Gasoline deep desulfurization method, and equipment used for gasoline deep desulfurization

A technology for deep desulfurization and gasoline, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of hydrogenation catalyst poisoning and coking, unfavorable hydrotreating, reducing solvent extraction sulfide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

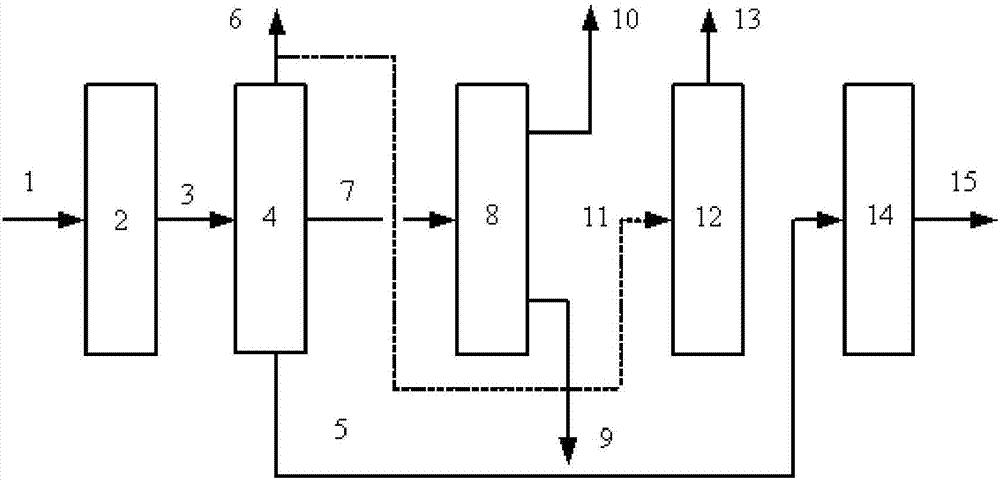

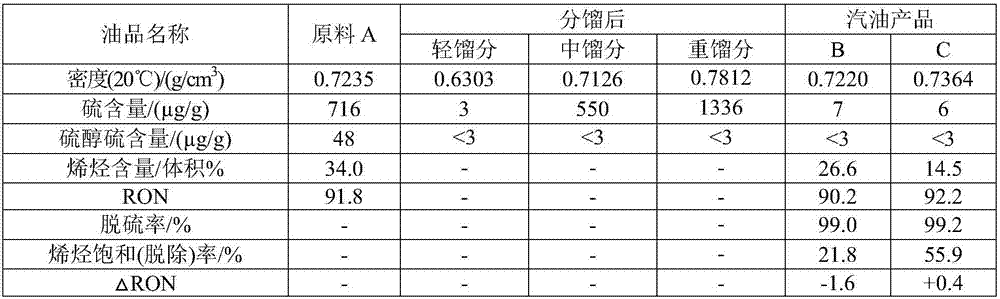

[0137] This embodiment adopts figure 1 The equipment shown in Table 1 performs advanced desulfurization treatment on the gasoline feedstock A.

[0138] The gasoline raw material A is subjected to a pre-hydrogenation reaction, and the conditions of the pre-hydrogenation reaction are: use a pre-hydrogenation catalyst Cat2, the reaction temperature is 80°C, the reaction pressure is 1.0MPa, and the liquid hourly volume space velocity is 4.0h -1 , the volume ratio of hydrogen to oil is 5, and the gasoline raw material after prehydrogenation is obtained.

[0139] The aforementioned pre-hydrogenated gasoline raw material is fractionated into light fraction, middle fraction and heavy fraction. The fractionation temperature of light fraction and middle fraction is 60°C, and the fractionation temperature of middle fraction and heavy fraction is 120°C. The yields (by mass fraction) of light fraction, middle fraction and heavy fraction after fractionation are about 20%, 45%, and 35%, res...

Embodiment 2

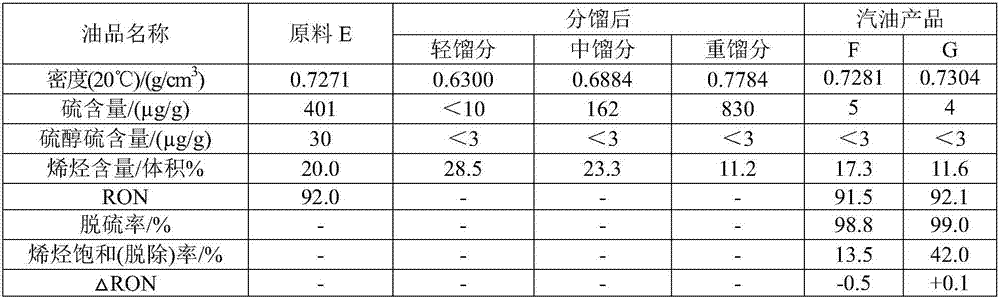

[0166] This embodiment adopts figure 1 The equipment shown is for advanced desulfurization of gasoline feedstock E.

[0167] The gasoline raw material E is subjected to a pre-hydrogenation reaction, and the conditions of the pre-hydrogenation reaction are: use a pre-hydrogenation catalyst Cat2, the reaction temperature is 100°C, the reaction pressure is 1.2MPa, and the liquid hourly volume space velocity is 5.0h -1 , the volume ratio of hydrogen to oil is 5, and the gasoline raw material after prehydrogenation is obtained.

[0168] The aforementioned pre-hydrogenated gasoline raw material is fractionated into light fraction, middle fraction and heavy fraction. The fractionation temperature of light fraction and middle fraction is 55°C, and the fractionation temperature of middle fraction and heavy fraction is 120°C. The yields (in terms of mass fraction) of light fraction, middle fraction and heavy fraction after fractionation are about 25%, 35%, and 40%, respectively.

[01...

Embodiment 3

[0183] This embodiment is carried out with the same raw material oil E and the same combined desulfurization process and the same process parameters as in Example 2, the difference is:

[0184] The extraction solvent used in the solvent extraction process of this example does not contain additives, and the rest are the same as in Example 2. As a result, the sulfur content in the middle fraction after solvent extraction is ≯10 μg / g.

[0185] After selective hydrogenation, the hydrogenated heavy fraction is obtained, and the sulfur content in the hydrogenated heavy fraction is ≯10 μg / g.

[0186] Mix light distillate, solvent extracted middle distillate and hydrogenated heavy distillate to form low-sulfur gasoline product H; or mix etherified distillate and hydrogenated heavy distillate to produce low-sulfur, low-olefin gasoline product I.

[0187] The properties of gasoline product H and gasoline product I are shown in Table 4.

[0188] It can be seen from Table 4 that the desu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com