Method of heavily desulfurating and reducing olefinic hydrocarbon for gasoline

A deep desulfurization and gasoline technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., and can solve the problem of large octane number loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

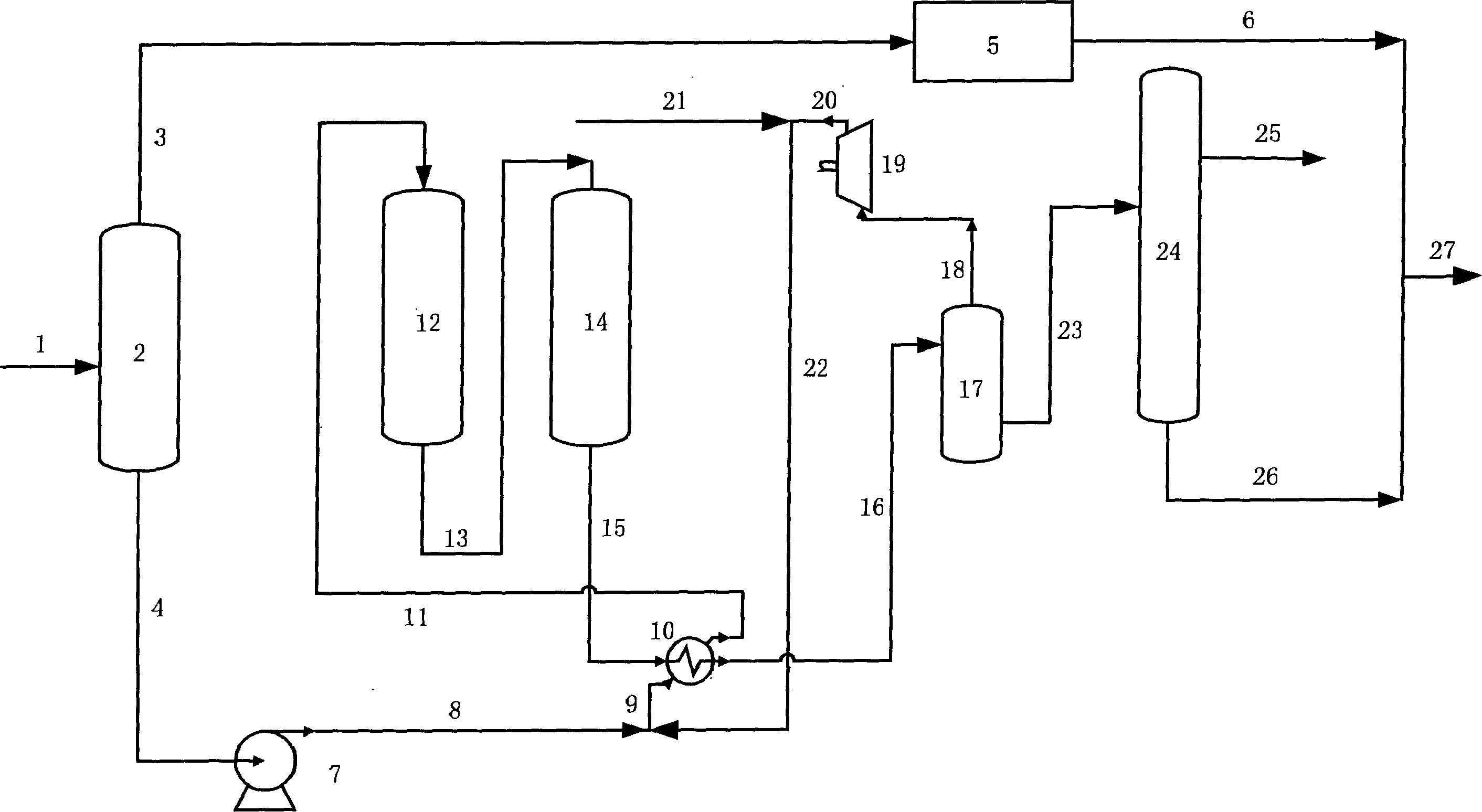

Method used

Image

Examples

Embodiment 1

[0036] Compared with the comparative example, in the case of the same raw materials, the heavy gasoline fraction and hydrogen are sequentially contacted with the catalyst CH-18 and RIDOS-1 for hydrotreating and octane recovery. The hydrogenated heavy gasoline fraction is blended with the sweetened light gasoline fraction to obtain a gasoline product. The process conditions and product properties are shown in Table 2. It can be seen from Table 2 that the sulfur content of the heavy gasoline fraction is 9ppm, the olefin content is 18.2v%, and the antiknock index has increased by 0.2 units.

Embodiment 2

[0038] Using FCC gasoline B as the raw material, the raw material is first cut, the cutting point is 88°C, and the heavy gasoline fraction accounts for 69.8% by weight of the raw material, and its properties are shown in Table 1. The heavy gasoline fraction and hydrogen are sequentially contacted with catalysts CH-18 and RIDOS-1 for hydrotreating and octane recovery. The hydrogenated heavy gasoline fraction is blended with the sweetened light gasoline fraction to obtain gasoline products. The hydrogenation process conditions and product properties are shown in Table 3. It can be seen from Table 3 that the sulfur content of the heavy gasoline fraction is 161ppm, the olefin content is 16.9v%, and the antiknock index has increased by 1.2 units.

Embodiment 3

[0040] Using FCC gasoline C as the raw material, the raw material is first cut, the cutting point is 95°C, and the heavy gasoline fraction accounts for 60.1% by weight of the raw material, and its properties are shown in Table 1. The heavy gasoline fraction and hydrogen are sequentially contacted with catalysts CH-18 and RIDOS-1 for hydrotreating and octane recovery. The hydrogenated heavy gasoline fraction is blended with the sweetened light gasoline fraction to obtain gasoline products. The hydrogenation process conditions and product properties are shown in Table 3. It can be seen from Table 3 that the sulfur content of the heavy gasoline fraction is 100ppm, the olefin content is 19.8v%, and the antiknock index loss is only 0.6 units.

[0041] raw material A

[0042] comparative example

[0043] Example 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com