Desulfurization catalyst and preparation method thereof, and hydrocarbon oil desulfurization method

A technology of desulfurization catalyst and alumina, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor desulfurization activity and stability, and achieve improved service life, good wear resistance, and reduced The effect of octane loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing a desulfurization catalyst, the method comprising: (1) performing a precipitation reaction on a mixed solution obtained by mixing a silver-containing compound, a zinc-containing compound and a precipitating agent, filtering and drying the mixture obtained by the precipitation reaction and roasting to obtain a precipitated product; (2) contacting a silica source, an alumina source, a molecular sieve with an MFI structure, water and an acid solution to form a slurry, and mixing the precipitated product obtained in step (1) with the slurry to form carrier mixture; then molding, drying and roasting the carrier mixture to form a carrier; (3) introducing a compound containing an active metal to the carrier obtained in step (2) and drying and roasting to obtain a desulfurization catalyst precursor; the active The metal is at least one of cobalt, nickel, iron and manganese; (4) reducing the desulfurization catalyst precu...

Embodiment 1

[0089] This example is used to illustrate the preparation method of the desulfurization catalyst of the present invention.

[0090] (1) Precipitation product is prepared. 10.9 kg of zinc acetate dihydrate powder (produced by Beijing Chemical Plant, analytically pure), 0.72 kg of anhydrous silver acetate (Sinopharm Chemical Reagent Company, analytically pure) and 18 kg of deionized water were mixed, and dissolved completely after stirring for 30 minutes. The precipitated product obtained by adding 1.8 kg of ammonia water was filtered, dried at 150° C. for 2 hours, and then calcined at 500° C. for 1 hour to obtain the precipitated product C1.

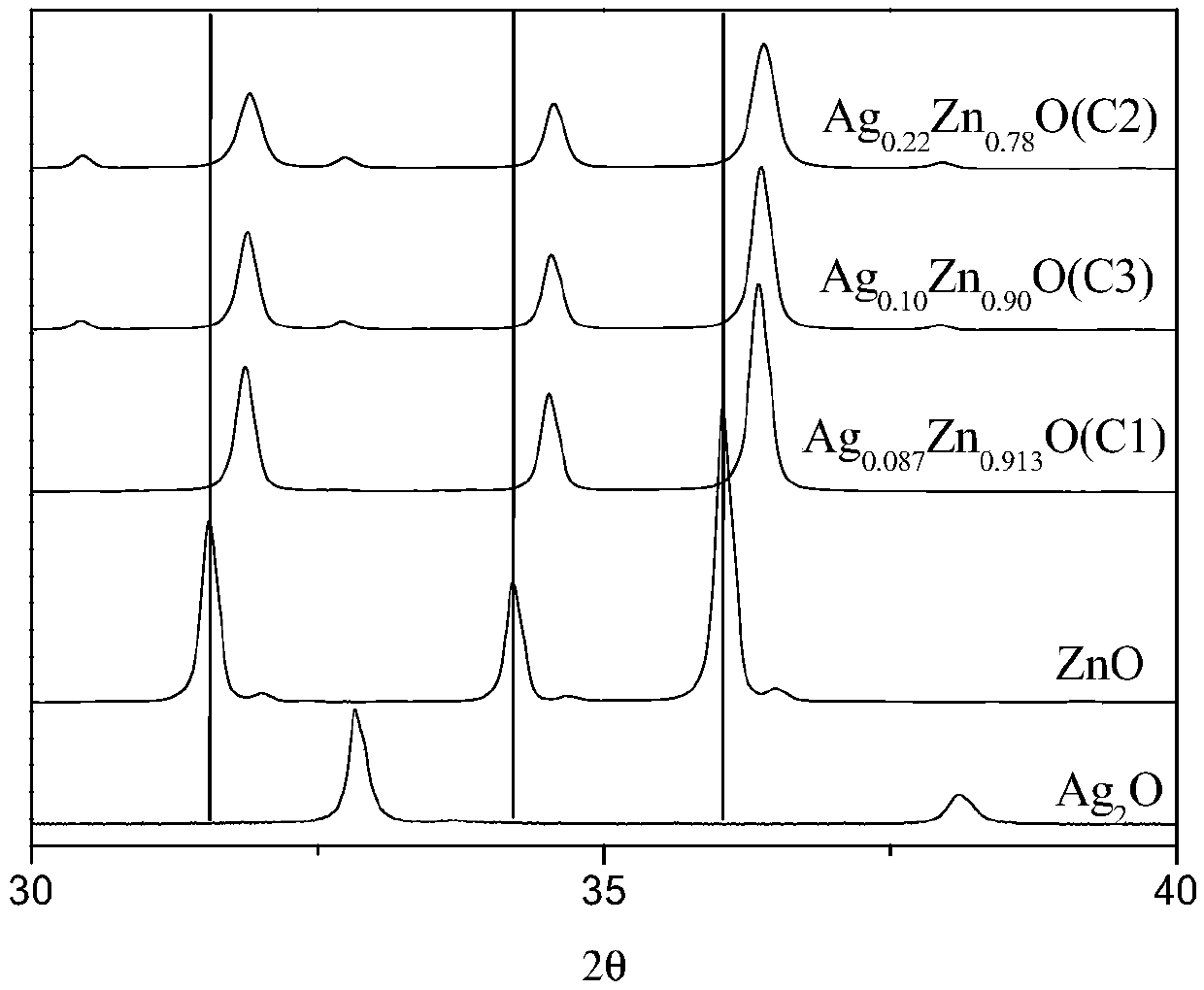

[0091] The precipitated product C1 was subjected to fluorescence analysis and XRD determination. In the XRD spectrum (see figure 1 ) without Ag 2 The diffraction peak of O, and the standard diffraction peak of ZnO shifted to the right, where A 100 -B 100 = 0.31°, A 002 -B 002 = 0.32°, A 101 -B 101 =0.31°, indicating that the Ag i...

Embodiment 2

[0099] This example is used to illustrate the preparation method of the desulfurization catalyst of the present invention.

[0100] (1) Precipitation product is prepared. 14.0 kg of zinc nitrate hexahydrate (produced by Beijing Chemical Plant, analytically pure), 1.76 kg of silver nitrate powder (Sinopharm Chemical Reagent Company, analytically pure) and 18 kg of deionized water were mixed, and after stirring for 30 minutes, 2.0 kg of urea was added and heated to After treatment at 80°C for 2 hours, a white precipitate was obtained. After filtration, it was first dried at 150°C for 2 hours, and then calcined at 500°C for 1 hour to obtain the precipitated product C2.

[0101] The precipitated product C2 was subjected to XRD determination. In the XRD spectrum (see figure 1 ) without Ag 2 The diffraction peak of O, and the standard diffraction peak of ZnO shifted to the right, where A 100 -B 100 =0.37°, A 002 -B 002 = 0.35°, A 101 -B 101 =0.35°, indicating that the Ag in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com