Calculation method of stress intensity factor for axial-radial cracks in outer wall of ultra-high pressure vessel

A technology of stress intensity factor and container cylinder, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, instruments, etc., can solve the problems that are not suitable for fast and concise calculation needs, and the calculation process is complicated and complicated, and achieve The calculation method is fast, concise and accurate, the consideration is comprehensive, and the calculation process is simple and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

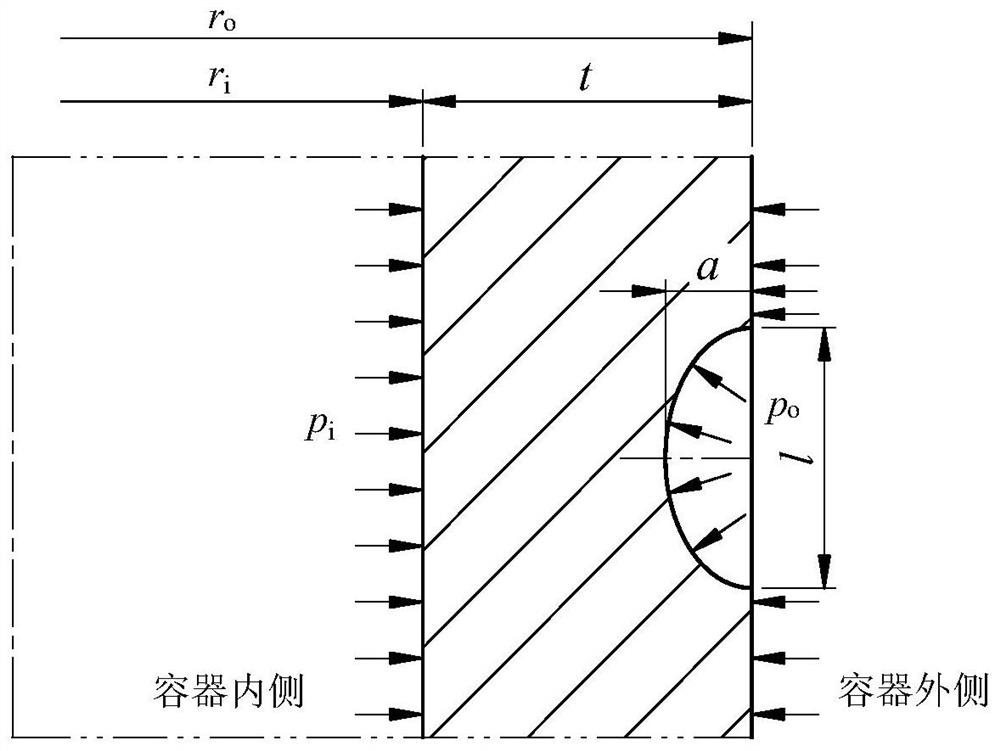

[0085] Assume that a certain ultra-high pressure vessel only bears the internal pressure load p i is 130MPa, the design temperature is normal temperature, and the material selected is 35CrNi3MoVR; the outer radius of the cylinder is r o is 400mm, the inner radius of the cylinder is r i is 200mm, the crack depth a obtained by measuring the oval crack is 15.5mm, and the crack length l is 46.5mm. Carry out the stress intensity factor K at the deepest point of the crack and at the free surface by the calculation method described in the present invention I The specific implementation steps include:

[0086] 1. According to the outer radius and inner radius of the cylinder, the diameter ratio K value of the cylinder is 2, which meets the requirements in formula 6.

[0087] 2. Calculate the required A' in formula 1 according to formula 6 i , get A' 0 , A' 1 , A' 2 , A' 3 They are: 86.15, 58.03, -37.28, 109.77.

[0088] 3. Calculate according to formula 3 to obtain the fittin...

Embodiment 2

[0093] Assume that the internal pressure load p of a certain ultra-high pressure vessel i 130MPa, bearing external pressure load p o is 30MPa, the design temperature is normal temperature, and the material selected is 35CrNi3MoVR; the outer radius of the cylinder is r o is 400mm, the inner radius of the cylinder is r i is 200mm, the crack depth a obtained by measuring the oval crack is 15.5mm, and the crack length l is 46.5mm. Carry out the stress intensity factor K at the deepest point of the crack and at the free surface by the calculation method proposed by the present invention I The specific implementation steps include:

[0094] 1. According to the outer radius and inner radius of the cylinder, the diameter ratio K value of the cylinder is 2, which meets the requirements in formula 6;

[0095] 2. Calculate the required A' in formula 1 according to formula 6i , we get A' 0 , A' 1 , A' 2 , A' 3 They are: 36.27, 44.64, -28.68, 84.44.

[0096] 3. Calculate the fitti...

Embodiment 3

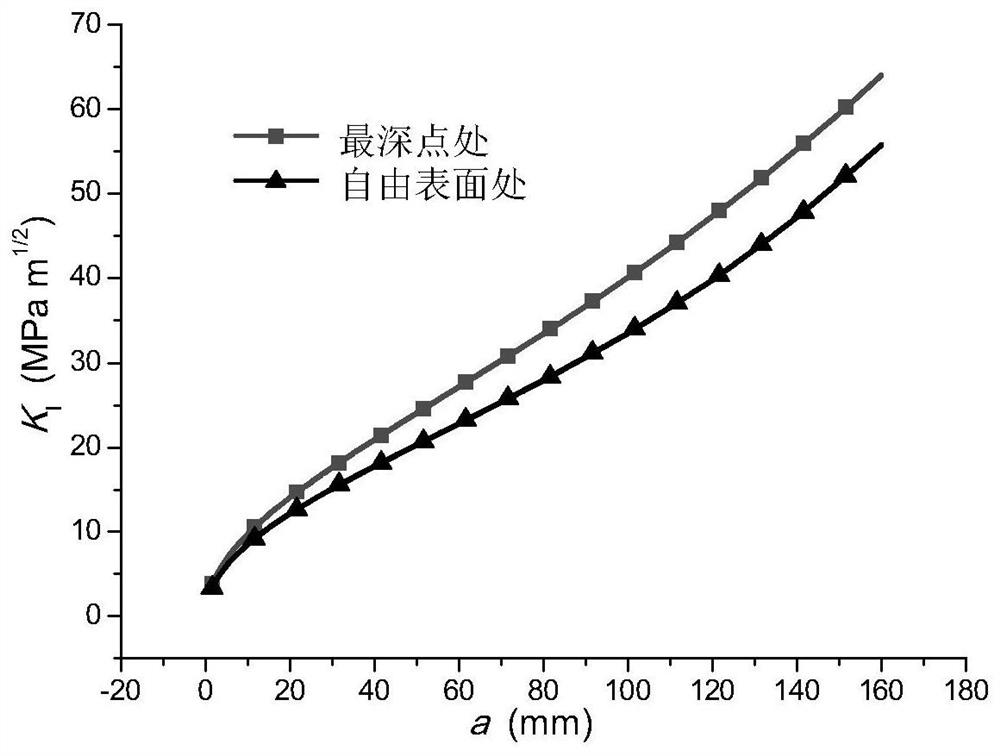

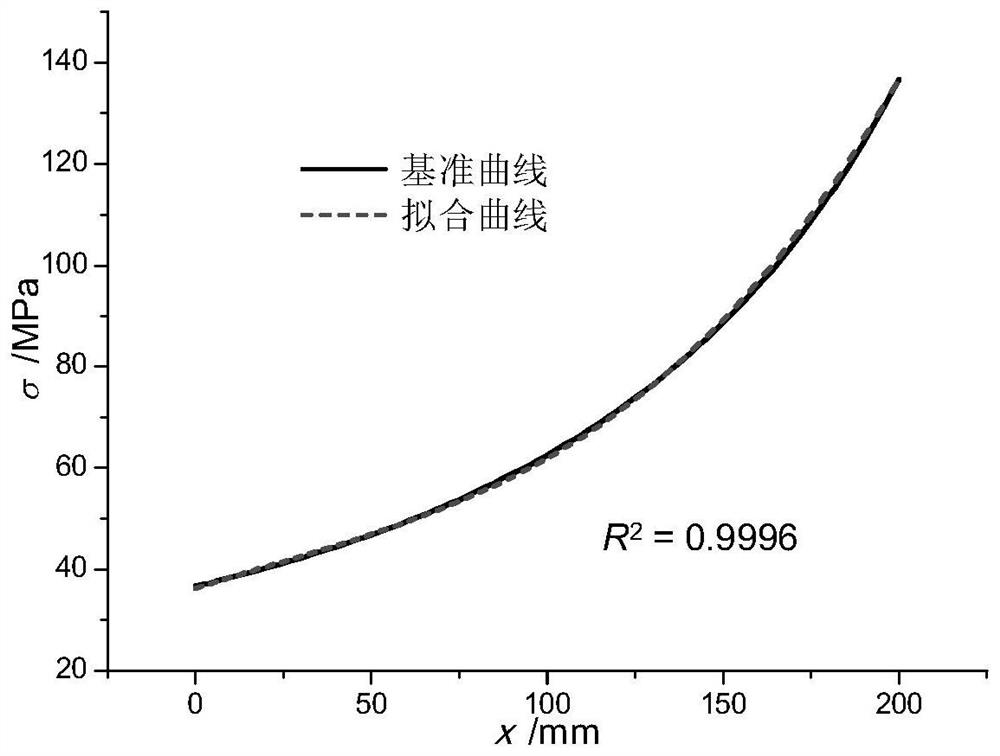

[0103] Assume that the internal pressure load p of an ultra-high pressure vessel i It is 130MPa and bears the external pressure load p o is 30MPa; the outer radius of the cylinder is r o is 400mm, the inner radius of the cylinder is r i is 200mm. The fitting curve calculated by the present invention is compared with the curve obtained by the general complex method, and the stress intensity factor K is calculated by the method of the present invention. I Compared with the calculation results obtained by the general complex method, the specific implementation steps include:

[0104] 1. According to the outer radius and inner radius of the cylinder, the diameter ratio K value of the cylinder is 2, which is between 1.2 and 3.0, which meets the requirements in formula 6;

[0105] 2. Calculate the required A' in Equation 1 according to Equation 6 i , we get A' 0 , A' 1 , A' 2 , A' 3 They are: 36.27, 44.64, -28.68, 84.44.

[0106] 3. Draw the stress distribution curve of fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| stress intensity factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com