A kind of naphtha upgrading method

A naphtha and upgrading technology, which is applied in the treatment of naphtha, petroleum industry, hydrocarbon oil, etc., can solve the problems of huge equipment investment and production energy consumption, strict requirements for raw material impurities, and unfavorable gasoline blending. Improve octane number, improve yield, and achieve the effect of continuous regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Preparation of dehydrogenation catalyst.

[0040] Take 100 grams of γ-Al 2 o 3 Carrier, its saturated water absorption is measured to be 82mL, is made into 140mL impregnating liquid with predetermined amount of chloroplatinic acid, hydrochloric acid, makes containing Pt 0.5 mass %, Cl 1.9 mass % (both relative to the quality of aluminum oxide dry basis) in impregnating liquid, The volume ratio of impregnation solution to carrier is 1.05:1. Separate the carriers into flasks, evacuate and control the vacuum at 0.085MPa, introduce the impregnating solution, rotate and impregnate at 30°C for 3 hours, and rotate at a linear speed of 0.10 m / s, then dry under reduced pressure, and then dry in dry air at 500 ℃, gas / solid volume ratio of 700:1 under the conditions of roasting for 4 hours to obtain a dehydrogenation catalyst, which contains 0.5% by mass of Pt and 1.0% by mass of Cl based on the dry basis of the alumina carrier.

example 2

[0042] Preparation of modified catalysts.

[0043] (1) Preparation of carrier

[0044] Take 67.6 kg of pseudo-boehmite powder (produced by Sasol Company, with an alumina content of 74% by mass), and under stirring conditions, add 300 kg of nitric acid aqueous solution with a concentration of 1.1% by mass, stir for 2 hours to peptize, and then add 55.0 kg of oxidized HZSM-5 zeolite powder (zeolite content: 91% by mass) with a silicon / alumina molar ratio of 60 was stirred at high speed for 3 hours. Drop the prepared slurry into an oily ammonia column containing 8% by mass of ammonia water, take out the wet ball formed in the oily ammonia column, dry at 60°C for 10 hours, and roast at 550°C for 3 hours to obtain a carrier, which is an HZSM-5-containing Zeolite 50% by mass alumina pellets.

[0045] (2) Preparation of modified catalyst

[0046] Get 50 kilograms of carrier, use 50 kilograms containing 4.7 mass % of zinc nitrate, 3.0 mass % of oxidized mixed rare earths (wherein l...

example 3

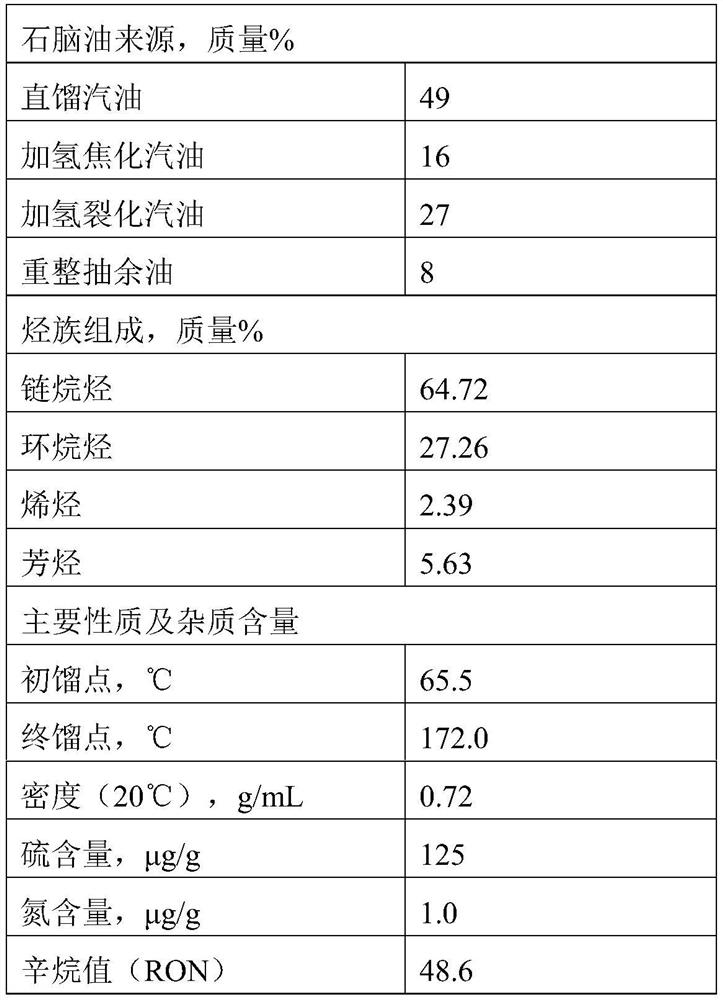

[0049] The naphtha is modified according to the method of the present invention.

[0050] The fixed-bed reaction zone is composed of an independent fixed-bed reactor, filled with the dehydrogenation catalyst prepared in Example 1, and the loading amount accounts for 30% by mass of the total catalyst. The moving bed reaction zone is composed of an independent moving bed reactor, loaded with the modified catalyst prepared in Example 2, and the loading amount accounts for 70% by mass of the total catalyst. Before the reaction, the dehydrogenation catalyst and the modified catalyst are activated in the device. The activation medium is nitrogen, the pressure is 0.4MPa, the volume ratio of nitrogen to catalyst is 500:1, the activation treatment temperature is 400°C, and the activation time is 2h.

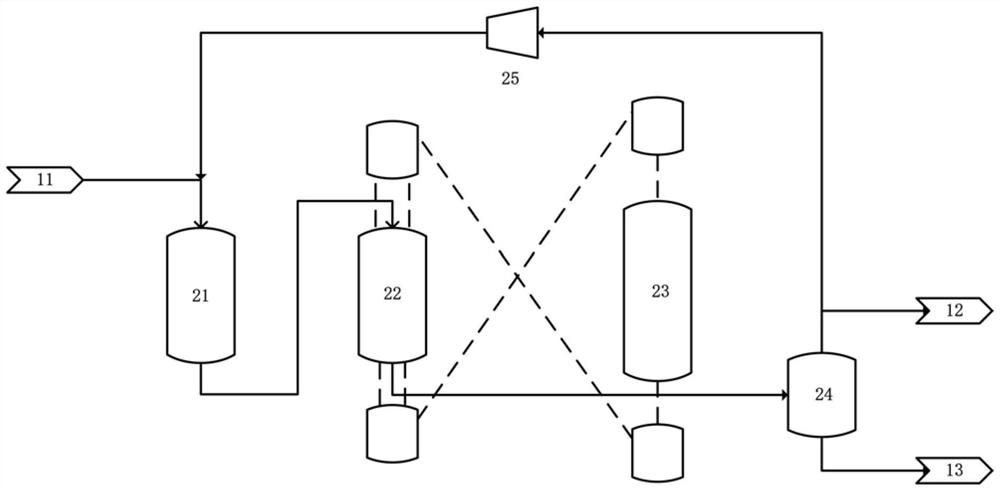

[0051] according to figure 1 In the process shown, the naphtha raw material is introduced into the fixed bed reaction zone for dehydrogenation reaction, and the obtained reaction product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com