Aeolian sand subgrade construction method

A construction method and aeolian sand technology, applied in chemical instruments and methods, roads, roads, etc., can solve problems such as great difficulty, weak compressive ability, and difficult compaction, and achieve improved shear and tensile strength. , Improve the overall stability, improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

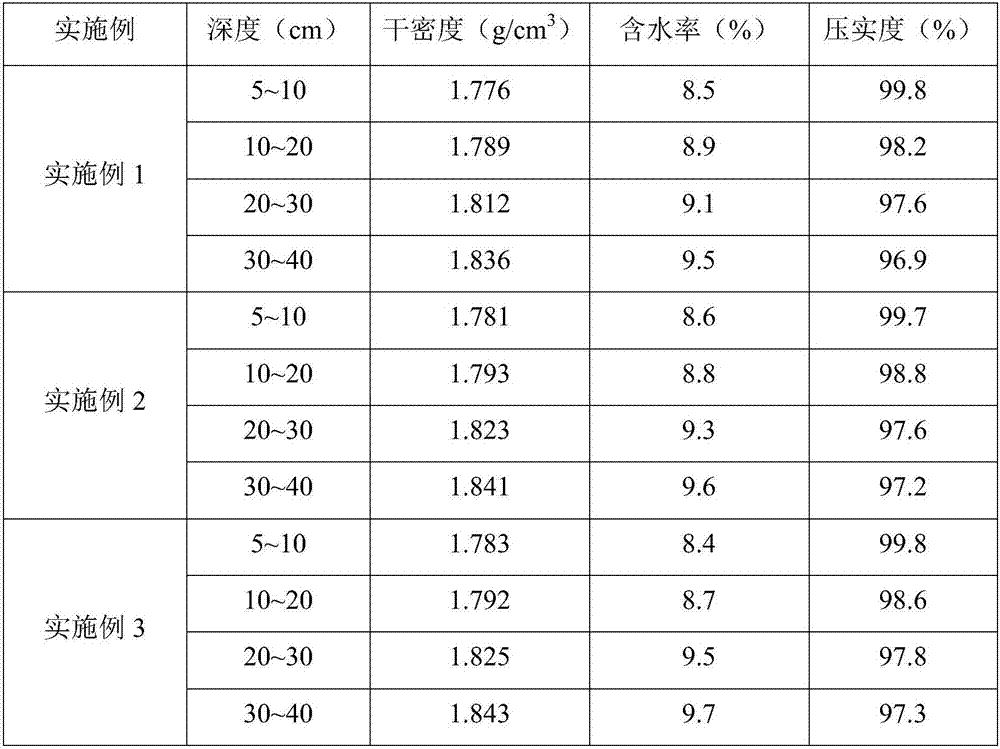

Embodiment 1

[0031] This example takes the first-class highway project of Duolun County Provincial Highway S308 in the southern area of Xilin Gol League as an example. It belongs to semi-arid grassland, mainly consisting of multi-ridged sandy land and sand dunes. It is an aeolian landform with severe wind and sand disasters. part.

[0032] The aeolian sand in this test has the following characteristics:

[0033] 1) Basic physical and chemical properties of aeolian sand

[0034]The test results show that the aeolian sand has loose structure, poor gradation, large porosity, strong water permeability, poor water retention, good water stability, low cohesion or even no cohesion, and low shear strength. Its mineral composition is mainly quartz, feldspar, and mica, and the content of soluble salt is very small. Its chemical properties are slightly alkaline and non-corrosive. The water content in the natural state is very low, the minimum is less than 1%, the maximum is not more than 5%, and...

Embodiment 2

[0064] A construction method for aeolian sand embankment, comprising the following steps:

[0065] (1) Measurement and setting out: mark the area that needs to be constructed, and the two sides of the roadbed exceed the design width of the roadbed by 70cm;

[0066] (2) Lay the bottom layer: remove the debris on the original road surface and level the ground surface; pave a 30cm gravel soil layer or gravel soil layer on the leveled ground surface, and roll it as the construction surface after leveling;

[0067] (3) Loading and unloading packing: Calculate the paving area of each vehicle according to the transport volume of the dump truck and the loose paving thickness of the aeolian sand, use a ruler to draw the line, draw the network white grid of the paving area, and use the dump truck to divide the aeolian sand by The grid is unloading backwards, so that the dump truck is always walking on the gravel soil layer or gravel soil layer; every time a car of aeolian sand is unload...

Embodiment 3

[0082] A construction method for aeolian sand embankment, comprising the following steps:

[0083] (1) Measurement and setting out: mark the area to be constructed, and the two sides of the roadbed exceed the design width of the roadbed by 80cm;

[0084] (2) Lay the bottom layer: remove the debris on the original road surface and level the ground surface; pave a 40cm gravel soil layer or gravel soil layer on the leveled ground surface, and roll it as the construction surface after leveling;

[0085] (3) Loading and unloading packing: Calculate the paving area of each vehicle according to the transport volume of the dump truck and the loose paving thickness of the aeolian sand, use a ruler to draw the line, draw the network white grid of the paving area, and use the dump truck to divide the aeolian sand by The grid is unloading backwards, so that the dump truck is always walking on the gravel soil layer or gravel soil layer; every time a car of aeolian sand is unloaded, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Modulus of resilience | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com