Pigment composition and preparation method and application thereof

A pigment composition and extender pigment technology, which is applied in the direction of pigment slurry, dyeing method, art paint, etc., can solve the problems of water resistance, yellowing of paint film, failure to achieve adhesion fastness, water resistance, rub resistance, and wash resistance and weather resistance to achieve good adhesion, good fastness, and avoid the use of volatile organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

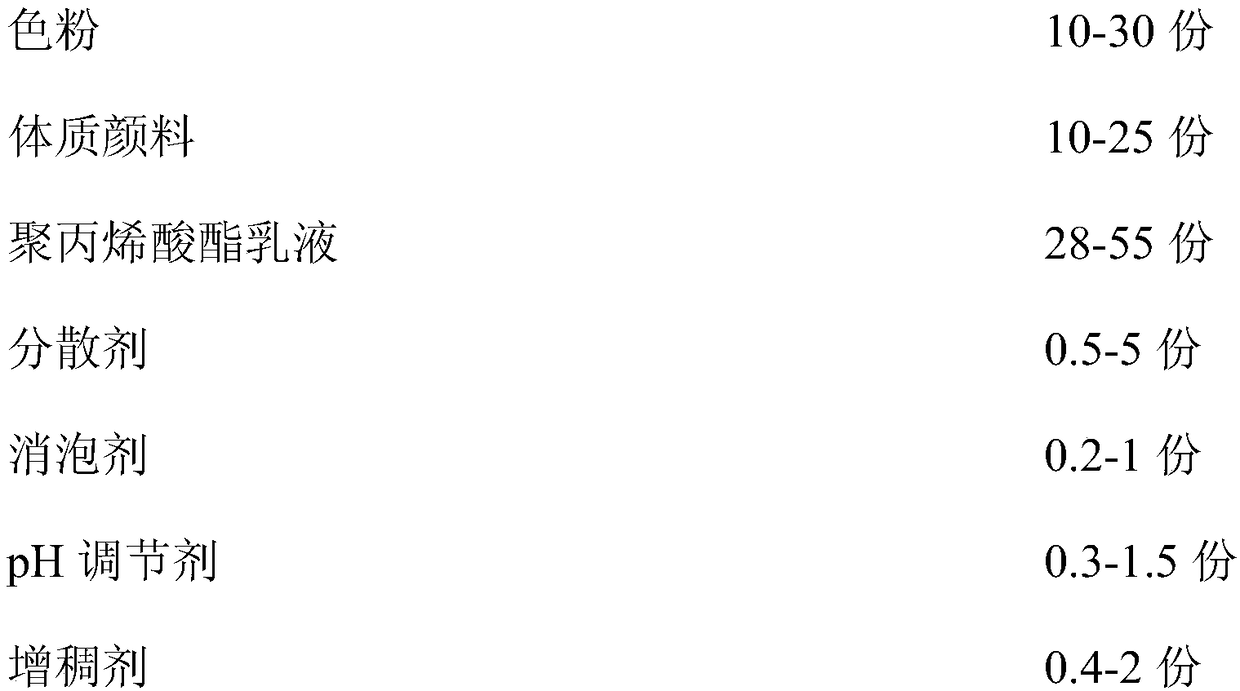

[0072] The pigment composition prepared by this implementation comprises the following components by weight:

[0073]

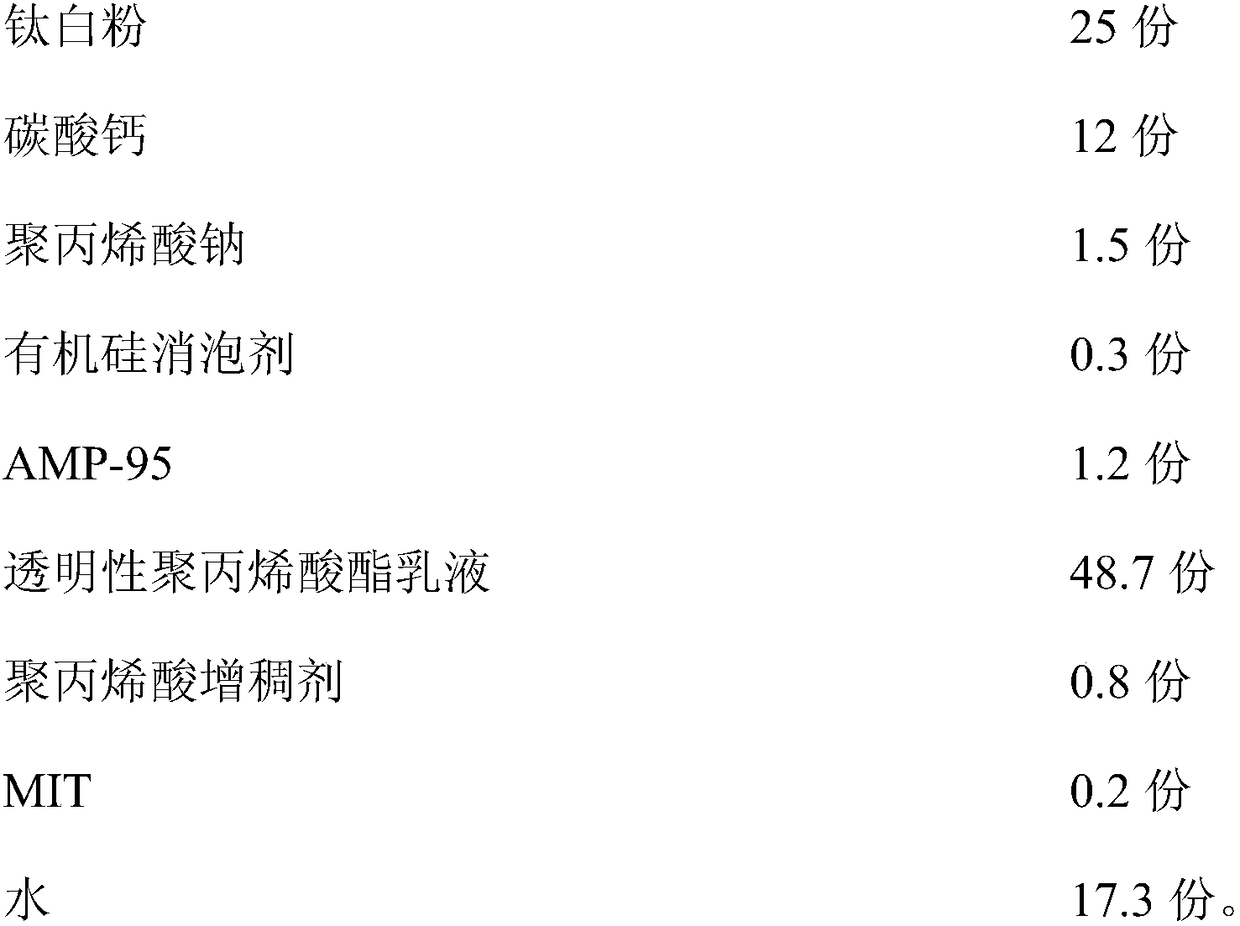

[0074] The preparation method comprises the following steps:

[0075] In the high-speed stirring dispersing tank, add 17.3 parts of water, 1.5 parts of sodium polyacrylate dispersant, 0.3 parts of silicone defoamer, 1.2 parts of AMP-95pH regulator, start stirring at 300 rpm, and then add 25 parts of titanium dioxide , 12 parts of 1250-mesh calcium carbonate, and then increase the stirring speed to 1500rpm / min to disperse for 30 minutes; then add 40 parts by weight of zirconium beads, and grind for 1 hour at a speed of 2000rpm / min. Use a scraper fineness meter to measure the fineness to 33 μm, stop the dispersion, and filter through 100 mesh to obtain a white slurry.

[0076] Add the prepared slurry into a stirred tank equipped with a vacuum mixer, slowly add 49.7 parts of transparent polyacrylate emulsion (wherein the solid content is 45%) under stirring ...

Embodiment 2

[0078] The pigment composition prepared by this implementation comprises the following components by weight:

[0079]

[0080] The preparation method comprises the following steps:

[0081] In the high-speed stirring dispersing tank, add 21.5 parts of water, 1.2 parts of sodium polyacrylate dispersant, 0.3 parts of mineral oil defoamer, 0.5 parts of AMP-95 pH regulator, start stirring at 300 rpm, and then add titanium dioxide 18 Parts, 8 parts of iron oxide black, 12 parts of 1200 mesh barium sulfate, and then increase the stirring speed to 2000rpm / min to disperse for 20 minutes; then add 40 parts of zirconium beads and grind for 1 hour at a speed of 2000rpm / min. Use a scraper fineness meter to measure the fineness to 22 μm, stop the dispersion, and filter through 100 mesh to obtain a white slurry.

[0082]Add the prepared slurry into a stirred tank equipped with a vacuum mixer, slowly add 38 parts of transparent polyacrylate emulsion (wherein the solid content is 40%) und...

Embodiment 3

[0084] The pigment composition prepared by this implementation comprises the following components by weight:

[0085]

[0086] The preparation method comprises the following steps:

[0087] In the high-speed stirring dispersing tank, add 24.2 parts of water, 2.5 parts of hydrophobically modified sodium polyacrylate dispersant, 0.5 part of mineral oil defoamer, 1 part of AMP-95 pH regulator, start stirring at 300 rpm, and then add 8 parts of titanium dioxide, 8 parts of Fast Yellow G, 12 parts of 1200 mesh barium sulfate, and then increase the stirring speed to 1600rpm / min to disperse for 30 minutes; then add 40 parts of zirconium beads and grind for 1 hour at a speed of 2000rpm / min. Use a scraper fineness meter to measure the fineness to 30 μm, stop the dispersion, and filter through 100 mesh to obtain a white slurry.

[0088] Add the prepared slurry into a stirred tank equipped with a vacuum mixer, slowly add 35 parts of transparent polyacrylate emulsion (wherein the soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com