Peeling type corn combine harvester and subtending leaf and seed separating and collecting device thereof

A technology of combine harvester and collection device, which is applied to harvesters, threshing equipment, agricultural machinery and implements, etc., can solve the problem that the leaves and seeds cannot be completely separated, the leaves and seeds are inseparable, and the seeds are leaking to the ground. In order to achieve the effect of reducing the rate of grain damage, high practical value, and small separation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention is further illustrated by non-limiting examples and in conjunction with the accompanying drawings:

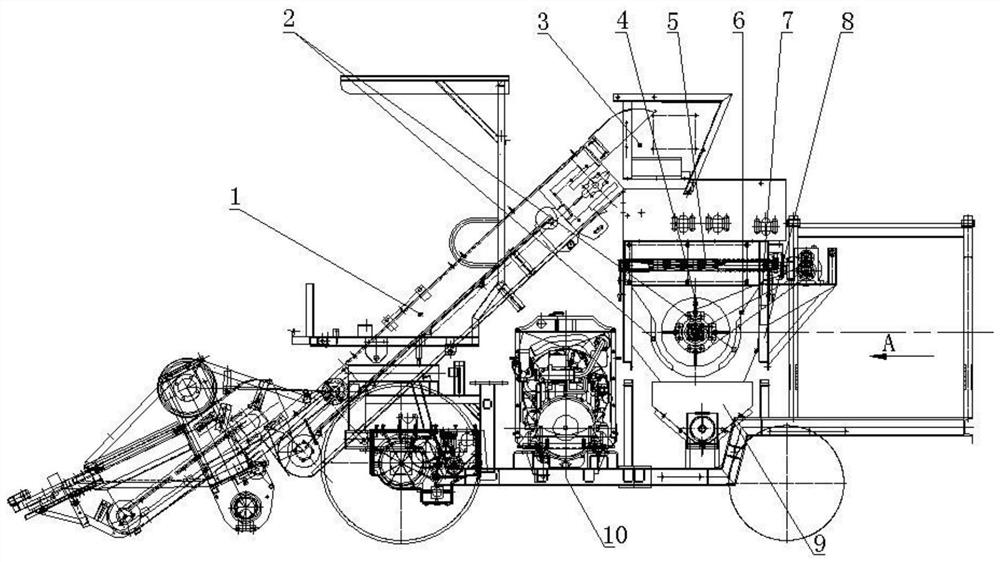

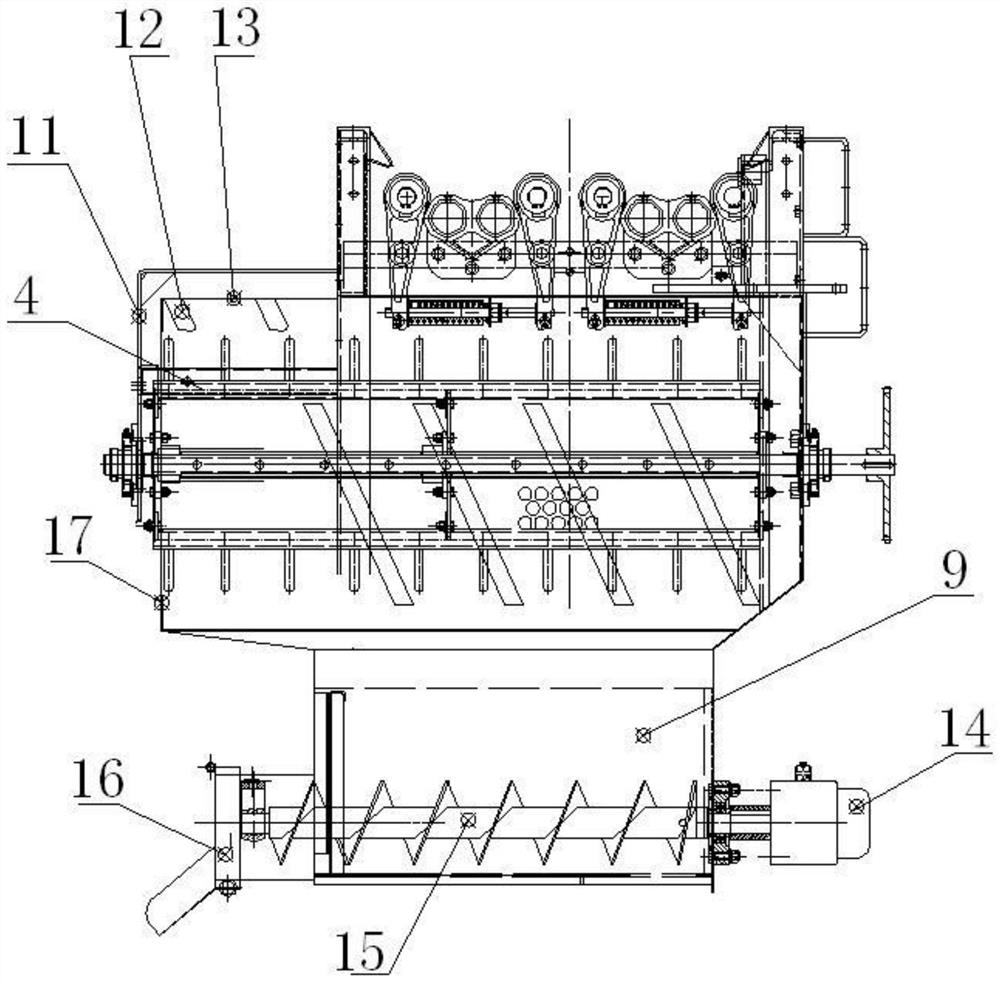

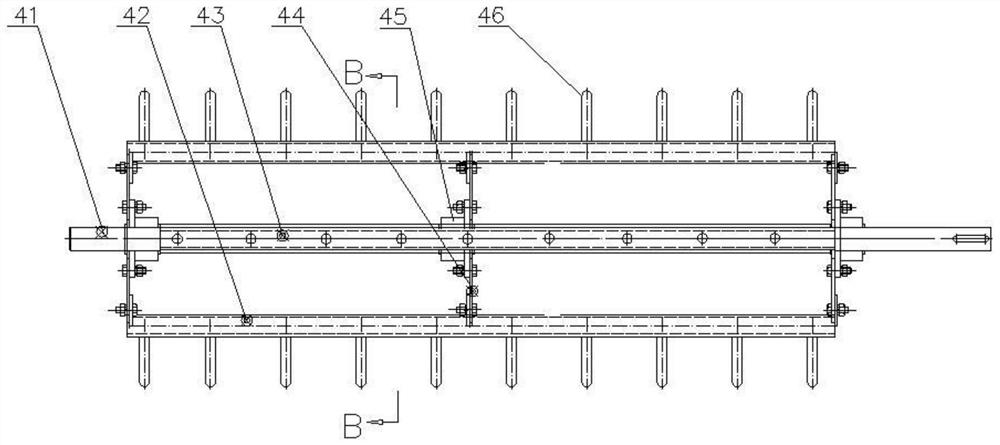

[0026]As shown in the drawings, a peeled corn combination harfiner includes a rack 10, a peeled maize 1, which is disposed on the rack 10, and a spyrus and a grain separation device, grains Collection device. The spurry and the grain separation device includes a separation drum 4, a separation recess 6, a roller cover 13, and the separation drum 4 is disposed below the discharge opening of the peeling machine 1, that is, the corresponding position The peeling roller 6 of the peeling machine 3 is below. The separation roller 4 includes a roller shaft 41 that is axially spaced apart from the roller shaft 41 and fixedly coupled to the drum shaft 41, a plurality of rods arranged in parallel, the web 44 passes through the web hub 45. Fixed with the drum shaft 41. The nip is uniformly arranged in the circumferential direction of the web 44 and is fixed to the web 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com