A kind of full silk smooth edge velvet and its weaving method

A silk and velvet technology, applied in the field of velvet, can solve the problems that the fluff is not helpful, the silk is not very suitable, and the fluff is easy to shed, so as to achieve the effect of easy standing, not easy to fall, and dense fluff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

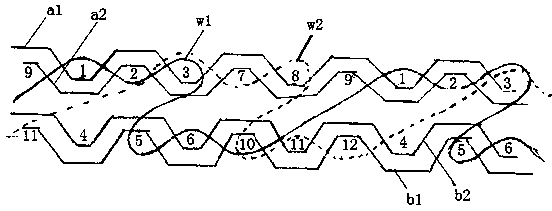

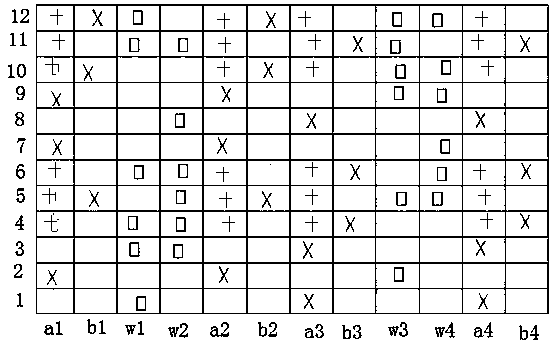

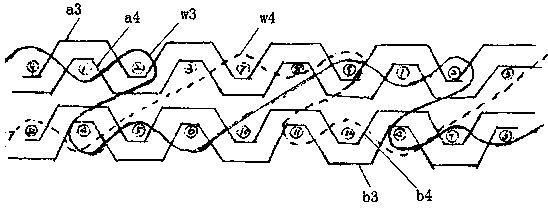

[0027] The present invention is achieved in this way, a kind of full silk smooth edge velvet, including ground warp, ground weft and velvet pile, is characterized in that: the above-mentioned ground warp, ground weft and velvet pile are subjected to doubling and twisting, The heald reed, ground texture and velvet texture of dense velvet are weaved in turn by three shuttles on the upper layer and three shuttles on the lower layer, and then trimmed after cutting the velvet. The ground warp is 20 / 22D real silk, the ground weft is also 20 / 22D real silk, and the velvet pile can be 20 / 22D real silk, or 150N silkworm or tussah silk.

[0028] A weaving method for full silk smooth-edged velvet, comprising the steps of paralleling and twisting ground warp, ground weft, and velvet yarn, inserting heddles in series, and lifting heddles and beating up wefts.

[0029] The ground warp silk is paralleled and twisted, and two 20 / 22D silkworm silks are used and combined into one, and 8 twists a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com