Stretch-twist combined fixture based on forward thread structure and reverse thread structure

A technology of positive and negative teeth and threads, which is applied in the field of material testing, can solve the problems of hydraulic fixtures that cannot meet the requirements of use, many auxiliary components, and difficult maintenance, and achieve reliable clamping, convenient maintenance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

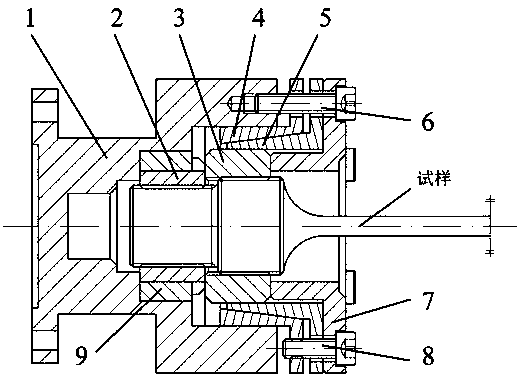

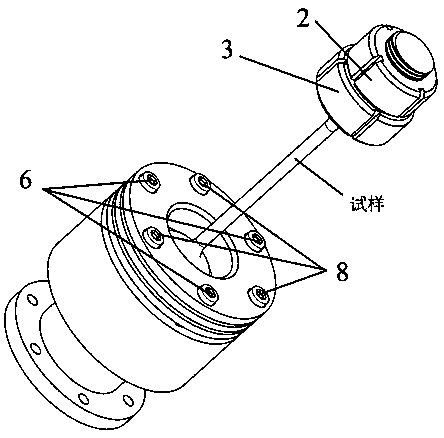

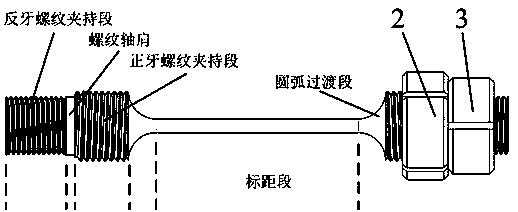

[0019] see Figure 1 to Figure 5 As shown, the tensile-torsion composite fixture based on the positive and negative thread structure of the present invention can realize reliable clamping of the sample in the material test of quasi-static and high-frequency dynamic tensile-torsion composite load loading , and the high-frequency dynamic loading includes but not limited to zero-crossing loading. The clamp includes a clamp shell part, a clamping part and an expansion part. The rear end of the clamp cup seat in the shell part is connected to the tensile torsion composite sensor through a flange; the clamping part is composed of two inner and outer end nuts with different diameters and opposite rotation directions, which realize threaded clamping of the sample, and It is connected with the fixture cup seat through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com