Safety evaluation method of high-temperature production facility or component defect

A technology for safety evaluation and production equipment, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of equipment reliability reduction, waste, structural cracks, etc., and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

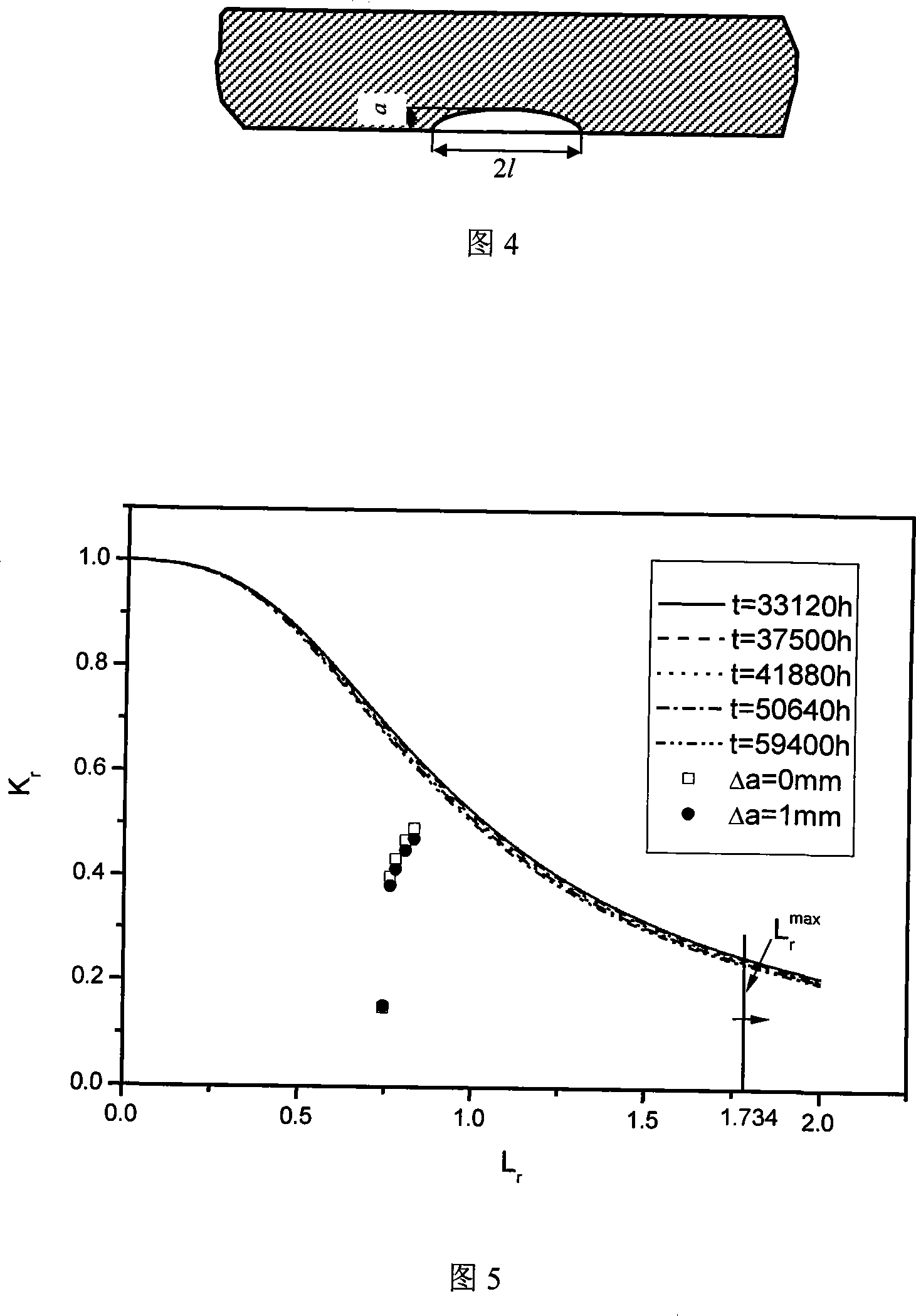

[0059] A key reaction equipment in a refinery was put into operation in November 1996. During a routine inspection in September 2000, a crack was found on the cylinder of the equipment. The crack is located on the inner surface of the cylinder with an inner diameter of 2800mm and a wall thickness of 45mm, distributed radially and perpendicular to the wall. The cracks were away from the weld, and there were no obvious signs of stress corrosion cracking during inspection. Due to the limitations of the production process, the equipment needs to continue to operate for one year before it can be overhauled. From being put into operation to finding cracks, the reactor has worked for a total of 33120 hours. Calculated as 365 days a year, the reactor needs to continue to run for 8760 hours.

[0060] In order to ensure the reliability of the operation of the reactor within one year thereafter, the safety evaluation method of the present invention is adopted, and the time-related fail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com