Process and installation for conversion of heavy petroleum fractions in a fixed bed with integrated production of middle distillates with a very low sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

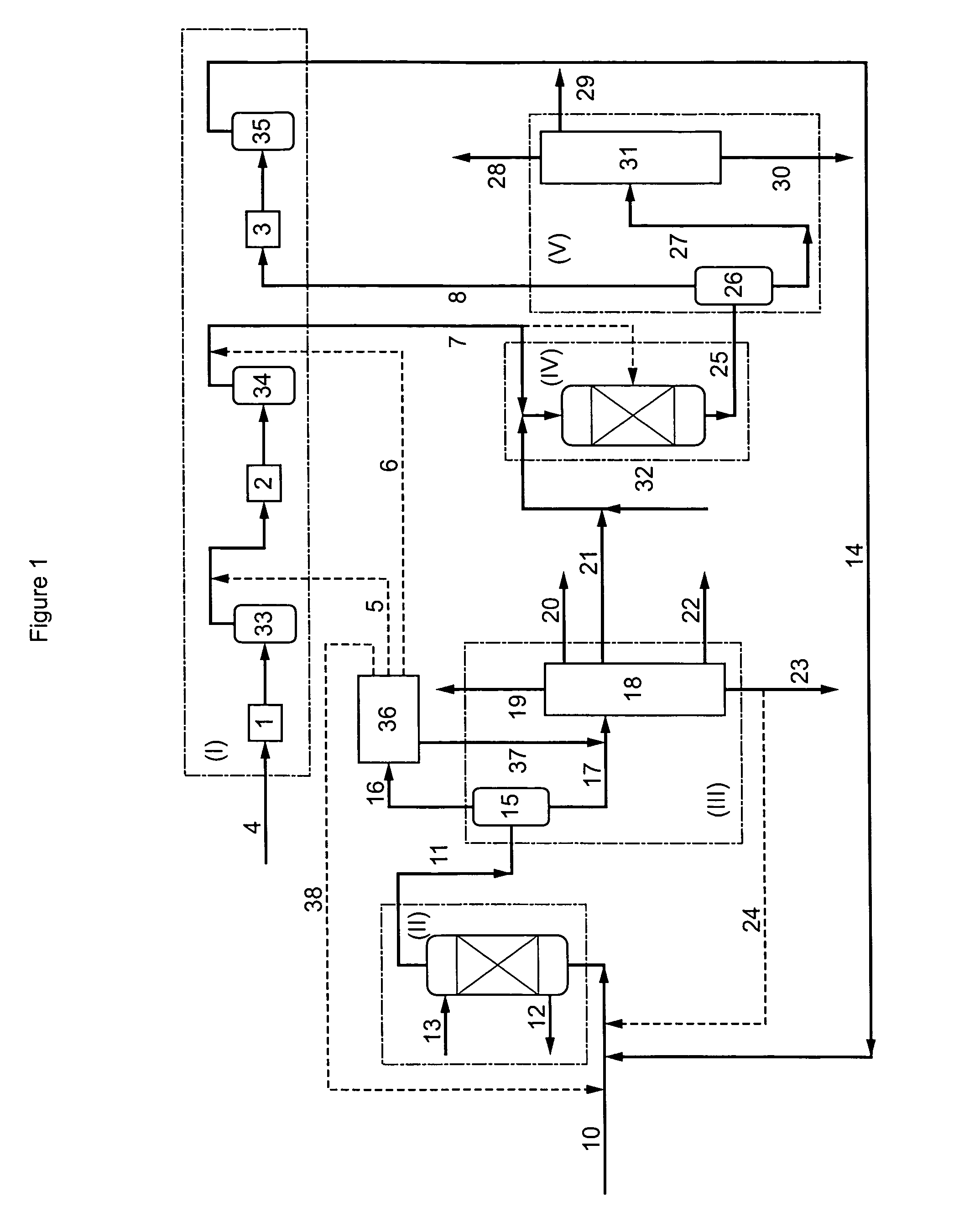

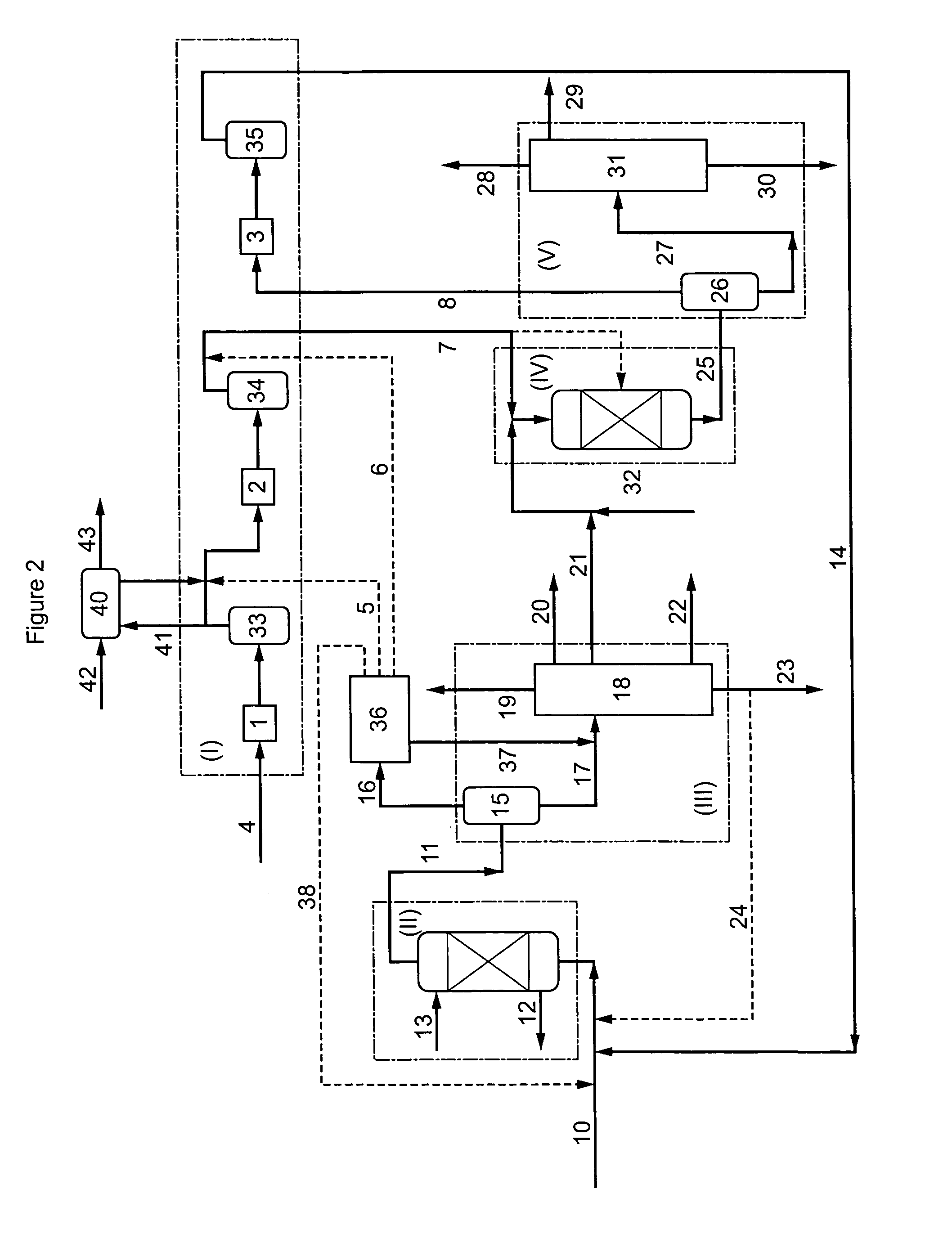

[0013]Thus, the process of the invention is a process for treatment of a heavy petroleum feedstock of which at least 80% by weight has a boiling point of greater than 340° C., which comprises the following stages:[0014](a) Hydrocracking in a fixed bed with at least one catalyst at a temperature of about 300 to about 500° C. and often from about 350 and 450° C., a pressure of at least 4 MPa and less than or equal to 17 MPa, an hourly space velocity of from 0.1 to 10 h−1 and in the presence of 50 to 5000 Nm3 of hydrogen per m3 of feedstock, the net conversion into products boiling below 360° C. being from 10 to 99% by weight,[0015](b) Separation of the effluent obtained from stage (a) into a gas containing hydrogen and H2S, a fraction comprising the gas oil, and optionally a fraction that is heavier than the gas oil and a naphtha fraction;[0016]c) Hydrotreatment by contact with at least one catalyst of at least the fraction comprising the gas oil obtained in stage (b) at a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com