Connection base on submerged pump and oil cylinder assembly comprising same

A technology for submersible pumps and connecting seats, which is applied to components, pump elements, pumps, etc. of pumping devices for elastic fluids, and can solve problems such as damage to submersible pumps, complicated manufacturing processes, and poor sealing performance, and achieve fastness and Good sealing, simple manufacturing process, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below with reference to the accompanying drawings and embodiments.

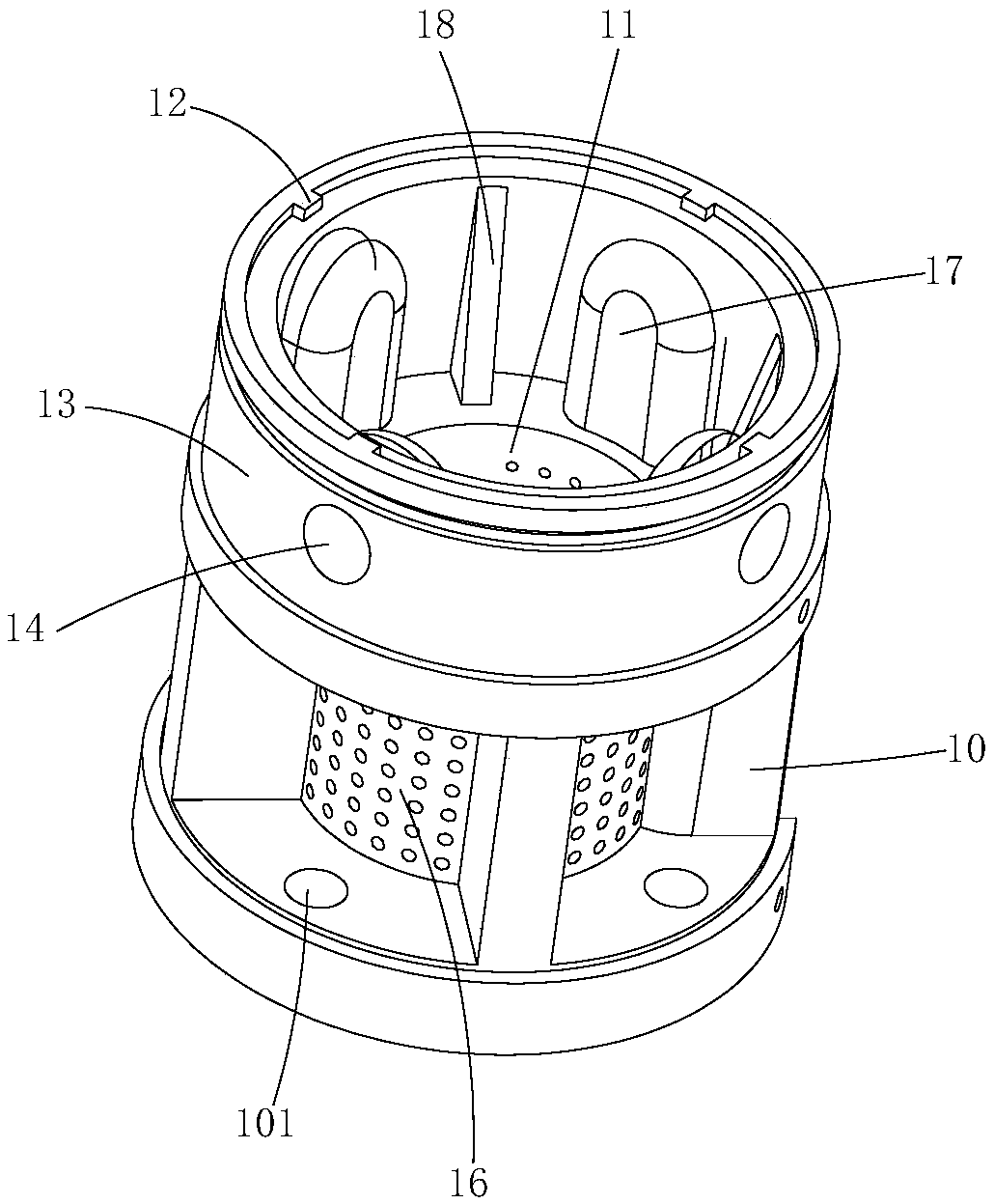

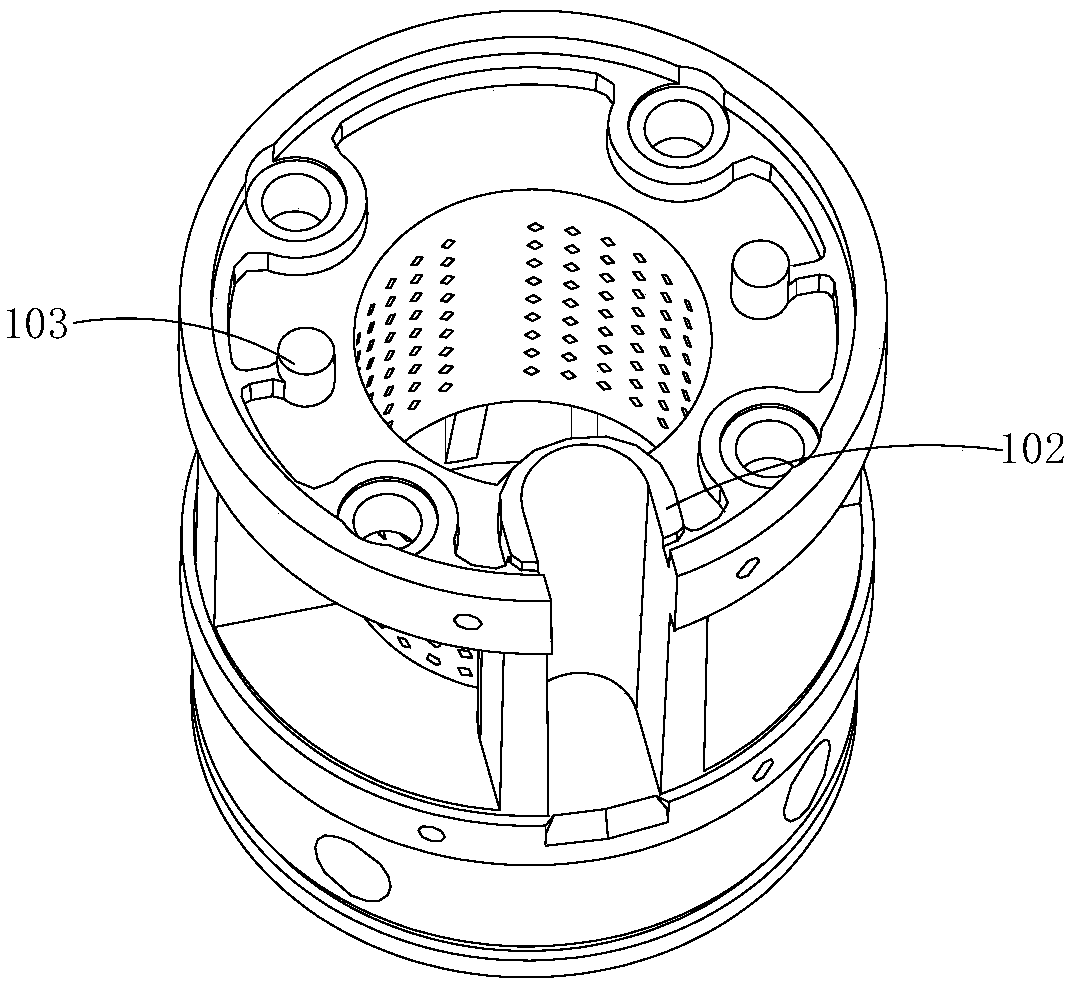

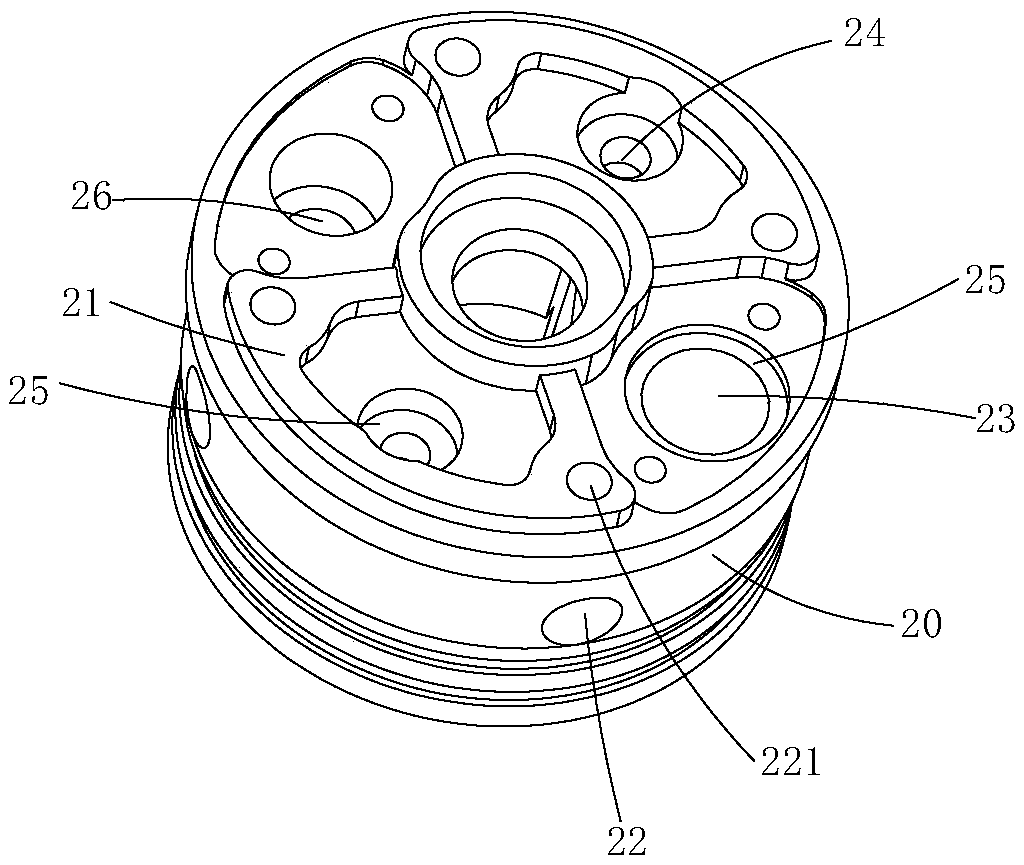

[0018] Example, see Figure 1 to Figure 3 Shown: a connecting seat on a submersible pump, including a seat body 10, on the upper end of the seat body 10 is provided with a clamping block 12 for the submersible pump pump head assembly; the seat body 10 is integrally formed of hard plastic material, The quality plastic is nylon plastic or ABS plastic or polycarbonate or PPS plastic. Compared with the existing pig iron material, it also has simple manufacturing process, low production and transportation cost, and it does not need to be used. Separate painting is more environmentally friendly; at the same time, hard plastic can facilitate the molding of the clip 12 (the pig iron material cannot be molded due to its o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com