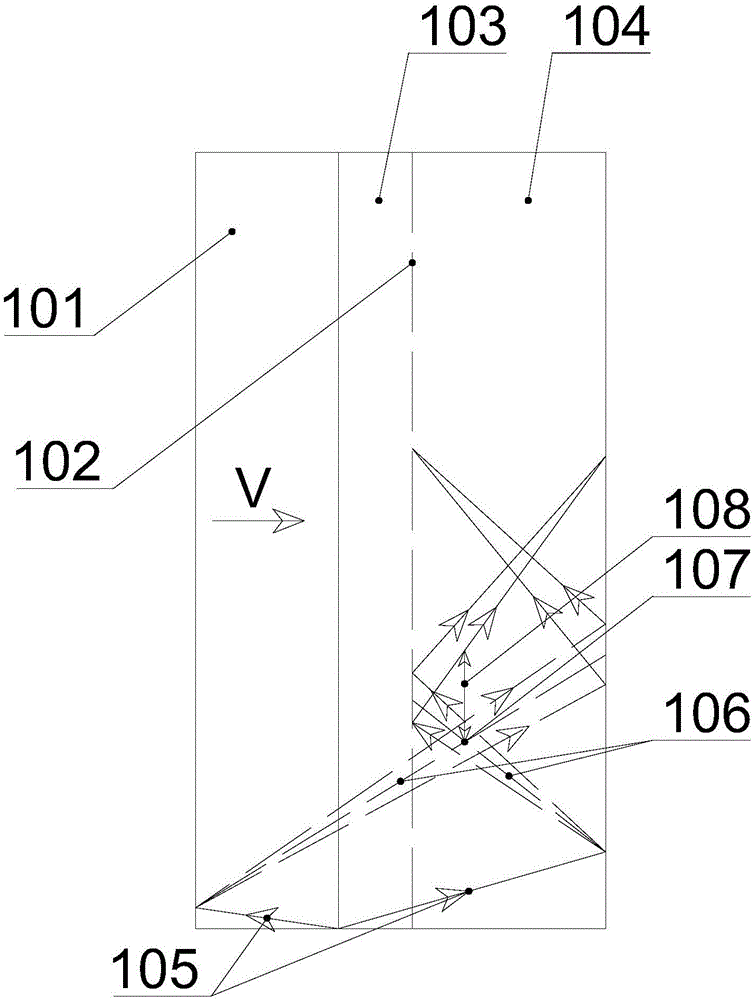

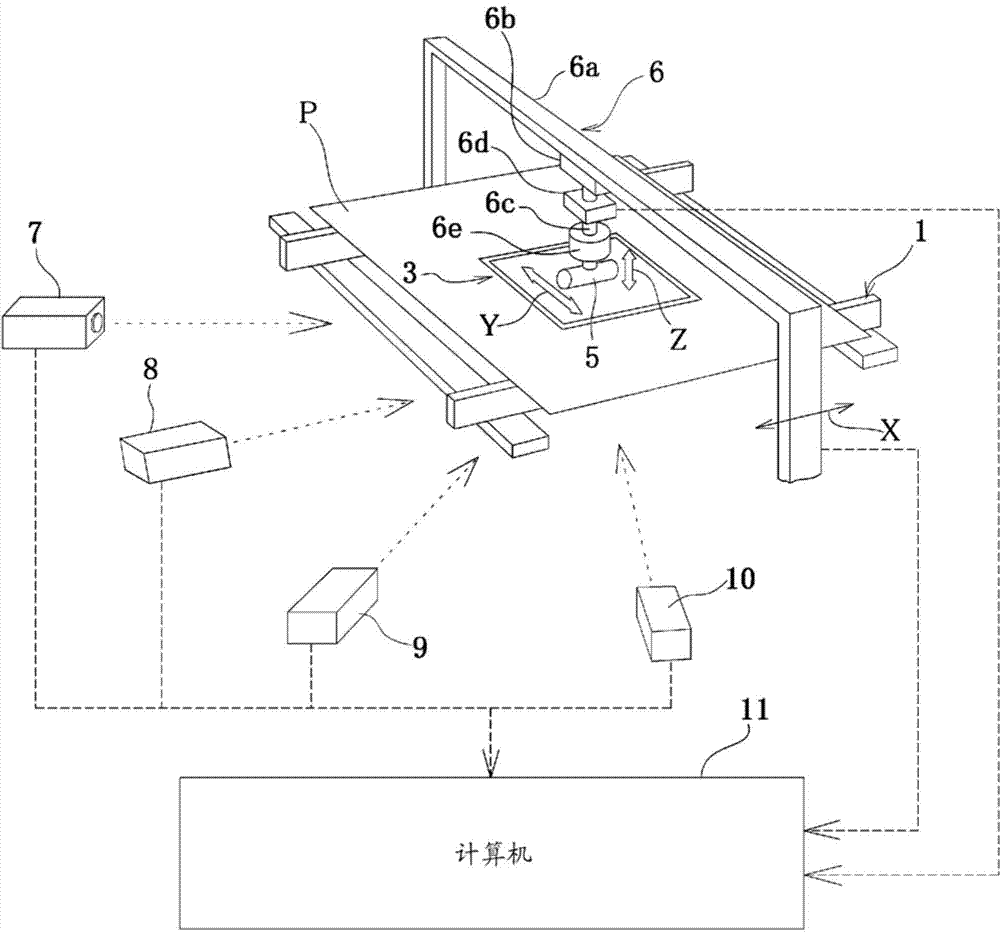

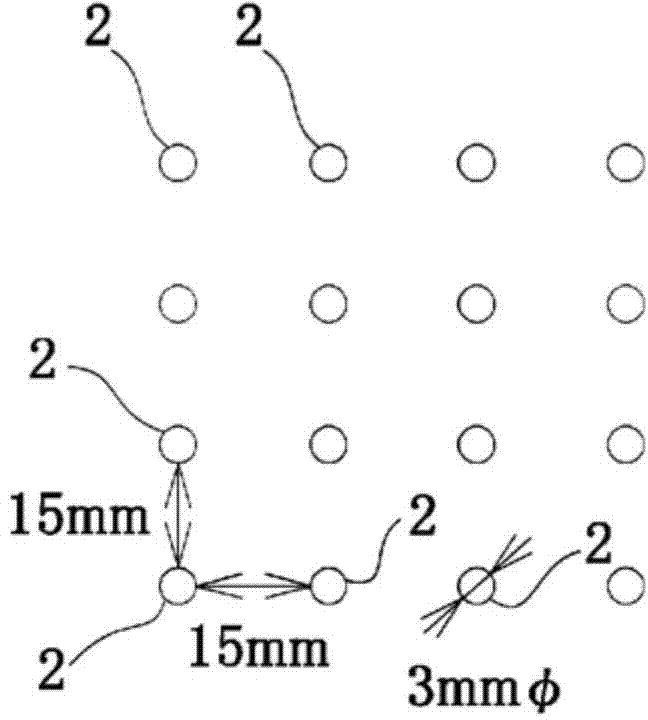

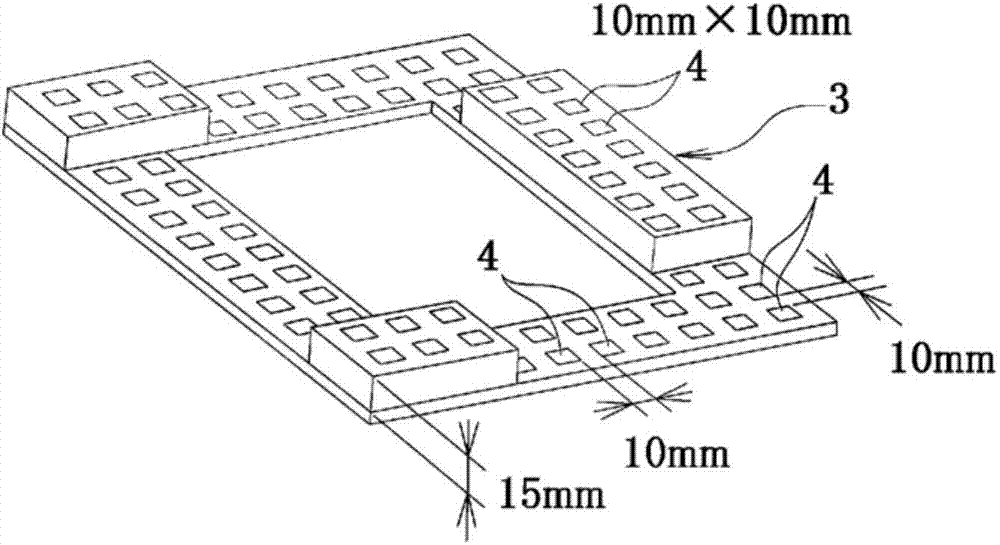

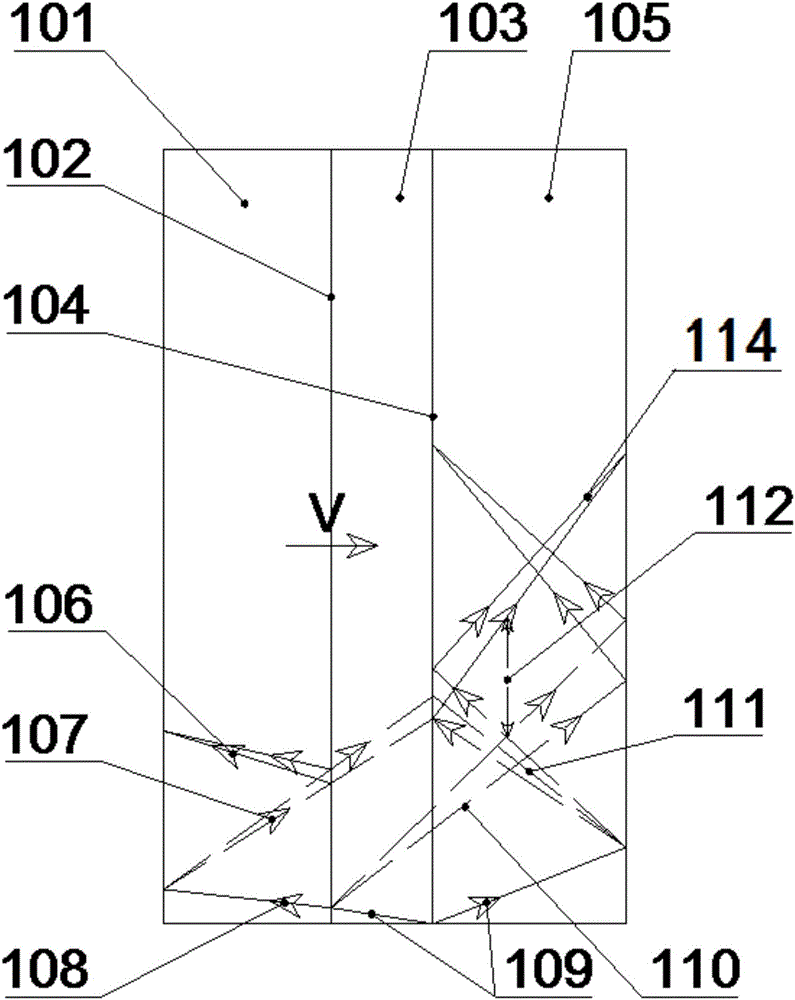

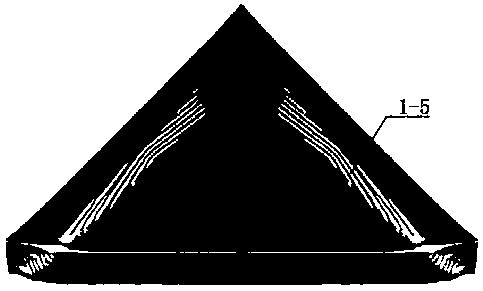

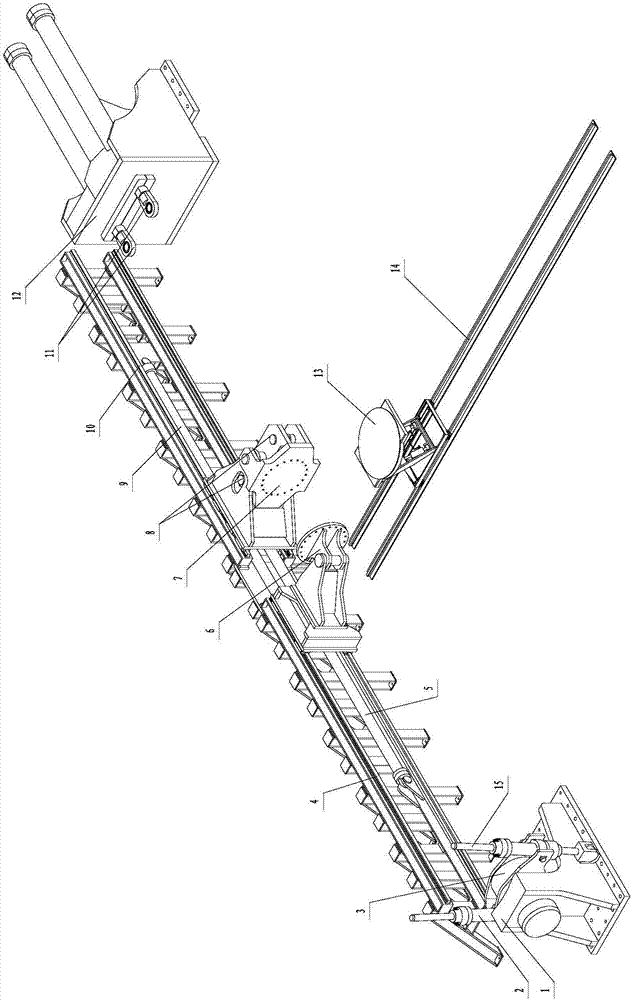

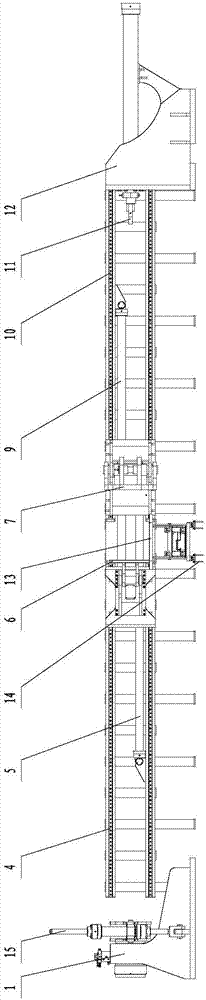

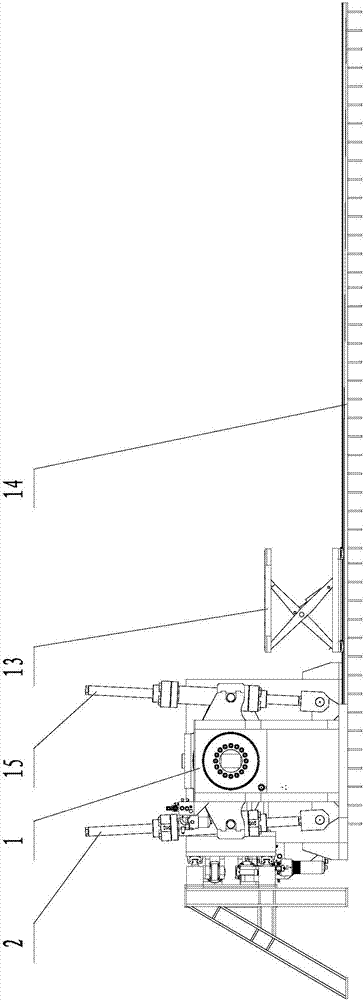

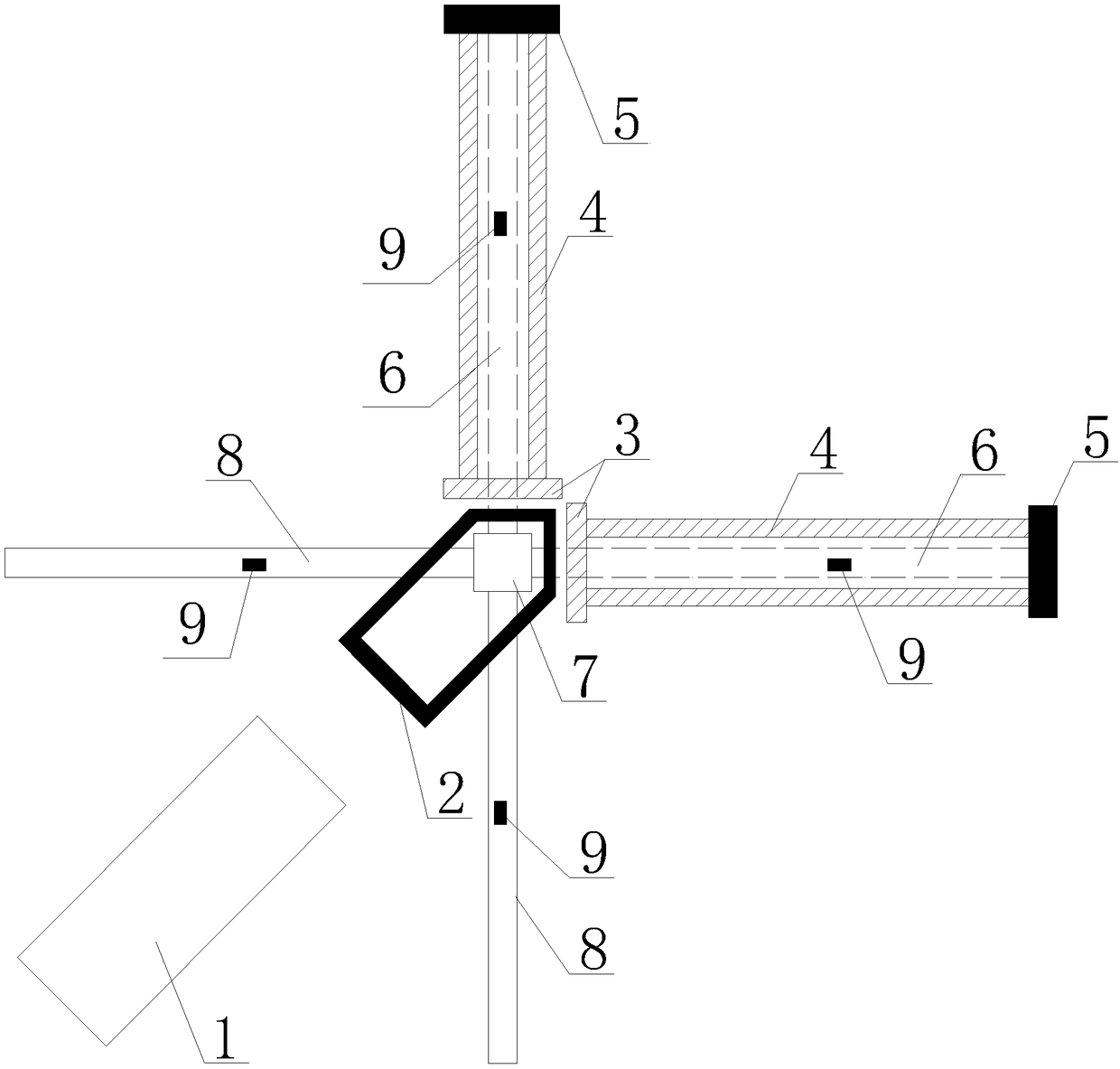

True biaxial dynamic stretching experiment apparatus

ActiveCN108398340AGuaranteed synchronicityMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceDynamic stretchingEngineering

The invention relates to an experiment apparatus for biaxial synchronous impact stretching loading on a material, concretely relates to a true biaxial dynamic stretching experiment apparatus, realizesthe true biaxial synchronous impact stretching experiment on the material, and is suitable for dynamic stretching performance research on the material under a biaxial state, and stretching waves of two shafts are simultaneously effected on a test piece, the stretching waveform has same amplitude and pulse width, loading waveform control is realized, so that the dynamic mechanical properties of the material under the biaxial stretching effect can be researched, and the experiment apparatus provides abundant dynamic mechanics experiment data for a material impact experiment.

Owner:GUANGZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com