Judgement method for cutter failure

A judgment method and failure judgment model technology, applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve problems such as increasing the defective rate of production products, tool failure, hidden dangers in production safety, etc., to speed up the calculation speed and calculation accuracy, to realize the effect of predicting in advance and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

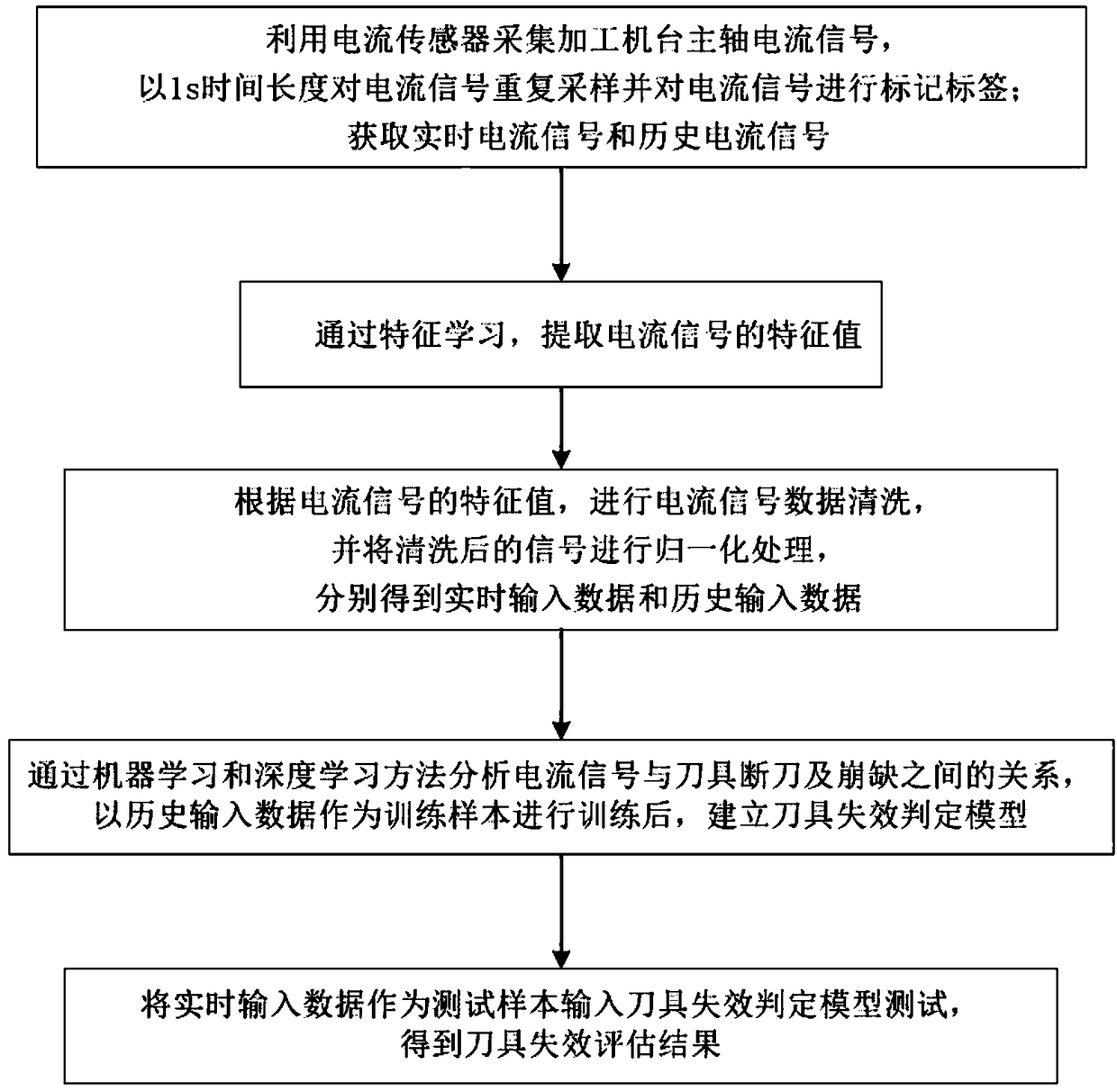

[0029] In this example, see figure 1 As shown, the present invention proposes a method for determining tool failure, comprising steps:

[0030] S1, use the current sensor to collect the current signal of the spindle of the processing machine, repeatedly sample the current signal with a time length of 1s and mark the current signal; obtain real-time current signal and historical current signal

[0031] S2, through feature learning, extract the eigenvalues of the current signal:

[0032] S3. Cleaning the current signal data according to the characteristic value of the current signal, and normalizing the cleaned signal to obtain real-time input data and historical input data respectively;

[0033] S4, analyze the relationship between the current signal and tool breakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com