Dynamic test apparatus for rubber pipeline, and test method thereof

A technology for dynamic testing of rubber pipes, applied in the application of repetitive force/pulsation force to test the strength of materials, the ductility of test materials, measuring devices, etc. problems, to achieve the effect of increasing flexibility and variety, avoiding lack of motivation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

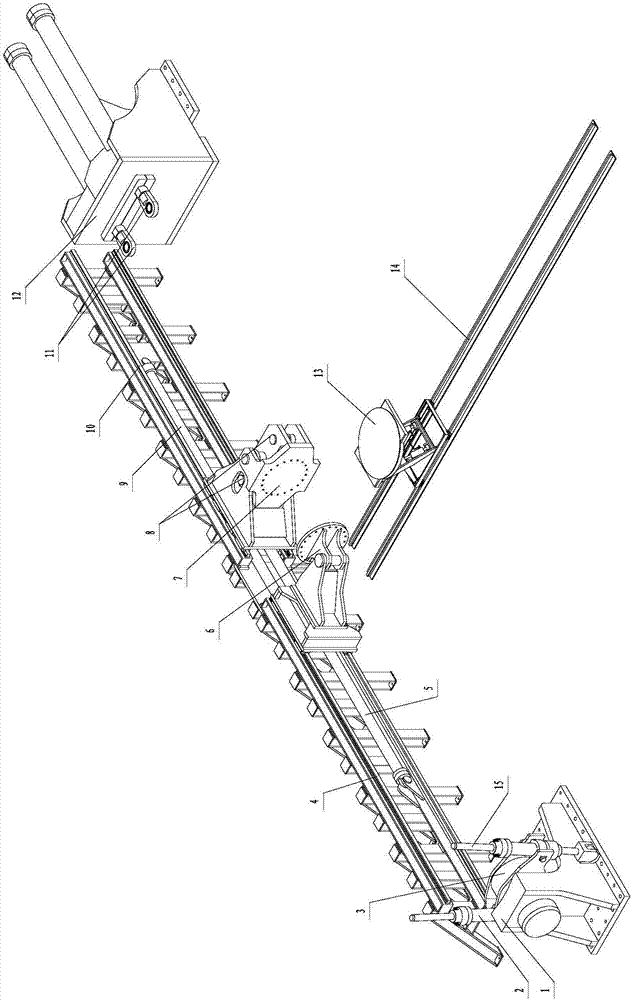

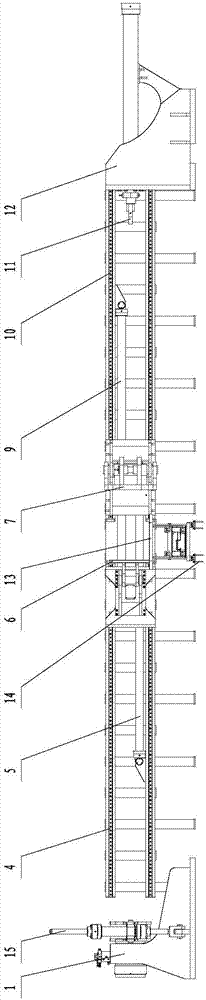

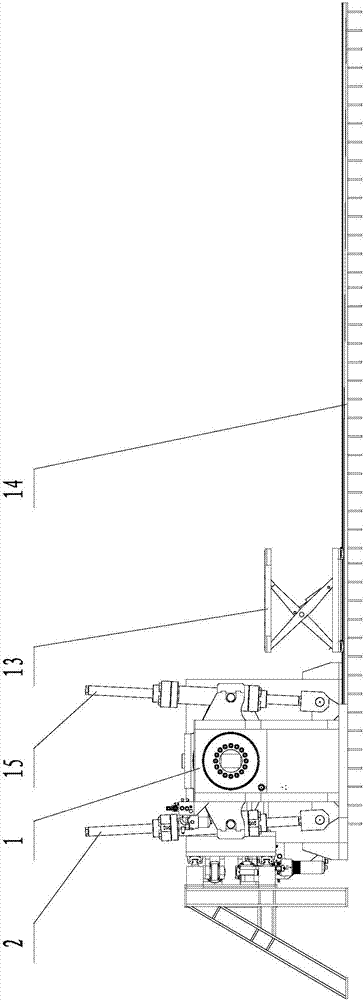

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Such as Figure 1~4 As shown, the dynamic testing equipment of the present invention comprises bending dolly 13, dolly guide rail 14, bending device, stretching device and torsion device, wherein bending device, stretching device and torsion device are all fixed on the level ground with independent attitude, pull The stretching device and the torsion device are respectively located on both sides of the bending device. A trolley guide rail 14 installed on the ground is arranged between the stretching device and the torsion device. A bending trolley 13 capable of reciprocating sliding is provided on the trolley guide rail 14 . One end of dolly guide rail 14 stretches to directly below between active dolly 6 and follow-up dolly 7.

[0026] The bending device comprises a left guide rail 4, a left bending oil cylinder 5, an active trolley 6, a follower tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com