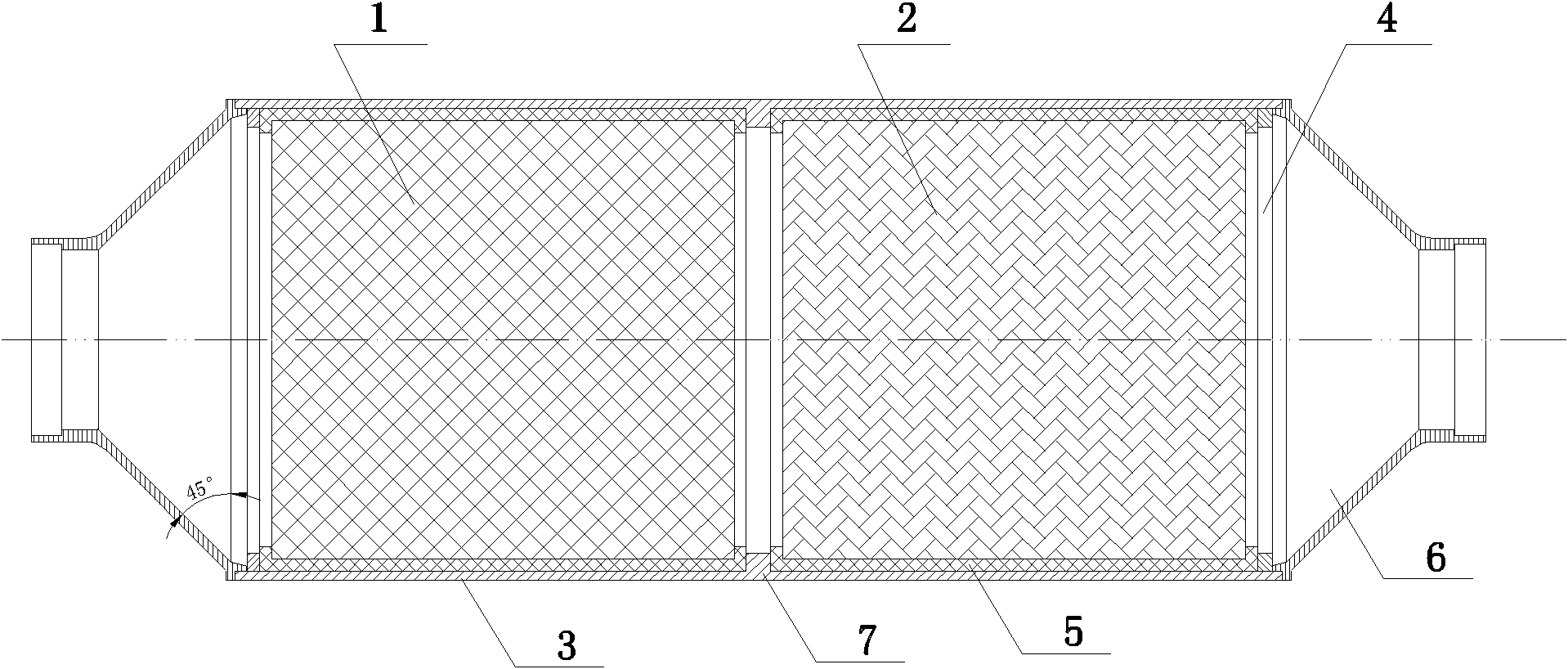

Catalyst for purifying tail gas of diesel automobiles, preparation method and purification device thereof

An exhaust gas purification, diesel vehicle technology, applied in physical/chemical process catalysts, exhaust devices, chemical instruments and methods, etc., can solve the problems of being easily poisoned by sulfur, need to be further improved, and limited PM elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

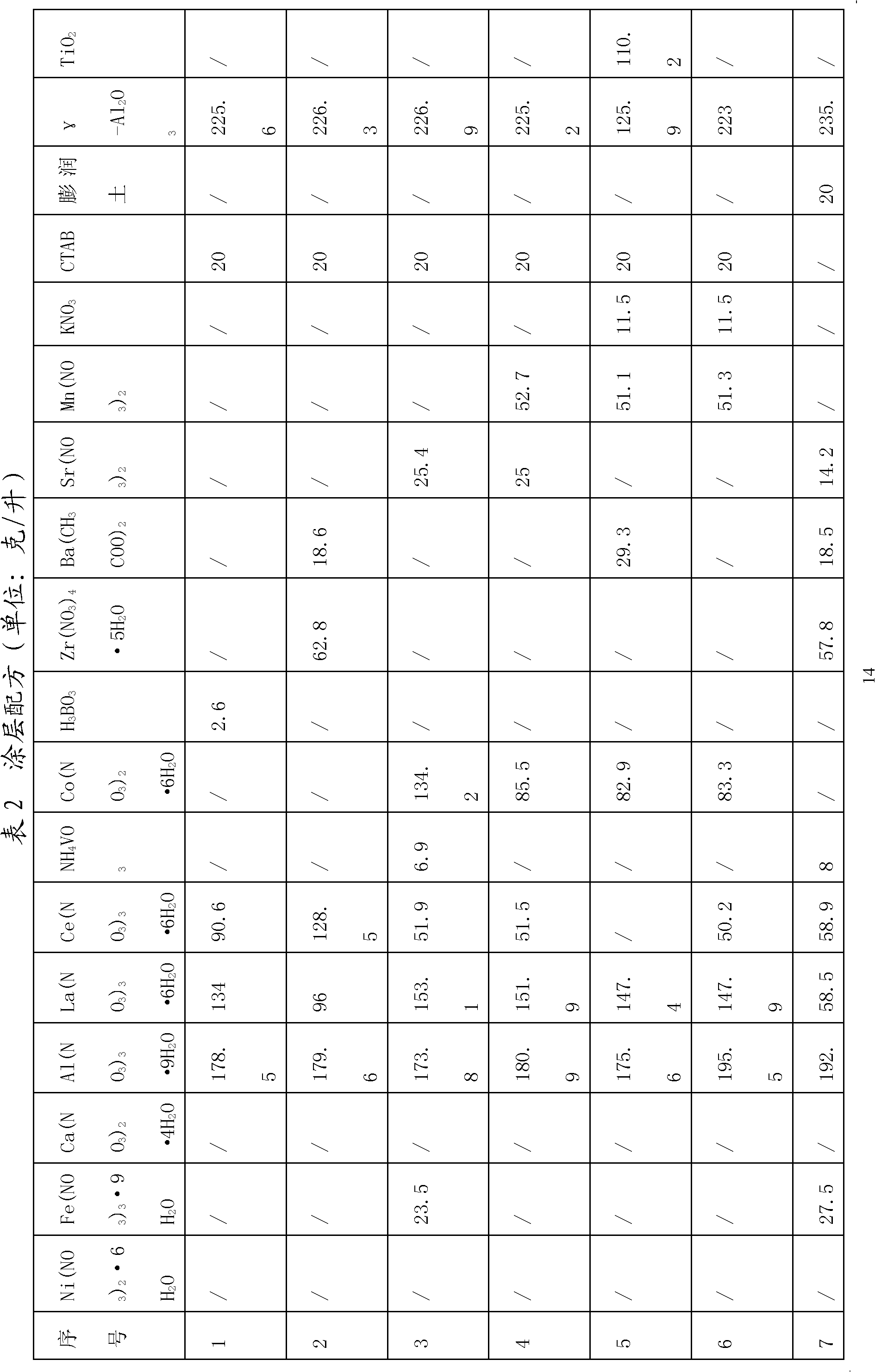

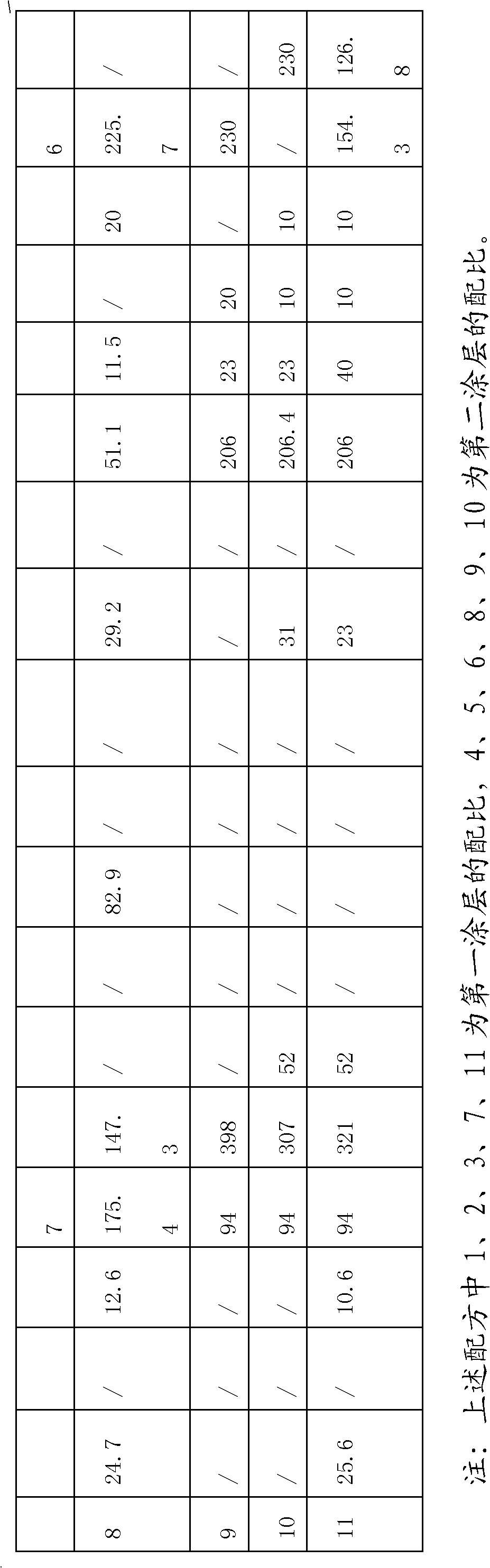

[0073] (2) Preparation of coating

[0074] 1) First coat

[0075] 1. take by weighing the proportioning corresponding nitrate (except Ba salt) of the first coating by the proportioning of table 2, heat and dissolve with a small amount of deionized water, must mix the nitrate solution;

[0076] ② Take the proportioning in Table 2 and weigh the Ba(CH 3 COO) 2 , add deionized water to dissolve, and obtain a solution containing Ba ions;

[0077] ③Weigh the ratio of Table 2 and weigh the γ-Al of the first coating ratio 2 o 3 powder, add the mixed nitrate solution described in step ①, and stir for 90-110min to obtain a mixed solution;

[0078] ④ Diffusely inject the Ba ion-containing solution obtained in step ② into the mixed solution obtained in step ③, and stir while adding to obtain the immersion solution;

[0079] ⑤ ball mill the immersion solution obtained in step ④ for 1 hour at a speed of 250r / min to obtain the first coating immersion solution;

[0080] 2) Second coat ...

Embodiment 1

[0093] Take one cordierite and one SiC wall flow carrier with a size of φ144mm×152mm, soak in deionized water for 30min, dry at 80°C for 4 hours, and bake at 350°C for 30min before use.

[0094] ① DOC preparation: weigh La(NO 3 ) 3 .6H 2 O: 243g, Ce(NO 3 ) 3 .6H 2 O: 235.5g, Zr(NO 3 ) 4 ·5H 2 O: 231.2g, Sr(NO 3 ) 2 : 56.7g, Fe(NO 3 ) 3 9H 2 O: 108.6g, NH 4 VO 3 : 32g, Al(NO 3 ) 3 9H 2 O: 770.6g, placed in a 5000ml beaker and heated to melt, then add 74.1g of Ba(CH 3 COO) 2 Saturated solution and 942.2g γ-Al 2 o 3 Nano powder, 80g inorganic thixotropic agent, the volume of the deployment solution is 4000ml, electric stirring for 100min., 250rpm ball milling for 1 hour to obtain the DOC coating immersion solution. Then immerse the treated cordierite carrier in the solution for 30min, and after taking it out, 0.3MPaN 2 Blow air, dry at 80°C for 4 hours, and bake at 550°C for 1 hour. Calculate the weight of the carrier to be used when it increases by more tha...

Embodiment example 2

[0100] What is different from embodiment 1 is to change DOC and CDPF composition, all the other process parameters are constant:

[0101] DOC coating composition is: La(NO 3 ) 3 .6H 2 O: 612g, Ce(NO 3 ) 3 .6H 2 O: 207.6g, Co(NO 3 ) 4 ·6H 2 O: 536.9g, Sr(NO 3 ) 2 : 101.5g, Fe(NO 3 ) 3 9H 2 O: 93.8g, NH 4 VO 3 : 27.7g, Al(NO 3 ) 3 9H 2 O: 695.4g, γ-Al 2 o 3 Nano powder 907.7g, inorganic thixotropic agent 80g

[0102] The composition of DPF is: La(NO 3 ) 3 .6H 2 O: 1232g, KNO 3 : 82.8g, Ce(NO 3 ) 3 ·6H 2 O: 177.6g, Mn(NO 3 ) 2 : 204.4g, Co(NO 3 ) 2 ·6H 2 O: 331.8g, Al(NO 3 ) 3 9H 2 O: 736g, γ-Al 2 o 3 Nano powder 503.7g, TiO 2 Nano powder 400g.

[0103] The test results of purification rate are: HC75.8%, CO96.8%, PM92.8%, NO x 56.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com