Coating method of catalyst and carbon smoke particle filter prepared with same

A catalyst and filter technology, applied in the field of air purification, can solve the problems of weak catalyst adhesion, different thermal expansion coefficients, shortened filter life, etc., and achieve the effect of improving catalytic effect and life, prolonging life, and improving adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038](2) Preparation of coating solution.

[0039] The catalyst source and carbon are weighed in a weight ratio of 1-10:1, placed in deionized water, and stirred evenly to obtain a coating solution; the catalyst source is a compound with a catalytic metal element.

[0040] It can be understood that the concentration of the catalyst source and carbon in the coating solution can be adjusted according to the required wrapping amount, but the catalyst source, carbon and deionized water are in a weight ratio of 1-10:1:1- 10, which can coat the catalyst source and carbon deposition on the surface of the metal-based carrier uniformly and in an appropriate amount.

[0041] Wherein, the catalyst source is a compound with a catalytic metal element, which only needs to be able to provide a catalytic metal element (such as noble metal, alkali metal, etc.) in the chemical deposition reaction. However, an alkali metal compound, such as a hydroxide of an alkali metal, is used. Lithium hydr...

Embodiment 1

[0051] A soot particle filter is prepared by the following catalyst coating method:

[0052] (1) Activation of metal-based supports.

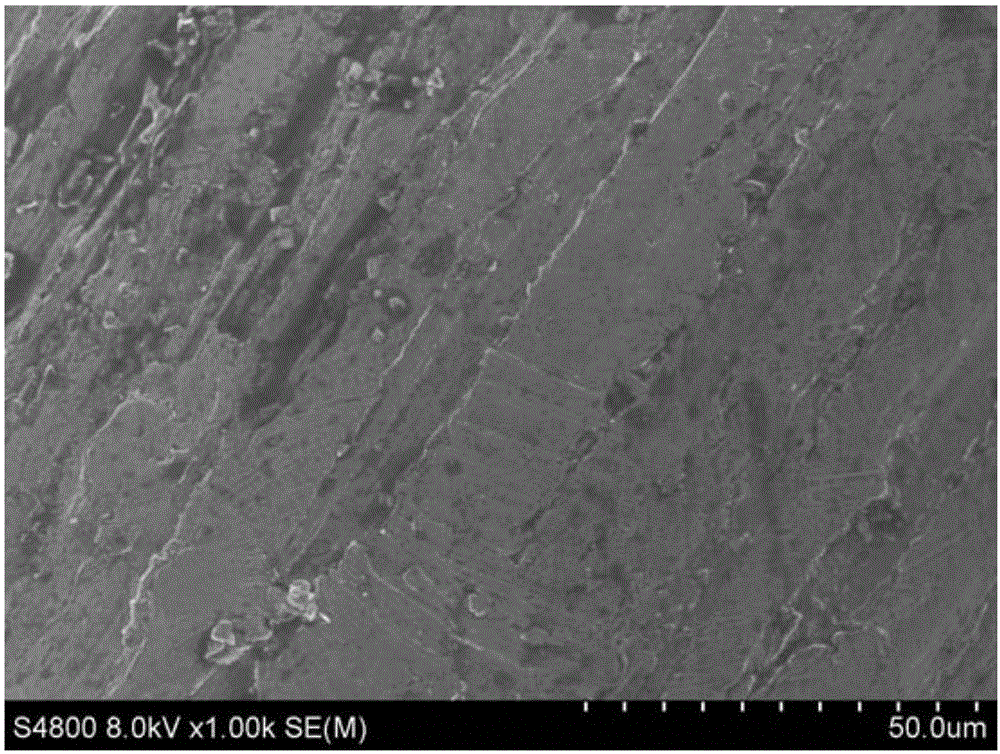

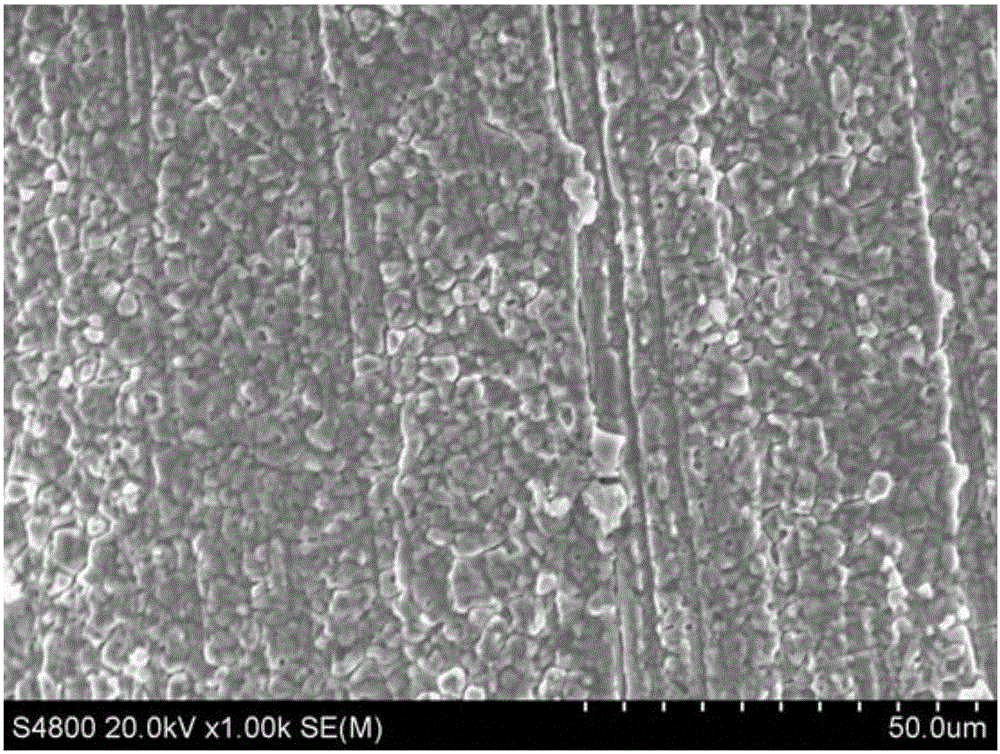

[0053] The wire mesh with wavy stainless steel wire stacked and wound is used as the metal base carrier. The scanning electron microscope image of the wire mesh is as follows: figure 1 As shown, the metal-based carrier was put into deionized water and ultrasonicated for 0.5 h, then placed in a tube furnace and heated to 800 °C, and activated at this temperature for 8 h to obtain an activated metal-based carrier.

[0054] (2) Preparation of coating solution.

[0055] In parts by weight, take 2 parts of potassium hydroxide and 1 part of carbon black, add them to 5 parts of deionized water, stir evenly, form a slurry, and prepare a coating liquid.

[0056] (3) Wrapping of metal-based carrier.

[0057] Put the activated metal-based carrier (wire mesh) prepared in step (1) into the above coating solution in time, after ultrasonication for 1 hour,...

Embodiment 2

[0063] A soot particle filter is prepared by the following catalyst coating method:

[0064] (1) Activation of metal-based supports.

[0065] A metal mesh made of wavy stainless steel wires is used as a metal-based carrier. After the metal-based carrier is placed in deionized water for 3 hours, it is placed in a tube furnace and heated to 850 ° C. The temperature is maintained and activated for 10 hours. Activated metal-based supports.

[0066] (2) Preparation of coating solution.

[0067] In parts by weight, 3 parts of cesium chloride and 1 part of carbon black were added to 5 parts of deionized water, and stirred evenly to form a slurry to obtain a coating liquid.

[0068] (3) Wrapping of metal-based carrier.

[0069] Put the activated metal-based carrier (wire mesh) prepared in step (1) into the above-mentioned coating solution in time, after ultrasonication for 2 hours, let it stand for 12 hours, and dry it at 110°C for 24 hours to obtain the coated solution Wrapped me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com