Large-scale missile engine six-component dynamometry and calibrating device

A technology for calibrating device and engine, applied in the direction of measuring device, force/torque/work measuring instrument calibration/test, measuring force component, etc., can solve the problem that there is no literature available for large-load six-component force measuring equipment, etc. Achieve the effect of saving development costs and maintenance costs, improving measurement accuracy, and high loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the present invention is described in detail, specifically as follows:

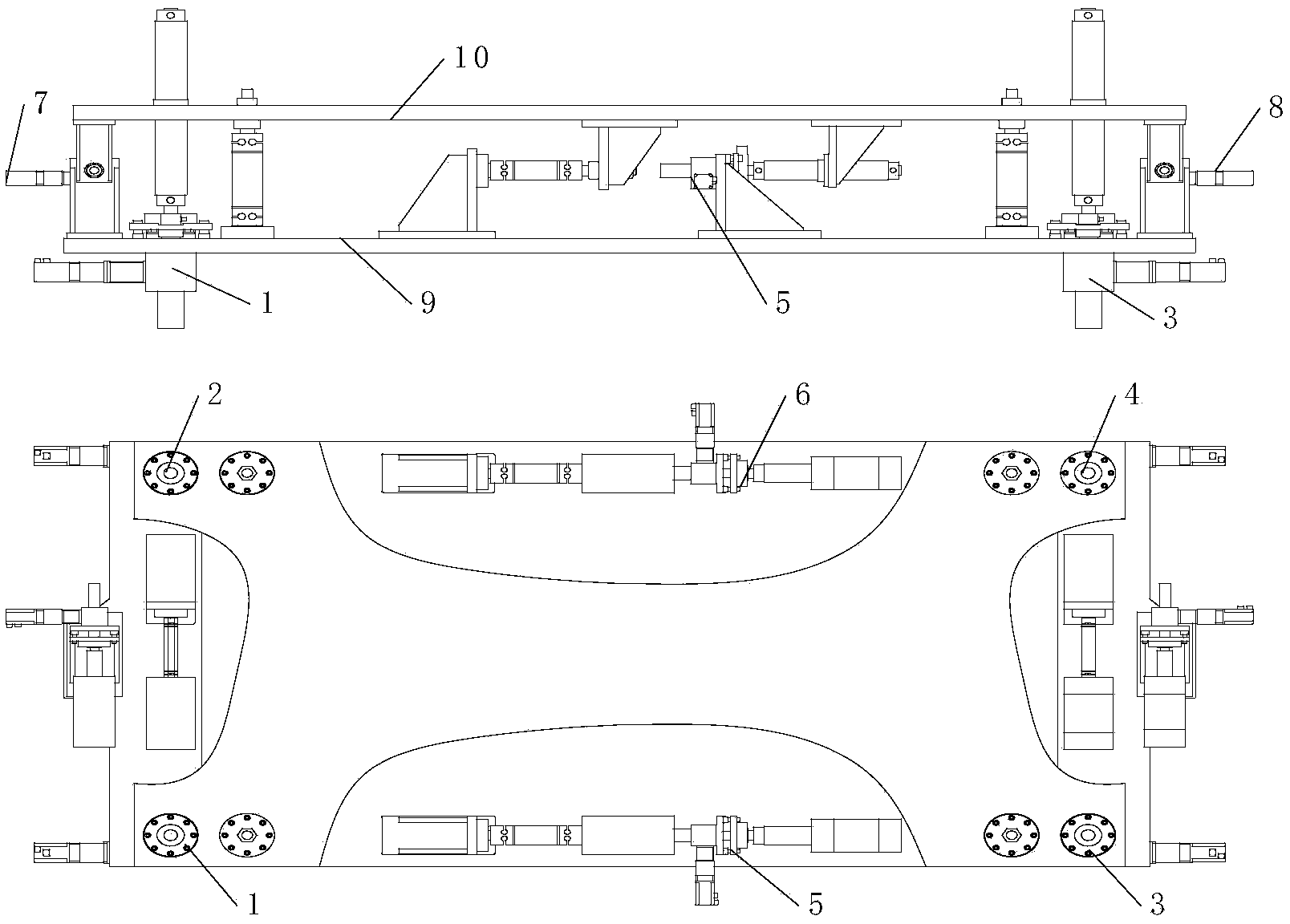

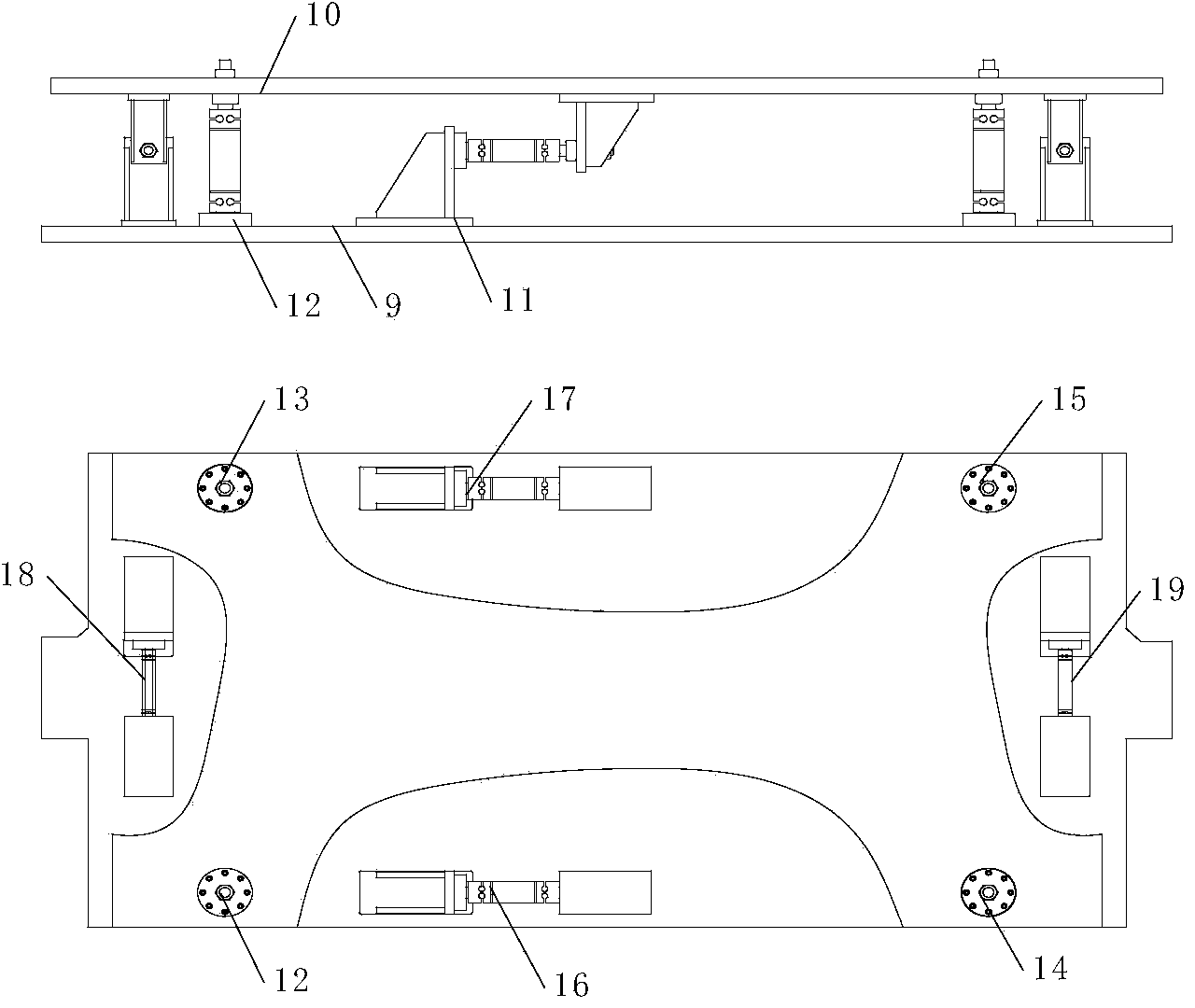

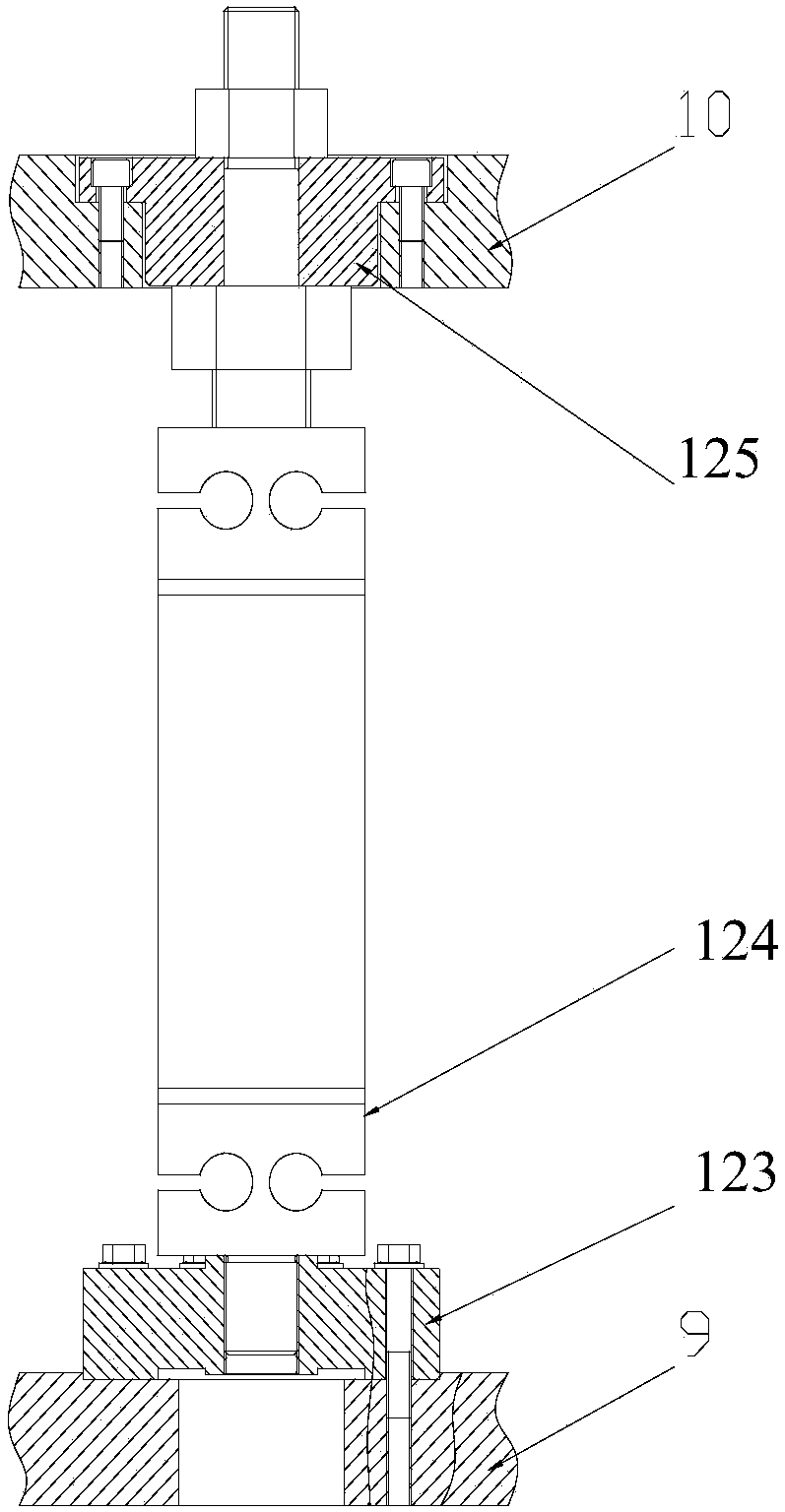

[0040] Such as figure 1 As shown, a six-component force measurement and calibration device for a large missile engine includes eight force generators 1-8, a fixed frame 9, a floating frame 10 and eight force transmission components 12-19; when the device is used to measure force, the force generator does not work, figure 2 The structure when the force generator is installed is given, hereinafter referred to as the force measuring device.

[0041] Among them, four force transmission components 12, 13, 14, 15 are vertically installed between the fixed frame 9 and the floating frame 10, and are arranged in a square shape; the other four force transmission components 16-19 are respectively fixed on the floating frame 10 through the upper and lower support frames. and on the fixed frame 9, and these four force transmission component axes 16-19 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com