Failure sensing device, monitoring and control system, and failure sensing method

A fault detection and fault technology, applied in the field of fault detection devices, can solve problems such as abnormal operation, and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

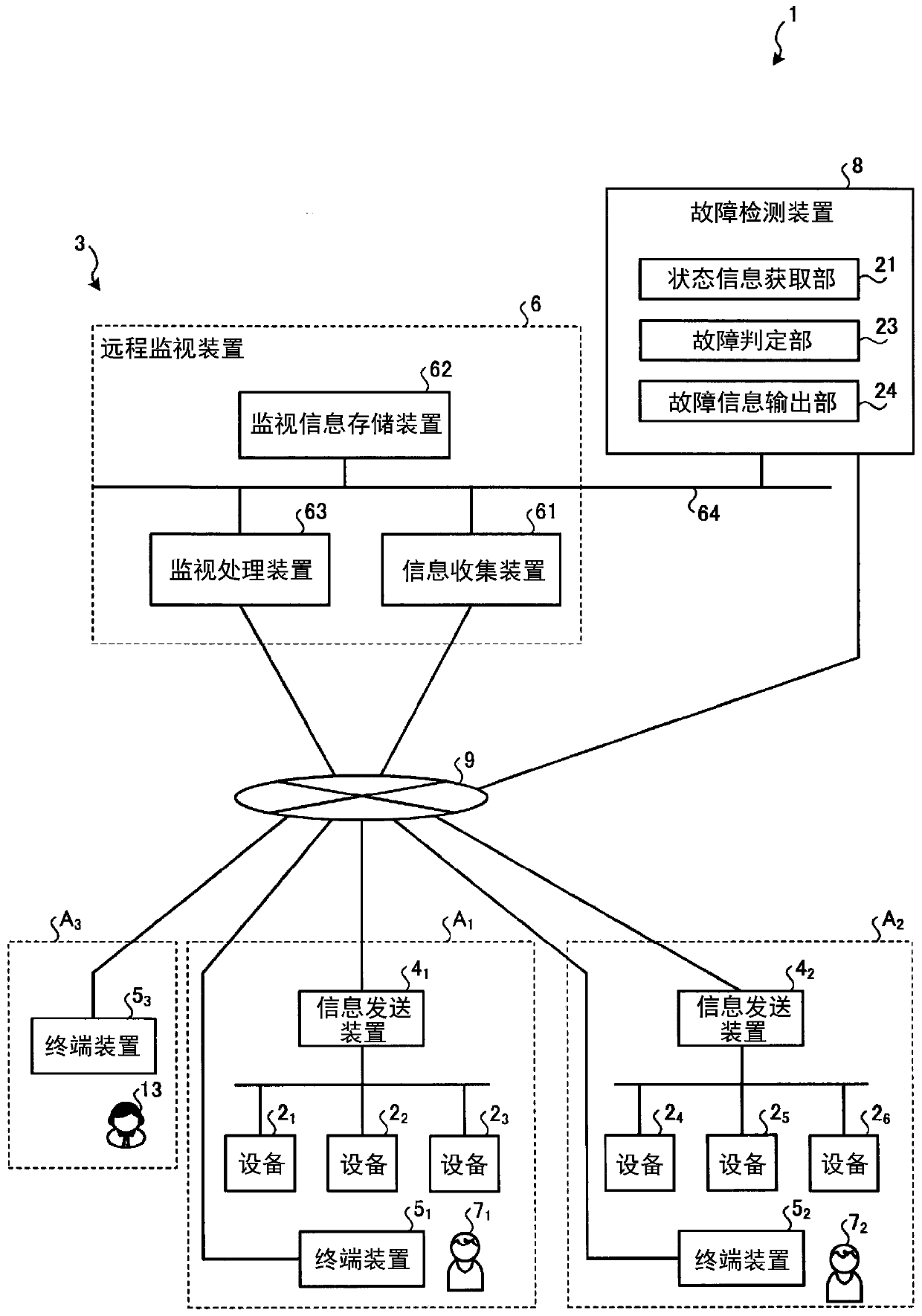

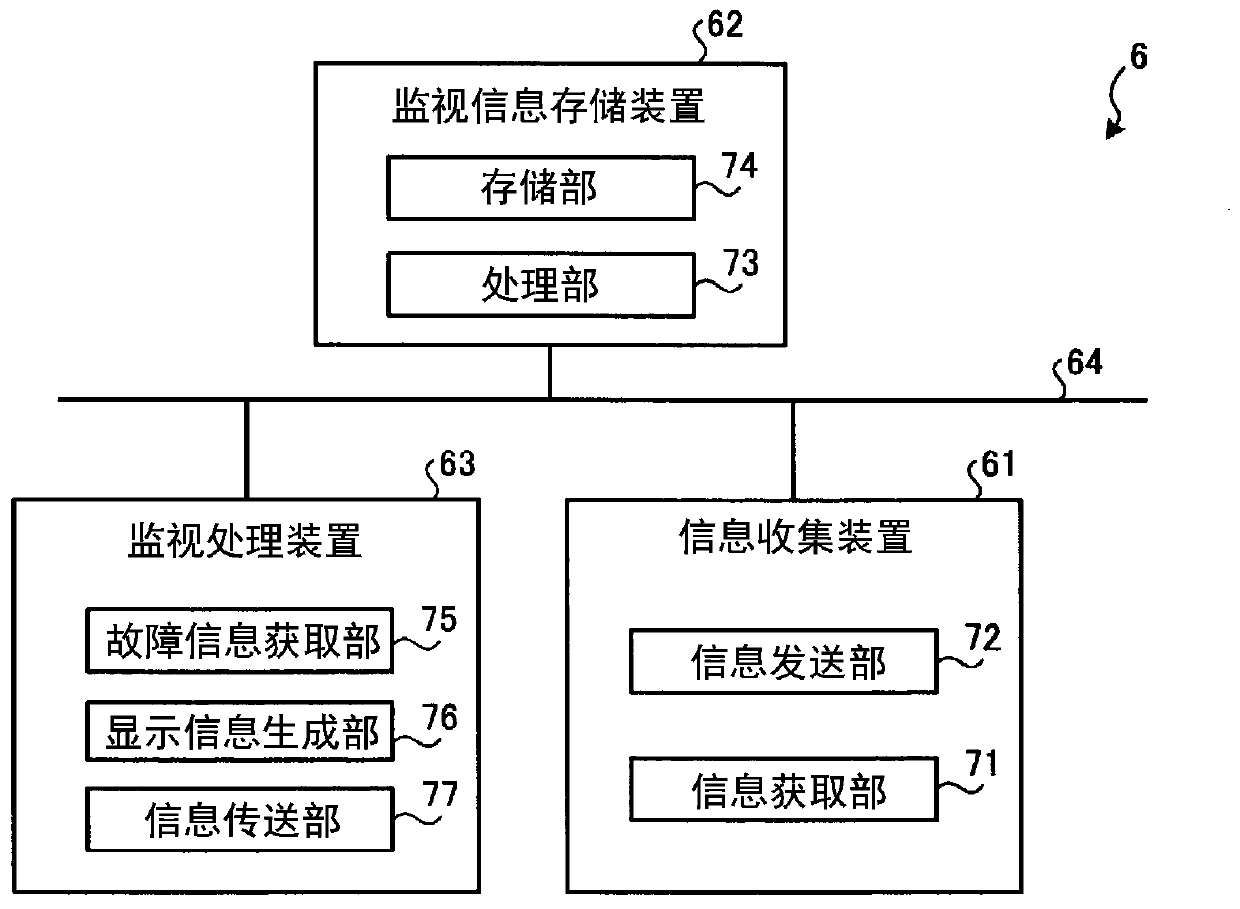

[0036] figure 1 It is a figure which shows the structural example of the monitoring control system concerning Embodiment 1. figure 1 The monitoring and control system 1 shown performs equipment 2 1 ~2 6 monitoring of the status of the device as well as 2 1 ~2 6 control. device 2 1 ~2 6 For example, equipment installed in plants or public facilities such as water purification plants, power plants, and factories includes one or more devices. device 2 1 ~2 3 Set up in the 1st area A 1 , device 2 4 ~2 6 Set up in the 2nd area A 2 . Below, in the wrong device 2 1 ~2 6 Each of the cases is separately distinguished, referred to as device 2.

[0037] The monitoring and control system 1 includes a remote monitoring system 3 that monitors equipment 2 installed in a remote place, and a failure detection device 8 that detects a failure of the remote monitoring system 3 . In addition, although not shown in figure, the monitoring control system 1 includes the equipment cont...

Embodiment approach 2

[0148] Embodiment 2 differs from Embodiment 1 in that processing for estimating the details of the failure is added. Hereinafter, the same code|symbol is attached|subjected to the structural element which has the same function as Embodiment 1, and description is abbreviate|omitted, and it demonstrates centering on the point which differs from the failure detection apparatus 8 of Embodiment 1. FIG.

[0149] Figure 19 It is a figure which shows the structural example of the failure detection apparatus concerning Embodiment 2. Such as Figure 19 As shown, the fault detection device 8A according to Embodiment 2 differs from the fault detection device 8 in that a processing unit 20A is provided instead of the processing unit 20 of the fault detection device 8 . The processing unit 20A differs from the processing unit 20 in that it includes a failure determination unit 23A instead of the failure determination unit 23 .

[0150] The failure determination unit 23A further includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com