A kind of preparation method of high melt strength polypropylene

A technology with high melt strength and polypropylene, applied in the field of polypropylene, can solve problems such as narrow application range, achieve low crosslinking degree, simple process, and avoid a large amount of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The twin-screw extruder used in this embodiment is a co-rotating twin-screw extruder with a screw diameter of 30 mm and a length-to-diameter ratio of 52.

[0035] 3 parts of styrene, 1.25 parts of benzoyl peroxide, 0.5 parts of triallyl cyanurate, 0.2 parts of β-(4-hydroxy-3,5-di-tert-butylphenyl)propionic acid Add n-octadecyl alcohol ester and 0.4 part of (2,4-di-tert-butylphenyl)phosphite triester into 3 parts of acetone and stir and mix thoroughly to obtain a mixture of additives. Add 100 parts of homopolypropylene powder with a melt flow rate of 0.2g / 10min into a medium-speed mixer, and in the presence of an inert gas, spray the above-mentioned mixture on the surface of the polypropylene powder several times. Finally, it is used as a mixture after thorough mixing.

[0036] The above compound is added into a twin-screw extruder for extrusion granulation. The extrusion temperature of the twin-screw extruder was 210°C. The speed of the main machine is 80rpm, the fee...

Embodiment 2

[0039] The twin-screw extruder used in this embodiment is a co-rotating twin-screw extruder with a screw diameter of 30 mm and a ratio of length to diameter of 46.

[0040] The rest are basically the same as in Example 1, but the polypropylene is changed to a homopolypropylene with a melt flow rate of 2g / 10min, and the extrusion temperature of the twin-screw extruder is changed to 190°C.

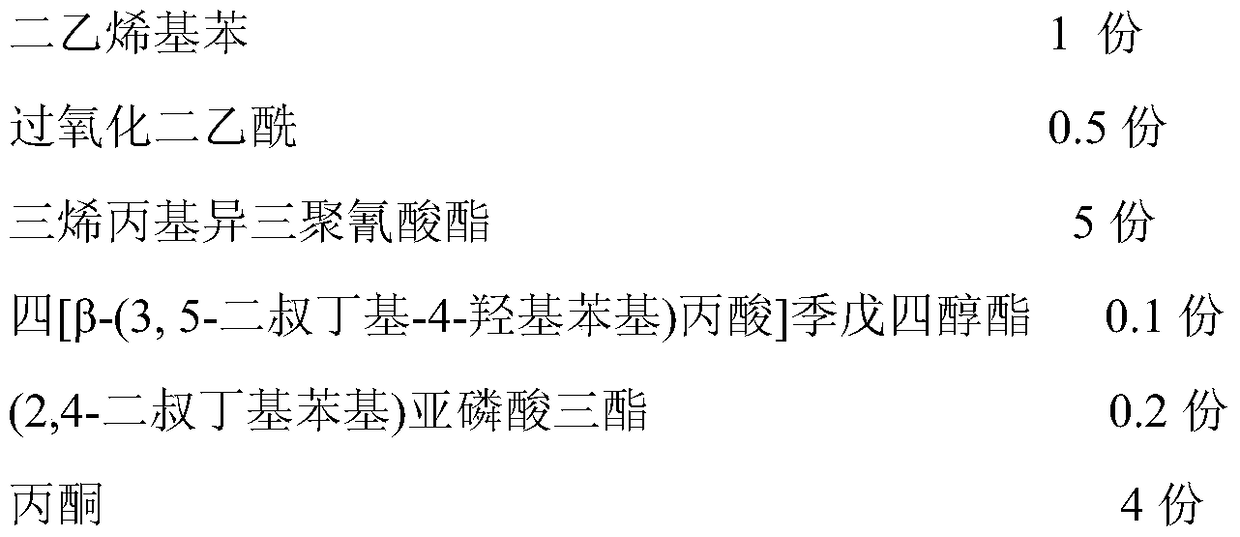

[0041] Auxiliary formula changed to:

[0042]

[0043] The melt flow rate of the obtained high melt strength polypropylene was 3.6 g / 10 min, the melt strength was 23 cN, and the degree of crosslinking was 0.5%. Ordinary polypropylene with the same melt flow rate has a melt strength of 3.5 cN.

Embodiment 3

[0045] The twin-screw extruder used in this embodiment is a co-rotating twin-screw extruder with a screw diameter of 30 mm and a ratio of length to diameter of 56.

[0046] All the other are basically the same as in Example 1, but the polypropylene is changed into 10% of ethylene copolymerization amount, the melt flow rate is the copolymerized polypropylene of 10g / 10min, and the extrusion temperature of twin-screw extruder is changed into 180 ℃.

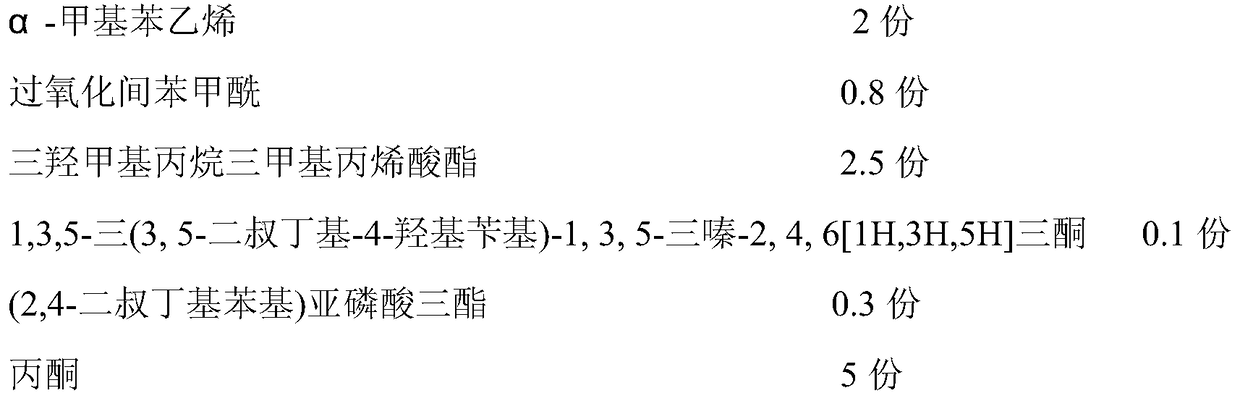

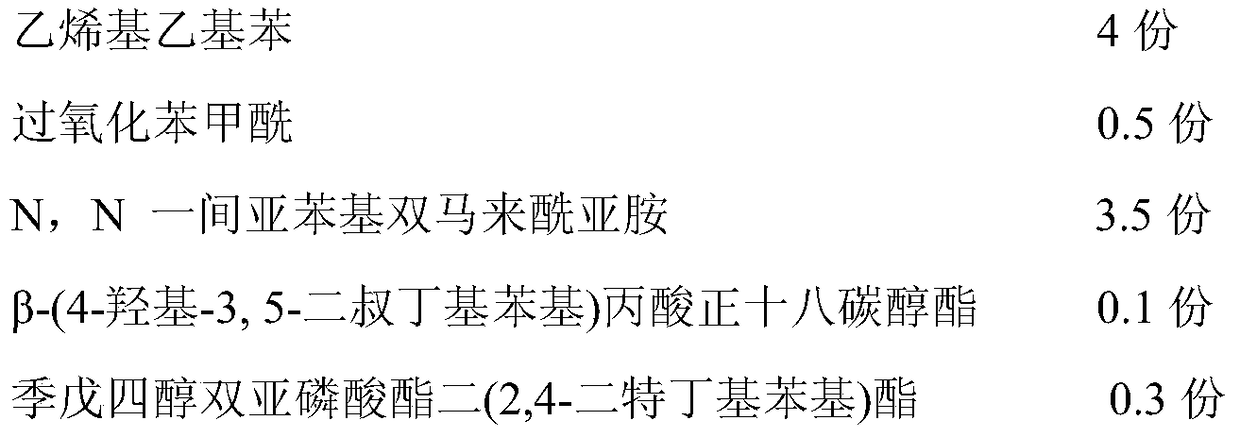

[0047] Auxiliary formula changed to:

[0048]

[0049] The melt flow rate of the obtained high melt strength polypropylene was 8.4 g / 10 min, the melt strength was 13.7 cN, and the degree of crosslinking was 0.3%. The melt strength of ordinary polypropylene with the same melt flow rate is 0.95cN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com