A kind of selective hydrodesulfurization method

A hydrodesulfurization and selective technology, applied in the field of desulfurization, can solve the problems of increased hydrogen consumption, high cutting temperature, lower octane number of gasoline, etc., and achieve the effects of increased activity, high desulfurization rate, and small loss of octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

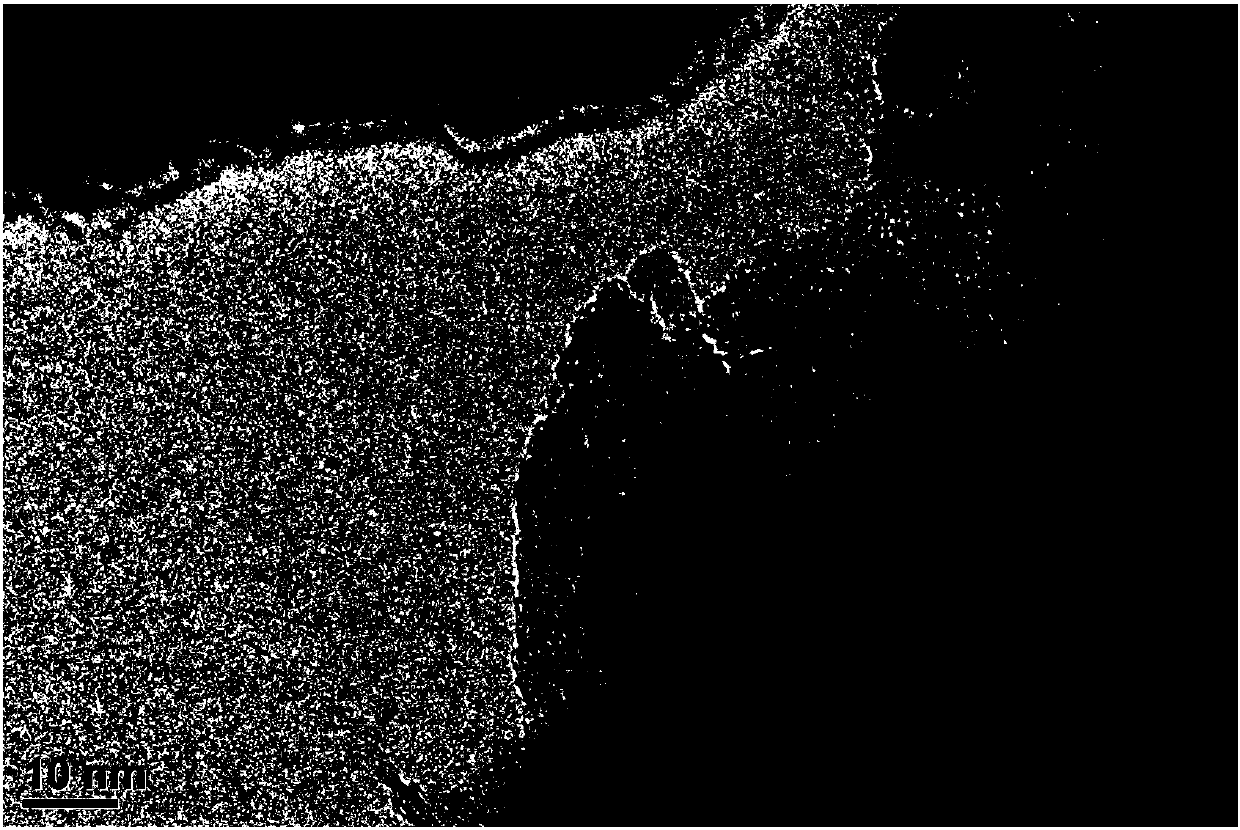

Image

Examples

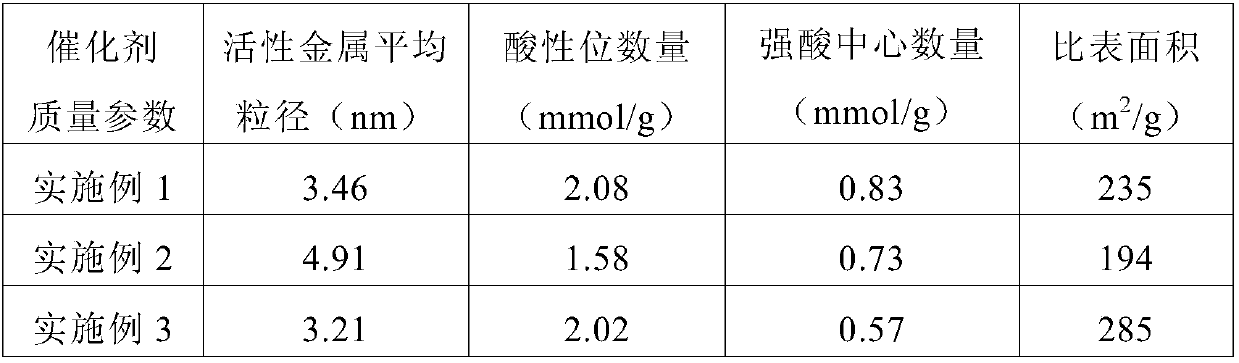

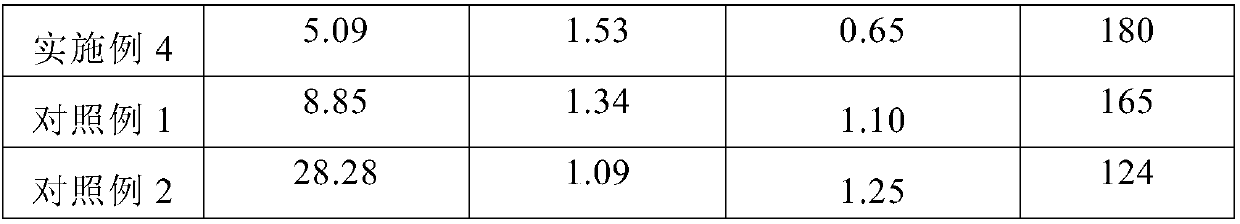

Embodiment 1

[0066] 1. Preparation of selective hydrodesulfurization catalyst

[0067] 1. Preparation of carrier

[0068] According to γ-Al 2 o 3 : KNO 3 : The mass ratio of water is 6:0.3:9, the γ-Al2 o 3 with KNO 3 The solution was impregnated with an equal volume, dried at 120°C for 4h after impregnated, and then calcined at 550°C for 4h to obtain a metal oxide treated with a metal salt (that is, treated with KNO 3 γ-Al treated by solution impregnation 2 o 3 ); grinding the above prepared metal oxide treated with metal salt to obtain a carrier.

[0069] 2. Atomic layer deposition

[0070] Nitrogen was used as the carrier gas and purge gas, and 10.3 parts by mass of CoSO were introduced into the reactor equipped with 100 parts by mass of the above carrier in a pulsed manner. 4 Steam and 21.3 mass parts (NH 4 ) 6 Mo 7 o 24 steam, followed by N 2 purge, steam purge and N 2 Purge, where the deposition temperature is controlled at 250°C and the gas flow rate is 250cm 3 / min, ...

Embodiment 2

[0092] 1. Preparation of selective hydrodesulfurization catalyst

[0093] 1. Preparation of carrier

[0094] According to γ-Al 2 o 3 : KNO 3 : The mass ratio of water is 6:0.6:9, the γ-Al 2 o 3 with KNO 3 The solution is impregnated with equal volume, dried at 120°C for 4h after impregnated, and then roasted at 550°C for 4h to obtain the metal oxide treated with metal salt (that is, γ-Al impregnated with KNO3 solution 2 o 3 ); grinding the above prepared metal oxide treated with metal salt to obtain a carrier.

[0095] 2. Atomic layer deposition

[0096] With nitrogen as the carrier gas and purge gas, 10.3 parts by mass of CoSO were introduced into the reactor equipped with 100 parts by mass of the carrier prepared in Example 1 in a pulsed manner. 4 Steam and 21.3 mass parts (NH 4 ) 6 Mo 7 o 24 steam, followed by N 2 purge, steam purge and N 2 Purge, where the deposition temperature is controlled at 200°C and the gas flow rate is 250cm 3 / min; repeat the above ...

Embodiment 3

[0116] 1. Preparation of selective hydrodesulfurization catalyst

[0117] 1. Metal salt treatment of metal oxides

[0118] According to γ-Al 2 o 3 : KNO3: water with a mass ratio of 6:0.3:9, the γ-Al 2 o 3 impregnated with equal volume of KNO3 solution, dried at 120°C for 4h after impregnation, and then roasted at 550°C for 4h to obtain the metal oxide treated with metal salt (i.e. γ-Al impregnated with KNO3 solution 2 o 3 ).

[0119] 2. Alkali treatment of molecular sieves

[0120] 500mL of Na with a concentration of 4mol / L 2 CO 3 After the temperature of the solution water bath was raised to about 70°C, 25g of ZSM-5 molecular sieve was added to it, and after stirring for about 200 minutes, the mixture was immediately lowered to room temperature in an ice bath, filtered and washed with deionized water for several times until the filter cake was filtered. After the pH value of the effluent is about 7, the obtained filter cake is dried in an oven at 110° C. for 4 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com