Stretchable zinc air battery array and preparation method thereof

A zinc-air battery and array technology, applied in the field of zinc-air battery array preparation, can solve problems such as separation of electrodes and current collectors, battery failure, etc., and achieve the effects of stable discharge performance, adjustable current, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

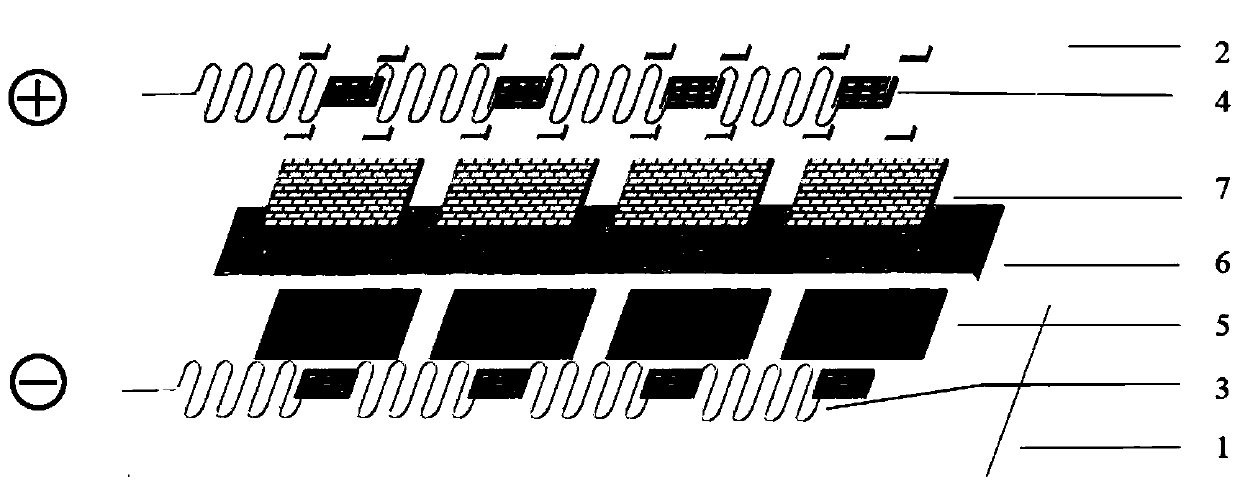

[0046] This embodiment relates to a method for preparing a stretchable zinc-air battery array, the steps of which are as follows:

[0047] Preparation of a copper wire circuit with a serpentine pattern embedded in the silicone rubber film: bend a copper wire with a diameter of 0.02 mm into a serpentine pattern with a width of 5 mm, and then weave the copper wire with a serpentine pattern into a circuit. Put the copper wire circuit in the mold, pour the commercial Ecoflex silicone rubber A and B liquid mixed evenly at 1:1, and let it stand at 60°C for 1 hour. The serpentine copper wire is fixed in the silicone rubber film and exposed to the silicone rubber. The copper wires on the outside of the membrane are woven into circuit contacts, and the serpentine copper wire circuit is embedded in the silicone rubber membrane. Take two pieces respectively as the first silicon rubber film layer and the second silicon rubber film layer.

[0048]Preparation of the zinc negative electrode...

Embodiment 2

[0062] This embodiment relates to a method for preparing a stretchable zinc-air battery array, the steps of which are as follows:

[0063] Preparation of a silicon rubber film embedded in a serpentine copper wire circuit: bend a copper wire with a diameter of 0.02mm into a serpentine pattern with a width of 5mm, and then bend the serpentine copper wire into a circuit of a specific shape, such as Figure 4 shown. Put the copper wire circuit in the mold, pour the commercial Ecoflex silicone rubber A and B liquid mixed evenly at 1:1, and let it stand at 60°C for 1 hour. The serpentine copper wire is fixed in the silicone rubber film and exposed to the silicone rubber. The copper wires on the outside of the membrane are woven into circuit contacts, and the serpentine copper wire circuit is embedded in the silicone rubber membrane. Take two pieces respectively as the first silicon rubber film layer and the second silicon rubber film layer.

[0064] Preparation of modified carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com