Evaluation method used for residual intensity of X80 pipeline circumferential weld crack type defect

An evaluation method, technology of girth welds, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

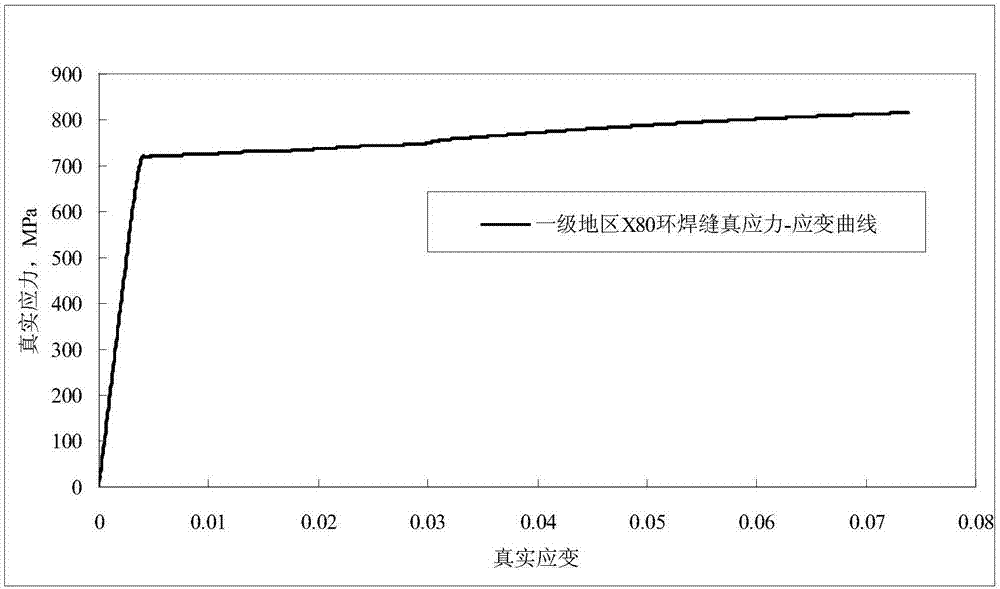

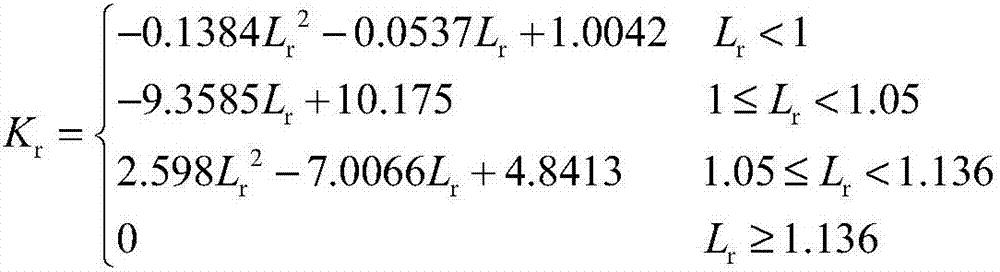

Method used

Image

Examples

Embodiment 1

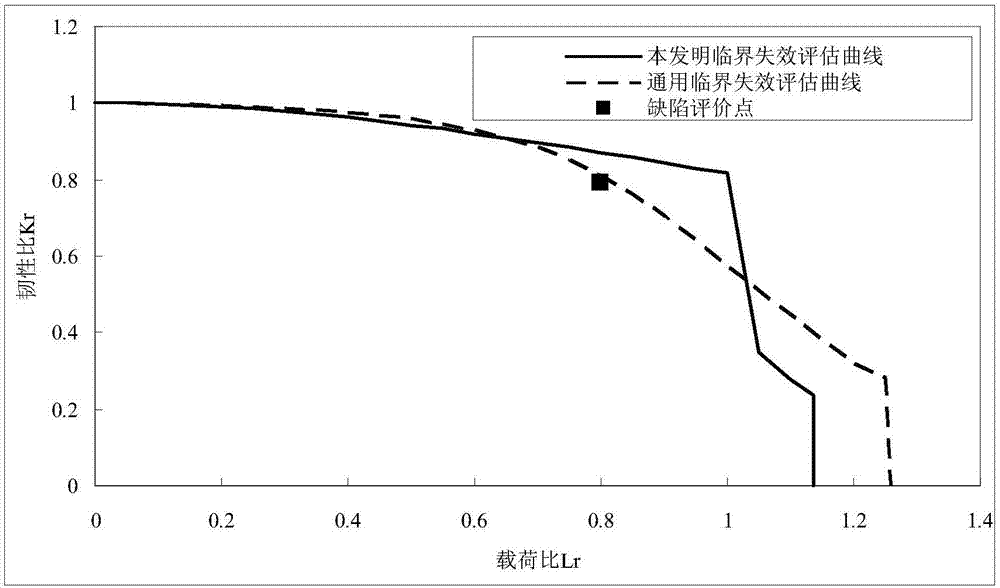

[0033] It is assumed that there is a circumferential semi-elliptical inner surface crack type defect in the girth weld of the X80 pipeline, the defect length is 300mm, the depth is 6.4mm, and the weld seam has a 7mm misalignment. The existing X80 pipeline girth weld specification is φ1219×18.4mm, the operating pressure is 12MPa, the yield strength is 555MPa, and the Charpy impact energy is 60MPa. It is necessary to evaluate whether the residual strength of the defective girth weld meets the requirements for continued service.

[0034] 1) Calculate the load ratio L of the pipeline with defects r , get L r The value is 0.800.

[0035] 2) Calculate the toughness ratio K of the pipeline with defects r , get K r The value is 0.793.

[0036] 3) Form data points with the load ratio as the abscissa and the toughness ratio as the ordinate, and draw the data points into the coordinate system, such as figure 2 shown.

[0037] 4) Draw the critical failure assessment curve in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com