Dynamic stretching-based ultra-high molecular weight polymer rolling forming method

An ultra-high molecular weight, forming equipment technology, applied in the field of ultra-high molecular weight polymer roll forming, can solve the problems of shear sensitivity, poor processing fluidity, small processing temperature range, etc., to reduce forming difficulty, increase output, reduce energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

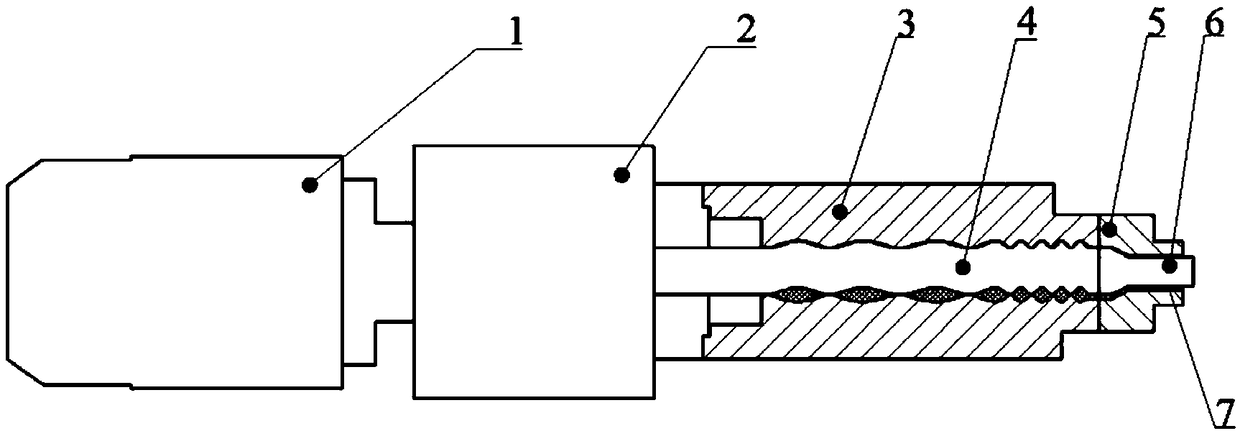

[0043] Roll-forming equipment for ultra-high molecular weight polymer pipes based on dynamic stretching, such as figure 1 Shown, including extensional rheological extruder and roll forming die. In this embodiment, the elongational rheological extruder adopts the eccentric rotor extruder described in the invention patent with the authorized notification number CN104002447B, including a power system 2, a stator 3 and a rotor 4, and the power system includes a motor 1.

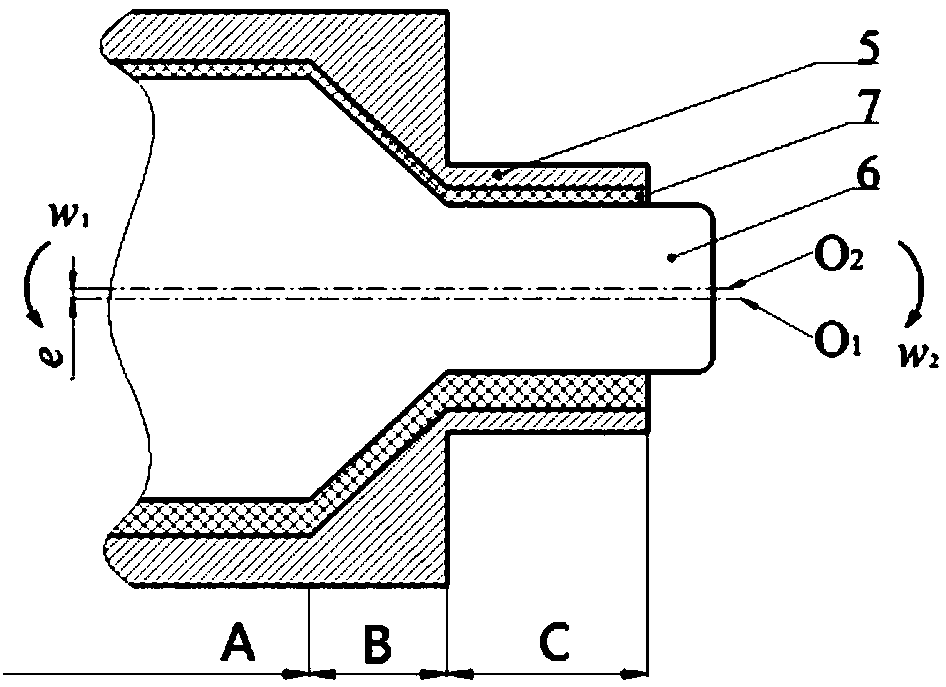

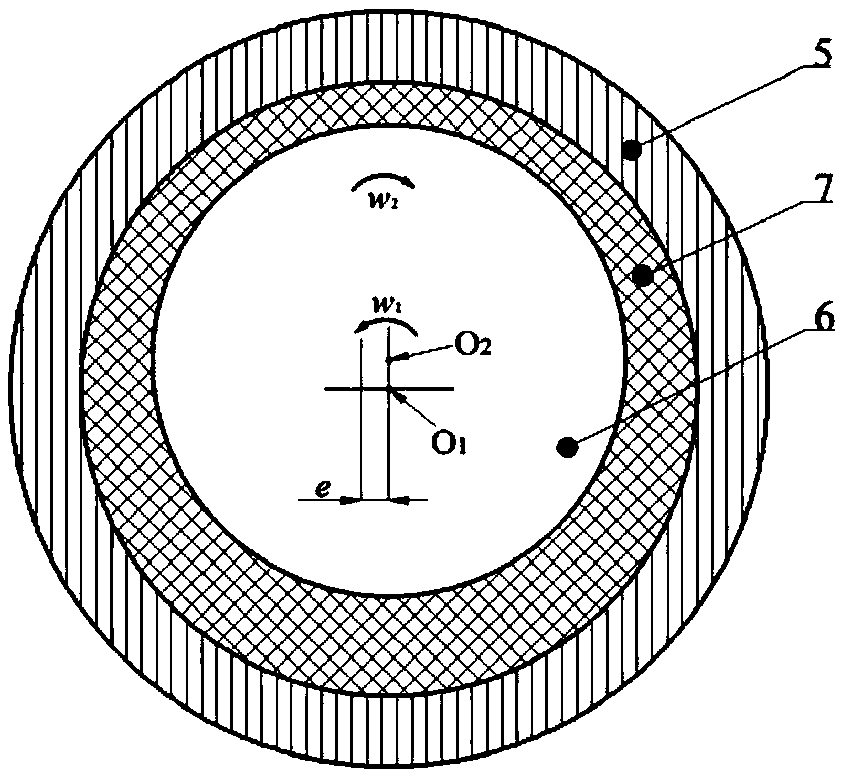

[0044] The rolling die head includes an outer die 5, a mandrel 6 and a temperature control system arranged on the outer circumference of the outer die. The stator 3 is connected to the outer die 5 coaxially, and the mandrel 6 is connected to the rotor 4 coaxially.

[0045] During installation, the axis O of mandrel 6 2 Axis O with the outer die 5 1 There is an eccentricity e. The roll forming die head is divided into embryo forming area, compression area and sizing area sequentially along the flow direction; t...

Embodiment 2

[0051] UHMW polymer sheet roll forming equipment based on dynamic stretching, such as Figure 6 As shown, it includes an extensional rheological extruder, a roll forming die head, and a sheet calendering roll assembly. The sheet calendering roll assembly is composed of two counter-rotating sheet calendering rolls 8, and between the two sheet calendering rolls The gap is the forming thickness of the sheet product 9, and the gap between the two calender rolls is adjustable, such as Figure 7 shown.

[0052] Based on the dynamic stretching ultra-high molecular weight polymer sheet rolling forming method, after the tubular embryo is obtained by the method of Example 1, it is formed into a sheet product 9 under the rolling of the sheet calendering roller assembly.

[0053] Parts not mentioned in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0055] UHMW polymer fiber roll-forming equipment based on dynamic stretching, such as Figure 8 As shown, it comprises an extensional rheological extruder, a roll forming die, a sheet calendering roll assembly, a cutting roll assembly, a rolling roll assembly and a traction roll 14; the cutting roll assembly is composed of a cutting roll 10 with a tapered knife and an The cutting roller 15 of tapered cutter is formed, and the surface equidistant of the cutting roller with tapered cutter is provided with some circumferential tapered grooves to form equidistant tapered cutter, as Figure 9 As shown; the rolling roll assembly is made up of two rolling rolls 12, and the surface of the rolling rolls is equidistantly provided with some circular arc grooves, and the circular arc grooves between the two rolling rolls form a number of cylindrical shapes one by one. cavity, such as Figure 10 shown.

[0056] Based on the ultra-high molecular weight polymer fiber rolling forming method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com