Headlight light source and assembly method thereof

A headlight and light source technology, applied in the field of headlights, can solve the problems of large light output angle and large energy loss of light output, and achieve the effects of reasonable reflection, increased luminous flux, and convenient light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

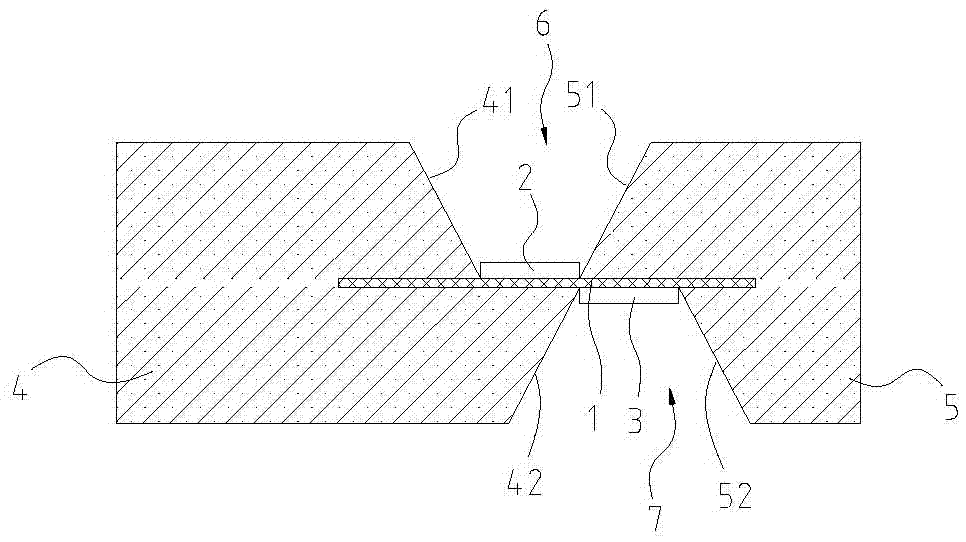

[0027] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0028] An LED headlight, which can be used on automobiles and motorcycles, has the functions of low beam irradiation and round high beam irradiation. The LED headlight includes a light source part and a reflector part. The reflector includes a reflector for cooperating with the low beam LED. reflectors and reflectors that work with high beam LEDs.

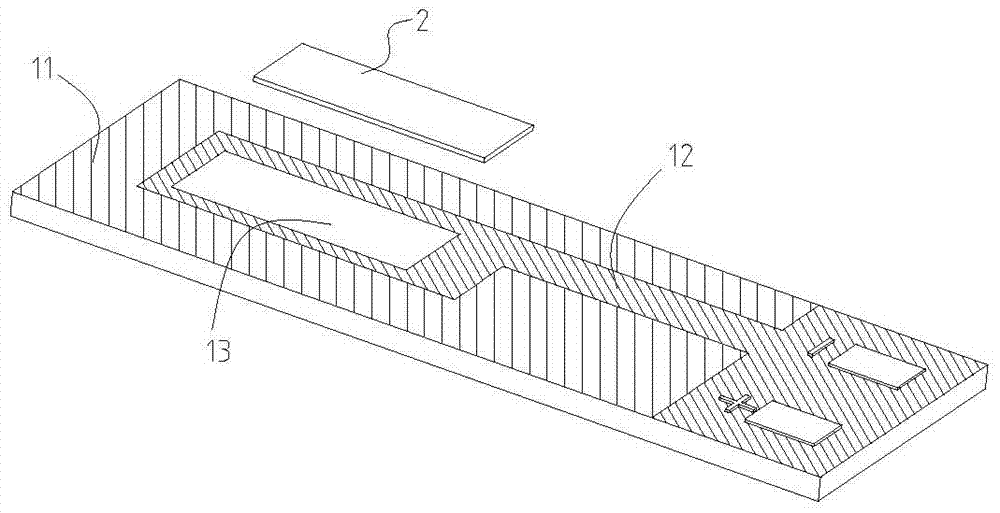

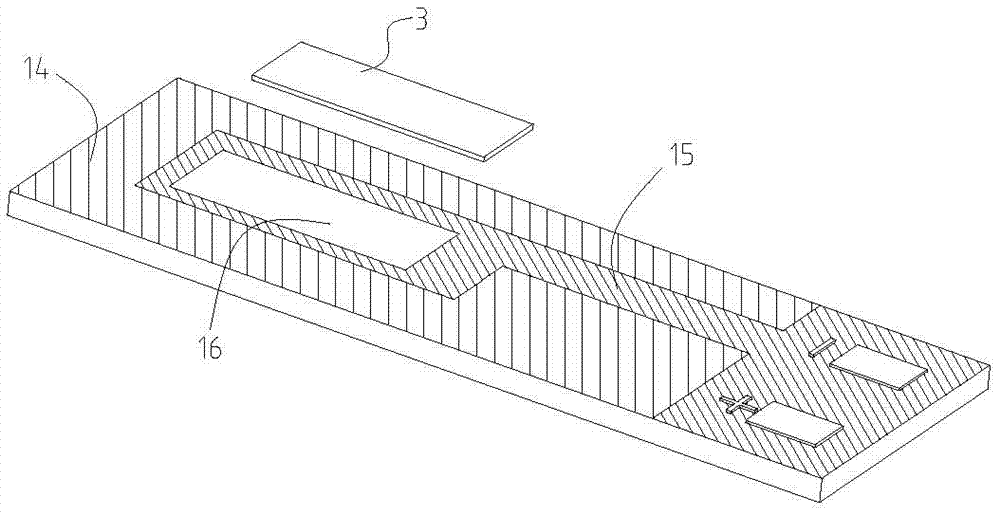

[0029] Such as Figures 1 to 3 As shown, the headlight light source includes a copper plate 1 , which is rectangular in shape. The thickness of the copper plate 1 is about 1 mm. The copper plate 1 is used as a carrier of the light source. When installed, the copper plate 1 is horizontally arranged. Such as figure 2 As shown, the top surface of the copper plate 1 is provided with a first wiring area 12, a first die-bonding area 13 and a first heat dissipation area 11; the first wiring area 12 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com