High-level assessment method for defects of welding joint area at piping safety end of pressure vessel of AP1000 nuclear reactor

A technology for nuclear reactors and pressure vessels, which is applied in the field of advanced evaluation of circumferential inner surface defects, can solve the problem of complex geometric structures and complex loads at the safety end of pipes that cannot be accurately used, advanced special methods for defect evaluation of dissimilar metal welded joints in nuclear power plants, and dissimilar metal joints Unable to accurately handle issues such as simplification of advanced assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] For the safe end of the AP1000 nuclear reactor pressure vessel with outer diameter D=952.5mm and pipe wall thickness t=82.6mm, if defects on the circumferential inner surface exceeding the standard are detected in the dissimilar metal weld area, or for defects that fail the simplified assessment, the The following methods are used for advanced assessment.

[0097] (1) Defect characterization:

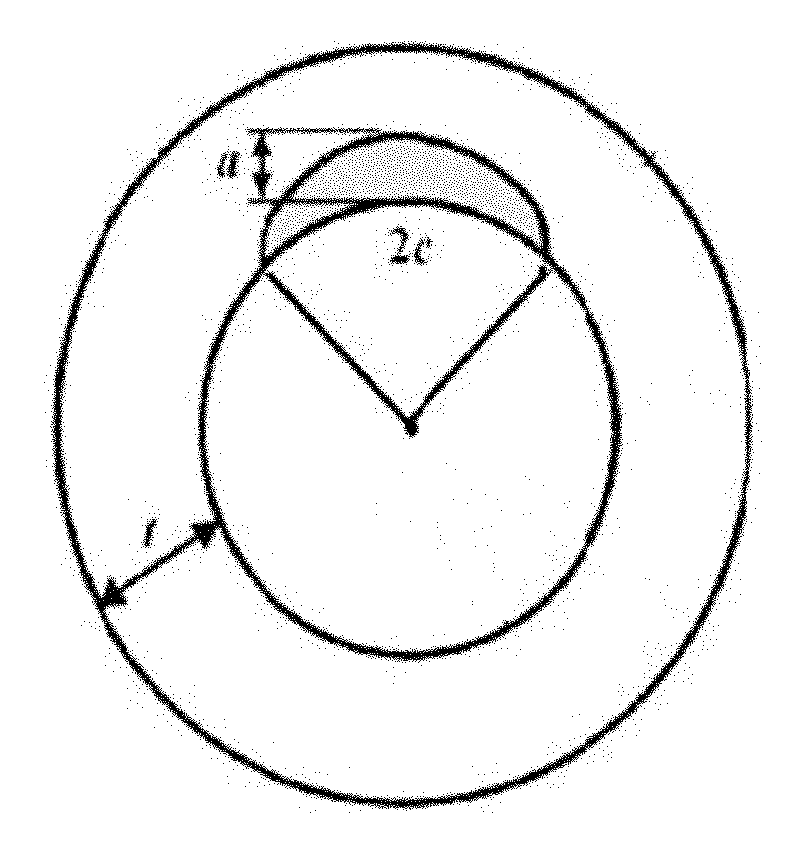

[0098] according to figure 1 To characterize the defect size, if the defect depth a=38mm, the defect length 2c=190mm; then the defect relative depth a / t=0.46, the defect shape parameter a / c=0.4.

[0099] (2) Selection of failure assessment curve:

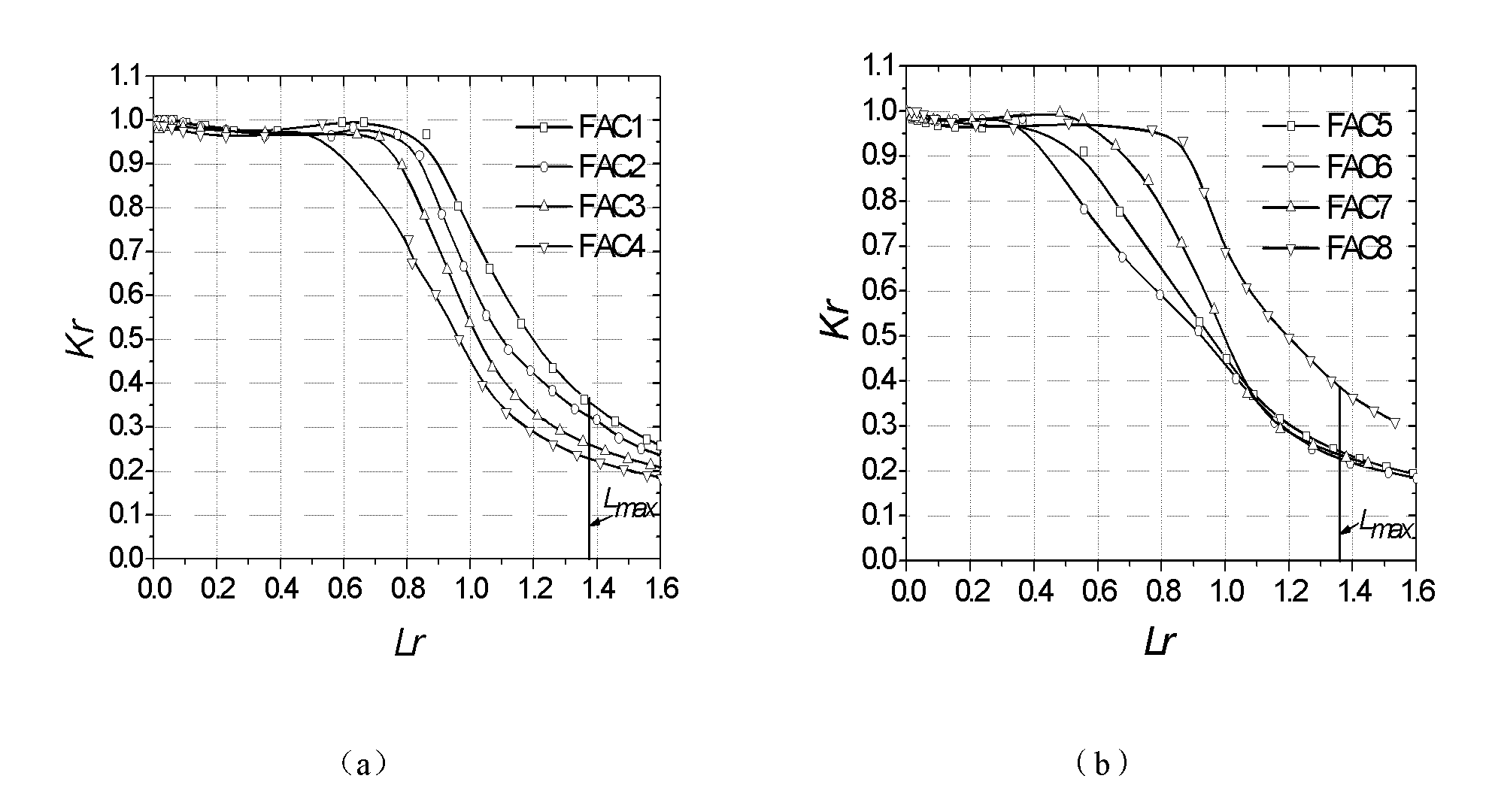

[0100] According to the characteristic defect size a / t=0.46, a / c=0.4, according to the above conservative principle, select the FAC4 failure assessment curve, that is figure 2 (a) Neutralize the curve of formula (4).

[0101] (3) Calculation of fracture ratio Kr:

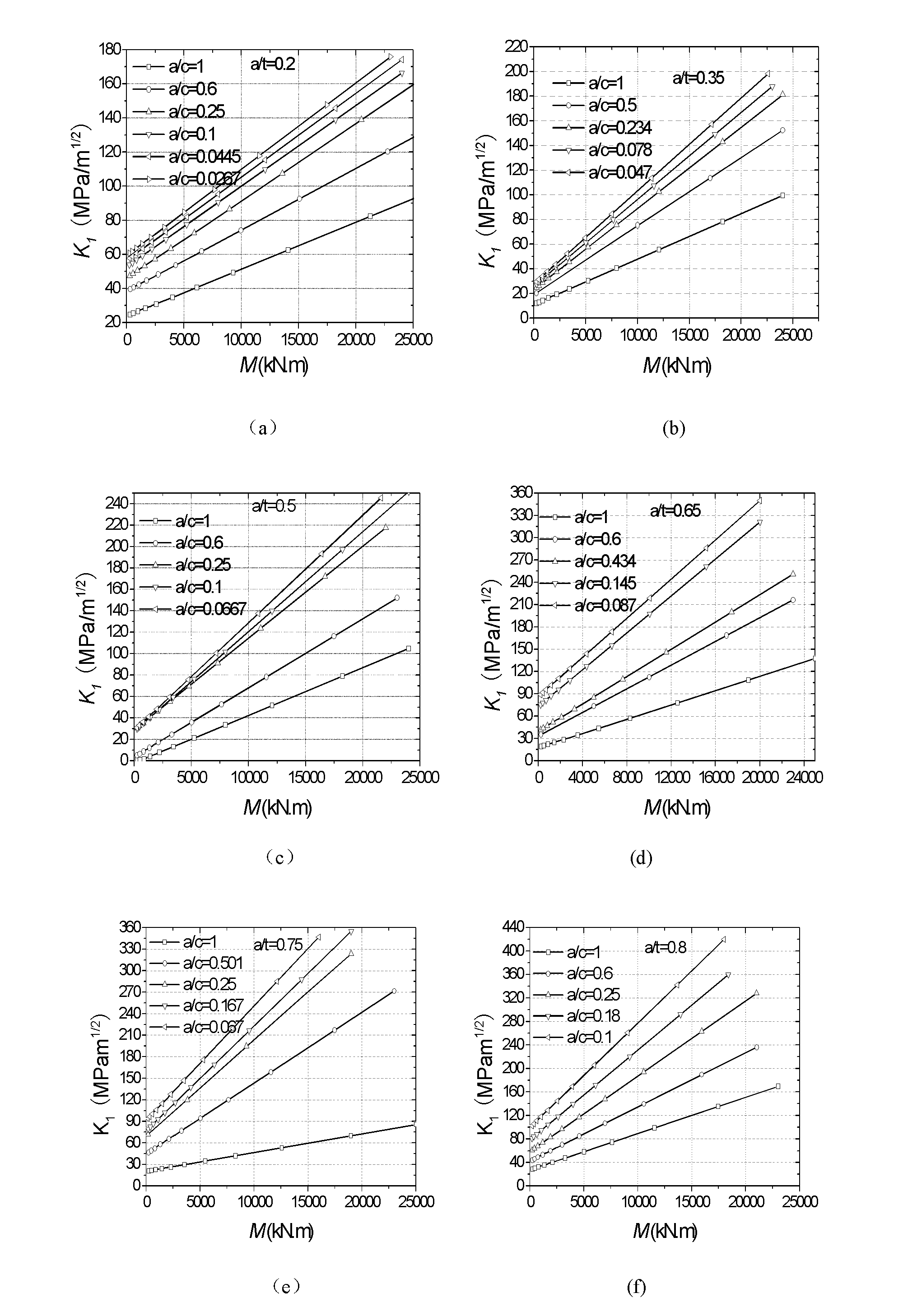

[0102] For example, the primary load bending moment M under a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com