Device and method for hoop tensile test based on laser impact biaxial loading

A bidirectional loading and hoop stretching technology, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as high risk, many influencing factors, and difficult control, achieving large energy and strain rate, simple loading process, The effect of few influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

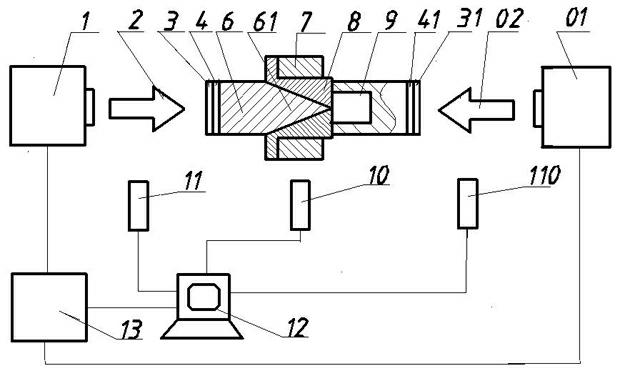

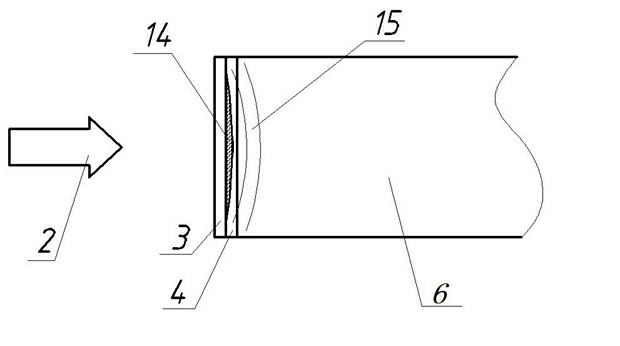

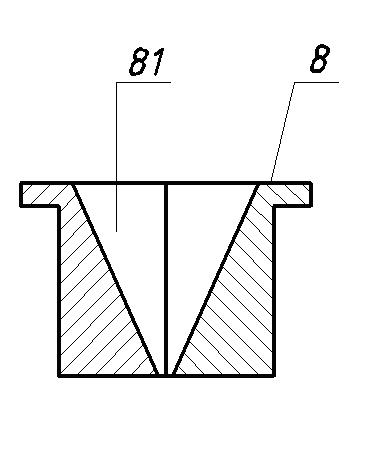

[0033] Such as figure 1 Shown, a kind of impact tensile test method and device loaded by laser shock, including 1. laser head A, 01 laser head B, 2. laser pulse A, 02. laser pulse B, 3. constrained layer A, 31. Constraining layer B, 4. Absorbing layer A, 41. Absorbing layer B, 6. Loading rod A, 61 cone, 7. Ring specimen, 8. Cylindrical driving ring, 81. Conical hole, 82. Driving block A, 83. Drive block B, 84. Drive block C, 9 Load rod B., 10. Laser interferometer, 11. Trigger A, 110. Trigger B, 12. Computer, 13. High power pulsed laser, load rod 6 The other end of the cylindrical drive ring 8 is provided with a cone 61. The cylindrical drive ring 8 is composed of three separate drive blocks A82, drive block B83 and drive block C84. One end of the cylindrical drive ring 8 is provided with a The other end of the cylindrical driving ring 8 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com